Mastering pcb board assembly manufacturing: From Fabrication to Functional Electronic Circuit Layout

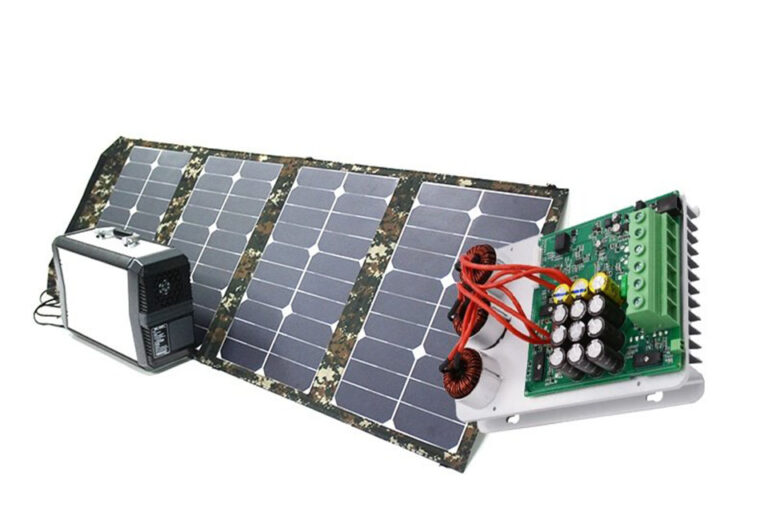

Abstracts

An extensive overview to recognizing pcb board assembly manufacturing procedures, manufacture methods, and just how to take advantage of PCB assembly solutions for developing trusted electronic products. Whether you’re designing a model or scaling to volume PCB assembly, this article covers the essentials of transforming bare published circuit boards right into fully useful circuit assemblies.

