What is FCT (Functional Circuit Test)Test ?

FCT function test: PCBA quality assurance of the key technology

I. What is FCT functional testing? Why has it become a key link in electronics manufacturing?

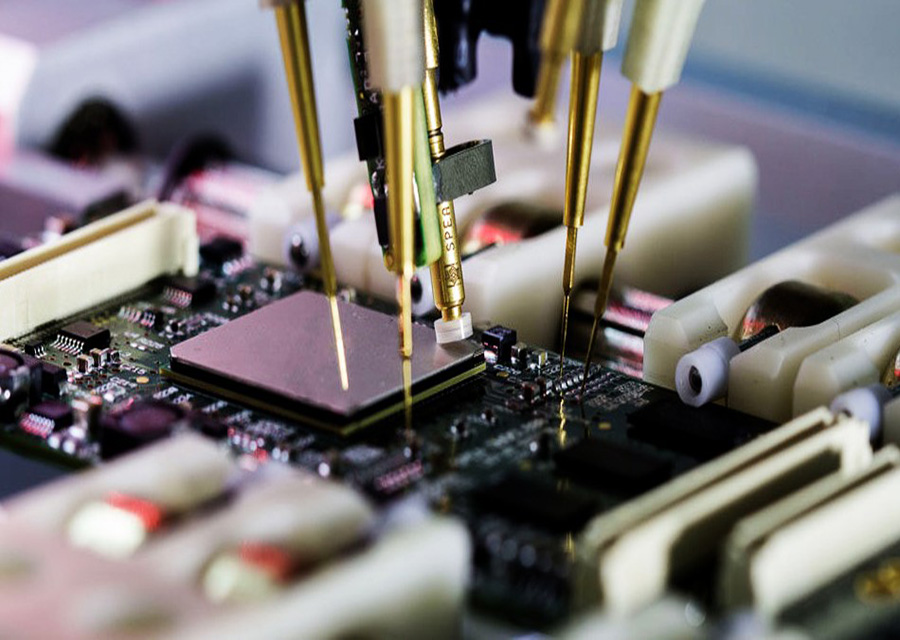

In the electronics manufacturing industry, FCT test (Functional Circuit Test) is a core process designed to verify the functional integrity of PCBA (Printed Circuit Board Assembly). It is a PCBA functional verification test, is an assessment of the board’s performance, the essence of which is to simulate the real operating environment , the circuit board to apply power, signal inputs and other excitation conditions, to detect whether the output response is in line with the design specifications. This dynamic test method can accurately capture the hardware circuitry, software programs and components work together anomalies, is the reliability testing of electronic products, is to ensure that electronic products “ out-of-the-box ” the cornerstone of the quality standard.

What is the key values of FCT Testing ?

Six key Values of FCT Testing: From Defect Prevention to Efficiency Escalation

Full Process Defect Interception

Through 20+ parameter tests such as voltage/current/power monitoring, frequency duty cycle analysis, brightness color calibration, etc., we can detect problems such as poor soldering, component failure, program logic errors, etc. in advance, and the defect detection rate is as high as 98% or more.Hardware-Software Collaborative Verification

Supports FLASH/EEPROM burning verification, motion control testing, character/sound recognition detection, ensuring zero-delay software/hardware interaction to meet the needs of complex scenarios such as IoT devices and smart terminals.Production cost optimization tool

Automated FCT equipment adopts open architecture design, supports multi-instrument integration and rapid program development, and the average daily testing capacity of a single device can be up to 5,000 pieces, which improves the efficiency of manual testing by 15 times.Real-time data-driven improvement

The testing process generates a Defects Traceability Database, which can be localized to specific work stations and operators, helping enterprises establish a closed-loop PDCA quality management system.Passport to Compliance Certification

Conforms to international standards such as ISO 9001, IECQ QC080000, etc., and provides key testing basis for product certification such as CE and FCC.Technology foresight and future adaptability

Compatible with AI/5G/IoT emerging technologies, Preset multi-protocol interfaces**, guaranteeing continuous upgrading capability of production lines

What the application of FCT test Systems ?

