What is Prototype PCB Assembly?

Prototype PCB Assembly: A Quick Guide for Engineers & Manufacturers

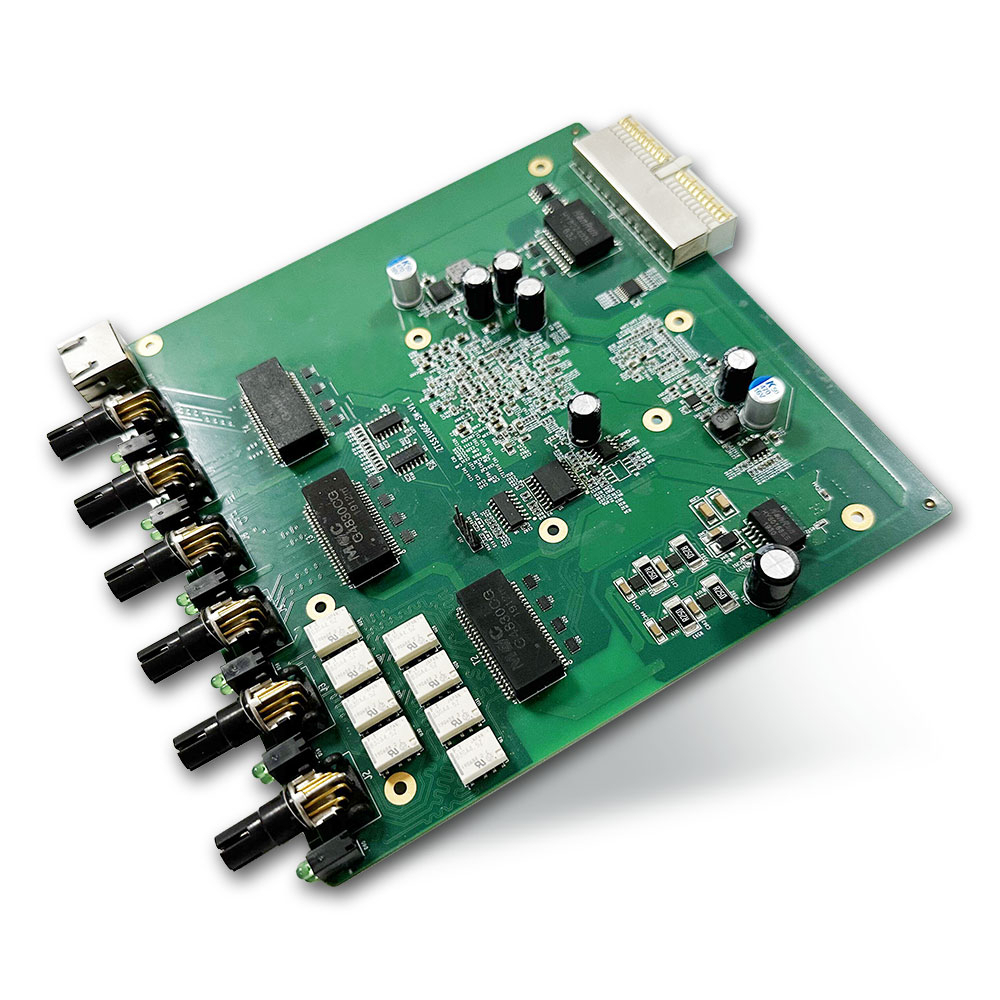

Prototype PCB Assembly is the trial production of printed circuit boards before mass production. It is always used by electronic engineers to conduct small-batch trial production in factory after design circuits and completing PCB. PCB prototypes (short name iscircuit board prototypes, and PCB prototypes) as an important role of PCB production. It is the first print circuit board physical board produced according to PCB design drawings and PCB manufacturing process requirements. It is used to verify the correctness of PCB design , inspect PCB manufacturing quality, conduct testing and debugging, and produce product samples. We can provide affordable, high quality, and fast turn prototype PCB assembly service solutions.

What is the cost for Prototype PCB Assembly ?

PCBA assembly cost (electronic component integration cost) is the core expenditure of hardware R&D. This article disassembles the core composition of SMT patch processing quotation, combines industry benchmark cases, and provides feasible cost reduction and efficiency improvement solutions to help you accurately control the R&D budget.

