Advanced Remote PCBA Manufacturing: Revolutionary Innovation Trends

Введение

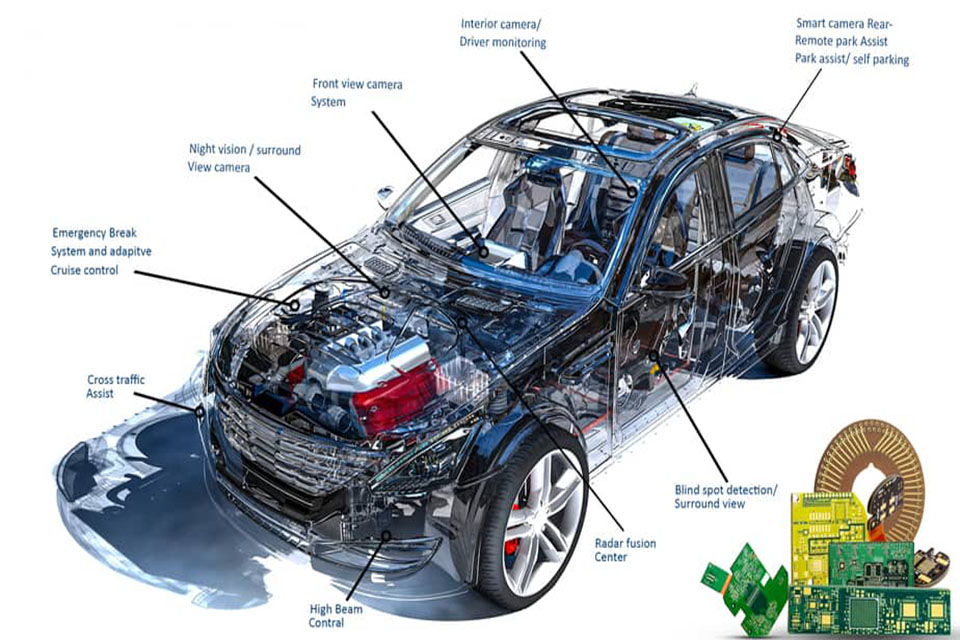

The automotive electronics market experiences unprecedented improvement via sophisticated remote PCBA producing innovations. Modern Сборка печатной платы processes revolutionize vehicle control systems, enabling innovative cordless communication capabilities and boosted customer experiences. This detailed analysis checks out advancement technologies in печатная плата manufacturing, automated manufacturing methodologies, and arising market opportunities that reshape the automotive electronic devices landscape.

Remote Control PCBA technology serves as the foundation of contemporary clever automobile systems. Manufacturers leverage progressed Сборка печатной платы methods to produce high-performance control modules that fulfill rigorous vehicle requirements. The evolution from standard motherboard to innovative печатная плата options demonstrates exceptional technological progression in the vehicle sector.

This short article supplies valuable insights for electronics makers, auto suppliers, and technology decision-makers seeking to understand Push-button control PCBA making quality. We take a look at technical specifications, production developments, and strategic execution techniques that drive sector success.

Table of Contents

Core Remote PCBA Production Technologies

Precision Assembly Specs and Criteria

Remote PCBA making demands phenomenal accuracy and dependability standards. Modern automobile applications need durable Сборка печатной платы processes that withstand severe ecological problems while keeping regular performance features.

