New PCB Board Manufacturing Standards: IPC‑6011 Class I, II, III Overview

Abstract .

This article clarifies PCB board manufacturing high quality classes under IPC‑6011. It defines Class I, II, III, describes when to choose each, and shows how OEMs optimize efficiency, cost, and integrity in PCB production. The post utilizes active voice, clinical structure, and vital terms uniformly throughout.

Table of Contents

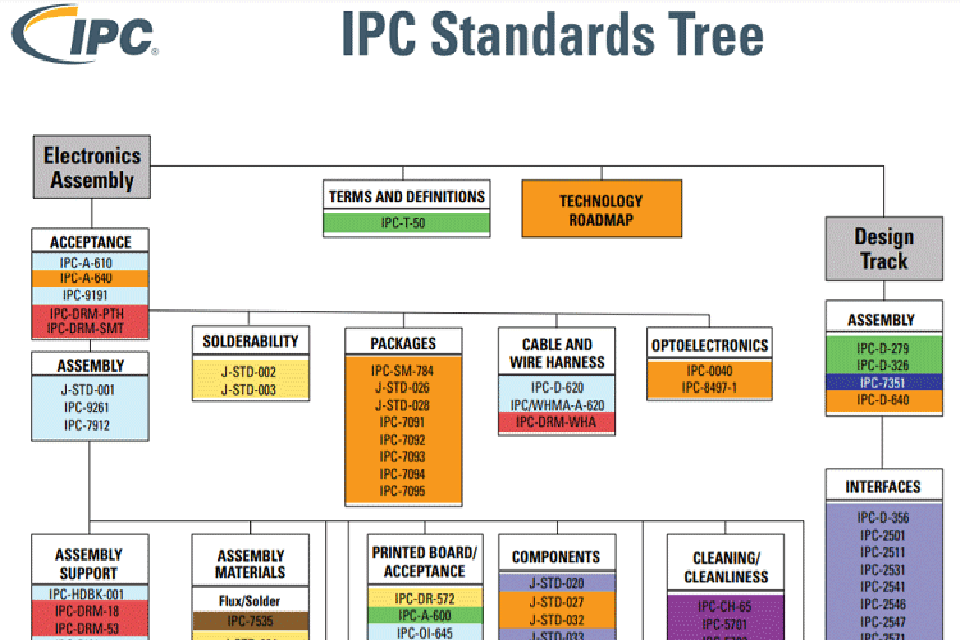

1. What is IPC‑6011 and why it matters for PCB Board Manufacturing ?

IPC‑6011 stands as the master requirement for PCB board manufacturing. It defines high quality degrees for published circuit boards. It categorizes boards right into Class I, Course II, and Course III. PCB Makers comply with these criteria to make sure reliability. This common guides every stage of PCB manufacturing. Designers and OEMs use it to select the correct production course.

The basic collections acceptance requirements, examination rules, and documentation protocols. It guarantees consistency across PCB production. It also sustains regulatory conformity in markets such as medical, vehicle, and aerospace. Using IPC‑6011 enhances integrity and aids search engine optimization authority for PCB manufacturing content.

2. What defines Course I in PCB Board Manufacturing?

IPC Class I , frequently called general‑purpose electronics, serves low‑reliability applications. Producers generate large volumes at low cost. They use fundamental tolerance levels. They call for very little evaluation steps.

Course I boards endure occasional defects and have shorter lifecycles. Normal products consist of playthings and basic consumer devices. The boards do standard functions, like lights LEDs or straightforward sensors. OEMs pick Class I when budget and quantity matter greater than long‑term dependability.

3. What specifies Course II in PCB board manufacturing?

IPC Course II improves integrity for dedicated‑service electronic devices. OEMs make these boards for extended lifecycle and stable performance. They apply more stringent resistances and more assessment steps than Class I.

Usage situations consist of tablets, devices, monitors. Early failings trigger aggravation yet not danger. Manufacturers follow more strenuous PCB manufacturing treatments. They implement tighter control of solder joints, trace sizes, and part placement. OEMs gain from lowered area failures and boosted user fulfillment.

4. What defines Class III in high‑reliability PCB production?

IPC Course III supports mission‑critical electronics. Instances: pacemakers, army and aerospace systems. These boards need to supply near‑zero failing rates over long lifetimes.

Makers apply optimal scrutiny: innovative inspection, expanded thermal biking, and tightened procedure controls. They make use of exceptional products, rigid evaluation documentation, and rigorous reliability tests. OEMs serve vital applications. They warrant higher PCB production expenses with consistent efficiency and safety and security criteria.

5. Just how do assessment and screening vary in between IPC classes?

PCB assessment requirements scale with class. Class I mandates very little tasting. It needs just necessary acceptance requirements. Class II adds methodical examination, such as X‑ray for buried vias, detailed solder fillet analysis, and more frequent sampling.

Class III demands complete documented inspection. It includes harmful screening, 100% optical assessment, and environmental stress and anxiety screening. PCB board manufacturing under Course III uses advanced examination devices and information monitoring. It guarantees detectability of micro‑cracks and early defects.

6. When should OEMs choose each IPC class?

OEMs make a decision based on item lifecycle and danger tolerance:.

- Select Class I when cost is key and reliability is not crucial. Examples: playthings, uniqueness electronics.

- Choose Class II when you require sustained efficiency at moderate expense. Instances: Televisions, tablet computers, home devices.

- Pick Class III when failure has severe effects. Instances: aeronautics, medical gadgets, army electronics.

OEM should review customer needs and end‑user threat. They must develop the PCB board complying with the appropriate IPC course from the start. They can frequently upgrade Course II develops to satisfy some Course III requirements– though not all.

