How to Pick the very best PCB Assembly Manufacturer service

Article Summary

This extensive guide offers essential insights for picking optimal PCB Assembly Manufacturer. Engineers and procurement experts will discover important examination requirements, technological factors to consider, and tactical approaches that ensure effective electronic product development. Comprehending these aspects decreases task threats and maximizes producing results.

Table of Contents

Intro

Electronic product advancement needs accurate production partnerships. PCB Assembly Manufacturer selection directly affects item quality, market competitiveness, and business success. Modern electronic devices require sophisticated assembly procedures that integrate advanced innovation with rigid quality assurance steps.

Manufacturing partnerships extend beyond easy vendor relationships. Strategic PCB Assembly Manufacturer selection includes thorough examination of technical capabilities, quality systems, and functional excellence. This analysis framework allows notified decision-making that lines up production capabilities with job requirements.

Comprehending PCB Assembly Manufacturing Landscape

What Makes PCB Assembly Manufacturing Complex?

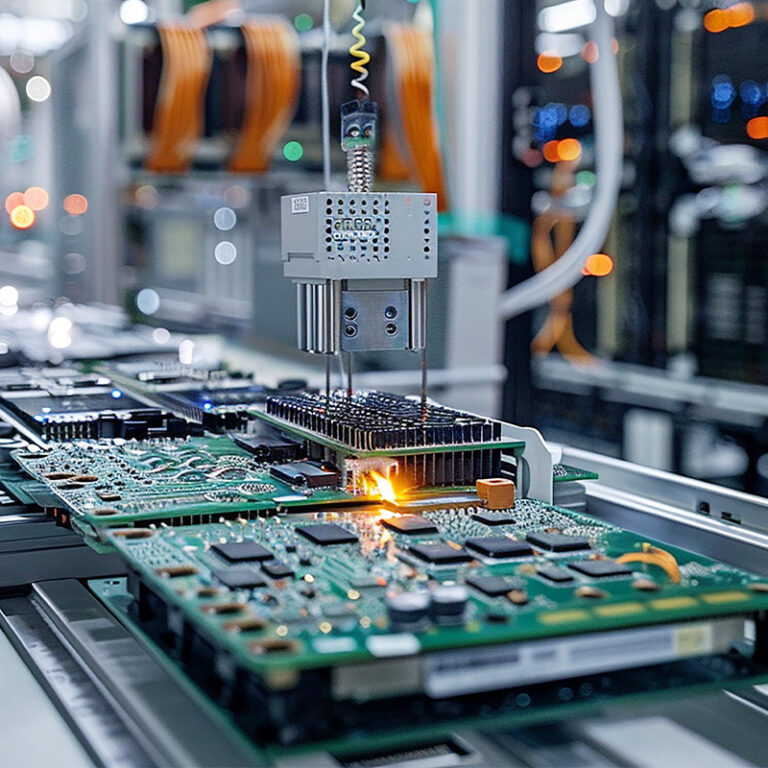

Contemporary PCB assembly encompasses several technological domains. Surface area install innovation (SMT) processes need precise component positioning with tolerances determined in micrometers. Through-hole assembly needs trustworthy soldering techniques that guarantee mechanical stability and electrical continuity.

