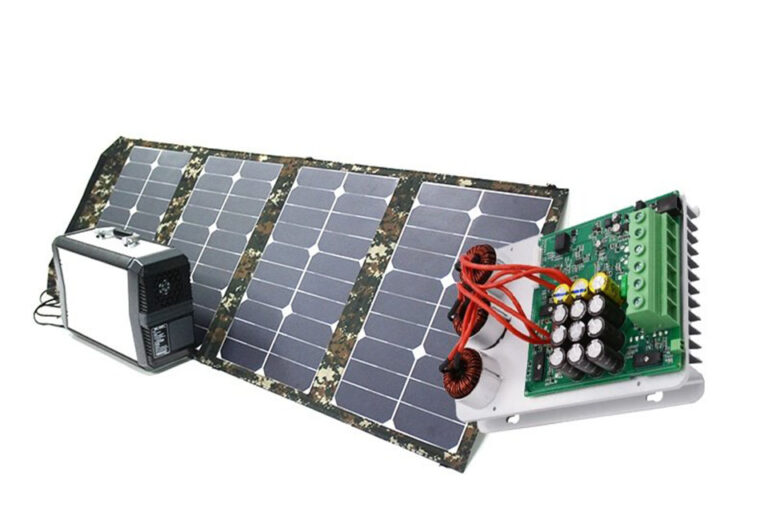

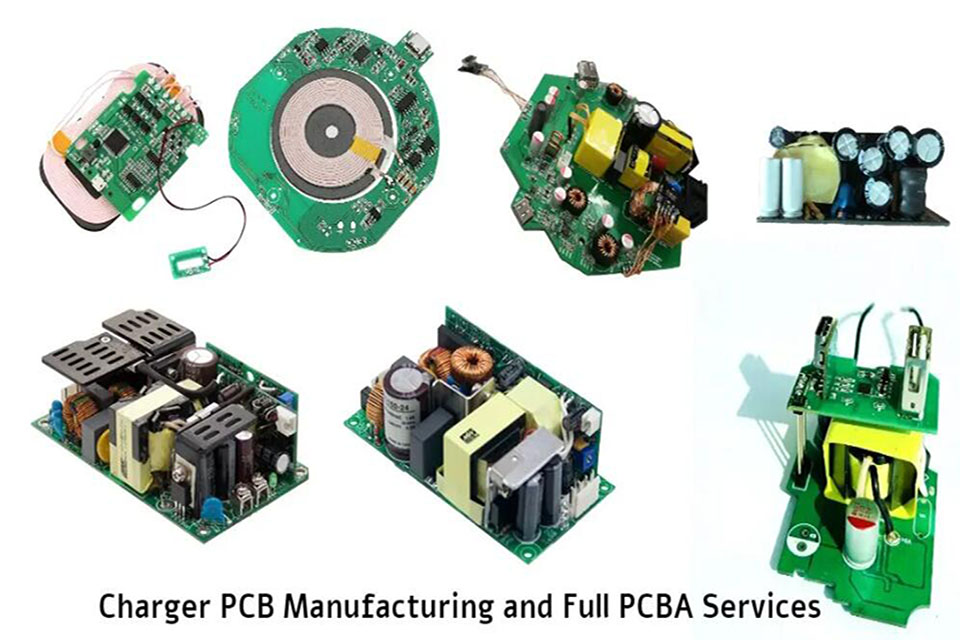

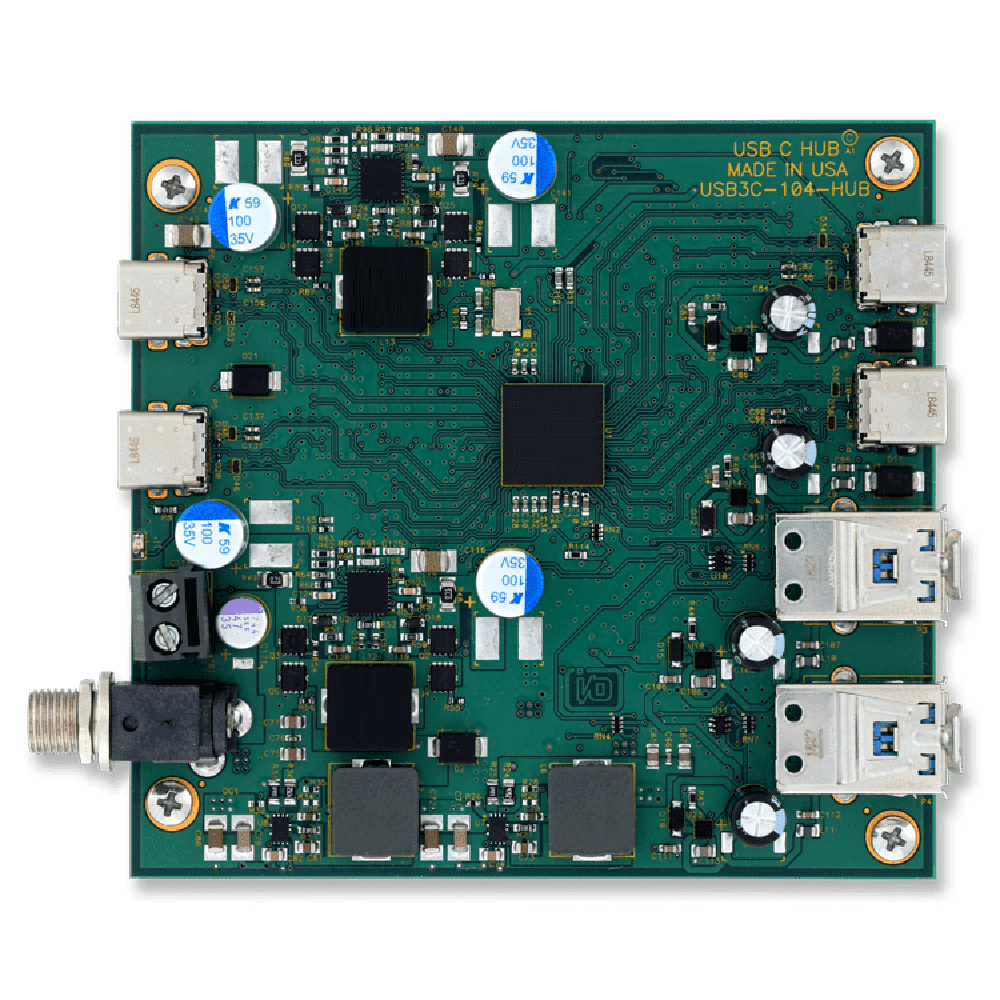

China Customized USB Charge PCB board Assembly for Smart Devices

Introduction

In the rapidly developing landscape of mobile technology, the demand for effective and trusted charging options has actually never been higher. As smart devices become essential to daily life, users progressively look for gadgets that charge quickly without jeopardizing battery durability. Central to this advancement is the USB Charge PCB Board Assembly , a critical part that makes it possible for quick charging abilities in contemporary smart devices. This short article explores the technical complexities of quick charging, focusing on the role of PCB board style, battery charging mechanisms, and industry-standard procedures such as USB Charge PCB Board Assembly (USB PD) and Qualcomm Quick Charge (QC). By comprehending these elements, engineers and enthusiasts can gain insights into optimizing charging effectiveness while making sure device security.

Table of Contents

The article is structured to provide a detailed overview of fast charging innovations, beginning with an explanation of lithium-ion battery charging phases and progressing to the design concepts of quick battery charger circuits. It likewise analyzes the role of USB Charge PCB Board Assembly in helping with high-power shipment and talks about the benefits of adopting standardized charging procedures. Through this expedition, readers will acquire a deeper understanding of how personalized USB Charge PCB Board Assemblycontribute to the performance and reliability of quick battery chargers.