Quotation reference for three typical Prototype PCB Assembly

| Project type | Core parameters | Unit price range | Cost reduction space |

|---|---|---|---|

| Basic double-sided board | 10 pieces/10x10cm/100 components | 13USD/piece | 15%-20% |

| Four-layer smart board | BGA chip/immersion gold process/5 pieces | 116USD/piece | 25%-30% |

| Six-layer communication board | Blind buried via/high frequency material/3 pieces | 619USD/piece | 35%-40% |

Turnaround Time for Prototype PCB Assembly ?

| Layer classification | PCB type | Core advantages | Standard delivery time | Expedited service | Applicable scenarios | Inquiry tips |

|---|---|---|---|---|---|---|

| Basic type | Single-sided board | Best cost, first choice for simple circuits | 1-2 days | 12 hours | Home appliance control board/toy circuit | Get a quote now |

| Double-sided board | Best price/performance ratio, supports medium-complexity circuits | 1-3 days | 24 hours | Industrial control equipment/consumer electronics | View case library | |

| Advanced type | 4-layer multilayer board | Excellent signal integrity, good EMI control | 4-5 days | 48 hours | Network equipment/medical instruments | Download design guide |

| 6-8-layer multilayer board | High-density wiring, supports complex system integration | 5-7 days | 72 hours | Server/communication base station | Make an appointment for technical consultation | |

| High-end | 10+ layer HDI board | Ultra-fine lines (3mil), interconnection at any layer | 7-10 days | 96 hours | 5G mobile phone/autopilot system | Apply for sample testing |

| Rigid-flexible board | 3D assembly, shock-resistant and bending-resistant | 5-8 days | 72 hours | Wearable devices/military equipment | Watch process video | |

| Special process | Metal substrate (aluminum/copper) | Heat dissipation performance improved by 300% | 3-5 days | 48 hours | LED lighting/power module | Get thermal simulation report |

| High frequency board (Rogers) | Dielectric loss as low as 0.001@10GHz | 5-7 days | 72 hours | Radar/satellite communication | View bill of materials |

Prototype PCB Assembly Technical Capabilities

| Specification | PCBA Capability |

| Board Type | Rigid PCBs, Flexible PCB, metal core PCBs, Rigid-Flex PCBs |

| Assembly Type | Surface Mount (SMT) Assembly Mixed technology (SMT & Thru-hole) Ball-Grid-Array (BGA) Assembly Single/Double-Sides Mixture Assembly Conformal coating |

| Assembly Time | From 24 hours to 7days once all parts are ready |

| Max. Board Size | 610mm×508mm |

| Board Thickness | 0.1mm~6 mm |

| Component Types | BGA 0.20mm ,QFP 0.15mm 0201 resistors / 1005 passive components Fine-pitch components 0.3mm/0.4mm pitch Hard metric connectors |

| Component Sourcing | Full turnkey (All components sourced by us) Partial turnkey Kitted/Consigned |

| Solder Types | Lead-Free (RoHS compliant) |

| Quality Inspection | SPI Visual inspection AOI checking 2D/3DBGA placement – X-RAY checking In-Circuit Test Functional test |

| IC programming | DIP,SDIP BGA.CSP QSOP SSOP TSSOP PLCC SOT SOP MSOP TSOP QFN.MLP QFP MLF DFN |

| Qualifications | ISO9001:2015 UL IPC-6012 Class 2-3 |

| Order Volume | 1-No limit |

| After-sales Service | Repair and rework service will be offered if it is defective or damaged ,Communication comes first. |

| Component Package | Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk. |

| Stencils | laser cut stainless steel stencils |

| Documents for Quote and Assembly | Bill of Materials & BOM Assembly drawings (not necessary but help) pick & place file Photos (not necessary but help) Gerber files Quantities |

| Production Line Capacity | SMT Capacity 18,000-30,000 components a hour THT Capacity – 9,600 pins per day |

| PCB Assembly Process | Drilling–Exposure–Plating–Etaching & Stripping–Punching–ElectricalTesting–SMT–Wave Soldering–Assembling–ICT–Function Testing–Temperature & Humidity Testing |

| Board Shape | Rectangular, Circular and any Odd Shapes |

What Benefits of Prototype PCB Assembly ?

1. [Precisely verify the design to avoid mass production risks]

“Test first, then put into production” PCBA fast proofing, circuit design verification, functional defect detection Electronic product prototype testing, intelligent hardware solution optimization

2. [Maximize cost control, save 60% trial and error costs]

“Small investment leverages big returns” Small batch trial production cost reduction, BOM list optimization, NPI service High cost-effective PCBA proofing solution, domestic component replacement verification

3. [Extremely fast delivery cycle, 48 hours to seize the opportunity]

“Speed is competitiveness” High-frequency PCB expedited proofing, agile development support, rapid iteration of intelligent hardware : Extremely fast verification of IoT terminals, rapid production of 5G modules

4. [Full-process quality inspection, zero defect guarantee]

“Military-grade reliability” ICT/FCT testing, environmental stress screening, automotive-grade certification High-reliability PCBA verification, medical equipment aging test

5. [Seamless mass production, yield rate exceeds 98%]

“Sample is mass production standard” SMT process optimization, DFM manufacturability analysis, first pass rate improvement Industrial control board mass production solution, 3D AOI precision inspection