Что такое индивидуальная сборка кабелей на печатной плате?

Что такое монтаж кабеля (провода) на печатной плате?

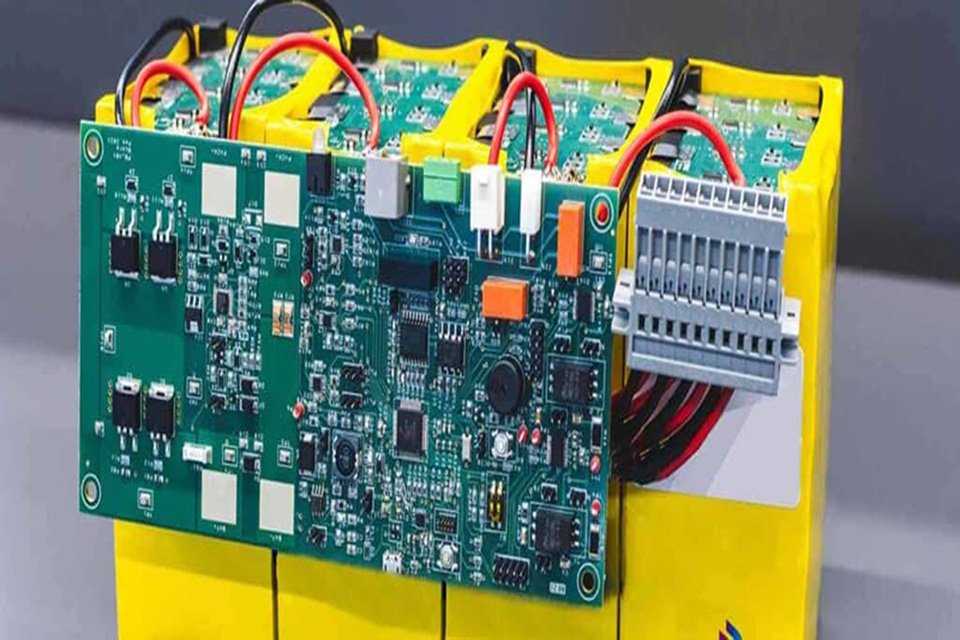

Сборка кабеля (провода) печатной платы относится к процессу объединения нескольких проводов и кабелей в структуру жгута для облегчения передачи сигнала и подачи питания в печатную плату (ПП). Этот процесс систематически соединяет компоненты ПП для эффективной передачи электроэнергии или сигналов. Сборка кабеля совместима как с активными, так и с пассивными компонентами, используемыми в крупносерийных ПП. Специальная сборка кабеля содержит десятки проводов, которые соединяют сотни клемм и материалов ПП. Ее экономичность и цифровые функции подключения делают ее надежным решением для производителей ПП. Кроме того, платы жгута проводов-затвора проходят несколько строгих процессов тестирования, которые гарантируют нераскрытую надежность и функциональность в услугах по производству ПП.

Сколько существует типов кабельных сборок для печатных плат?

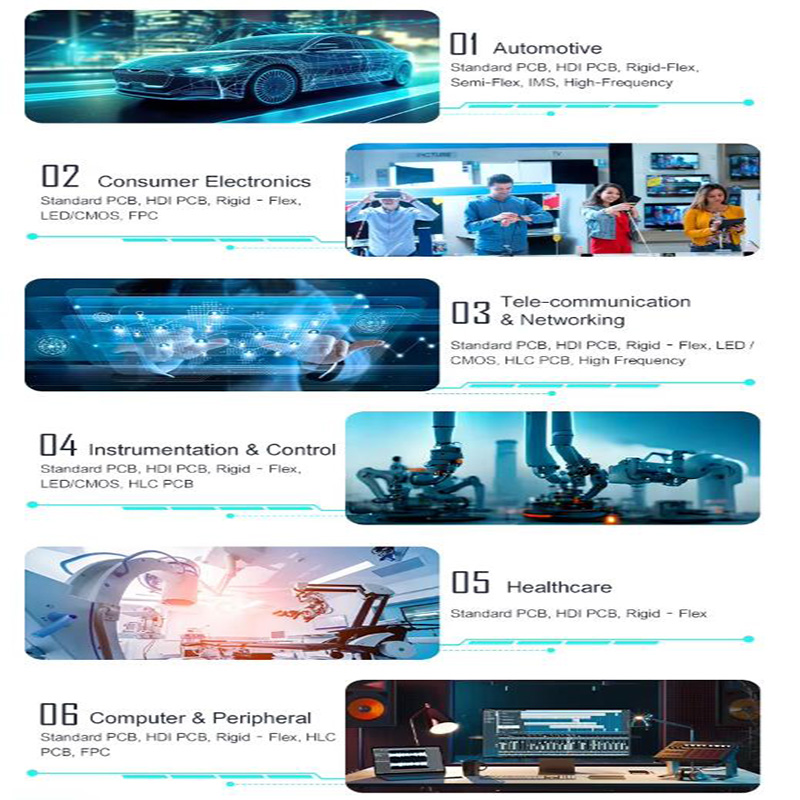

- Сборка автомобильного жгута проводов – Профессиональное производство автомобильных жгутов проводов, подходящих для всех типов транспортных средств.

- Жгут проводов электронного оборудования – Индивидуально разработанная прецизионная электронная проводка для удовлетворения различных потребностей в электрических соединениях.

