How much does pcb assembly cost?

2025 PCB Assembly cost Guide: Understanding Pricing & Techniques for Cost Performance

Abstract

The 2025 PCB Assembly cost Guide offers a detailed failure of factors influencing printed circuit card (PCB) setting up expenses. From component pricing and labor prices to hidden costs and geographic considerations, this guide gears up engineers and suppliers with workable understandings to enhance budget plans without endangering high quality. By evaluating fads, study, and cost-saving strategies, readers can achieve considerable savings in their PCB projects.

Table of Contents

Intro

Did you recognize that PCB assembly cost expenses can differ by over 2500% depending upon style intricacy, production volume, and supplier location? Comprehending these variables is essential for enhancing your electronic devices manufacturing spending plan. This guide looks into the details of PCB setting up pricing, using a roadmap to minimize expenses while keeping top quality criteria. Whether you’re a designer, engineer, or procurement professional, the insights below will certainly encourage you to make enlightened choices in 2025 and past.

Recognizing PCB assembly cost : A Foundational Summary

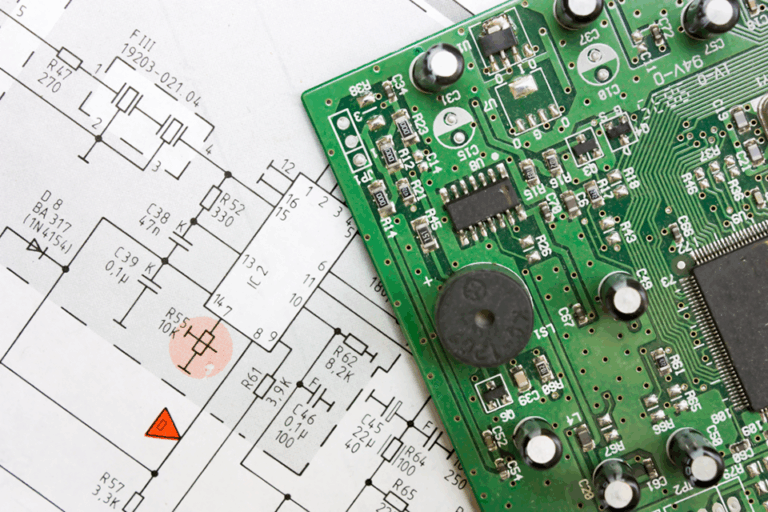

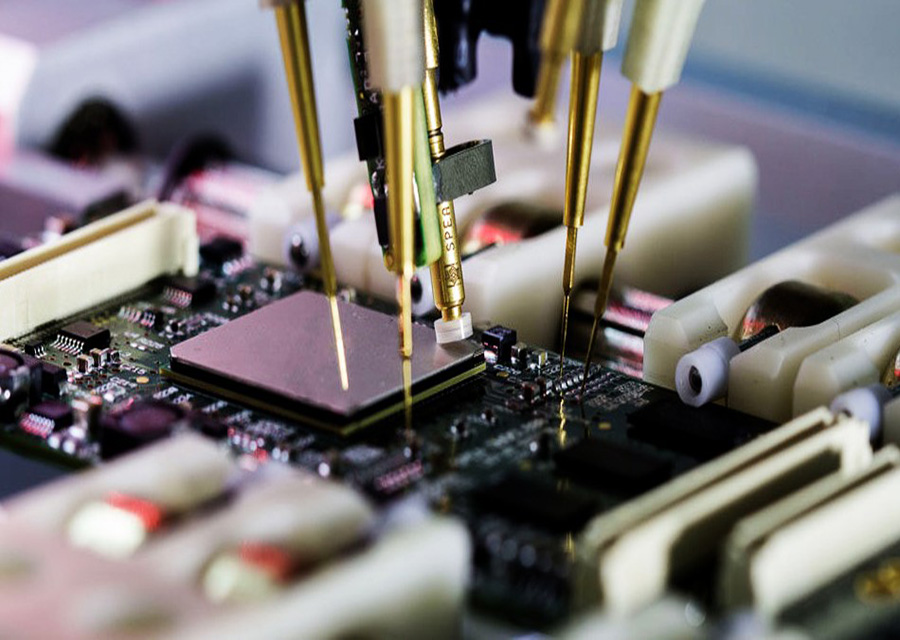

PCB assembly cost entails soldering digital elements onto a bare board to produce functional circuits. 3 key techniques define this process:.

