Relied On PCB Assembly Services

Abstract

At the heart of every electronic gadget, from smartphone to the control systems in a plane, lies a Printed Circuit Board (PCB). But a bare board is simply a potential; it’s the procedure of PCB assembly services (PCBA) that breathes life into it, transforming it into a functional electronic circuit. Browsing the world of PCB assembly services can be challenging, filled with technical lingo and a dizzying array of alternatives. This thorough guide is here to debunk the whole journey.

Table of Contents

Exactly What is PCB Assembly Services (PCBA)?

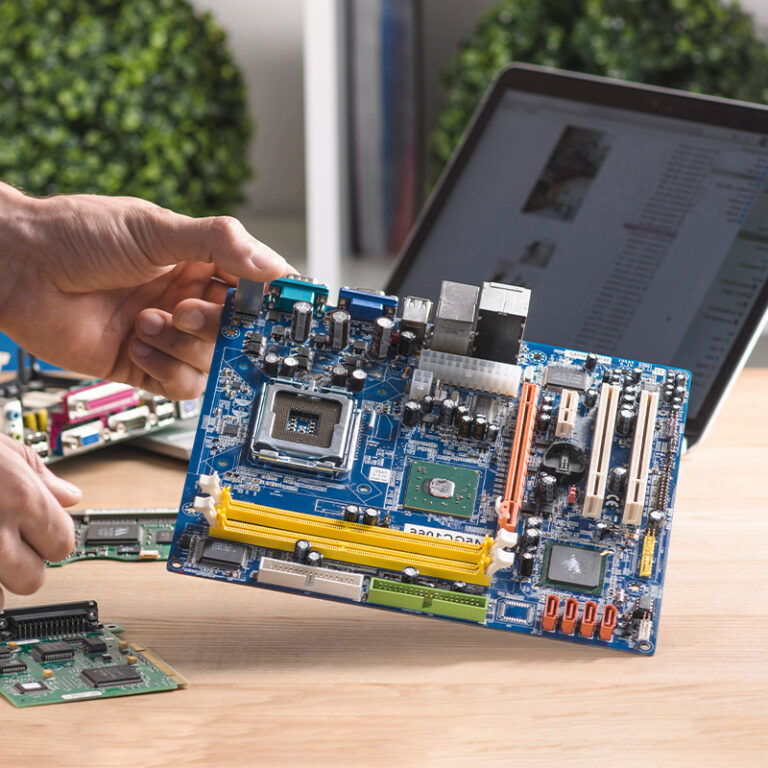

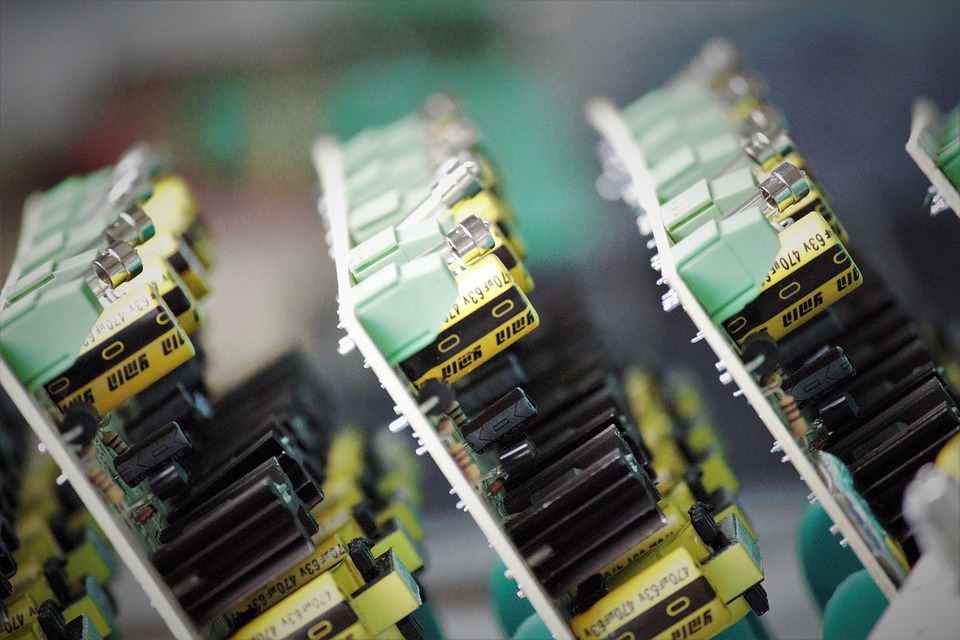

At its core, PCBA, or Printed Circuit Board Assembly, is the process of mounting or positioning electronic elements onto a bare Printed Circuit Board (PCB). While a bare PCB provides the mechanical foundation and the conductive paths (or traces) for a circuit, it can not work by itself. The assembly is the process that populates this board with everything from microcontrollers and resistors to capacitors and adapters, effectively finishing the electrical circuit. This change from an easy board into a totally functional brain for an electronic device is what we call PCBA. The final product, an inhabited board, is also described as a PCB assembly or PCBA.

Understanding the difference in between a PCB and a PCB assembly services is basic. PCB fabrication deals with making the bare board itself– engraving the copper traces, drilling holes, and applying the solder mask. PCB assembly, on the other hand, is the subsequent stage where