The Science of Quick Charging

Lithium-Ion Battery Charging Phases

Fast charging in smart devices counts on the distinct homes of lithium-ion batteries, which are the most typical energy storage option in modern-day mobile devices. The charging process of a lithium-ion battery happens in 2 distinct phases: constant present (CC) charging and continuous voltage (CV) charging .

- Constant Present Phase (0%– 50%): . Throughout the initial phase, the battery draws a high current at a constant voltage (normally 4.2 V) to quickly replenish its charge. This stage is where fast charging innovations are most effective, as the battery accepts a large quantity of energy in a short time. The existing remains steady up until the battery reaches around 50% of its capability.

- Continuous Voltage Phase (50%– 100%): . Once the battery reaches 50%, the charging process transitions to a constant voltage phase. In this stage, the voltage remains fixed while the present slowly decreases to prevent getting too hot and lengthen battery life. This phase is slower than the very first, as the battery becomes less efficient at accepting added fee.

Understanding these phases is important for developing fast charger circuits, as engineers must balance speed and safety to prevent harming the battery. Advanced charging controllers keep an eye on temperature, voltage, and existing in genuine time to optimize efficiency.

Quick USB Charge PCB Board Assembly Standards.

USB Power Shipment (USB PD).

USB Power Shipment is a widely embraced fast charging standard that permits gadgets to negotiate greater power levels through a USB-C port. Presented in 2012, USB PD supports bidirectional power transfer, making it possible for smartphones to charge other devices such as laptop computers or tablets. Key features of USB PD include:.

- High Power Output: USB PD can provide up to 100W of power, making it ideal for charging high-capacity devices.

- Dynamic Power Modification: The standard enables devices to request specific power levels based on their present requirements.

- Compatibility: USB PD is supported by a broad series of producers, reducing the requirement for proprietary chargers.

USB PD operates by utilizing an information protocol to interact between the charger and the gadget. This procedure ensures safe power delivery by changing voltage and current in real time. For example, a smart device might at first ask for 9V at 2A (18W) and later boost to 15V at 3A (45W) as the battery nears full capacity.

Qualcomm Quick Charge (QC).

Qualcomm USB Charge PCB Board Assembly is another popular quick charging standard, particularly created for devices powered by Qualcomm processors. Unlike USB PD, which is a universal requirement, QC is exclusive to Qualcomm and requires compatible hardware to work. Secret aspects of QC consist of:.

- Voltage Scaling: QC adjusts the output voltage in increments (e.g., 5V, 9V, 12V, 20V) to take full advantage of charging efficiency.

- Processor Combination: QC relies on on-chip charge controllers within Qualcomm processors to handle power shipment.

- Rapid Charging Rates: Devices supporting QC 4.0 can achieve charging speeds of as much as 28W.

One advantage of QC is its ability to preserve lower temperatures during high-power charging. This is accomplished through sophisticated thermal management strategies, such as dynamic voltage scaling and real-time temperature tracking.

Comparison of Quick Charging Standards.

| Function | USB Power Delivery (USB PD) | Qualcomm Quick Charge (QC) |

|---|---|---|

| Maximum Power | 100W | 28W (QC 4.0) |

| Compatibility | Universal (USB-C) | Qualcomm processors just |

| Bidirectional Power | Yes | No |

| Voltage Scaling | 5V, 9V, 15V, 20V | 5V, 9V, 12V, 20V |

| Dynamic Power Change | Yes | Yes |

This comparison highlights the strengths and constraints of each standard. While USB Charge PCB Board Assembly greater flexibility and universal compatibility, QC is enhanced for Qualcomm-powered gadgets.