- Surface Area Mount Technology (SMT): Parts are put straight onto the PCB surface area making use of automated equipment.

- Through-Hole Setting Up: Element leads are put right into pierced openings and soldered manually or semi-automatically.

- Mixed-Technology Assembly: Incorporates SMT and through-hole approaches for complex layouts.

Post-assembly, boards undertake examining to make sure capability, consisting of Traveling Probe Testing and Automated Optical Examination (AOI) .

PCB Assembly cost Trick Trends in 2025

- Material Shortages: Global chip scarcities remain to drive up element costs, specifically for microcontrollers and FPGAs.

- Automation Innovations: Increased use of robotics and AI lowers labor expenses for high-volume SMT manufacturing.

- Miniaturization Needs: Growing demand for portable, high-density boards necessitates specialized setting up techniques.

The Makeup of PCB Assembly cost

To understand expense control, explore the components of PCB assembly cost.

1. Element Pricing Break Down

Part prices develop the foundation of setting up expenditures. Below is a 2025 recommendation table for normal cost arrays:.

| Element Kind | Rate Array (USD) |

|---|---|

| Easy Components | $0.001–$ 0.01 |

| Integrated Circuits (ICs) | $0.10–$ 20 |

| Connectors/Headers | $0.05–$ 5 |

Key Influencers: .

- Amount Discounts: Mass purchases lower per-unit expenses.

- Market Volatility: Supply chain disruptions (e.g., semiconductor scarcities) create cost spikes.

2. Labor vs. Equipment Prices

Setting up technique straight affects cost performance:.

| Method | Cost per Joint (USD) | Usage Case |

|---|---|---|

| SMT Machine Positioning | $0.001–$ 0.02 | High-volume production |

| SMT Guidebook Positioning | ~$ 0.05 | Models or small batches |

| Through-Hole Setting up | $0.03–$ 0.10 | High-reliability applications |

Why SMT is Affordable: Automated SMT decreases labor dependency, making it excellent for large orders.

3. Hidden Fees You Can Not Neglect

Neglected fees can blow up spending plans:.

- Configuration Fees: $50–$ 200 for machine shows and calibration.

- Pattern Costs: $30–$ 100 for solder paste application.

- Testing Fees: .

- Flying Probe Screening: ~$ 0.05 per board.

- AOI: $0.05–$ 0.10 per board.

- Pro Idea: * Constantly request a thorough cost failure from suppliers to identify these charges upfront.

5 Key Factors Driving PCB Assembly Cost

1. Part Kind & Schedule

- SMD Parts: Less expensive to put together because of automation compatibility.

- Through-Hole Components: Greater labor costs but required for high-power applications.

- Availability Crisis: MCU prices increased 15% in 2025 due to provide chain traffic jams.

2. Order Amount

| Order Volume | Per-Board Price (USD) | Example |

|---|---|---|

| Models (5– 10) | $50–$ 200 | Perfect for layout validation |

| Bulk (1,000+ units) | $2–$ 20 | Economies of scale lower expenses |

Study: A client reduced per-unit expenses by 60% by enhancing order volume from 100 to 1,000 systems.

3. Turn-around Time

- Standard (7– 14 days): Base prices.

- Thrill (24– 72 hours): 50%– 300% costs.

