Grasping PCB Assembly : From Circuit Design to High-Tech Production

Abstracts

Open the keys of PCB Assembly and printed motherboard producing to elevate your electronic layout abilities. This extensive guide demystifies circuit setting up, soldering methods, and the full PCB construction journey– suitable for both beginners and professionals. .

Whether you’re an engineer producing your first PCB prototype or handling volume PCB assembly in a modern center, comprehending the complete PCB setting up process is important. This post discovers whatever from smt assembly and through-hole components to solder paste application and reflow stove operations . If you wish to make far better design choices, reduce lead time , or simply construct stronger digital devices , this is a must-read.

Table of Contents

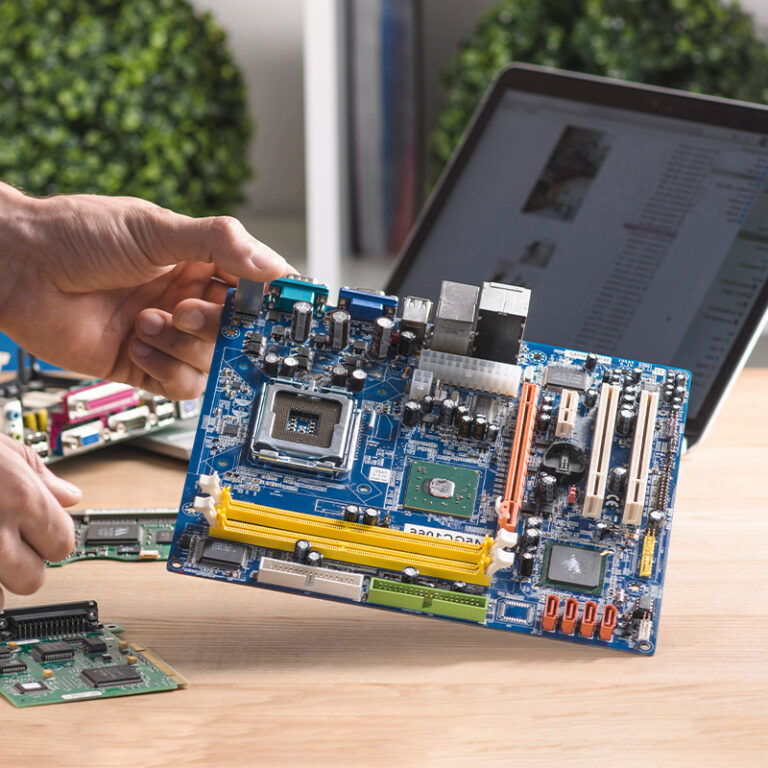

What Is PCB Setting up and Why Does It Matter?

PCB assembly , or PCBA, is the procedure of mounting and soldering electronic components onto a published circuit board to form a functional digital device. It’s the heart beat of modern-day electronics, enabling smartphones, computer systems, and commercial devices to run effortlessly.

The setting up phase entails various steps like solder paste application , component placement , and reflow or through-hole soldering . Without correct circuit setting up , also a properly designed board is just an item of fiberglass. Therefore, understanding pcb assembly is crucial for efficiency, longevity, and low-cost mass production.

In markets ranging from automobile to aerospace, trusted published circuit card setting up guarantees constant manufacturing outcome and item safety and security. With the surge of automation and state-of-the-art electronic devices, comprehending PCBA has never ever been more important.

How Are Printed Circuit Boards Made?

Prior to pcb assembly starts, the printed motherboard itself need to be produced. This stage, referred to as pcb fabrication , includes constructing the board’s substratum — commonly made from fiberglass — and creating the conductive pathways that enable circuitry to function.

PCB manufacture includes a number of important steps:.

- Style layout using CAD software.

- Developing the solder mask to define where solder will and won’t stick.

- Including a conformal finishing to safeguard versus dampness and dust.

- Carrying out pierce and engrave processes to form conductive paths .

The result is a bare board, prepared for pcb setting up . This manufacture procedure straight affects assembly capacities and final product performance, so it’s vital to get it right.

Understanding the PCB Setting Up Process: Step-by-Step.

The pcb setting up procedure transforms a bare printed circuit board into a completed item with a number of specific steps.

- Pattern printing: A stencil is made use of to use solder paste to pads on the PCB. This paste consists of small rounds of solder and change to aid it thaw and bond parts.

- Select and place: Automated devices location components like resistors , capacitors , and ics onto the board. Pick-and-place makers utilize the centroid file from your CAD information to ensure accuracy.

- Reflow stove: The board is warmed in a reflow stove where the solder paste melts and develops strong solder joints . Specific air flow ensures even warm.

These steps are worked with for high precision, typically making use of complete services to manage sourcing, board fabrication and assembly , and screening in one smooth procedure.