Table of Contents

1. What is PCB Setting up and Why is it Important for Electronic Products? .

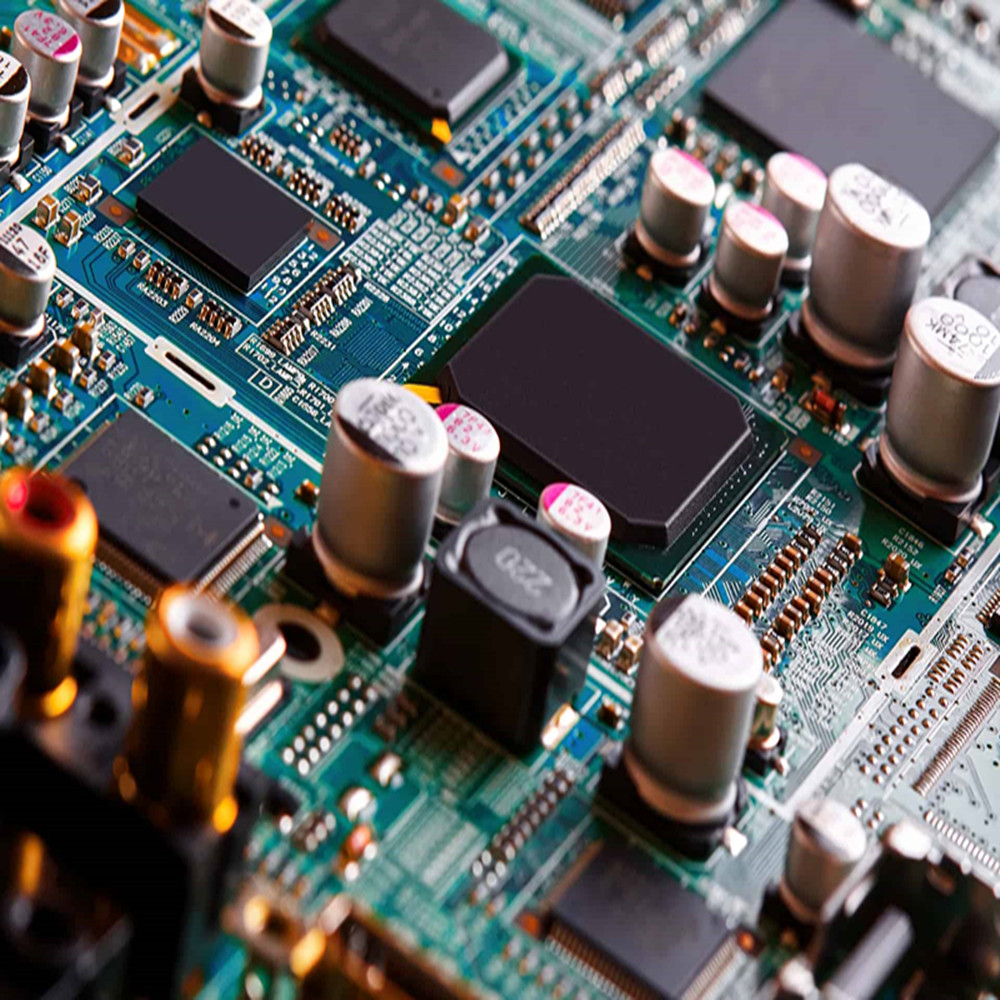

PCB board Assembly manufacturing is the procedure of installing electronic components onto a bare printed motherboard (PCB) to develop a useful circuit. This process transforms a blank board into a working digital item, whether it’s a straightforward consumer gadget or an intricate commercial system. The dependability of PCB assembly directly affects the efficiency and longevity of electronic devices, making it a keystone of modern-day electronic devices making.

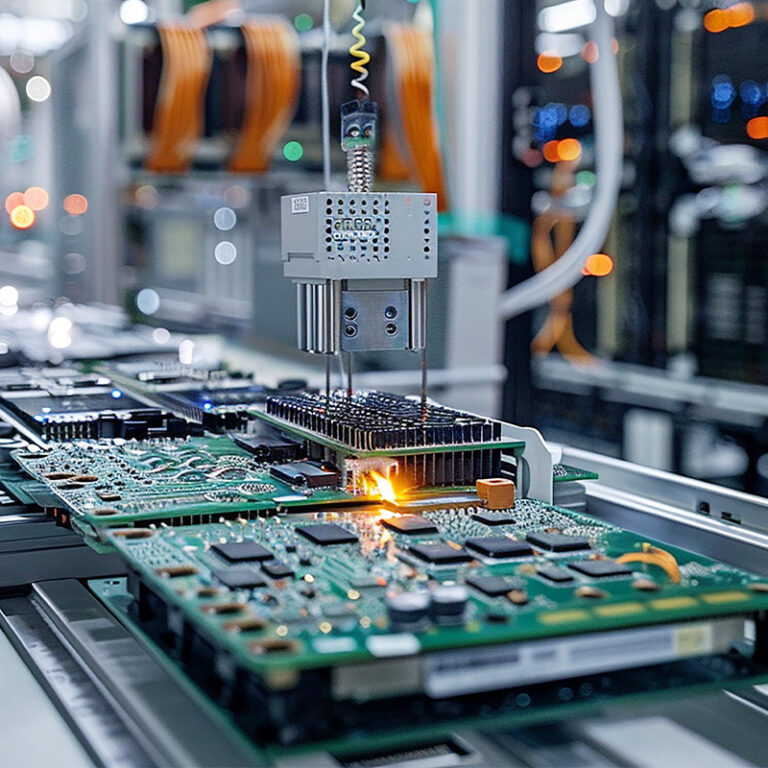

The assembly process involves precise positioning of parts, soldering, and detailed testing to make sure electrical integrity. For instance, solder paste is related to the PCB design, and surface place modern technology (SMT) elements are positioned utilizing automatic pick-and-place makers. The board after that passes through a reflow oven, where solder thaws to develop permanent connections. This method is critical for high-volume PCB board Assembly manufacturing, where rate and accuracy are critical.

Without proper PCB assembly, even the most innovative PCB style can fall short. Issues like solder bridging, misaligned elements, or inadequate solder joints can bring about circuit failures. That’s why partnering with a respectable PCB board Assembly manufacturing solution guarantees your job meets market requirements and features accurately.