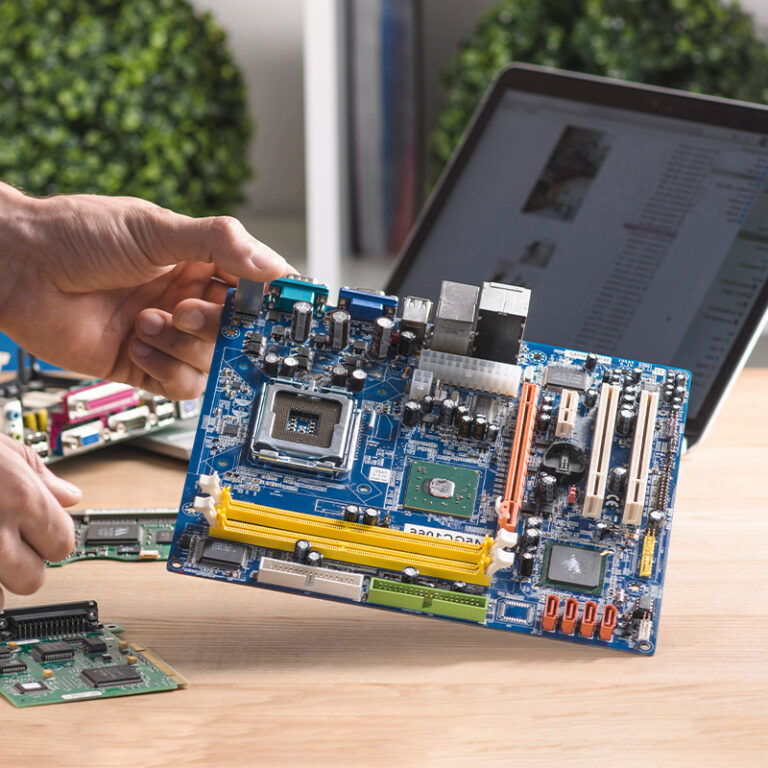

Creating a Quick USB Charge PCB Board Assembly.

Elements and Circuit Style.

Producing a fast battery charger includes creating a USB Charge PCB Board Assembly efficient in delivering high existing and voltage while maintaining stability. A key part in this process is the LM338 voltage regulator , a flexible IC that can supply up to 7A of present at adjustable voltages (2– 25V DC). The LM338 is perfect for quick charger circuits due to its capability to manage high power loads and its compatibility with external resistors for voltage adjustment.

The fundamental LM338 circuit includes the following components:.

- LM338 IC: Acts as the core regulator for voltage and present control.

- Resistors (R1 and R2): Utilized to set the output voltage. A normal configuration utilizes a 120Ω resistor (R1) and a 5kΩ variable resistor (R2).