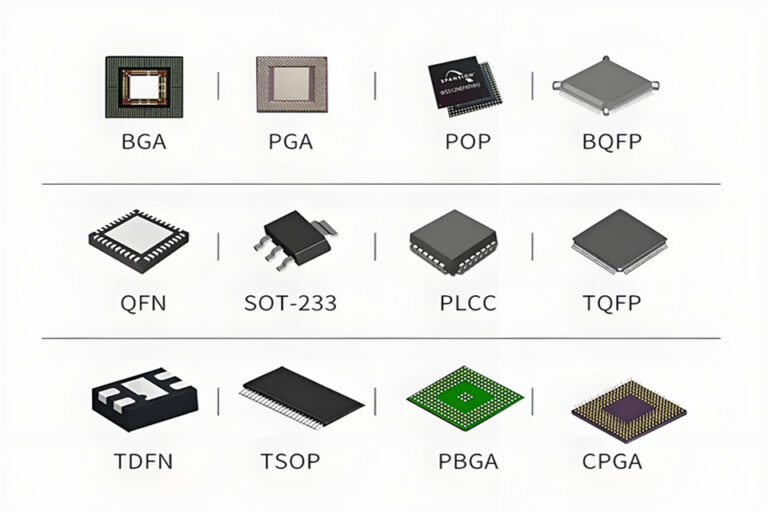

Advanced substrate products make it possible for exceptional Remote Control PCBA capability. Настройка печатной платы procedures make use of FR-4, polyimide, and PTFE products to accomplish optimum signal transmission homes. These materials support high-frequency communication protocols vital for modern-day lorry control systems.

Manufacturing accuracy straight influences Remote PCBA efficiency. печатная плата manufacturing centers implement limited resistance controls, accomplishing line size precision of 75μm and aperture accuracy of 0.20 mm. Such specifications make certain dependable electric links and regular signal honesty throughout all manufacturing batches.

Превосходство технических характеристик

Remote Control PCBA making incorporates numerous technical specifications that specify performance capabilities. Настройка печатной платы processes should suit differing copper density needs, ranging from 1/3oz to 6oz configurations. This adaptability allows suppliers to enhance печатная плата designs for specific application demands.

Board density control stands for another critical parameter in Remote Control PCBA production. Настройка печатной платы centers preserve thickness tolerances in between 0.21-6.0 mm, balancing miniaturization demands with architectural honesty demands. This accuracy ensures optimum печатная плата efficiency in compact automotive atmospheres.

Surface area therapy innovations enhance Remote PCBA dependability and environmental resistance. Настройка печатной платы processes make use of HASL, gold plating, OSP, and lead-free HASL therapies to enhance soldering high quality and long-lasting longevity. These therapies safeguard печатная плата parts from oxidation and ecological deterioration.

Что обеспечивает эффективную работу удаленного оборудования PCBA?

Традиционные концепции процедуры удаленного ключа

Push-button control PCBA systems run via innovative superhigh frequency communication procedures. Настройка печатной платы designs integrate FSK modulation circuits with microcontroller devices to enable reliable wireless transmission. These печатная плата systems support several regularity bands, including 27MHz, 40MHz, and 62MHz setups.

Power monitoring stands for a critical aspect of Remote PCBA design. Настройка печатной платы engineers optimize circuit designs to decrease power usage, typically accomplishing much less than 0.5 W functional requirements. Efficient печатная плата styles expand battery life while preserving regular efficiency features.

Signal handling abilities specify Push-button control PCBA efficiency. Сборка печатной платы systems include delicate receiver circuits efficient in finding signals as low as -100 dBm. This level of sensitivity makes certain reliable печатная плата operation throughout extended communication ranges and challenging ecological conditions.

Advanced Smart Remote PCBA Secret Technologies

Modern Remote PCBA systems integrate easy sensing innovations for improved customer ease. Сборка печатной платы layouts integrate low-frequency wake-up systems running at 125kHz regularities. These advanced печатная плата systems make it possible for keyless access and leave capability through distance discovery.

Encryption innovations enhance Remote PCBA protection features. Настройка печатной платы systems implement AES-256 encryption algorithms to avoid unauthorized gain access to efforts. This safety improvement ensures печатная плата systems withstand hacking efforts for prolonged periods, commonly going beyond 10 years of security.

Near-field interaction assimilation expands Push-button control PCBA abilities. Настройка печатной платы layouts integrate NFC visitors within door manage assemblies, making it possible for recognition arrays under 10cm. This technology permits печатная плата systems to provide seamless user authentication and gain access to control.

Как автоматизированная сборочная линия меняет производство PCBA?

Гибкие производственные решения

Automated assembly line reinvent Push-button control PCBA manufacturing with enhanced flexibility and accuracy. Настройка печатной платы centers apply quick-change tooling systems that enable rapid product shifts. These automated печатная плата production lines achieve changeover times under 15 mins while maintaining high compatibility prices exceeding 95%.

