🧠What is Printed Circuit Assembly in 2025?

Abstract .

Printed circuit assembly (PCBA) is the procedure of occupying and soldering electronic elements onto a published motherboard (PCB) . This important operation transforms a blank board into an operating circuit setting up . Comprehending PCBA aids manufacturers, developers, and engineers make sure dependability, performance, and manufacturing performance. This post dives deep right into the phases of circuit setting up, involved technologies, screening standards, and its real-world applications.

Table of Contents

Intro .

Every modern electronic device– from mobile phones to satellites– counts on published circuit card . However a PCB alone can not do any type of feature. It’s the process of printed circuit setting up that takes a breath life right into these boards. This post describes what published circuit setting up is, its process steps, innovations entailed, and why it is a foundation of electronic devices making.

1. What is Printed Circuit Assembly? .

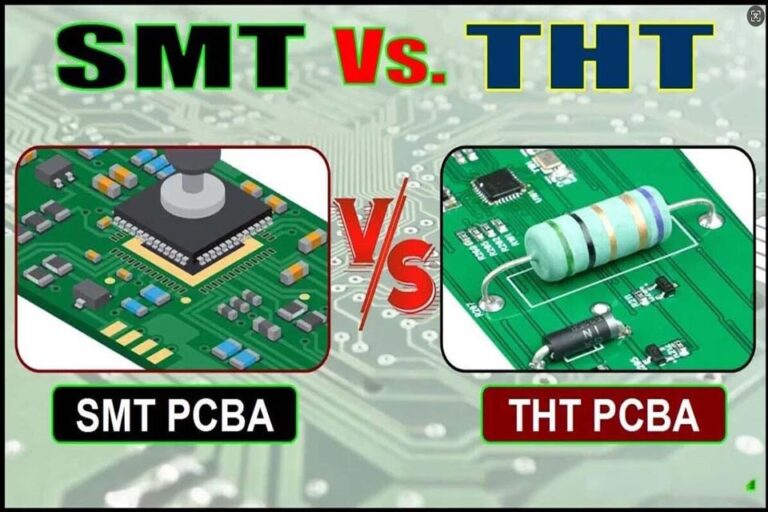

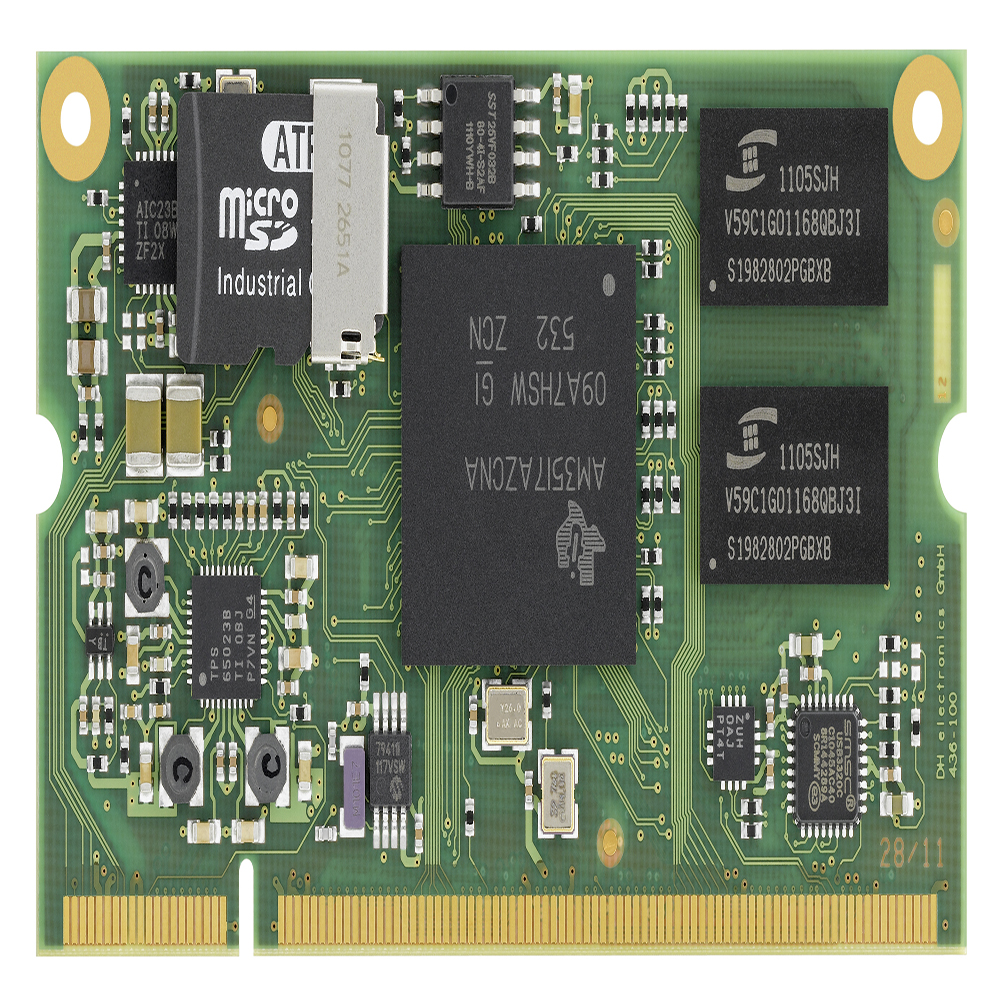

Printed circuit assembly (PCBA) is the procedure of attaching electronic components to a printed circuit board (PCB) to create a useful setting up. The procedure uses either surface-mount modern technology (SMT) , through-hole technology , or a combination of both.