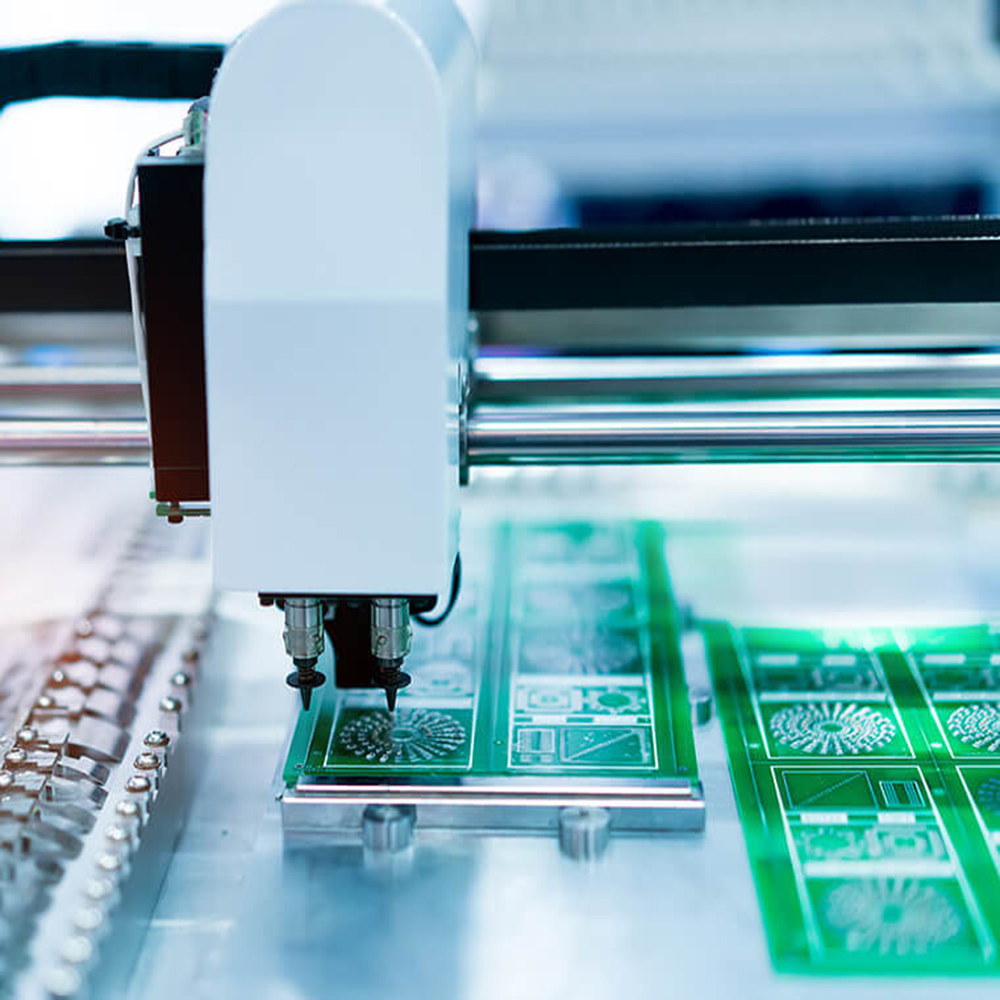

PCB Assembly Manufacturer operations incorporate automated systems with human expertise. Pick-and-place devices attain positioning accuracies of ± 25 micrometers while preserving production speeds surpassing 50,000 components per hour. These abilities make it possible for high-volume manufacturing while maintaining assembly quality.

Element miniaturization drives producing complexity. Modern assemblies integrate components with pitch sizes listed below 0.4 mm. Ball Grid Range (BGA) bundles consist of numerous affiliations within compact footprints. These technological needs require specific equipment and proven proficiency.

How Do Production Standards Impact Quality?

Quality management systems form the structure of trustworthy PCB assembly operations. ISO 9001 accreditation shows organized quality approaches that incorporate design control, procedure validation, and continuous enhancement. These frameworks ensure consistent manufacturing results across production batches.

Industry-specific standards provide extra quality control. IPC-A-610 develops acceptance requirements for electronic assemblies. This standard defines workmanship requirements for soldering, part positioning, and tidiness. PCB Assembly Manufacturer compliance with IPC-A-610 suggests dedication to market best practices.

Automotive applications need IATF 16949 certification. This standard addresses automotive-specific quality requirements including statistical procedure control and mistake-proofing techniques. Medical device production needs ISO 13485 compliance, making sure quality systems fulfill regulative requirements for health care applications.

Necessary Technical Capabilities Assessment

What Production Technologies Should You Evaluate?

Modern PCB Assembly Manufacturer centers use varied manufacturing technologies. Surface area mount technology (SMT) lines make use of high-speed placement devices efficient in managing components from 0201 passive devices to big area range bundles. Reflow ovens supply precise thermal profiles that ensure trustworthy solder joint development.

Through-hole assembly capabilities enhance SMT processes. Selective soldering systems offer targeted heat application for mixed-technology assemblies. Wave soldering equipment handles high-volume through-hole part accessory with consistent joint quality.

