Mastering Custom PCB Assembly: The Total Guide to Printed Circuit Board Manufacture and Assembly Services

From prototype to production, understanding the PCB setting up procedure is crucial to building reliable electronic gadgets. . In the fast-paced globe of electronics, the need for top notch custom PCB assembly and published circuit board solutions is proliferating. Whether you’re working on a model or managing volume PCB setting up , understanding the assembly procedure — from PCB fabrication to soldering , assessment , and last delivery — is essential for building reliable and trusted circuits. This blog is your comprehensive guide to navigating the globe of PCB assembly services , providing insights into circuit layout, board fabrication , and modern-day setting up abilities .

Whether you’re a designer, start-up owner, or item manager, this short article is worth analysis due to the fact that it simplifies the complexities of PCB manufacturing and helps you recognize the important actions that make certain a top quality PCB — from picking a distributor to last evaluation . With suggestions on automating , improving turn-around time , and using modern devices like AOI and X-ray , this overview provides you everything you require to optimize your following digital task.

Table of Contents

1. What Is custom PCB Assembly and Why Is It Vital in Electronics Production?

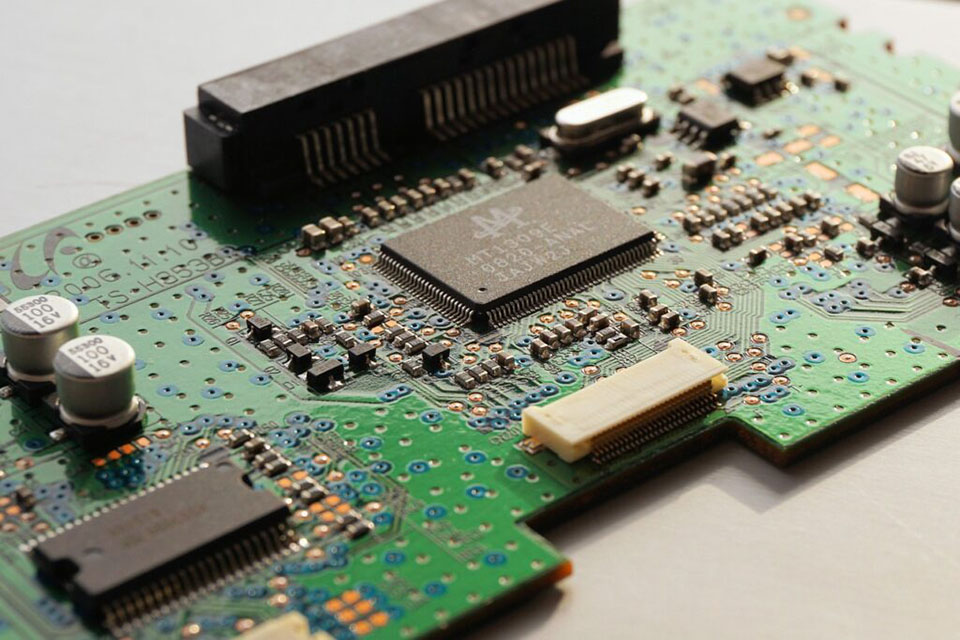

PCB setting up describes the process of installing and soldering electronic parts onto a printed motherboard to produce a useful circuit . This action is important in changing a bare board right into a functional item.

Without accurate PCB setting up , even one of the most sophisticated circuit design would certainly be ineffective. From customer electronics to clinical gadgets and aerospace systems, virtually all contemporary digital devices rely upon correctly set up motherboard . This makes precision PCB assembly not just a technological demand yet a foundation for reputable product efficiency. Moreover, the intricacy of today’s high-frequency circuits requires innovative setting up methods, including smt (surface-mount technology), x-ray assessments, and automated choice and area makers to make sure remarkable execution of the style schematic.

2. What Are the Steps in the custom PCB Assembly Process?

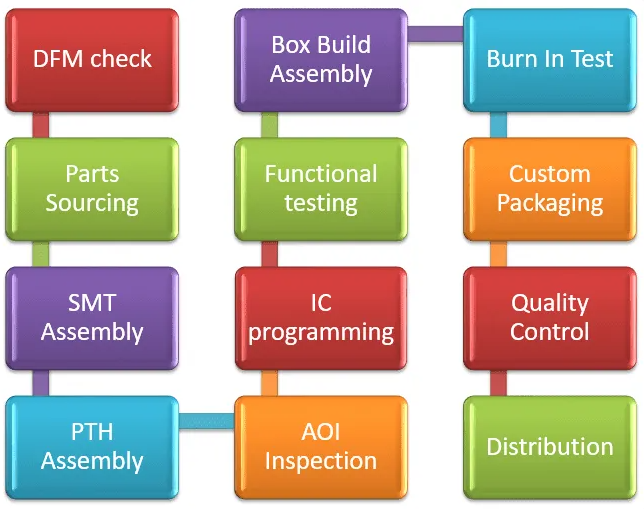

The pcb setting up procedure involves a number of important stages:.