2. How Does PCB Fabrication Differ from PCB Setting Up? .

PCB manufacture and pcb board assembly manufacturing are 2 distinct phases in the lifecycle of a published motherboard. Fabrication involves developing the bare board, while assembly focuses on occupying it with parts. Comprehending these differences is essential to managing your project’s timeline and spending plan.

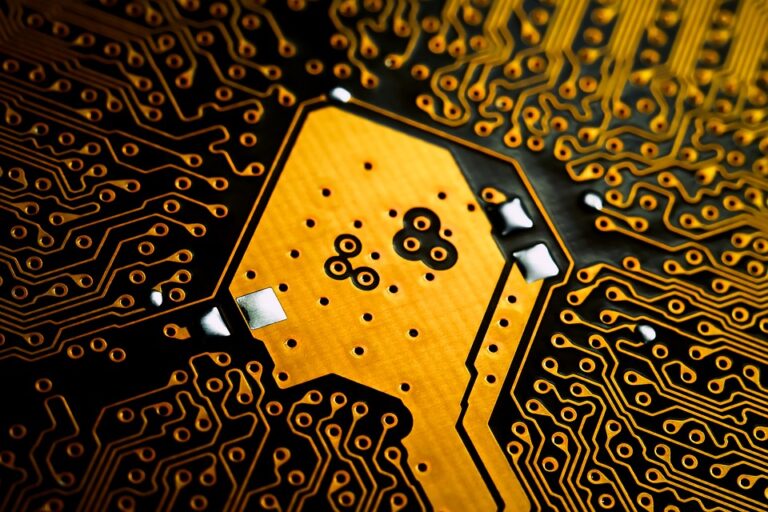

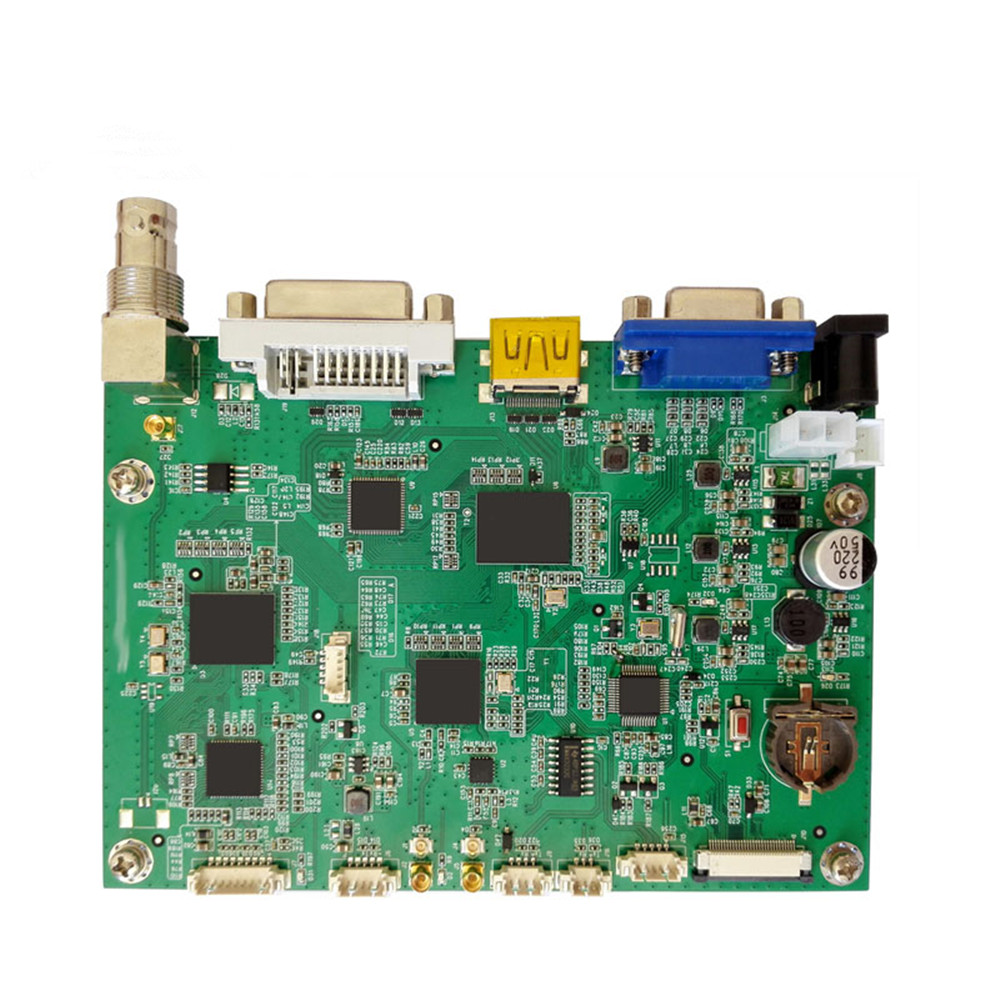

In PCB construction , the process begins with developing the PCB format utilizing specialized software application. Copper layers are engraved to create copper traces, and openings are drilled for through-hole parts. A solder mask is related to secure the board, and a silkscreen layer adds component designators for very easy identification. This stage results in a bare printed circuit card ready for assembly.

Conversely, PCB board Assembly manufacturing needs sourcing digital components and putting them onto the produced board. Surface area mount technology (SMT) and through-hole setting up are both main methods. SMT utilizes solder paste and reflow stoves for automation, while through-hole components are soldered by hand or with wave soldering. With each other, these processes develop the foundation of PCB manufacturing and assembly solutions .

Fabrication and setting up typically take place at separate facilities, yet lots of firms offer integrated PCB manufacture and setting up to streamline production. This minimizes preparation and reduces mistakes throughout the shift between stages.

3. Understanding the Stages of the pcb board assembly manufacturing Process .

The PCB setting up procedure is a multi-step operations that makes sure parts are placed and soldered appropriately. Let’s break down the crucial stages:.

- Solder Paste Application : A pattern is utilized to use solder paste to the PCB pads. This paste holds parts in position throughout reflow.

- Part Placement : Automated pick-and-place makers setting surface area mount elements (SMT) or through-hole parts onto the board. Precision is important to prevent imbalance.

- Reflow Soldering : The board passes through a reflow oven, where solder paste thaws to develop solid electric and mechanical links.

- Evaluation and Screening : Automated optical examination (AOI) checks for flaws, while in-circuit testing confirms functionality.

For high-volume PCB setting up, advanced equipment like pick-and-place equipments and reflow ovens are essential. These devices make sure uniformity and reduce human mistake. Furthermore, through-hole parts might call for hand-operated soldering or wave soldering for safe and secure add-on.

The final step involves evaluating the assembled PCB board Assembly manufacturing(PCBA) to confirm it satisfies layout specs. This consists of limit scan testing and useful testing to detect mistakes. A well-executed setting up procedure makes certain the board becomes a trustworthy PCB for its intended application.