Advanced assembly strategies broaden manufacturing possibilities. Flip-chip bonding enables ultra-high-density interconnections. Wire bonding offers electrical connections for specialized applications. These abilities suggest manufacturing adaptability and technological development.

| Manufacturing Innovation | Common Accuracy | Production Speed | Application Variety |

|---|---|---|---|

| SMT Positioning | ± 25 μm | 50,000 CPH | 0201 to 50mm plans |

| Through-hole | ± 100 μm | 5,000 CPH | Connectors, transformers |

| BGA Positioning | ± 50 μm | 3,000 CPH | High I/O count gadgets |

| Fine-pitch QFP | ± 25 μm | 8,000 CPH | 0.4 mm pitch and listed below |

How Essential Is Devices Modernization?

Production devices straight affects assembly quality and efficiency. Cutting edge placement machines integrate vision systems that validate component orientation and placement precision. These systems discover placement mistakes in real-time, preventing malfunctioning assemblies from advancing through production.

Reflow oven innovation affects solder joint dependability. Convection ovens provide uniform heating throughout PCB assemblies. Nitrogen environment abilities prevent oxidation during soldering procedures. Temperature profiling systems guarantee thermal cycles match part and PCB requirements.

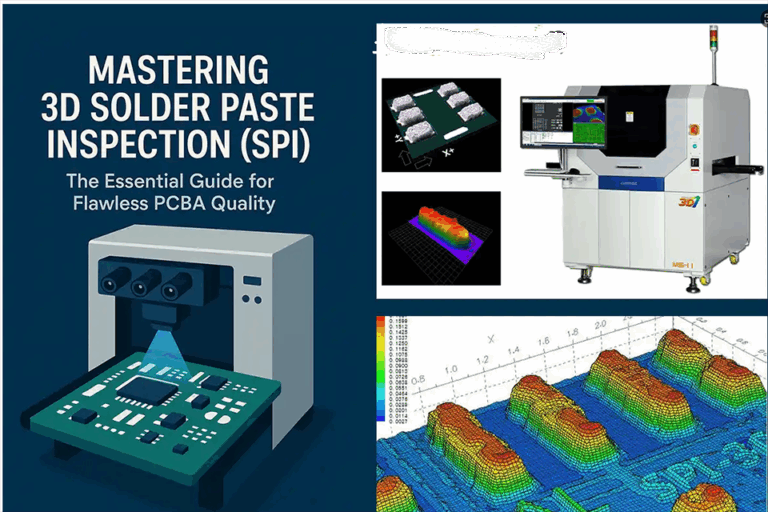

Examination equipment abilities determine problem detection effectiveness. 3D Automated Optical Evaluation (AOI) systems identify element positioning errors, solder joint problems, and missing out on elements. X-ray inspection reveals surprise defects in BGA and other location variety plans.

Quality Management and Accreditation Framework

Which Certifications Indicate Production Excellence?

Quality certifications provide unbiased proof of PCB Assembly Manufacturer abilities. ISO 9001 certification shows methodical quality management approaches. This basic requires recorded procedures, management obligation, and continuous improvement processes.

IPC accreditations confirm technical proficiency. IPC-A-610 training ensures assembly workers understand approval criteria for electronic assemblies. IPC J-STD-001 accreditation covers soldering requirements and strategies. These certifications suggest technical competence and commitment to market requirements.

Industry-specific accreditations resolve specialized requirements. AS9100 certification uses to aerospace applications, incorporating threat management and setup control requirements. ISO 14001 environmental management accreditation demonstrates dedication to sustainable production practices.

What Quality Control Processes Ensure Reliability?

Extensive quality assurance systems carry out multiple examination checkpoints throughout assembly processes. Inbound assessment verifies element requirements and quality before assembly starts. This avoids defective elements from going into production streams.

In-process examination monitors assembly quality throughout production. Analytical procedure control (SPC) strategies track key specifications and recognize procedure variations before they impact item quality. Control charts offer visual signs of procedure stability and capability.

Final examination confirms finished assemblies versus requirements. Functional testing validates electrical performance under specified conditions. Ecological stress screening (ESS) exposes hidden defects through controlled stress application.

Supply Chain Excellence and Part Management

How Does Supply Chain Management Affect Assembly Quality?

PCB Assembly Manufacturer supply chain practices directly impact element quality and schedule. Licensed distributor relationships guarantee part credibility and traceability. Counterfeit elements pose considerable dependability dangers that can jeopardize item performance and security.