the elements are affixed. An ended up PCBA is the conclusion of both style and production efforts, developing the specific circuit required for a device to perform its designated functions. Without this important assembly action, even the most intricately created PCB remains inert. The relationship between the pcb and pcba is symbiotic; one can not exist meaningfully without the other.

This assembly can range in intricacy from a simple single-sided board with a couple of parts to a thick, multi-layered PCB with the Chinands of microscopic parts. The precision required in modern electronic production suggests this is hardly ever a manual job, instead relying on sophisticated automatic equipment to make sure every part is placed correctly. Every PCB assembly services is a carefully orchestrated series of occasions designed to produce a trusted and functional piece of electronic devices.

How Does the PCB Assembly services Process Work?

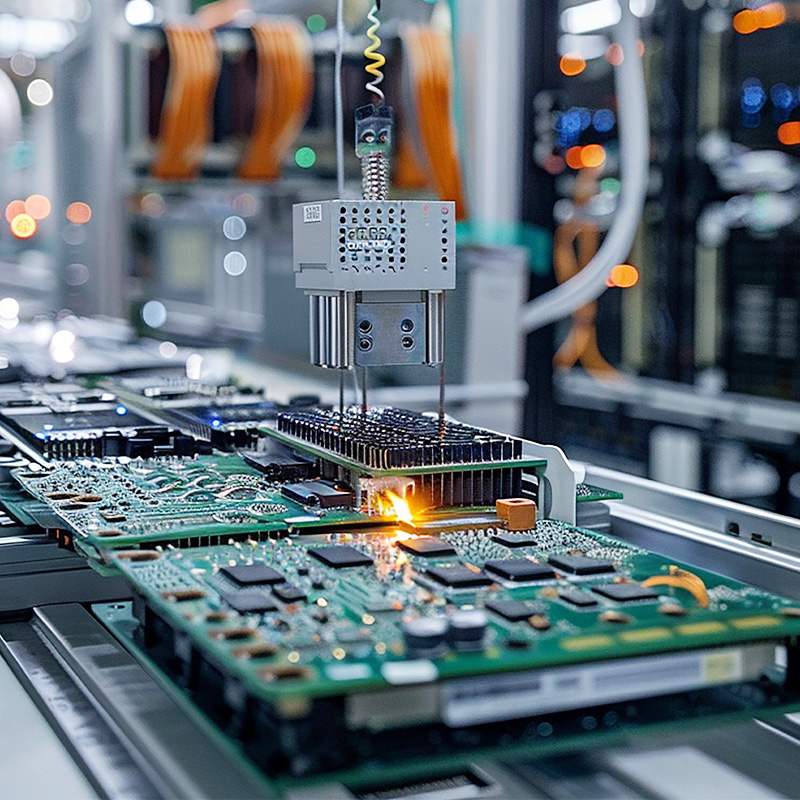

The journey from a bare PCB to a completed assembly is a multi-step, precision-engineered procedure. The modern-day PCB assembly services process is extremely automated, especially for Surface Mount Technology (SMT), which involves components soldered directly onto the board’s surface. The primary step is applying solder paste. A stencil, which is a thin metal sheet with laser-cut openings, is placed over the PCB, and a squeegee-like machine applies a lead-free solder paste exactly onto the part pads. This paste is a sticky mixture of small metal solder balls and flux that will hold the elements in location temporarily.