During PCBA, resistors, capacitors, diodes, ICs, and adapters are mounted and soldered to certain contact pads. This transforms an easy PCB into an operational electronic circuit assembly . Trick Terms : printed circuit assembly, circuit setting up, published circuit board .

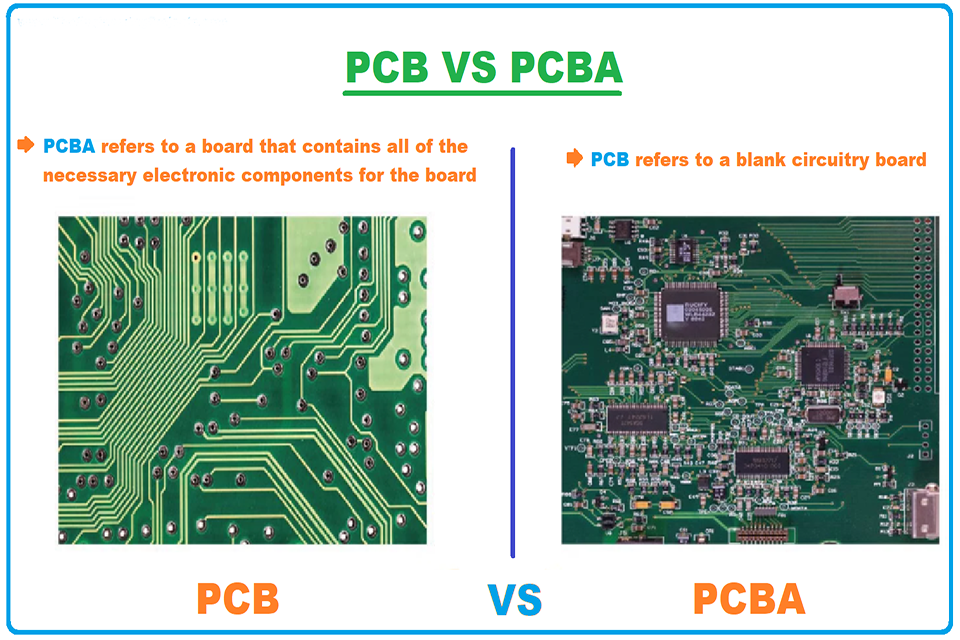

2. Exactly how Does a Printed Circuit Board Differ from Printed Circuit Assembly? .

A PCB is just the base board with copper traces but without any energetic components. A PCBA is the put together PCB , equipped with all needed digital parts.

- PCB = Non-active, unpopulated board .

- PCBA = Active, assembled circuit board .

This distinction is vital in electronic devices layout and manufacturing.

3. Why is the PCBA Refine Essential to Circuit Setting Up? .

The circuit assembly process makes certain that components are precisely put, soldered, and functionally verified. A single lost chip or soldering mistake can make a product ineffective. Appropriate PCBA sustains:.

- Reliable signal flow.

- Reduced power loss.

- Product reliability.

- Heat dissipation.

- Area optimization.