Component traceability systems track parts from original manufacturers through assembly procedures. Lot tracking allows fast identification of impacted assemblies in case of part quality problems. This capability helps with efficient recall procedures and source analysis.

Inventory management systems balance component schedule with storage expenses. Just-in-time shipment reduces stock bring expenses while ensuring component accessibility for production schedules. Demand forecasting algorithms enhance stock levels based upon historic use patterns.

| Supply Chain Aspect | Finest Practice | Risk Mitigation |

|---|---|---|

| Components Sourcing | Licensed suppliers only | Counterfeit avoidance |

| Inventory Management | Real-time tracking systems | Obsolescence avoidance |

| Supplier Credentials | Multi-level approval process | Quality assurance |

| Need Preparation | Analytical forecasting | Scarcity prevention |

What Role Does Element Obsolescence Management Play?

Component lifecycle management addresses obsolescence challenges that impact long-lasting item sustainability. PCB Assembly Manufacturer must keep an eye on part lifecycle status and supply proactive obsolescence notices. Early warning systems allow design updates before parts end up being not available.

Alternative part identification services assist preserve supply continuity. Cross-reference databases recognize functionally comparable parts that can replacement for obsolete parts. This ability ensures continued making assistance throughout item lifecycles.

Last-time-buy suggestions enhance inventory financial investments for end-of-life parts. Procurement planning considers product demand forecasts and part storage capabilities. These strategies minimize obsolescence threats while managing stock expenses.

Advanced Testing and Inspection Methodologies

What Testing Techniques Make Sure Assembly Dependability?

Comprehensive screening procedures validate PCB Assembly Manufacturer output quality through several inspection stages. Automated Optical Assessment (AOI) systems record high-resolution images of put together PCBs and compare them against reference requirements. Artificial intelligence algorithms continuously enhance defect detection capabilities.

X-ray examination reveals internal assembly features invisible to optical examination. This technology identifies spaces in solder joints, misaligned components under gadgets, and internal shorts. Advanced X-ray systems offer 3D imaging capabilities for complicated assemblies.

In-Circuit Screening (ICT) validates electrical performance of individual elements and circuit networks. Test components supply electrical access to circuit nodes through specialized probes. Parametric measurements confirm element values and circuit efficiency.

How Does Functional Testing Validate Efficiency?

Practical testing exercises put together PCBs under reasonable operating conditions. Test programs replicate real application environments and validate performance specs. This screening technique identifies system-level flaws that component-level screening might miss out on.

Limit scan testing uses built-in test abilities of digital gadgets. JTAG user interfaces offer access to internal device functions without physical penetrating. This method allows extensive testing of complicated digital assemblies with minimal test fixture requirements.

Ecological testing verifies assembly efficiency under extreme conditions. Temperature biking exposes thermal growth mismatches that could trigger solder joint failures. Vibration screening reveals mechanical style weaknesses that could impact reliability.

Interaction Quality and Consumer Support

What Interaction Standards Ensure Task Success?

Reliable interaction forms the structure of successful PCB Assembly Manufacturer partnerships. Task management systems supply real-time presence into production status, quality metrics, and shipment schedules. Web-based portals allow stakeholder access to job info and paperwork.

Design for Manufacturability (DFM) examines determine potential assembly challenges before production starts. Engineering teams analyze PCB layouts and element choices to optimize manufacturing processes. Early cooperation avoids expensive style modifications and production hold-ups.

Technical documentation management guarantees precise details transfer throughout task lifecycles. Modification control systems track style changes and keep setup stability. Electronic approval workflows accelerate file processing while keeping change control.

How Essential Is Client Assistance Facilities?

Committed client assistance groups supply responsive support throughout manufacturing collaborations. Technical assistance engineers use expertise in assembly procedures, component choice, and style optimization. Account management guarantees consistent interaction and relationship development.

Training and education services help consumers comprehend manufacturing abilities and constraints. Workshops and workshops share finest practices for design optimization and expense decrease. Understanding transfer initiatives develop consumer proficiency and improve partnership effectiveness.

Post-production support consists of field failure analysis and restorative action implementation. Return Material Permission (RMA) procedures facilitate faulty product analysis and resolution. Continuous improvement programs incorporate consumer feedback into procedure enhancement efforts.

Expense Optimization and Value Engineering

How Do Manufacturing Expenses Effect Item Economics?

