How do robotic control board makers select suppliers with trusted quality?

Intro

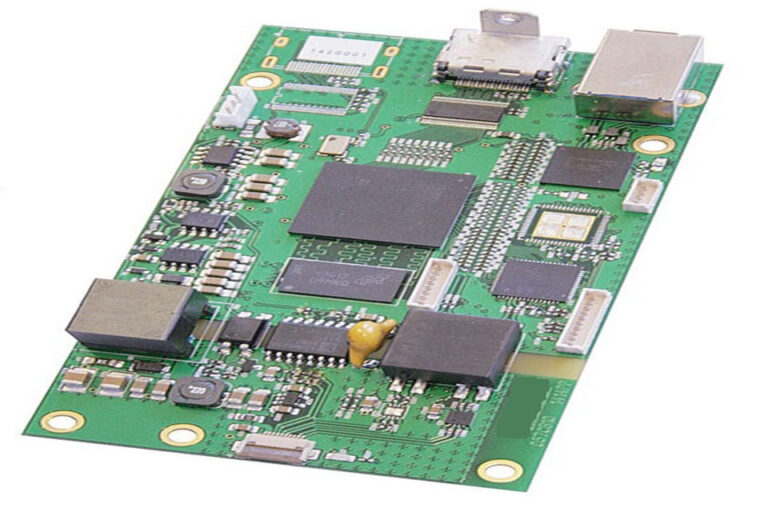

Today, with the fast development of robotic innovation, printed circuit boards (PCBs), as one of the core elements, directly impact the stability and intelligence level of devices. For robot control board producers, picking providers with professional capabilities is an essential link to make sure item efficiency and minimize failure rates. This short article will systematically evaluate how to evaluate top quality suppliers from the measurements of technical examination, quality system, cost control, etc, and provide useful references for the industry through data comparison and case analysis.

Table of Contents

Abstract

The intricacy of robot control board needs suppliers to have multi-layer board manufacturing, accuracy technology and rigorous quality assurance capabilities. This post proposes an organized supplier assessment structure from 8 dimensions such as market accreditation, technical criteria, delivery efficiency, and expense model, integrated with typical application situations such as video camera control panel and video camera PCBA, to help companies develop a steady supply chain.

1. Supplier credentials certification: building a foundation of trust

When selecting a robotic control board provider, market certification is the first threshold. Here are the crucial accreditations and their functions:

| Accreditation Type | Core Worth | Application Scenario Examples |

|---|---|---|

| ISO 9001 | Standardization of the entire quality management system | High-end commercial robot motherboard |

| UL certification | Safety efficiency meets global standards | Medical robot power module |

| IPC-A-600 | Circuit board acceptability specification | Automated welding electronic camera control board |

| RoHS/REACH | Environmental compliance assurance | Consumer service robot PCBA |

Action recommendations : Require providers to offer complete certification files, and offer top priority to producers with more than 3 reliable certifications. Throughout the field investigation, concentrate on whether the production links covered by the certification are comprehensive.