4. What Are SMT and Through-Hole Technologies in PCB Assembly? .

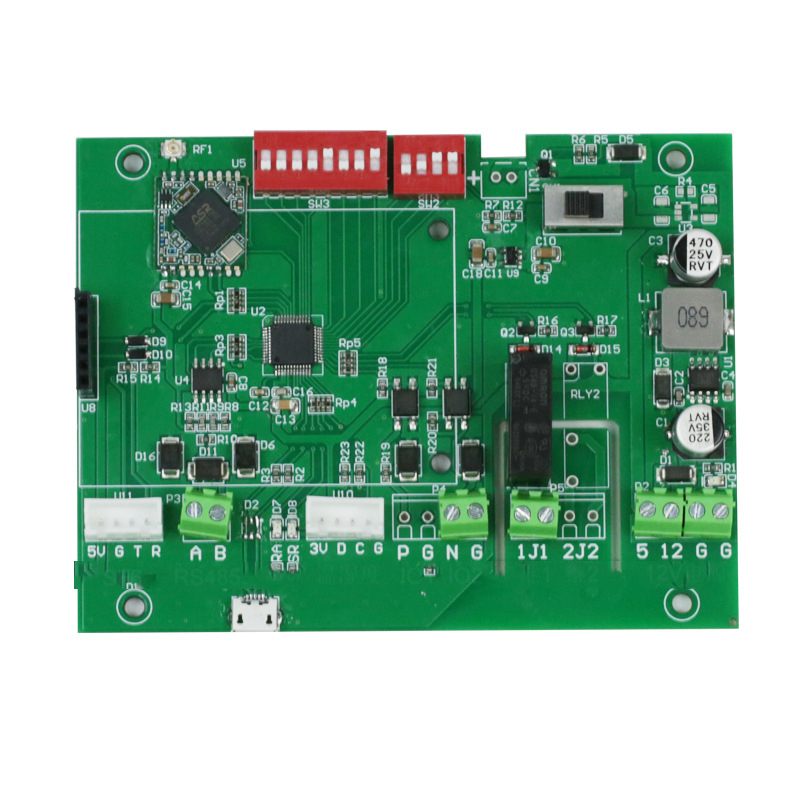

Surface Area Mount Technology (SMT) and through-hole setting up are the two main approaches for installing elements on a PCB. Each has special advantages depending upon the project’s requirements.

SMT is excellent for compact, high-density boards. Components are put directly onto the PCB surface area, and solder paste protects them during reflow. SMT enables faster setting up and smaller sized type factors, making it popular in customer electronic devices like mobile phones and laptops. However, SMT parts are a lot more delicate and might need innovative equipment like reflow stoves.

Through-hole assembly involves putting element introduces pierced holes and soldering them on the opposite side. This technique offers stronger mechanical bonds, making it suitable for high-vibration atmospheres or prototypes. While through-hole elements are simpler to change or repair, they eat a lot more board area and require wave soldering or hands-on soldering.

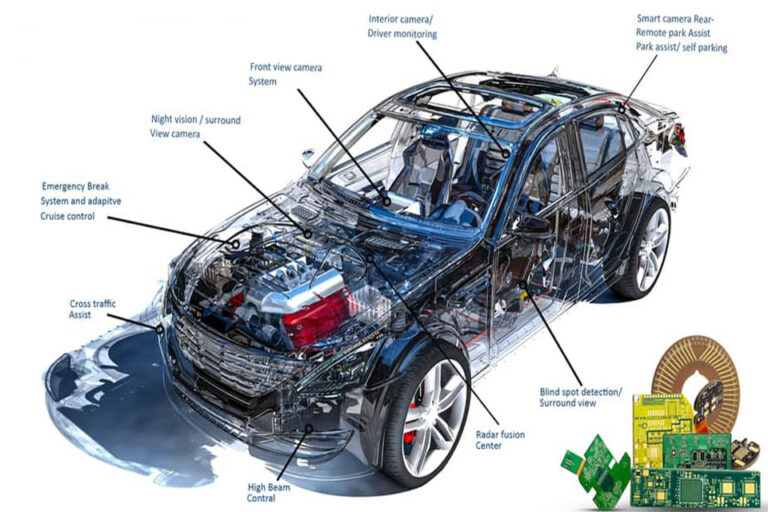

Lots of PCBs use a hybrid method, incorporating SMT and through-hole elements. As an example, SMT may be utilized for resistors and capacitors, while through-hole is scheduled for adapters and heat sinks. Selecting the best innovation relies on factors like part size, environmental conditions, and manufacturing quantity.

5. Just how to Pick the Right PCB board Assembly manufacturing Solution for Your Job .

Selecting the appropriate PCB assembly service is important for project success. Below are vital factors to consider:.

- Experience and Experience : Search for a provider with proven experience in your market. For example, a service with experience in vehicle PCBs might have various abilities than one specializing in clinical tools.

- Advanced Devices : Advanced centers with pick-and-place makers, reflow stoves, and AOI systems make certain premium setting up.

- Quality Control : A reliable PCB board Assembly manufacturing solution must provide strenuous inspection and testing, consisting of AOI and in-circuit screening.