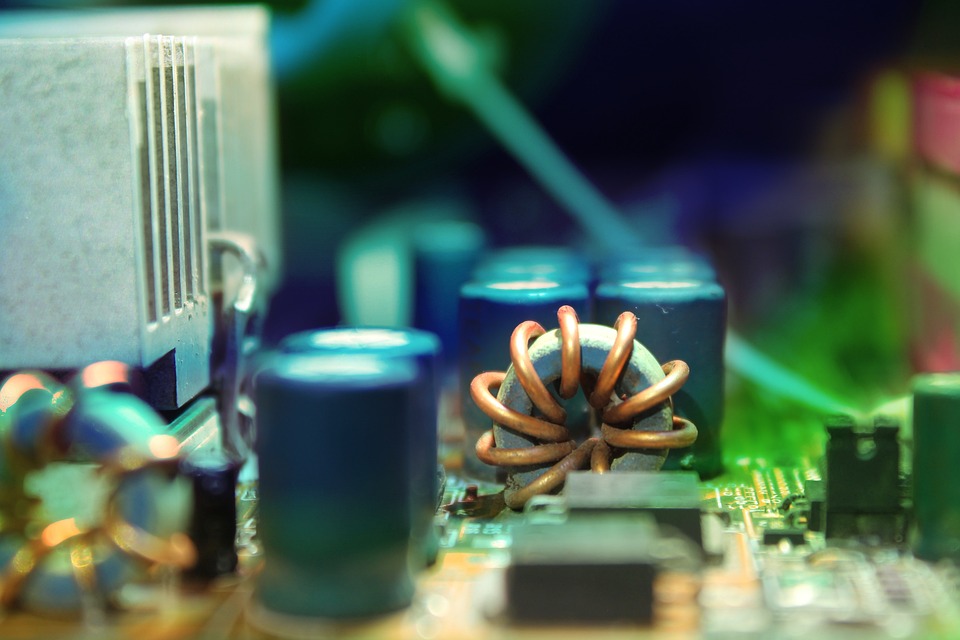

- Capacitors: Offer stability by filtering input and output ripple.

- Transformer and Diodes: Transform a/c power to DC and remedy the signal for the LM338.

The output voltage is determined utilizing the formula:. $$ V _ = 1.25 V \ times \ left( 1 + \ frac R2 R1 \ right) $$. By changing R2, engineers can fine-tune the voltage to meet the requirements of the target gadget.

Dollar Converter for High-Efficiency Power Shipment.

To reduce power loss throughout transmission, quick chargers often utilize a buck converter , a kind of switch-mode power supply that steps down voltage while increasing present. This style is based on the concept that power loss in a cable is proportional to $ I ^ 2R $, where $ I $ is present and $ R $ is resistance. By increasing the voltage and minimizing the present, buck converters considerably lower resistive losses.

For instance, a 40W fast battery charger operating at 10V and 4A experiences less power loss than a 5V, 8A charger over the same cable length. This performance makes buck converters important for high-power fast charging applications.

Safety and Thermal Management.

Fast charging generates heat, which can deteriorate battery efficiency if not managed correctly. To resolve this, contemporary fast charger circuits include:.

- Thermal Sensors: Display the temperature of the battery and charger to prevent overheating.

- Existing Restricting Circuits: Immediately reduce power shipment if the system finds extreme current draw.

- Voltage Regulators: Guarantee stable output by changing for fluctuations in the power supply.

These safety systems are crucial for preserving the durability of both the battery and the charging hardware.

Conclusion.

The evolution of fast charging in smartphones is a testament to developments in USB Charge PCB Board Assembly and power electronic devices. By leveraging innovations such as USB Charge PCB Board Assembly and Qualcomm Quick Charge, producers can provide high-speed charging without jeopardizing gadget safety. The style of quick battery charger circuits, particularly those making use of the LM338 voltage regulator and dollar converters, plays a pivotal function in enhancing efficiency and dependability. As consumer need for quicker charging continues to grow, the significance of customized USB Charge PCB Board Assembly will just increase. Engineers and designers should remain informed about emerging requirements and finest practices to guarantee their products meet the highest performance and safety criteria.

FAQs.

1.. What is the distinction between USB Charge PCB Board Assembly and Qualcomm Quick Charge?

USB Charge PCB Board Assembly Shipment is a universal requirement that supports bidirectional power transfer and is compatible with USB-C ports. Qualcomm Quick Charge is an exclusive standard created for Qualcomm-powered devices and provides fast charging rates however does not have universal compatibility.

2. How do quickly chargers prevent battery damage? .

Quick chargers use thermal sensing units, voltage regulators, and existing restricting circuits to monitor and adjust power shipment in real time. These mechanisms make sure that the battery remains within safe operating specifications.

3. Can I build a quick battery charger in the house? .

Yes, but it needs a solid understanding of electronic devices and security precautions. Sets utilizing parts like the LM338 voltage regulator are readily available for DIY enthusiasts.

4. What is the function of USB Charge PCB Board Assembly in fast charging? .

PCB assemblies function as the foundation of quick battery chargers, integrating elements such as voltage regulators, capacitors, and ports to guarantee efficient power shipment and stability.