1.Examination and Screening : Approaches like AOI (automated optical examination), x-ray , and functional testing look for problems . Each step in the assembly process needs cautious tracking. Incorrect soldering or misaligned components can result in malfunctioning circuits, boosted turn-around time , and added expense. Devices like centroid files and BOM (expense of materials) information assist optimize this phase.

2.Solder Paste Application : A pattern is used to apply solder paste on the board pads.

3.Part Placement : High-speed pick and position devices populate the board with elements.

4.Reflow Soldering : The booming board is passed through a reflow oven to melt the solder paste.

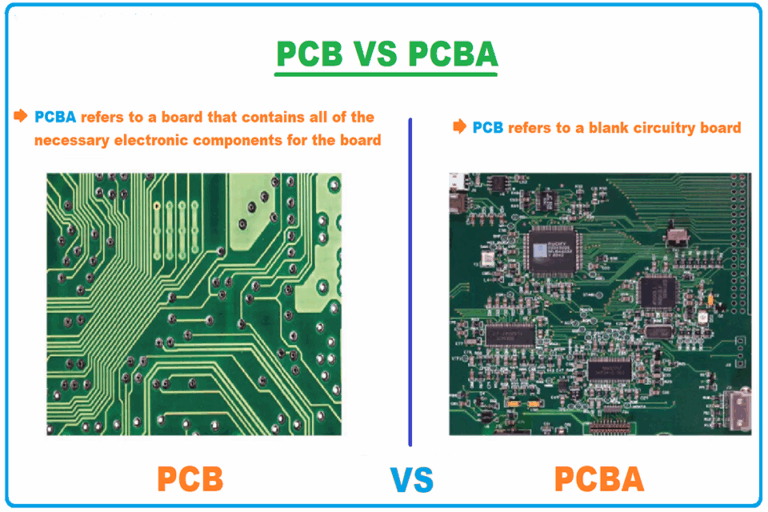

3. Exactly How Does custom PCB Manufacture Differ from PCB Setting Up?

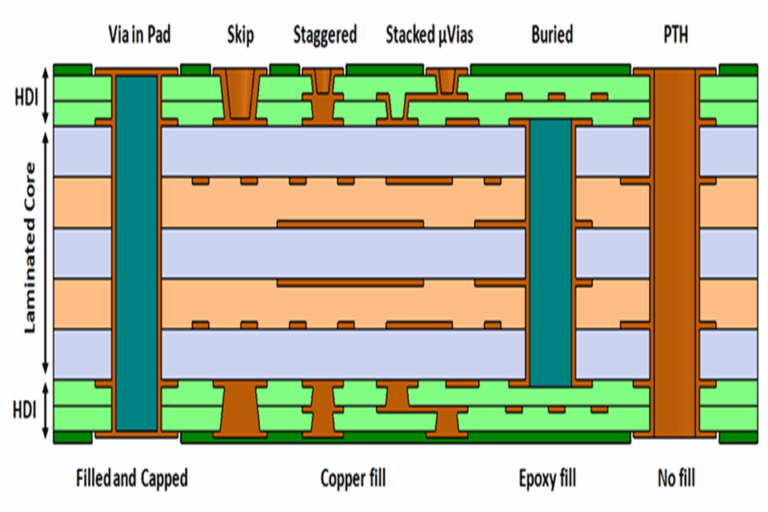

PCB construction is the procedure of developing the physical published circuit board , while pcb setting up has to do with attaching parts to it. Think of fabrication as developing the structure, and assembly as electrical wiring the house. Throughout manufacture , layers of copper are engraved and laminated flooring to develop traces that connect parts. Key elements include silkscreen printing, piercing vias, and applying a solder mask. The outcome is a high-quality pcb ready for assembly. On the other hand, the assembly procedure entails smt , tht (through-hole modern technology), and numerous kinds of examination to ensure integrity. Recognizing the difference is essential when sourcing setting up solutions or handling pcb manufacturing jobs.

4. What’s the Function of a Prototype in the Setting Up Refine?

A pcb prototype allows engineers to examine a circuit prior to scaling approximately quantity pcb setting up . It’s an important part of reducing risks and validating efficiency. A prototype pcb is specifically valuable in capturing problems , improving solder accounts, and ensuring elements are properly positioned before full-blown production. It additionally enables changes to the schematic and bom without affecting the whole batch. When time-to-market is an aspect, quick turn services assist produce tiny run models quickly. Leading companies like JLCPCB use immediate on the internet quotes and quick delivery , lowering preparation dramatically.

5. SMT vs. THT: Which Modern Technology Fits Your Circuit Best?

SMT (Surface Mount Modern technology) is widely utilized for its automation ability and performance. Components are placed straight onto the board , which allows high-speed assembly line and compact circuit design. THT (Through-Hole Modern Technology), on the other hand, includes putting component leads via drilled openings and soldering them on the opposite side. It’s optimal for high-frequency , high-reliability applications like army or aerospace. Choosing between smt and tht depends upon your board requirements, sturdiness requirements, and expense factors to consider. Many sophisticated pcb assembly services specialize in both technologies, using hybrid options for intricate circuit boards .

