PCB Prototype Assembly & Fabrication

Article Summary

In today’s rapidly developing electronic devices landscape, PCB prototypes assembly is the structure of development. From IoT gadgets to consumer electronics, bringing a new design to life starts with a trusted printed circuit board . Whether you’re dealing with a quick-turn PCB model or planning volume Printed circuit board assembly for market deployment, understanding the complete scope of PCB assembly services — from design files to the last printed circuit board assembly — is vital.

This article walks you through every important action of model PCB assembly , from PCB fabrication and element sourcing to SMT soldering, assessment, and last screening. If you’re going for quick turn-around, low expenses, and reliable quality– whether utilizing services like JLCPCB , PCBWay ,SevenPCBA or others– this is a must-read guide.

Table of Contents

1. What Is PCB Prototype Assembly and Why Is It Crucial for Prototyping?

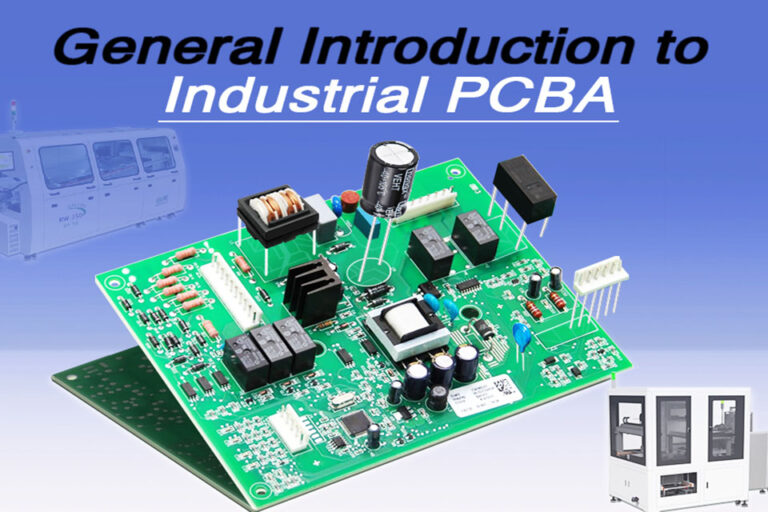

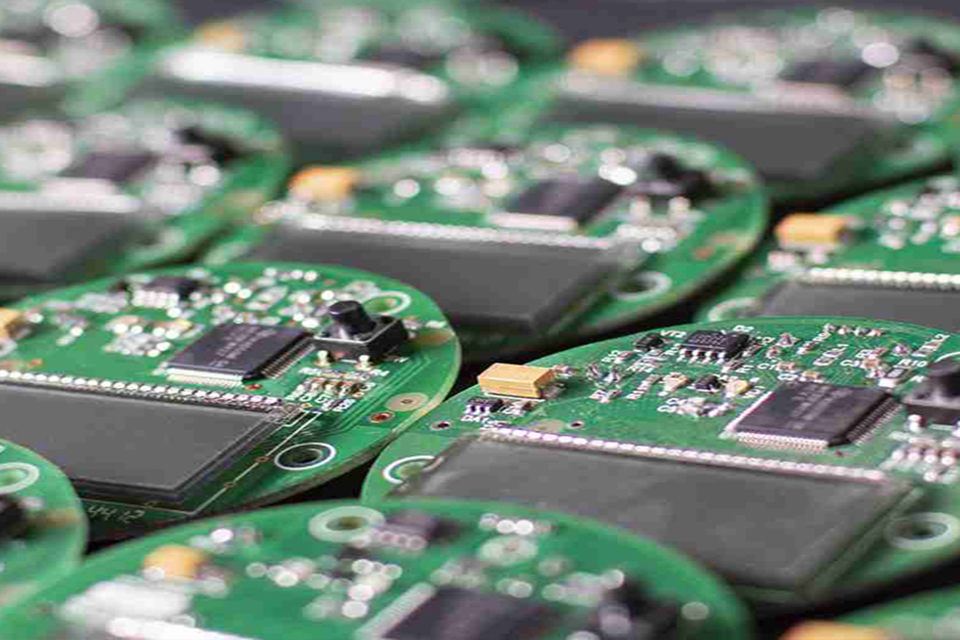

Print circuit board assembly (PCBA) is the procedure of installing electronic elements onto a printed circuit board to produce a totally practical electronic system. Whether you’re establishing a consumer gizmo or commercial controller, the mount phase turns your style into a concrete item.