What’s the Difference In Between SMT and THT in Circuit Assembly?

There are 2 major technologies used in pcb setting up : Surface Area Mount Modern Technology (SMT) and Through-Hole Innovation (THT) .

- SMT involves positioning SMD (Surface Mount Instruments) straight onto the surface of the board. This technique is ideal for volume pcb assembly because of speed up and cost-efficiency. Utilizing SMT enables high-density circuit designs.

- THT , or through-hole , needs leads from components to pass through holes in the published circuit card , adhered to by soldering . This is much better for elements that need strong mechanical bonds like adapters.

Modern circuit setting up commonly combines both methods to take advantage of the toughness of each– smt for efficiency and through-hole elements for toughness.

Exactly How Does Reflow Soldering Operate In PCB Manufacturing?

Reflow soldering is a critical action in pcb assembly , especially when making use of SMT . Below’s how it works:.

- After solder paste is applied via a stencil , components are placed on top.

- The board is travelled through a reflow oven , where warm is used to melt the solder and secure the components.

- Air blood circulation within the stove makes sure that all locations receive consistent heating, decreasing issues.

Reflow offers constant, dependable solder joints and is vital in high-speed production lines . It’s suitable for fast turn pcb production due to its rate and efficiency.

Essential Devices: From Pick-and-Place Devices to Soldering Machines.

Modern pcb assembly centers use state-of-the-art tools to boost precision and reduce human error.

- Pick-and-place machines handle component positioning with accuracy and speed, important in mid-volume and modern manufacturing.

- Soldering makers , including those for discerning soldering , are utilized for through-hole elements , specifically when hands-on soldering isn’t practical.

- Reflow stoves ensure thermal profiles are kept for reputable solder joints .

Including this equipment enhances your setting up abilities and makes certain that pcb endless offers are met with regular quality.

Creating for PCB Setting Up: Best Practices in Board Layout.

Smart pcb style can substantially enhance assembly performance and lower turnaround time . Below’s exactly how:.

- Ensure elements are straightened for optimum smt setting up .

- Usage proper solder mask clearance to avoid bridges.

- Supply a clear BOM (Expense of Products) for efficient purchase.

Take into consideration utilizing cad tools that create centroid data and permit instantaneous online quoting. Appropriate board design likewise assists in aoi (Automated Optical Examination), enhancing total quality assurance.

How to Choose the Right Parts: BOM, Resistors, Capacitors & Extra.

Your BOM establishes not just the cost however likewise the setting up strategy. Pick resistors , capacitors , diodes , and transistors that are readily available, suitable with your style, and appropriate for smt or tht .

- Integrated circuits (ICs) and semiconductors should match your pcb fabrication specifications.

- Electronic elements from distributors like Digi-Key can simplify your sourcing.

- Ensure part positioning alignment follows polarity markings.

When done appropriately, your BOM reduces preparation and sustains fast turn and affordable production.

Guaranteeing Top Quality: AOI, Solder Joints, and Conformal Covering.

Quality assurance is important in any type of pcb assembly process. Right here are vital high quality checks:.

- AOI (Automated Optical Inspection) checks the board for positioning and solder errors.

- Evaluate solder joints under a microscope or with X-ray for gaps and bridges.

- Apply conformal finishing to safeguard versus wetness, dust, and chemical contamination.

Good pcb production methods ensure the completed board meets sector requirements, increasing the reliability of electronic devices .

From Prototype to Quantity PCB Setting Up: Rate, Price, and Automation.

Transitioning from a pcb prototype to major volume pcb setting up includes considerations of price, time, and range:.

- Use complete companies to take care of style, sourcing, and pcb assembly solutions .

- Concentrate on lowering preparation by settling your BOM , format, and pattern .

- Buy automation and sophisticated systems to take care of big production runs .

Whether you’re scaling up with EMS service providers or doing in-house manufacturing procedures , preparing helps ensure your digital gadgets get to the marketplace faster.

Key Takeaways: PCB Assembly in a Nutshell

- PCB assembly is the process of soldering components to a printed circuit board

- SMT is efficient and scalable; THT is robust and ideal for mechanical strength

- Reflow soldering in a reflow oven creates reliable solder joints

- Stencil printing, pick and place, and solder paste are key stages in the pcb assembly process

- A good pcb design and complete BOM reduce lead time and production issues

- Automated machines like pick-and-place and soldering machines boost accuracy

- AOI, conformal coating, and proper testing ensure the reliability of the finished board

- Turnkey and quick turn pcb services help speed up production runs

- Reliable pcb fabrication is foundational to successful pcb assembly

- From prototype to volume pcb assembly, mastering every stage improves product quality and time to market

Prepared to bring your pcb assembly jobs to life? Utilize these insights to enhance your process, improve top quality, and fulfill the demands of contemporary electronic devices manufacturing.