6. Exactly how to Choose a Dependable PCB Setting Up Service?

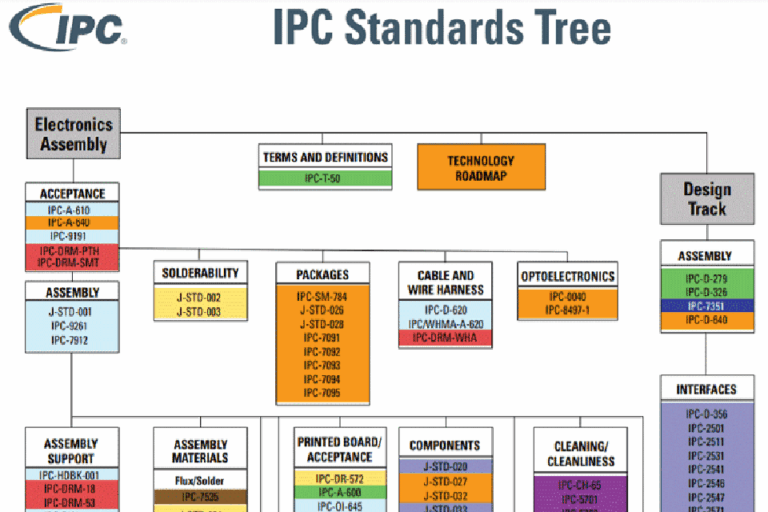

Choosing the ideal pcb setting up service can make or break your task. Search for partners that are ISO licensed and IPC 610 Course certified to guarantee high requirements. An excellent provider will certainly offer support throughout the whole process — from reviewing the schematic and bom to taking care of board construction and assembly . They should additionally sustain consignment and turnkey choices, depending upon your demands. Trick features to evaluate consist of assembly abilities , lead time , assessment technologies (like AOI and x-ray ), and experience with advanced plans such as QFN . Trusted carriers like JLCPCB or EMS companies additionally offer electronic devices manufacturing solutions at a inexpensive without endangering quality.

7. What Are the Benefits of a One-Stop PCB Setting Up Service?

A one-stop option simplifies the whole pcb production and assembly workflow. From pcb manufacture to component sourcing and box construct setting up , it simplifies interaction and reduces hold-ups. Using a turnkey version, the provider manages whatever: board manufacturing, part procurement, smt or tht assembly, testing, and also shipment . This lowers preparation , decreases the threat of problems , and provides much better quality assurance. Such companies additionally normally use instantaneous online quotations and fast turn-around , which is perfect for startups or business creating a new electronic device with tight routines.

8. Just how Are Top Quality and Conformity Ensured in custom PCB Assembly?

Preserving top quality in pcb setting up begins with conformity to international requirements such as ISO and IPC 610 Class . These certifications assist certify that your item fulfills strict safety and security and efficiency criteria. Quality control includes rigorous evaluation phases– like AOI , X-ray , and even useful testing — to find issues early. For complex components like QFN , x-ray guarantees right solder bonding where optical approaches can’t get to. Integrating traceability in the setting up process also aids in post-production auditing, making certain any concern can be mapped back to its resource on the assembly line .

9. What’s the Influence of Turn-around Time on PCB Projects?

Turnaround time directly influences project shipment routines. Hold-ups in pcb construction , component purchase, or assembly services can interfere with whole item launch timelines.

Aspects that improve turn-around include choosing a one-stop provider, enhancing the bom , and making use of automate devices for pick and place and examination . Suppliers that provide instant online platforms for pricing quote and buying additional improve the process. Quick turnaround doesn’t need to imply jeopardized quality– seek solutions with proven documents of delivering top notch boards on tight deadlines.

10. What’s the Future of High-Tech and High-Speed custom PCB Setting Up?

The future of pcb setting up is being formed by automation, AI-driven assessment , and high-speed equipment. Suppliers are significantly utilizing modern assembly line and robotics to boost accuracy and decrease errors.

Integration of high-frequency components, miniaturized circuits, and multi-layer boards indicates that assembly services should progress rapidly. This consists of supporting sophisticated products, smt packages like QFN , and more robust fabrication methods.

As electronic devices manufacturing ends up being more complicated, the demand for specialized and certified assembly abilities continues to grow. Suppliers that specialize in specific niche areas such as aerospace or medical gadgets will lead this modern revolution.

Secret Takeaways

- PCB assembly is the procedure of attaching parts to a printed circuit board , turning it into a working circuit .

- The assembly procedure consists of solder paste application, part placement , reflow , and examination .

- PCB fabrication develops the board , while assembly completes the electronic gadget .

- A model pcb helps validate design and performance before scaling approximately volume pcb assembly .

- Selecting in between SMT and THT depends upon design intricacy and dependability requirements.

- A trustworthy pcb assembly service offers quality control, quick turn-around , and strong assembly capabilities .

- One-stop options streamline the entire process , providing advantages in time, expense, and quality.

- Compliance with ISO and IPC 610 Class ensures premium pcb output.

- Much shorter turnaround time can speed up development cycles without compromising quality.

- The future lies in high-tech , automated , and accuracy pcb assembly services.

By understanding each step and choosing the ideal partners, you can guarantee your next pcb assembly project is effective, trustworthy, and all set for success.