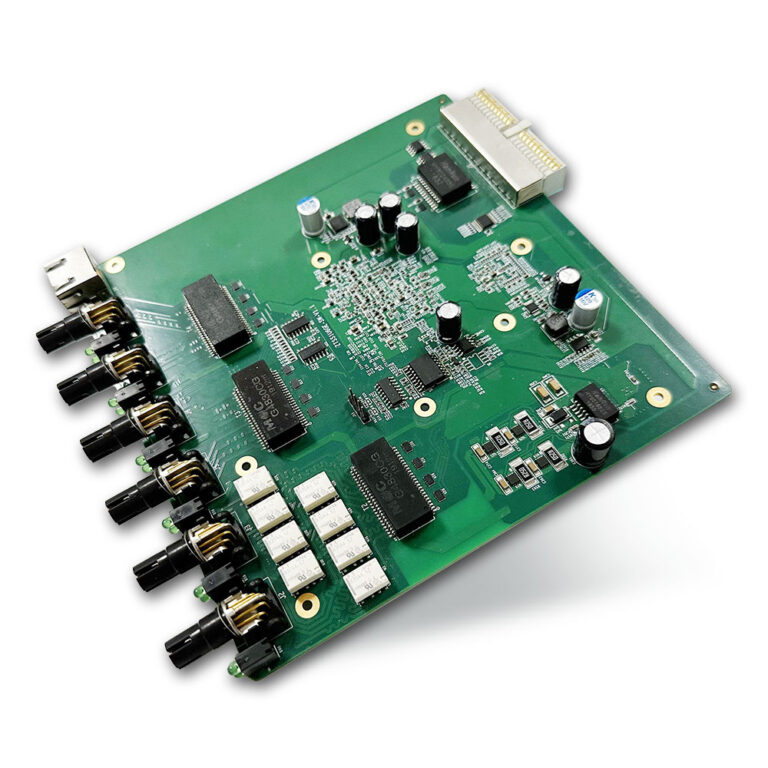

4. Board Complexity

| Layout Attribute | Cost Effect |

|---|---|

| Layer Matter (8 vs. 2) | 4x greater assembly expense |

| HDI/Rigid-Flex Boards | $100+ per board compared to $10 |

Layout Optimization Suggestion: Streamline layer matters and prevent ultra-fine traces (below 0.5 mm) to cut costs.

5. Geographical Location

| Area | Per-Component Cost (USD) | Added Factors to consider |

|---|---|---|

| China (JLCPCB, PCBWay) | $0.05–$ 0.50 | Quick shipping, IP security issues |

| USA/EU (Advanced Circuits) | $0.50–$ 2.50 | Greater labor expenses, more stringent guidelines |

Decision Structure: Balance cost financial savings with logistics and IP threats when picking a vendor.

Techniques to Reduce PCB Assembly Cost

1. Mass Order Discounts

Take advantage of economic situations of scale:.

- Instance: A 1,000-unit order slashes per-board costs by 60% compared to 100 systems.

- Risk Reduction: Companion with vendors using adaptable repayment terms for bulk orders.

2. Design Optimization

- Panelization: Arrange multiple boards on a solitary panel to conserve 20% on assembly.

- Product Selection: Use basic FR-4 as opposed to high-performance materials (e.g., Rogers) to cut prices by 90%.

3. Supplier Comparison

Compare prices and abilities:.

| Vendor | SMT Cost per Joint (USD) | Staminas |

|---|---|---|

| JLCPCB | $0.0015 | Competitive rates, quick delivery |

| PCBWay | $0.002 | Advanced testing, worldwide reach |

Activity Step: Request quotes from 3– 5 providers to determine the very best value recommendation.

Case Study: Real-World PCB Assembly Cost Optimization

Project: 100-unit order of 4-layer IoT PCBs with mixed SMT/through-hole parts.

First Price: $1,200 ($ 12/unit). After Optimization: .

- Bulk Order: Enhanced to 500 systems → $800 ($ 1.60/ system).

- Style Simplification: Decreased layers from 4 to 2 → $600 ($ 1.20/ system).

- Provider Change: Chose JLCPCB over PCBWay → $500 ($ 1.00/ device).

Total Savings: 58% reduction in expenses.

Frequently asked questions

1. What element kind is most cost-efficient for PCB assembly?

SMD parts are generally more affordable to put together because of automatic SMT processes.

2. Exactly how can I minimize PCB setting up costs without endangering top quality?

Maximize layout (e.g., streamline layers, utilize basic products), rise order quantity, and contrast distributors.

3. Are hidden charges typical in PCB assembly?

Yes, arrangement fees, pattern costs, and testing costs are usually neglected yet can significantly affect budget plans.

4. Is offshore PCB setting up always more affordable?

While China-based suppliers offer lower per-component prices, think about logistics, IP threats, and quality control.

5. What’s the largest element impacting PCB setting up prices?

Order volume has the most substantial effect, with bulk orders minimizing per-unit costs by 50% or even more.

6. How do I choose in between SMT and through-hole setting up?

SMT is optimal for high-volume, small layouts, while through-hole is better for high-reliability or high-power applications.

Conclusion

Mastering PCB setting up costs in 2025 needs a calculated technique that stabilizes design optimization, provider option, and production volume. By understanding element prices, leveraging mass price cuts, and taking on cost-saving innovations like SMT automation, makers can minimize costs by as much as 30% without compromising high quality. As material shortages continue and automation advancements, remaining educated regarding market trends will certainly be vital for maintaining competitive rat