Technical innovation and industry application of FCT test system

1. Advantages of intelligent test platform

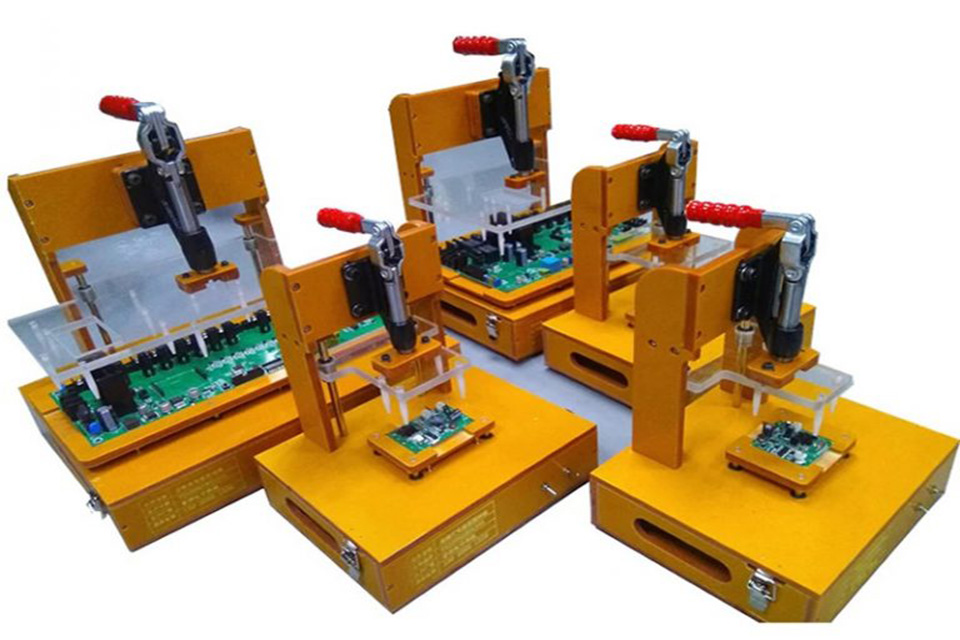

- Modular hardware architecture: Supports universal test fixture fast switching, adapting to diversified product lines from consumer electronics to industrial control

- AI algorithm support: Introducing machine learning models for fault mode prediction, the accuracy rate is 40% higher than traditional methods

- Cloud data management: Realize visual dashboard and cross-department sharing of test results, and shorten the decision response speed by 60%

2. Typical application scenarios

| Industry field | Core test requirements | Technical highlights |

|---|---|---|

| Consumer electronics | Touch screen response, wireless communication stability | Multi-protocol concurrent testing capabilities |

| Industrial automation | PLC control accuracy, sensor signal acquisition | High temperature and high humidity environment simulation |

| Medical equipment | Bioelectric signal processing, safety isolation detection | Microampere leakage current monitoring |

| Automotive electronics | CAN bus communication, EMC anti-interference capability | ISO 11452 standard stress test |

What the synergistic effect of FCT and other testing?

The synergistic effect of FCT and other testing technologies

In a complete PCBA test system, FCT often complements ICT online testing (short circuit/open circuit detection) and AOI optical inspection (appearance defect recognition):

- ICT: Focuses on electrical connectivity detection, suitable for early production process stages

- FCT: Focuses on functional integrity verification, corresponding to the final product quality checkpoint

- AOI: Supplements visual dimension detection, covering issues such as solder joint shape and component offset

This three-in-one detection solution can reduce the overall defect rate by 35% and significantly improve the product MTBF (mean time between failures) index.

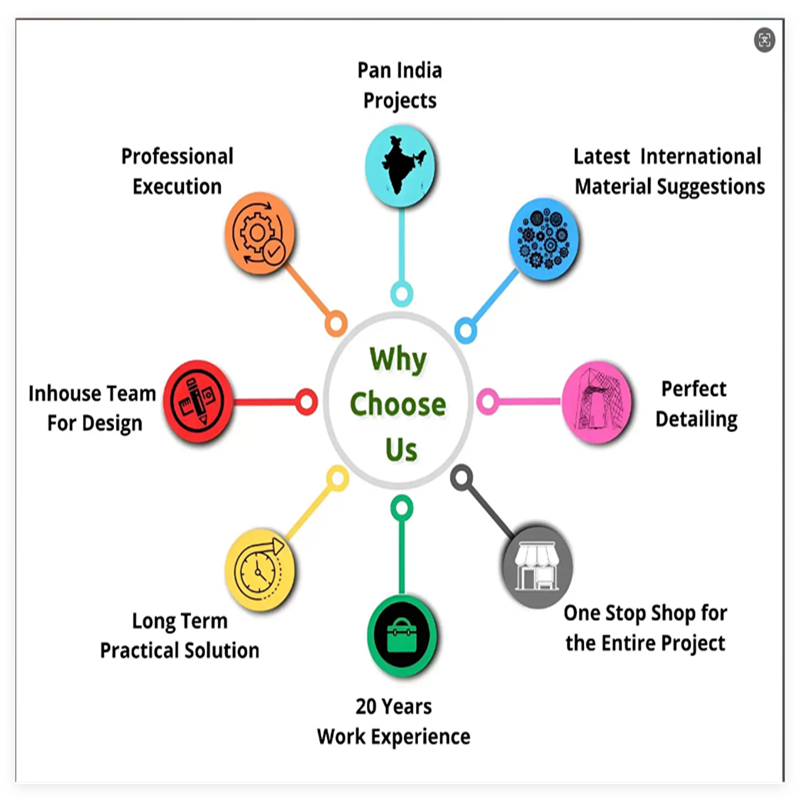

Why choose our professional FCT testing solution?

Seven PCBA provides full series of FCT test equipment and services with six core advantages:

✅ Customized Development Capability: Provide customized fixtures and test programs for special scenarios such as new energy automobile BMS, photovoltaic inverters, etc.

✅ Global Technical Support Network: 7×24 hours response mechanism with a team of 200+ certified engineers

✅ Maximize Return on Investment: equipment leasing + pay-per-use billing model, lowering the initial investment threshold for small and medium-sized enterprises (SMEs)

✅ AI Algorithm to Optimize Efficiency: Intelligent Defect Prediction System, increasing testing speed by 30% and shortening debugging cycle

✅ Medical-grade Data Encryption: Certified by ISO 27001, safeguarding customers’ data privacy and intellectual property rights

✅ Industry Benchmark Endorsement: Serving Global TOP 10 electronics foundries, cumulatively delivering more than 5,000 sets of test systems