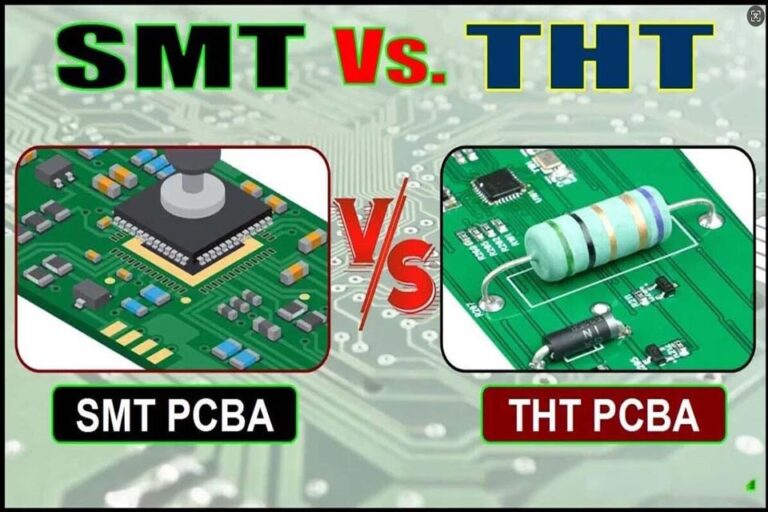

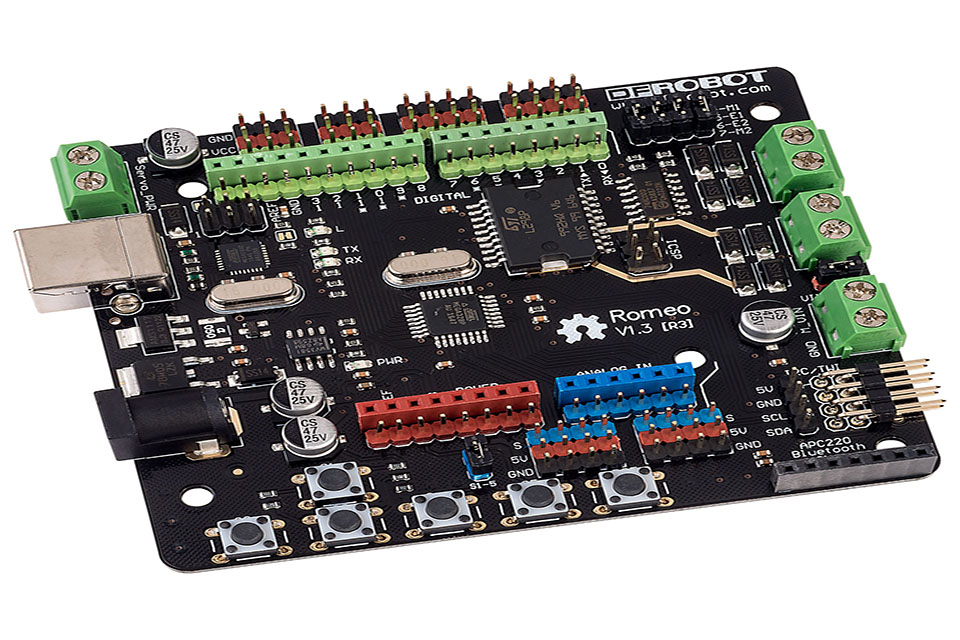

2. Technical capability evaluation: matching item requirements

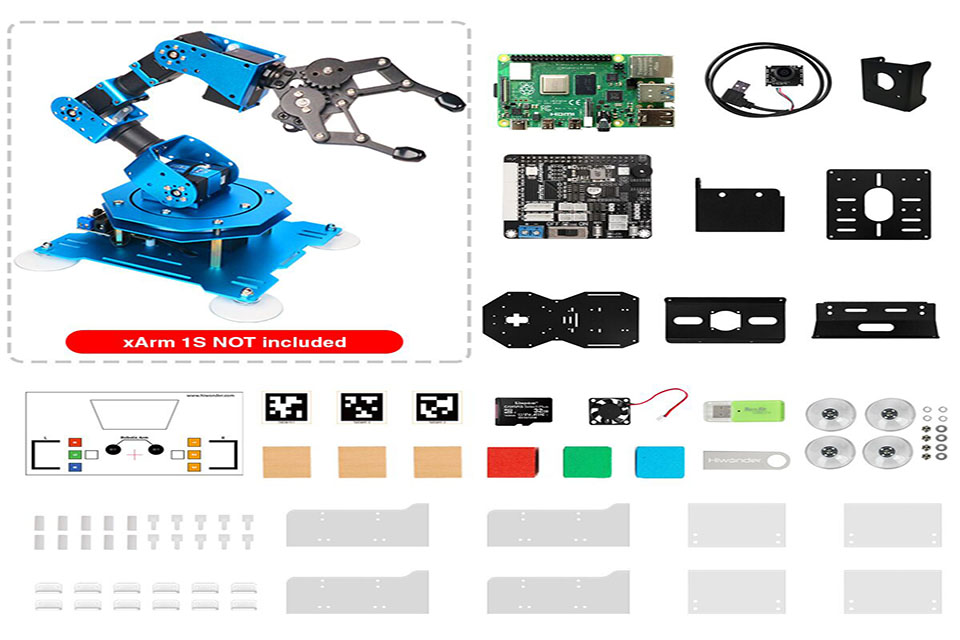

Robotic control board typically involves complicated procedures such as high-density adjoin (HDI) style and impedance control, and the following technical signs need to be verified:

- Multilayer board capability .