PCB Assembly Manufacturer cost structures affect item success and market competitiveness. Product expenses generally represent 60-70% of total assembly expenses, making component choice and procurement crucial success aspects. Volume acquiring arrangements can attain significant expense reductions for high-volume products.

Labor costs vary significantly based on manufacturing place and automation levels. Automated assembly processes decrease direct labor requirements while increasing capital equipment investments. Cost modeling helps evaluate compromises between automation and manual assembly techniques.

Overhead costs include facility costs, equipment devaluation, and administrative assistance. Efficient manufacturing operations distribute these expenses throughout larger production volumes, lowering per-unit overhead allocation. Manufacturing place choices balance cost considerations with quality requirements and supply chain distance.

What Value Engineering Approaches Reduce Costs?

Element standardization decreases procurement complexity and attains volume prices advantages. Design teams must minimize special part varieties and make use of common parts throughout product households. Standardization also simplifies inventory management and decreases obsolescence threats.

Assembly simplification gets rid of unneeded process steps and reduces manufacturing complexity. Design optimization can get rid of secondary operations such as conformal covering or selective soldering. Process debt consolidation reduces handling requirements and enhances manufacturing effectiveness.

Test optimization balances protection requirements with cost considerations. Risk-based testing methods focus resources on crucial functions while lowering test time for low-risk areas. Parallel testing techniques can minimize test cycle times without jeopardizing protection.

Innovation Trends and Future Preparedness

What Emerging Technologies Affect PCB Assembly?

Industry 4.0 innovations transform PCB Assembly Manufacturer operations through increased automation and data analytics. Smart production systems integrate maker information with quality information to enhance procedures in real-time. Predictive maintenance algorithms prevent devices failures and lower downtime.

Artificial intelligence applications improve defect detection and process optimization. Machine learning algorithms analyze assessment data to recognize patterns and forecast quality issues. AI-powered procedure control systems immediately adjust criteria to keep optimal performance.

Web of Things (IoT) connection allows remote monitoring and control of production devices. Cloud-based information storage and analytics provide scalable processing capabilities for large datasets. These technologies allow worldwide production exposure and coordination.

How Do Environmental Regulations Impact Manufacturing?

RoHS (Limitation of Hazardous Compounds) compliance needs lead-free assembly procedures and materials. PCB Assembly Manufacturer operations should carry out lead-free soldering procedures and element handling treatments. Material traceability systems guarantee compliance paperwork and audit support.

REACH (Registration, Evaluation, Authorization, and Limitation of Chemicals) regulations affect component and material choice. Manufacturers must maintain chemical structure databases and supply compliance paperwork for European markets. Supply chain transparency ends up being critical for regulatory compliance.

Ecological management systems resolve waste reduction and energy performance. ISO 14001 accreditation demonstrates dedication to ecological stewardship. Green producing initiatives reduce environmental effect while potentially decreasing operating expense.

Risk Management and Organization Continuity

What Threats Should You Assess in PCB Assembly Manufacturer Choice?

Supply chain disturbances pose considerable risks to making continuity. PCB Assembly Manufacturer partners need to keep numerous supplier relationships and geographic diversity to mitigate disruption risks. Company continuity strategies should resolve natural catastrophes, geopolitical occasions, and financial interruptions.

Quality risks include element defects, procedure variations, and assembly mistakes. Danger evaluation methodologies determine possible failure modes and execute preventive steps. Failure Mode and Effects Analysis (FMEA) strategies methodically examine risks and focus on mitigation efforts.

Financial stability evaluation ensures producing partner viability throughout product lifecycles. Credit assessments and monetary declaration analysis recognize prospective company threats. Long-term partnerships need stable making partners with appropriate funds.

How Essential Is Intellectual Property Security?

Copyright (IP) defense safeguards exclusive designs and technologies. PCB Assembly Manufacturer partners should execute comprehensive confidentiality agreements and information security steps. Physical security controls avoid unapproved access to making locations and design information.

Cybersecurity procedures protect digital design files and producing data. Network security systems prevent unauthorized access to create databases and producing systems. Routine security audits make sure continuous protection effectiveness.

Export control compliance guarantees adherence to global trade guidelines. Innovation transfer constraints may restrict manufacturing area alternatives or require special licenses. Compliance programs need to deal with both US and worldwide export control requirements.