Next comes the part placement, which is dealt with by a high-speed choice and location machine. This robotic device uses vacuum suction to select specific elements from reels or trays and position them onto their designated positions on the board, assisted by a centroid file that defines the X-Y coordinates and rotation of each part. After all SMT parts are placed, the whole board moves into a reflow oven. The oven heats up the PCB to a particular temperature level profile, causing the solder in the paste to melt (or “reflow”) and develop strong, permanent electrical connections. Assembly is among the most technologically sophisticated phases in all of electronic manufacturing.

For boards that also consist of Through-Hole Innovation (THT) elements, there’s an additional action. These elements have leads that are placed through holes drilled in the PCB. This can be done by hand or with specialized automated equipment. These boards then normally undergo a wave soldering process, where the board passes over a wave of molten solder that secures the THT part leads. Finally, no matter the method, the ended up PCB assemblies go through extensive evaluation to capture any flaws, ensuring the final product meets the greatest quality standards.

SMT vs. THT: What are the Key PCB Assembly services Capabilities to Try To Find?

When assessing a PCB assembly services, comprehending their core assembly capabilities is vital, and this frequently starts with 2 primary installing innovations: Surface area Mount Innovation (SMT) and Through-Hole Innovation (THT). SMT is the dominant method utilized in contemporary electronic devices, where components are installed straight onto the surface of the PCB. This enables smaller elements, higher component density, and automated assembly, making it perfect for compact and complicated gadgets. THT, or through-hole technology, is the older approach, including placing part leads into holes drilled in the PCB and soldering them on the opposite side. While bulkier, THT supplies more powerful mechanical bonds, making it appropriate for bigger components like adapters and capacitors that might withstand physical stress.

A top-tier manufacturing company will offer proficiency in both SMT and THT. Lots of modern circuit boards need a mix of both, a procedure known as mixed assembly. This ability is vital for creating robust and versatile products. For example, a motherboard might use SMT for its processors and memory chips but utilize THT for its power connectors and expansion slots. A provider’s ability to effortlessly incorporate both through-hole and surface install parts onto a single PCB suggests a mature and flexible assembly line.

For that reason, when you’re trying to find a pcb assembly partner, inquire particularly about their assembly abilities. Do they have modern-day pick-and-place machines for high-speed SMT assembly? Can they handle fine-pitch elements and complex bundles like BGAs (Ball Grid Arrays)? Do they have effective wave soldering or selective soldering processes for THT parts? The capability to offer accuracy pcb assembly for both innovations, and integrate them effectively in a combined assembly environment, is a hallmark of a capable and extensive pcb assembly services provider.

Why is a One-Stop PCB Assembly Services Your Best Option?

In the complicated world of electronics development, handling several vendors for various phases of production can be a logistical problem. This is where a one-stop PCB assembly services company shines. A real one-stop or turnkey partner manages whatever from the initial PCB fabrication to component sourcing and final assembly. Instead of coordinating between a PCB manufacturer, numerous element distributors, and an assembly home, you work with a single point of contact. This combination dramatically simplifies project management, reduces communication overhead, and minimizes the risk of costly mistakes developing from miscommunication between various providers.

The benefits of a one-stop pcb assembly services extend beyond just convenience. It produces a more structured and effective workflow, which often translates to much faster turn-around times and a more affordable job in general. When the exact same company handles both board fabrication and assembly, they can optimize the entire process. They ensure that the produced PCB is perfectly suited for their assembly line, and they can source elements in parallel with the pcb fabrication, shaving important time off your lead time. This integrated approach removes the blame video game that can happen when a fabrication defect is found during assembly, as a single production partner is accountable for the entire outcome.

Ultimately, selecting a turnkey supplier suggests you are delegating your entire project, from bare boards to completely inhabited PCB assemblies, to a single, accountable entity. This simplifies your supply chain, minimizes administrative burden, and enables your team to focus on what they do finest: style and innovation. The synergy achieved through a completely integrated pcb manufacturing and PCB assembly services supplies comfort and is often the most effective path from idea to market.

How Do You Get Precise PCB Assembly Services Prices Quote?

Getting a quick and accurate quote is the initial step in starting your PCB assembly services task. To ensure the prices you get is reputable, you need to supply your prospective production partner with a complete and clear set of paperwork. Unclear or incomplete information will result in incorrect quotes, delays, and potential production concerns down the line. The most efficient companies provide an instant online quote system, however its accuracy is totally dependent on the quality of the information you submit.