- Layer range: 4-12 layers (camera control board normally needs more than 8 layers).

- Board thickness tolerance: within ± 0.05 mm.

- Accuracy processing parameters .

- Minimum line width/spacing: ≤ 3mil (0.076 mm).

- Impedance control accuracy: ± 5Ω (key indicator for camera signal transmission).

- Special material processing .

- High-frequency materials (such as PTFE): suitable for 5G interaction modules.

- Metal substrates (such as aluminum substrates): Electronic camera brackets with high heat dissipation requirements.

Confirmation method :.

- Need Cam PCBA samples for functional screening.

- Use AOI (automated optical evaluation) equipment to verify process consistency.

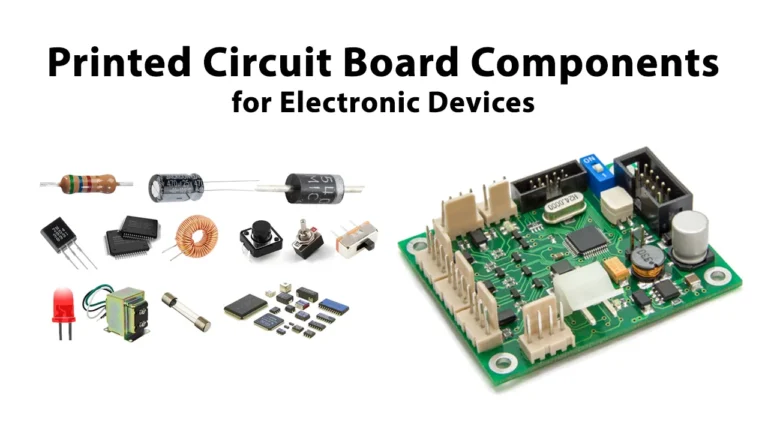

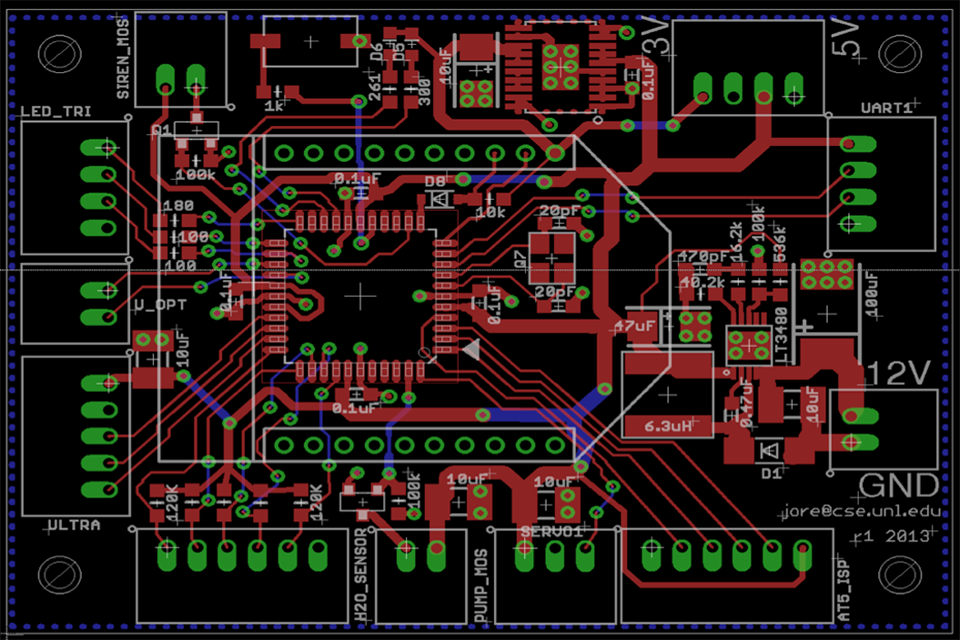

3. Quality control system: Get rid of flaws from the source.

Premium providers need to establish a three-level quality monitoring system:.