During prototyping, effective and accurate PCB assembly is vital. This is when concepts are tested, errors determined, and performance optimized. By leveraging assembly services with experience in model PCB assembly , engineers acquire self-confidence in both function and manufacturability.

Prototyping also permits flexible, small-batch PCB production , ideal for R \ & D , startups, and customized applications. Quick recognition cycles depend on robust pcb and pcba integration to keep advancement timelines brief and innovation constant.

2. How Does the PCB Prototype Fabrication Process Work?

PCB fabrication is the production procedure of creating the physical circuit boards used in electronics. It starts from Gerber files — which include the copper layer, solder mask, and silkscreen data– and ends with plated and etched boards all set for assembly .

Fabrication consists of actions like CNC grating , plating , and the application of the solder mask . Leading PCB fabrication manufacturers like JLCPCB and PCBWay offer immediate online quotes and short as 24 hours turnaround options for quick turn PCB prototypes .

Before PCBs are sent for smt , they must be validated versus style specifications. Mistakes in pcb fabrication might result in open circuits, shorts, or misalignments– all of which impact the success of the assembly process .

3. What Should You Include in a PCB Prototype Order?

A total PCB order needs numerous files and specifications. This includes:.

- Gerber files for each layer.

- BOM (Bill of Materials) noting all electronic components.

- Centroid file for choice and location programs.

- Design notes or unique instructions.

When working with a pcb manufacturer or pcba service , supplying accurate information guarantees your circuit boards are developed to exact requirements. The more in-depth your order, the smoother the assembly workflow ends up being.

Don’t forget to specify crucial parameters like board density, copper weight, and surface (ENIG, HASL, etc). These information affect solder efficiency and SMT precision.

4. What Is PCB Prototype Assembly and How Does It Differ from Full Production?

Prototype PCB assembly includes low-volume, fast-turnaround assembly runs used to evaluate brand-new designs. Unlike full-blown manufacturing, prototype assembly concentrates on versatility and quick model, frequently dealing with small run quantities.

Key advantages of prototype assembly consist of:.

- Fast turn-around (often under 72 hours).

- Cost-effective testing of design modifications.

- Lower threat before devoting to volume PCB prototype assembly.

Since prototypes may use distinct or hard-to-source elements, it’s important to work with an assembly service that can acquire and deal with a diverse BOM . Flexibility in SMT , through-hole , or blended technologies is likewise vital at this phase.

5. How to Choose the Right PCB prototype Service for Your Needs.

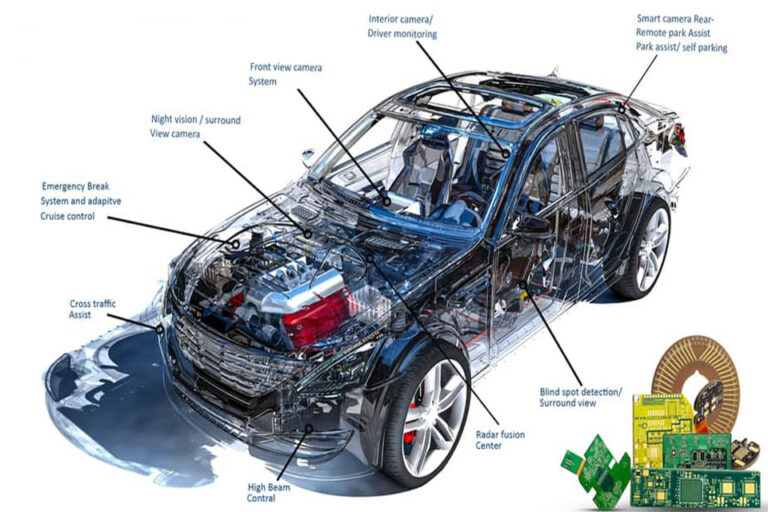

Not all PCB prototype assembly services are created equivalent. Depending on your application– whether for IoT, automobile, or consumer electronic devices — you’ll require a service that satisfies your particular needs in regards to innovation, timeline, and expense.