- Жгут проводов промышленного оборудования – Прочный и долговечный промышленный жгут проводов для повышения механической эффективности.

- Жгут проводов для бытовой техники – Специальные решения по электропроводке для бытовой техники, обеспечивающие безопасность и эффективность.

- Жгут проводов медицинского оборудования – Высокоточная сборка медицинских жгутов проводов для поддержки медицинских технологий.

- Система жгутов проводов для авиации – Услуги по сборке жгутов проводов авиационного класса для обеспечения безопасного и надежного полета.

- Кабель коммуникационного оборудования – Эффективная сборка кабеля связи для оптимизации качества передачи сигнала.

- Электропроводка для нового энергетического транспортного средства – Специальная проводка для новых энергетических транспортных средств для содействия экологически чистым путешествиям.

- Жгут проводов для особых условий эксплуатации – Конструкция жгута проводов, устойчивая к суровым условиям окружающей среды, позволяет адаптировать его к экстремальным условиям.

В чем разница между кабельными сборками и жгутами проводов?

1.Разница в структуре проводника: Интеграция многожильного кабеля против независимости одного провода (передача питания/обслуживание сигнала)

2.Различные компоненты единиц: модульная сборка кабелей против жгутов проводов (промышленная проводка/автомобильная сборка)

3.Применение ландшафтного разделения: Кабель фокусируется на существующих сценариях, в то время как проводная система фокусируется на взаимосвязи (сеть центров обработки данных/транспортных средств)

4.Разница в уровне защиты: сертификация кабельной сборки IP69K по сравнению с гибкой оболочкой жгута проводов (экстремальные условия/защита от вибрации)

5.Особенности технологического процесса: Приоритет сварки обжимом кабеля против доминирования заклепок с креплением проволоки (автоматическая сборка/ручная обвязка)

6.Сравнение структуры затрат: Соотношение стоимости материалов для сборки кабеля и трудозатрат на жгут проводов выше (стоимость содержания меди/оптимизация процесса)

7.Степень адаптации: Кабель имеет множество стандартизированных интерфейсов, в отличие от топологии жгута проводов, которая является гибкой (plug and play/оптимизация для транспортного средства)

8.Различные системы сертификации: Сертификация кабелей UL/IEC в сравнении со стандартами автомобильной электроники (бытовая электроника/TS16949)

9.Фокус на производительности трансмиссии: Кабель имеет хорошую долговечность в сильных помехозащищенных условиях по сравнению с проводом, имеющим хорошую долговечность (экранирование от электромагнитных помех/стойкость к теплу и маслу)

Какое применение у нашей кабельной сборки?

🌟 8 основных применений кабельной сборки | Охват рынка стоимостью в сотни миллиардов долларов, стимулирование модернизации отрасли!

1️⃣ Высоковольтные жгуты проводов для новых энергетических транспортных средств • Платформа 800 В адаптируется к электрификации, а легкие алюминиевые провода увеличивают срок службы аккумулятора.

2️⃣ Жгуты проводов для интеллектуальных подключенных автомобилей • Передача данных с датчиков ADAS, жгуты проводов Ethernet ускоряют сетевое взаимодействие транспортных средств.

3️⃣ Гибкие жгуты проводов для промышленных роботов • Гарантия высокой точности движения для роботизированных рук, жгуты проводов управления ПЛК оптимизируют сигналы.

4️⃣ Высокоскоростные жгуты проводов для базовых станций 5G • Высокочастотные и помехозащищенные оптические кабели с низкими потерями передачи подходят для экстремальных условий.

5️⃣ Провода, устойчивые к высоким температурам, для аэрокосмической отрасли • Углеродное волокно снижает вес на 40%, а сверхпроводящие материалы преодолевают экстремальные температурные ограничения.

6️⃣ Медицинские стерильные жгуты проводов • Сертификация по электромагнитной совместимости совместима с МРТ, а устойчивые к коррозии силиконовые провода адаптированы для хирургии.

7️⃣ Микропроводка для умного дома • Дистанционное управление подключением к Интернету вещей, гибкое пространство сжатия печатной платы.

8️⃣ Новая фотоэлектрическая электропроводка • Конструкция, устойчивая к атмосферным воздействиям, позволяет выдерживать воздействие пустынь и океанов, а также обеспечивает высокую передачу тока для оптимизации энергоэффективности.

Почему мы должны быть вашим партнером по сборке кабелей на печатных платах?

- Современное производственное оборудование – Использование новейших технологий для повышения эффективности производства и стандартов качества.

- Строгий контроль качества – Точный процесс тестирования гарантирует, что каждая подвеска соответствует высоким стандартам.

- Крупномасштабные производственные мощности – Массовое производство тысяч изделий в день для удовлетворения потребностей клиентов без давления.

- Индивидуальный дизайн-сервис – Предоставлять профессиональные индивидуальные решения для удовлетворения различных специальных требований.

- Быстрая реакция на рынок – Гибко настраивайте производственную линию, чтобы быстро реагировать на изменения рынка.

- Выбор экологически чистых материалов – Используйте экологически чистые материалы для поддержки целей устойчивого развития.

- Опыт применения в различных отраслях – Богатые кейсы в различных областях, таких как автомобилестроение, электроника и медицина.

- Эффективная логистика и дистрибуция – Глобальная дистрибьюторская сеть, гарантирующая своевременную доставку продукции.

- Группа технической поддержки – Профессиональная послепродажная поддержка для решения любых вопросов клиентов.