- Incoming material inspection .

- Copper foil pureness test (≥ 99.99%).

- Prepreg glue material test.

- Process control .

- Laser drilling position accuracy: ± 2μm.

- Electroplating density harmony: ± 5%.

- Final assessment standard .

- 100% flying probe test (relevant to small batch cam PCBA).

- Thermal cycle test (-40 ℃ ~ 85 ℃, 500 cycles without failure).

Data recommendation : The defective rate of premium suppliers in the industry need to be ≤ 0.1%, and the pass rate must be ≥ 98%.

4. New measurement: Supply chain resilience assessment.

In addition to traditional evaluation elements, modern robot control board producers also need to pay attention to the threat resistance of suppliers:.

Subtitle: Supply chain strength assessment model.

| Evaluation measurements | Key indicators | Credentials standards |

|---|---|---|

| Basic material reserves | Secret material stocking cycle | ≥ 3 months of safety inventory |

| Production capability elasticity | Emergency order action time | ≤ 72 hours |

| Geographical distribution | Number of production bases (cross-regional design) | ≥ 2 independent factories |

| Digital management | MES system coverage | 100% visualization of production links |

Case : A camera control panel provider successfully reacted to the chip lack crisis in 2022 by establishing dual bases in the Yangtze River Delta and the Pearl River Delta, achieving on-time shipment of 98% of orders.

5. Expense optimization strategy: balance quality and budget.

Use TCO (overall expense of ownership) model rather of basic rate comparison:.

“‘ plaintext. TCO = unit rate + transportation cost + quality expense + technical support cost. “‘.

Cost breakdown (taking video camera PCBA as an example):.

- Standard price: $120/piece.

- Quality cost (rework rate 2%): $3/piece.

- Technical service charge (style optimization): $15/piece.

- Total cost: $138/piece.

Recommendation : Offer top priority to providers that supply free DFM (design for manufacturability) analysis, which can lower 30% of possible quality threats.

VI. Long-lasting cooperation value: Structure a tactical collaboration.

High-quality suppliers ought to have the following attributes:.

- Technology insight : Yearly R&D financial investment ≥ 8% of profits.

- Capability expansion plan : Strategy to add 2 HDI assembly line in the next 2 years.

- Localized service : Set up a 24-hour technical assistance group.

- Cultural versatility : Embrace nimble advancement model (Scrum framework).

FAQ.

Q1: How to quickly confirm the provider’s video camera control board production capacity?

Needs IPC-6012 basic test report and on-site inspection of laser drilling devices (recommended Japanese DISCO or German Mitsubishi).

Q2: What is the permitted range of impedance control mistake of cam PCBA?

According to the IPC-2581 requirement, the impedance tolerance of high-speed signal lines should be controlled within ± 5Ω.

Q3: How to assess the supplier’s emergency situation shipment ability?

Simulate sudden orders (such as 1,000 pieces/week) and observe its production reaction speed and material scheduling plan.

Q4: Which certifications are especially important for customer robot PCBs?

In addition to standard certifications, special attention ought to be paid to CE (electro-magnetic compatibility) and FCC (US market access) accreditations.

Q5: How to work out volume discounts?

Adopt a step-by-step quote strategy, such as 8% discount for orders of 1,000 pieces and 15% discount for orders of 5,000 pieces.

Q6: How to avoid the threat of provider technology leak?

Sign an NDA contract, limit drawing storage authorizations, and use an encrypted file transfer system (such as Procore).

Conclusion.

The choice of robotic control board suppliers must be managed throughout the entire item life process. By methodically assessing the supplier’s cam control board R&D capabilities, camera PCBA production process and supply chain durability, business can substantially improve item dependability and market competitiveness. It is recommended to establish a quarterly provider review mechanism, routinely update technical requirements and quality standards, and develop a dynamically enhanced supply chain system.