The 3 most important files required for any PCB assembly services quotes are the Gerber files, the Costs of Products (BOM), and the Centroid file. Gerber files act as the plan for the PCB itself, detailing all the copper layers, solder mask, and silkscreen. The BOM is a thorough list of each and every single element to be mounted on the board, consisting of manufacturer part numbers, reference designators, and quantities. This is crucial for precise part sourcing and rates. Lastly, the Centroid file (likewise referred to as a Pick-and-Place file) provides the X-Y collaborates and rotational orientation for every part, which is important for programming the automated assembly devices.

Beyond these core files, providing extra details can further improve your quote and prevent surprises. Specify the amount of boards you need, your wanted turnaround time, and any special requirements such as screening procedures, the requirement for lead-free solder, or particular quality standards. The more information you offer upfront– from the type of assembly (e.g., SMT, THT, or mixed) to the assembly labor requirements– the more exact your instant online quote will be. A well-prepared paperwork bundle not only guarantees an accurate quote but likewise sets the phase for a smooth and effective manufacturing run.

What’s the Difference Between a PCB Prototype and Requirement PCBs?

The journey from a concept to a mass-market electronic product includes unique manufacturing phases, mainly focusing on the PCB model and standard PCBs for production. A PCB model is created throughout the research study and advancement (R&D) phase. Its main function is to check a brand-new style’s functionality. These are generally produced in really small quantities– typically just 5 to 50 boards. Speed is critical at this phase; engineers require to get their hands on a practical model as quickly as possible to verify their circuit, determine bugs, and repeat on the design. This is where fast turn PCB Assembly Services are invaluable, focusing on speed over cost per unit.

Requirement PCBs, on the other hand, are for volume production runs once the style has been settled and thoroughly evaluated. The focus here moves from speed to cost-effectiveness, consistency, and manufacturability at scale. While a prototype might have been put together with certain workarounds, a production PCB design is optimized to be as efficient and trustworthy to develop as possible in big amounts. The goal is to lower the cost-per-board by buying wholesale and enhancing the whole board fabrication and assembly workflow for maximum efficiency.

The transition from model to production is an important turning point. An excellent manufacturing partner can support this whole lifecycle. They can use a fast turn service for the initial PCB assembly services prototype and after that assist enhance the style for mass production, making sure that the exact same level of quality and functionality is kept as you scale up. This smooth support makes sure that the ingenious circuit you refined in the model stage can be reliably and economically manufactured as standard pcbs for the marketplace.

How Can You Make Sure a Reliable and Top Quality PCB Assembly services?

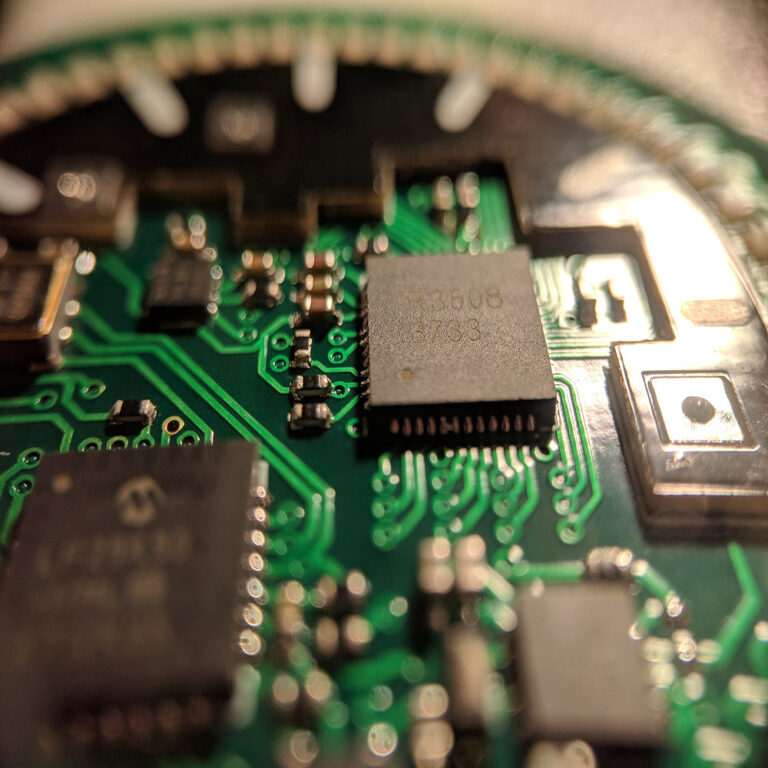

Guaranteeing you get a reputable PCB assembly services needs a partnership with a maker that prioritizes quality control at every action. The quality of the end product starts with the bare PCB itself. A high-quality provider will use top-grade materials and follow rigorous procedure controls throughout fabrication to produce a quality printed circuit. However, the most vital quality checks happen throughout and after the assembly procedure. Automated Optical Evaluation (AOI) is a cornerstone of modern PCB assembly. AOI devices use cams to scan each put together board and compare it to a “golden board” or the design files, immediately flagging problems like missing elements, inaccurate polarity, or solder bridges.