- Lead Time and Scalability : Quick-turn PCB assembly solutions are ideal for prototypes, while volume PCB assembly requires efficient production capacities.

When examining suppliers, inquire about their procedure for managing style adjustments and taking care of the costs of materials. A transparent partner will connect plainly and aid you avoid costly delays.

6. The Duty of Solder in PCB board Assembly manufacturing and Its Kind .

Solder is the foundation of PCB board Assembly manufacturing, developing the electric and mechanical bonds that hold elements in position. There are 2 primary kinds: solder paste for SMT and wave soldering for through-hole.

Solder paste is a steel alloy blended with change, applied via a pattern to PCB pads. During reflow, the paste melts to develop solder joints. It’s specific and optimal for high-volume PCB assembly.

Wave soldering entails passing the board over a wave of liquified solder, which layers the element leads. This approach is generally used for through-hole elements and hybrid boards.

Solder top quality is important. Contaminated or poorly used solder can create chilly joints, bring about circuit failures. Automated optical evaluation (AOI) assists discover flaws early, ensuring a reliable PCB.

7. What is the Importance of PCB Format in Assembly Success? .

The PCB format straight influences the simplicity and performance of setting up. A well-designed format decreases errors and optimizes element positioning. Key factors to consider include:.

- Element Spacing : Adequate spacing stops solder linking and helps with automated positioning.

- Silkscreen and Designators : Clear silkscreen markings assist technicians identify parts throughout manual setting up.

- Thermal Management : Proper placement of heat-generating components (e.g., ICs) protects against overheating throughout reflow.

Collaboration in between developers and setting up groups makes sure the format straightens with producing capabilities. For example, avoiding tight clearances can minimize rework and boost return prices.

8. Exactly How Do Automated Optical Assessment (AOI) and Checking Guarantee High Quality? .

Automated optical assessment (AOI) is a critical step in PCB assembly, utilizing cameras and software program to spot defects like missing parts, solder bridges, or misaligned parts. AOI systems examine the board at various stages, making sure conformity with IPC requirements.

9. Why Quantity PCB board Assembly manufacturing Needs State-of-the-Art Tools .

Quantity PCB assembly demands accuracy, rate, and uniformity. Modern devices like high-speed pick-and-place machines and reflow stoves enable automation while keeping top quality. These systems can deal with hundreds of boards per hour, minimizing human error.

Advanced facilities additionally use AOI and X-ray evaluation to spot concealed defects in BGA bundles. For through-hole components, wave soldering makers make certain uniform solder coverage.

Investing in such equipment is crucial for firms scaling to quantity PCB assembly. It decreases preparation and makes certain the end product meets the demands of modern digital items.

10. Typical Challenges in PCB Setting Up and Just How to Conquer Them .

Usual obstacles include solder bridging, part misalignment, and thermal anxiety during reflow. To reduce these:.

- Optimize PCB Layout : Use style regulations to avoid solder connecting and guarantee correct spacing.

- Adjust Devices : On a regular basis preserve pick-and-place makers and reflow stoves for accuracy.

- Implement AOI : Identify defects early with automated optical inspection.

Partnering with a knowledgeable PCB setting up service can assist browse these concerns. Their expertise in process optimization and quality control guarantees a smooth shift from style to practical circuit assembly.

Trick Takeaways .

- PCB setting up is necessary for transforming bare boards right into functional electronic items.

- Construction produces the PCB, while assembly populates it with components.

- SMT and through-hole technologies offer different requirements in PCB design.

- Solder paste and wave soldering are essential for secure element add-on.

- AOI and in-circuit testing make sure premium, defect-free settings up.

- Quantity PCB setting up relies upon modern devices for efficiency and scalability.

- Picking the best PCB assembly service is vital to project success.

- A well-designed PCB format decreases assembly mistakes and enhances yield.

- Quality assurance procedures like AOI and useful screening are non-negotiable.

- Resolving difficulties like solder linking requires partnership in between design and production groups.

By understanding these principles, you can guarantee your PCBs are reputable, cost-efficient, and all set for any kind of application.