4. What Are the Main Steps in a Printed Circuit Setting Up Refine? .

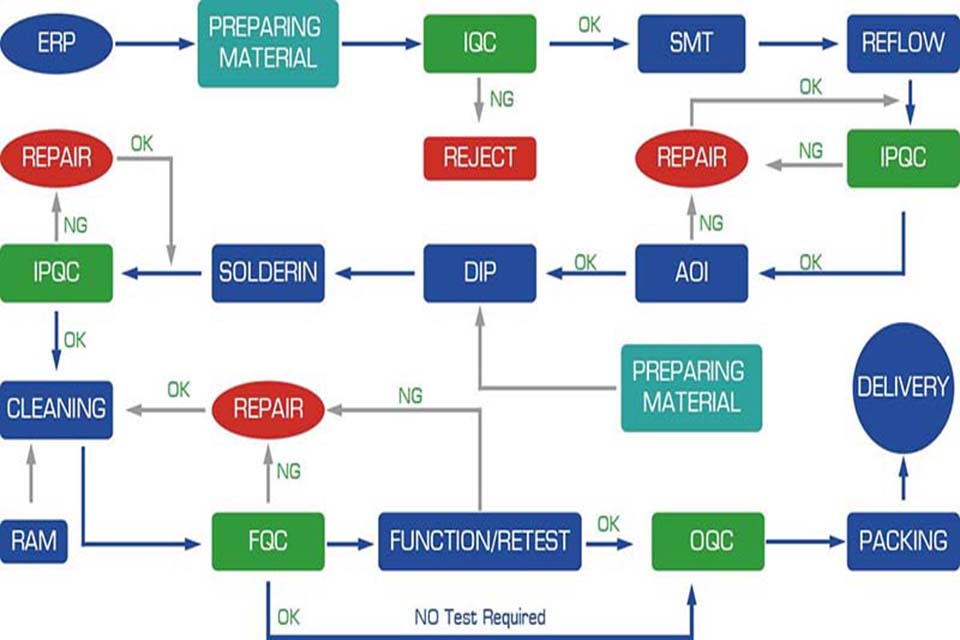

➤ Action 1: Solder Paste Application.

Solder paste is applied to the PCB’s pads using a stencil. This paste holds components prior to reflow.

➤ Step 2: Choose and Area.

High-speed automated makers put elements like ICs, resistors, and capacitors with high precision.

➤ Step 3: Reflow Soldering.

The board travels through a reflow oven, melting the solder and bonding the components to the board.

➤ Action 4: Through-Hole Insertion.

For elements with leads, holes are pierced, and the parts are placed and soldered using wave soldering.

➤ Action 5: Assessment and Screening.

Optical evaluation, X-ray, and functional screening guarantee no brief circuits or misalignments exist.

5. What Are the Sorts Of Parts Utilized in Printed Circuit Assembly?

A published circuit assembly includes:.

- Surface-Mount Devices (SMDs): Installed directly onto the board’s surface area. Ideal for miniaturized designs.

- Through-Hole Components: Put into pierced holes and soldered on the opposite side. Made use of for toughness and stability.

Usual parts: Resistors, capacitors, LEDs, transistors, microcontrollers, ports, oscillators.

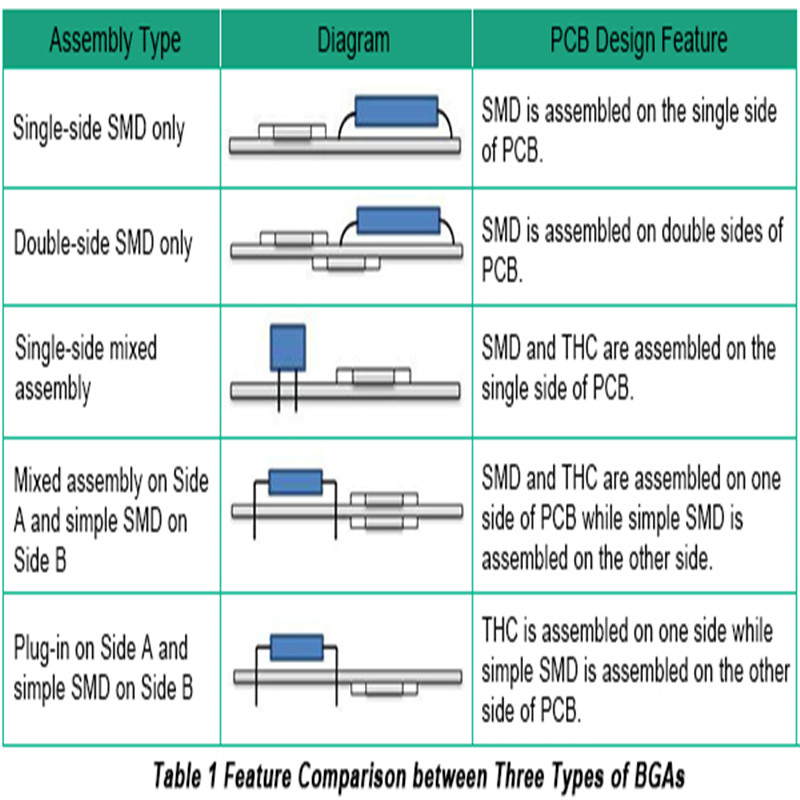

6. What Technologies Are Utilized in Printed Circuit Board Assembly?

➤ Surface Area Mount Modern Technology (SMT).