7. Just how do cost and customer needs affect PCB production class selection?

Cost associates highly with IPC course:.

- Course I makes use of low‑cost products and very little labor.

- Class II boosts expenses for tighter tolerances and more examination.

- Class III commands highest cost for exceptional materials and extensive screening.

Consumer demands usually drive the decision. Regulative criteria (e.g., ISO, FDA, DO‑178) might require Class III. OEMs weigh the cost‑benefit proportion. A medical OEM might approve greater PCB manufacturing costs to stay clear of area failing. A toy maker would prefer Course I for quantity and cost sensitivity.

8. Exactly how to make sure a PCB board maker fulfills IPC class requirements?

First, validate that the PCB board producer holds IPC certification for Courses II or III. Inquire about their documented top quality systems and audit documents. Validate they execute the needed evaluations for your selected class.

Second, evaluation sample information : check actual PCBs the maker made under the exact same specifications. Examine solder fillets, voids, trace adherence, and plating. Third, demand procedure flow sheet and quality certificates (e.g., ISO 9001, IPC membership). Finally, examine their laboratory capability. They ought to show devices for X‑ray, thermal cycling, and microscopy measures.

9. What long‑tail key words and synonyms sustain search engine optimization in PCB board production web content?

Make use of these additional terms to strengthen SEO ranking:.

- “published motherboard production process”.

- “IPC‑6011 PCB top quality criteria”.

- “high‑reliability PCB manufacturing”.

- “PCB fabrication and examination”.

- “PCB assembly quality class meanings”.

Incorporate them normally in listings, vibrant keyword phrases, and Frequently asked questions. Use synonyms like “PCB fabrication,” “board construction,” “electronic board production,” “circuit board top quality course,” and long‑tail variants. Repeat core terms (PCB board production, PCB board, PCB production) at \ ~ 1.2% density, distributed in title, introductory, body, and verdict.

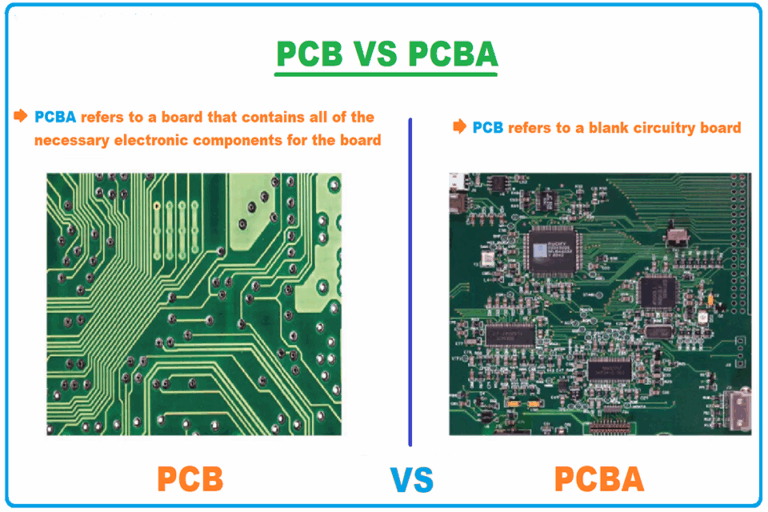

10. How does adding technical imagery enhance understanding of IPC‑6011 classes?

Including clear images assists readers visualize:.

- a cross‑section showing solder gaps or trace geometry,.

- evaluation microscopic lense sights of solder joints,.

- flowchart of Class II vs Class III examination actions.

Area images under pertinent H2 areas (e.g. Course III). Add ALT text like “PCB board inspection microscopic lense photo for Course III” to aid access and SEO. Correctly inscription pictures boosts on‑page authority and client count on. Pictures likewise sustain dwell time and site visitor interaction.

Frequently asked questions.

What is IPC‑6011 Class II in PCB board manufacturing?

IPC‑6011 Class II specifies dedicated‑service electronics. It needs sustained efficiency and modest assessment, suitable for tablets and TVs.

Can a PCB board made for Course II fulfill Class III?

A Course II style can satisfy some Course III demands– yet generally not all. Class III requires tighter tolerances and complete evaluation.

Just how does inspection differ between Class I and Course III? .

Course I uses very little examination (sampling). Class III requires extensive screening, including harmful examinations, 100% examination, and ecological tension screening.

How much more does Class III expense than Course II?

Class III demands exceptional materials and comprehensive screening. That boosts manufacturing expense by 20% to 50% depending upon intricacy and quantity.

Why does Course III issue in PCB manufacturing?

Class III makes sure high integrity in mission‑critical electronic devices. It sustains applications where failure might create harm or major disturbance.

How do I find a certified PCB board manufacturer? .

Ask for IPC accreditation, inspection records, sample PCBs, and top quality system documentation (e.g. ISO 9001). Confirm use of called for examination tools.

Final Thought and Key Points to keep in mind.

- IPC‑6011 categorizes PCB board manufacturing high quality right into Class I, II, and III .

- Course I provides low‑cost, general‑purpose PCBs with marginal evaluation.

- Class II fits dedicated‑service electronics with moderate reliability demands.

- Course III fits high‑reliability applications and implements rigorous evaluation.

- OEMs select course based on lifecycle, risk, and consumer assumption.

- Examination regulations enhance across courses: from fundamental to full documents and testing.

- Price climbs with top quality level, yet so does efficiency and safety and security.

- Confirm maker’s IPC qualification and inspect sample outcomes.

- Usage SEO‑rich long‑tail basic synonyms and strong key phrases.

- Include technological images for clearness, interaction, and SEO authority.