Performance Metrics and Continuous Improvement

What Key Performance Indicators Procedure Success for PCB Assembly Manufacturer?

Quality metrics offer unbiased procedures of PCB Assembly Manufacturer performance. First-pass yield rates suggest procedure capability and quality assurance effectiveness. Flaw rates per million chances (DPMO) make it possible for benchmarking against industry requirements and constant enhancement targets.

Delivery efficiency metrics determine schedule adherence and customer satisfaction. On-time shipment rates suggest manufacturing planning effectiveness and supply chain reliability. Lead time consistency shows procedure predictability and resource management capabilities.

Expense efficiency signs track making effectiveness and competitiveness. Expense reduction efforts should demonstrate quantifiable improvements gradually. Value engineering contributions suggest partner commitment to customer success and expense optimization.

| Performance Metric | Target Range | Measurement Frequency |

|---|---|---|

| First-pass Yield | > 95% | Weekly |

| On-time Delivery | > 98% | Monthly |

| DPMO | <100 | Continuous |

| Cost Reduction | 3-5% annually | Quarterly |

How Does Continuous Improvement Drive Excellence for PCB Assembly Manufacturer?

Continuous improvement programs systematically enhance manufacturing processes and capabilities. Kaizen events focus improvement efforts on specific areas and generate rapid results. Employee suggestion programs engage workforce expertise in improvement initiatives.

Statistical process control (SPC) identifies process variations and improvement opportunities. Control charts track key parameters and trigger corrective actions when processes exceed control limits. Process capability studies quantify improvement potential and guide resource allocation.

Customer feedback integration ensures improvement efforts align with customer priorities. Voice of Customer (VOC) programs capture customer requirements and satisfaction levels. Closed-loop feedback systems track improvement implementation and effectiveness.

Regularly Asked Concerns (FAQs).

Q1: What is the most crucial factor when choosing a PCB Assembly Manufacturer ?

Quality certifications and showed manufacturing abilities represent the most crucial choice factors. ISO 9001 certification integrated with IPC basic compliance suggests methodical quality techniques and technical competency.

Q2: How can I validate a PCB Assembly Manufacturer ‘s element sourcing practices?

Request documentation of licensed distributor relationships and element traceability procedures. Verify anti-counterfeiting measures and request referrals from other clients in similar applications.

Q3: What testing methods are important for trusted PCB assembly manufacturer?

Comprehensive screening should consist of AOI assessment, X-ray examination for surprise problems, in-circuit testing for electrical verification, and practical screening under realistic operating conditions.

Q4: How crucial is geographical place in pcb assembly manufacturer choice?

Place affects shipping costs, lead times, and supply chain resilience. Consider distance to element providers, shipping infrastructure, and company connection requirements when evaluating manufacturing areas.

Q5: What function does Market 4.0 technology play in modern-day PCB assembly?

Smart producing innovations enable real-time procedure optimization, predictive upkeep, and enhanced quality control. These capabilities enhance performance and reduce manufacturing threats.

Q6: How can I guarantee intellectual property protection with making pcb assembly manufacturer?

Carry out extensive privacy agreements, confirm physical and cybersecurity steps, and guarantee compliance with export control guidelines. Regular security audits aid preserve protection efficiency.

Seven PCBA Inc is a good choice for your PCB Assembly manufacturer ,13 Years of Precision PCB Assembly Manufacturing.

Summary

Selecting an optimal PCB Assembly Manufacturer requires systematic evaluation of multiple critical factors:

- Quality accreditations demonstrate organized techniques to making excellence and regulative compliance

- Technical capabilities should line up with item requirements including element types, assembly complexity, and volume needs

- Supply chain management guarantees element quality, schedule, and traceability throughout item lifecycles

- Checking and inspection protocols confirm assembly quality and reliability through comprehensive flaw detection

- Communication excellence assists in cooperation, analytical, and project success through responsive assistance

- Cost optimization balances quality requirements with economic restraints through worth engineering methods

- Innovation readiness positions producing partnerships for future requirements and emerging trends

- Threat management addresses potential interruptions and makes sure company connection through extensive preparation

- Efficiency measurement makes it possible for unbiased evaluation and continuous enhancement through essential metrics tracking

- Strategic collaboration approach guarantees long-lasting partnership success beyond easy supplier relationships