Widely utilized because of speed, price, and space effectiveness.

➤ Through-Hole Innovation.

Utilized in power electronics, aerospace, and armed forces PCBs because of its mechanical strength.

➤ Mixed Technology.

Incorporates both for complicated circuits or gadgets with both power and reasoning areas.

Other modern technologies consist of: .

- Reflow soldering.

- Wave soldering.

- Discerning soldering.

- Automated Optical Assessment (AOI).

- X-ray Inspection.

7. What Inspection and Screening Techniques Guarantee PCBA High Quality?

A robust published circuit assembly calls for strenuous screening:.

- Visual Inspection .

- AOI (Automated Optical Inspection) .

- X-Ray Evaluation .

- In-Circuit Testing (ICT) .

- Functional Examining (FCT) .

These guarantee there are no shorts, opens up, solder bridges, or component misplacements.

8. Just How Does PCBA Affect Item Performance and Integrity?

Improper circuit setting up causes very early failures. Top quality PCBA makes sure:.

- Signal honesty .

- Power circulation .

- Thermal security .

- Electro-magnetic compatibility .

This is particularly vital in automotive , clinical , and aerospace electronics where reliability is non-negotiable.

⚠ 9. What Are Common Obstacles in Printed Circuit Setting Up?

Despite automation, PCBA comes with challenges:.

- Element imbalance .

- Soldering issues .

- Electrostatic damage .

- Board warping .

- Element accessibility delays .

Design for Manufacturability (DFM) and good distributor partnership reduce these problems.

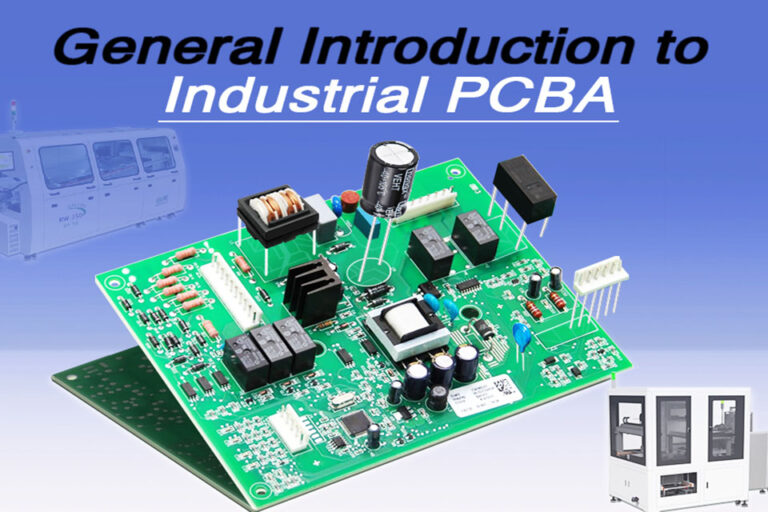

10. What Are Real-World Applications of PCBAs?

Printed circuit settings up power a variety of devices:.

- Customer Electronic Devices — Phones, laptop computers, Televisions.

- Medical Equipment — Screens, imaging tools.

- Automotive Solutions — ECUs, infomercial, sensors.

- Industrial Controls — PLCs, HMIs, relays.

- Aerospace Systems — Navigation, radar, avionics.

Every industry depends on high-precision circuit settings up for efficiency and security.

❓ Frequently asked questions.

What’s the distinction in between PCB and PCBA?

A PCB is a bare board; a PCBA includes all mounted elements ready for use.

Why is solder paste utilized in circuit assembly?

It holds and links parts during reflow soldering.

Which is far better: SMT or through-hole?

SMT is optimal for compact designs; through-hole deals mechanical strength.

Just how do you evaluate a published circuit assembly?

Utilizing AOI, X-ray, in-circuit, and useful examinations.

Can I recycle a PCBA?

Typically no. Desoldering can harm traces and components.

What sectors use PCBAs?

Electronics, automobile, aerospace, clinical, commercial automation.

✅ Summary.

Below are the bottom lines to remember concerning printed circuit setting up :.

- A PCBA is a functional version of a PCB.

- It uses SMT, through-hole, or blended innovations.

- Core steps consist of solder paste, choose and position, reflow, and evaluation.

- Checking guarantees reliability and decreases flaws.

- Applications cover industries from mobile phones to satellites.