Examine the following before selecting a company:.

- Capability in SMT , through-hole , and hybrid assembly.

- Availability of turn-key or turnkey services.

- Quality assurance tools like AOI , X-ray , and SPI .

- Experience with low-volume or volume PCB assembly .

- Reputation for on-time delivery and technical support.

Leading suppliers like JLCPCB use extensive services from pcb fabrication to full pcba , simplifying the supply chain with single-point responsibility and faster lead time .

6. SMT vs Through-Hole: What Assembly Process Should You Use for pcb prototype ?

In modern-day PCB assembly , 2 primary methods control: Surface Mount Technology (SMT) and Through-Hole Technology .

SMT involves mounting parts straight onto the surface of the PCB. It’s ideal for automated, high-density designs and works with modern pick and place makers and reflow ovens .

Through-hole , on the other hand, locations element leads through drilled holes in the board. It’s better for mechanical strength and is still utilized in aerospace, commercial, and power electronics.

Each process impacts your assemblies cost, lead time , and board design. Prototype jobs frequently mix both techniques depending on element availability and style requirements.

7. What Files and Documents Are Required for PCB prototype Assembly?

For a successful PCB assembly , prepare and send the following:.

- Gerber files : Design information for each PCB layer.

- BOM (Bill of Materials) : A list of all components, consisting of part numbers, values, and footprints.

- Centroid file : For SMT positioning devices.

- Design files : Including schematics and design details.

- Assembly illustrations : Optional however valuable for manual confirmation.

A complete file set enables the Surface Mount Technology service to accurately put and solder elements, ensuring performance and reducing errors. Some providers offer instantaneous online quoting based on these inputs.

8. What Are the Key Machines Used in Modern PCB prototype Assembly?

Modern PCB assembly involves a suite of sophisticated machines to guarantee speed and accuracy:.

- Pick and position makers : Automate part placement.

- Reflow oven : Solder SMT elements utilizing regulated heat profiles.

- SPI (Solder Paste Inspection) : Verifies right paste volume and positioning.

- AOI (Automated Optical Inspection) : Checks for solder defects and misalignments.

- X-ray examination : Used for hidden joints (e.g., BGA, QFN).

These makers form the foundation of a dependable assembly procedure , ensuring consistent pcb quality and reducing rework expenses.

9. How Are PCBs Tested After Assembly work ?

Evaluating is an important phase of the pcb assembly workflow. It makes sure that the last PCBA functions as planned.

Typical approaches consist of:.

- AOI : Quickly scans for visual problems.

- X-ray : Examines solder joints under concealed plans.

- Functional screening : Powers the board to verify real-world efficiency.

Testing assists capture mistakes presented throughout fabrication , soldering , or element placement. A thorough management system makes sure each board satisfies quality standards before delivery.

10. How to Reduce Cost and Lead Time in PCB and PCBA Projects.

Speed and spending plan are frequently the biggest concerns in hardware development. Here’s how to enhance both:

- Choose low-cost services for prototyping like JLCPCB

- Use quick turn PCB and prototype PCB assembly services for fast iteration

- Consolidate fabrication and assembly with one supplier

- Optimize your BOM with commonly stocked components

- Limit complexity in your first PCB prototype

- Plan for volume PCB assembly only after thorough testing

Leveraging a partner with a robust management system , structured purchasing tools, and reputable logistics can considerably cut turnaround time and production headaches.

✅ Key Takeaways.

- PCB assembly is necessary for turning style ideas into practical electronics.

- PCB Prototype assembly permits quick, low-risk version throughout item development.

- Provide comprehensive Gerber , BOM , and centroid files to guarantee accurate builds.

- SMT and through-hole have unique advantages depending upon your style.

- Testing tools like AOI , X-ray , and SPI guarantee quality control.

- Use services like JLCPCB or PCBWay for quick, cost-efficient builds.

- Reducing lead time and expense includes planning, simplification, and selecting the right partner.

- A unified approach to fabrication and assembly assists accelerate delivery and decrease errors.

- Embrace turnkey services to simplify procurement, pcb fabrication , and assembly .

- Always model before scaling to volume PCB assembly .

With the ideal approach, tools, and assembly services , your path from idea to product becomes much faster, more effective, and significantly more dependable.