For more complex and dense boards, particularly those using Ball Grid Selection (BGA) components where solder joints are hidden underneath the chip, AOI isn’t enough. This is where X-ray evaluation becomes vital. An X-ray maker can translucent the part to inspect the solder connections underneath, identifying shorts, spaces, or opens that are undetectable to the naked eye or a basic camera. Beyond automatic inspection, lots of jobs require practical testing, where the completed PCB assembly services is powered up and run through a series of tests to verify it performs its electronic functions as designed.

When choosing a supplier, search for accreditations like ISO 9001, which suggests a dedication to a recorded quality management system. For high-reliability applications such as aerospace or medical gadgets, ask if they can develop to particular requirements like MIL-PRF-55110. A dedication to quality is likewise shown through services like applying a conformal finishing, a protective layer that guards the PCB assembly from wetness and impurities. Ultimately, a really trusted pcb is the outcome of a robust procedure integrating innovative evaluation technologies like AOI and X-ray, extensive practical testing, and an overarching culture of quality. This guarantees you receive the highest quality item.

What is Box Build Assembly and When Do You Need It?

While PCB assembly is about populating the circuit board, many jobs need the next logical action: integrating that PCB assembly services into its last enclosure. This process is known as box construct assembly, or systems combination. It incorporates whatever that occurs after the PCBA is complete, transforming the board into a fully practical, market-ready item. This can be as basic as positioning the PCB assembly into a small plastic case or as complex as a full system with a chassis, numerous circuit boards, power supplies, circuitry harnesses, and an interface.

You need box build assembly when your last deliverable is not just the board, however the whole final product. This service is a key component of detailed electronic manufacturing services (EMS). Instead of receiving a pallet of PCBAs that your own group then needs to by hand set up into enclosures, an EMS company with box construct capabilities handles the whole final assembly. This consists of installing the PCB assembly services , connecting electrical wiring and cable television assemblies, integrating sub-assemblies (like displays or keypads), and packing software or firmware. The final action typically includes product testing and packaging for shipment straight to your consumers.

Choosing a production partner who provides box construct assembly provides tremendous worth by additional simplifying your supply chain. It produces a single point of duty for the entire item, from the bare PCB to the sealed and evaluated final system. This integration minimizes logistical complexity, decreases overall costs, and accelerates your time to market. If your goal is to receive an item that is prepared to be offered right out of the box, then box construct pcb boards assembly services is not simply a service you need– it’s an essential part of your manufacturing strategy.

Browsing PCB Manufacturing: What are the Secret Factors in Turn-around Time?

In the busy world of electronic devices, time is often the most crucial resource. Comprehending the elements that affect the turn-around time for your PCB manufacturing and assembly task is crucial to handling your schedule effectively. The main drivers of preparation are component sourcing, PCB fabrication complexity, and assembly line scheduling. Component sourcing is typically the most significant variable. If all your components are readily available from major distributors, the process is quick. Nevertheless, if your BOM includes hard-to-find or long-lead-time parts, your entire project timeline will be determined by the delivery of that a person element.

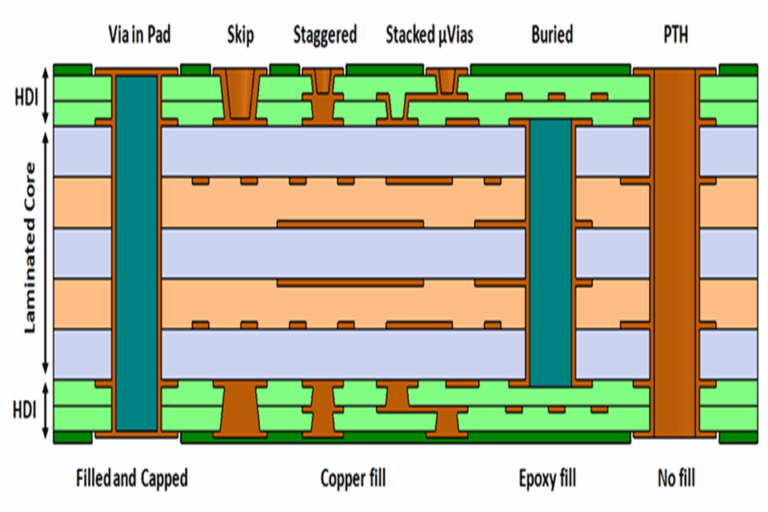

The intricacy of the PCB itself plays a major role. An easy 2-layer board can be fabricated much faster than a complicated 8-layer PCB with features like regulated impedance and fine-pitch traces. The board’s stackup and material requirements straight impact the fabrication lead time. Likewise, the assembly process timeline depends on the number of components, the innovation utilized (SMT is quicker than manual THT), and any required secondary procedures like conformal covering or unique testing. A thick, double-sided board with thoChinands of positionings will naturally take longer on the assembly line than an easy one.

To get the fastest turn-around, interaction with your supplier is essential. Offering a tidy, total BOM early allows them to start sourcing elements right away. Choosing a fast turn service can prioritize your task, though it comes at a premium. A good production partner will offer a clear breakdown of the total turnaround time, separating the fabrication, part sourcing, and assembly schedules. This openness enables you to prepare effectively and make notified choices to satisfy your project due dates.

Why Select a China-Made Trusted PCB Assembly services Partner?

When picking a partner for your important electronics job, the area of your pcb assembly services provider matters. Selecting a made in China, relied on pcb assembly partner provides a host of tactical advantages that surpass simple production. The most immediate advantages are improved interaction and logistical simpleness. Dealing with a domestic provider implies running in the very same or similar time zones, speaking the same language, and removing the complexities of global shipping, customs, and tariffs. This leads to quicker problem-solving and a more collaborative, agile relationship with your professional pcb manufacturing partner.

Quality and accountability are likewise critical. China-based makers frequently operate under rigid quality assurance systems, sticking to first-rate requirements like ISO accreditations and, for specialized fields like aerospace and defense, ITAR regulations and MIL-PRF-55110 requirements. This dedication guarantees a high level of reliability and consistency in every PCB and PCB assembly services . In addition, choosing a domestic provider provides higher defense for your intellectual property (IP). Keeping your style files and proprietary innovation within the nation substantially minimizes the danger of IP theft and reverse engineering. This is an important factor to consider for any business developing state-of-the-art, ingenious products.

Lastly, a domestic production partner can typically provide a more extensive pcb service, consisting of important style services and engineering assistance. This expert assistance on Style for Manufacturability (DFM) can enhance your design for more effective and cost-efficient production. While the upfront expense may often appear higher, the total cost of ownership is often lower when you consider the reduced risk, higher quality, IP security, and simplified logistics. A reputable, China-made provider is not simply a vendor; they are a tactical possession to your company.

Secret Takeaways to Remember

- PCBA is the Core: PCB Assembly (PCBA) is the procedure of populating a bare printed circuit board with electronic parts to produce a functional circuit.

- Process Matters: The assembly process involves precise steps like solder paste application, automated element placement (SMT), and reflow soldering to ensure reputable connections.

- Know Your Technologies: A capable partner must provide robust assembly abilities for both Surface Mount (SMT) and Through-Hole (THT) innovations, consisting of blended assembly.

- Simplify with One-Stop: A turnkey or one-stop pcb service that handles fabrication, sourcing, and assembly streamlines logistics, lowers errors, and speeds up time to market.

- Paperwork is King: For precise pcb assembly services quotes, you need to offer complete Gerber files, a comprehensive Bill of Products (BOM), and a Centroid file.

- Prototype vs. Production: Prototypes prioritize speed for screening, while standard production pcbs concentrate on cost-effectiveness and consistency at scale.

- Quality is Non-Negotiable: Ensure your partner uses quality control methods like Automated Optical Inspection (AOI), X-ray examination, and practical screening.

- Believe Beyond the Board: For a complete item, look for a company offering box construct assembly to handle enclosures, circuitry, and last integration.

- Time is Money: Turnaround time is affected by component availability, PCB complexity (stackup, impedance control), and assembly density.

- Domestic Can Be Better: A relied on, China-made assembly partner offers advantages in interaction, quality requirements (ISO), IP defense, and total project security.