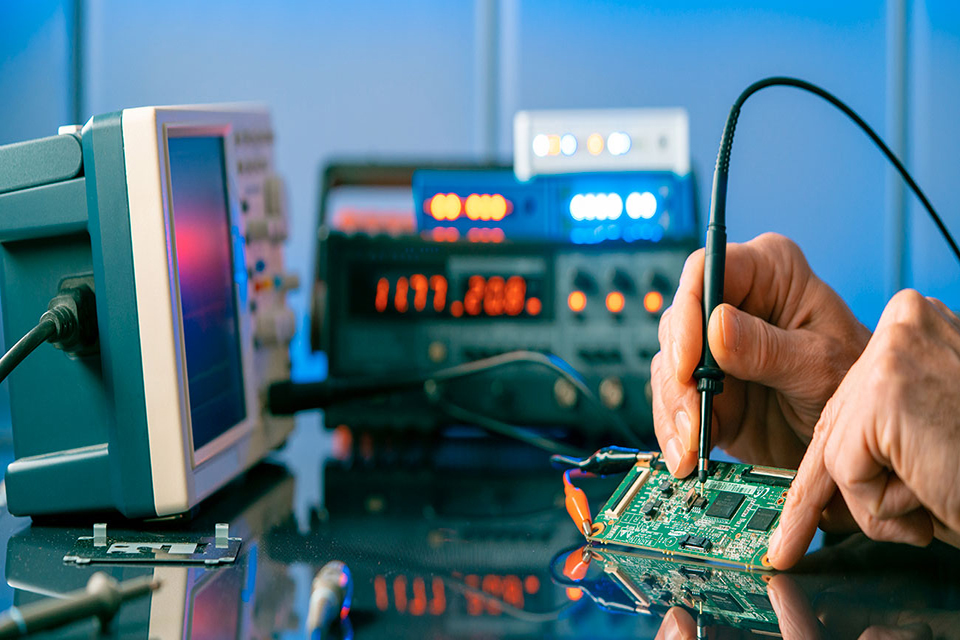

Real-time high quality surveillance systems ensure Remote PCBA producing quality. Сборка печатной платы processes integrate dual-parameter stress and variation tracking with precision tolerances of ± 0.1 N. These keeping an eye on systems make it possible for печатная плата manufacturers to preserve regular top quality requirements throughout production cycles.

Digital traceability systems improve Remote Control PCBA manufacturing accountability. Настройка печатной платы centers integrate RFID innovation with MES systems to achieve thorough data collection. These systems ensure печатная плата products preserve full traceability documents for durations exceeding 5 years.

Достижения в области повышения эффективности производства

Automated Push-button control PCBA production lines show remarkable effectiveness improvements over standard manufacturing techniques. Сборка печатной платы centers achieve manufacturing yields exceeding 99.5%, standing for significant innovation over conventional procedures. These efficiency gains allow печатная плата suppliers to fulfill enhancing market needs while preserving high quality criteria.

Cycle time optimization identifies contemporary Push-button control PCBA production. Сборка печатной платы lines accomplish manufacturing cycles of 360 secs each, standing for 400% renovation over manual manufacturing approaches. This effectiveness enables печатная плата manufacturers to scale production capacity while reducing operational expenses.

Labor expense decrease comes with automated Push-button control PCBA making application. Сборка печатной платы facilities lower labor price percentages to under 10% of overall production expenditures. This expense optimization makes it possible for печатная плата suppliers to preserve competitive rates while improving earnings margins.

Почему формируются отраслевые модели развития современных технологий PCBA?

Новый эффект мощного грузовика

Electric vehicle fostering drives Remote Control PCBA modern technology advancement. Настройка печатной платы manufacturers react to federal government policy campaigns targeting electrical automobile penetration prices. China targets 20% electric lorry adoption by 2025, while the EU prepares to prohibit fuel cars by 2035. These policies create significant demand for sophisticated печатная плата technologies.

Silicon carbide integration boosts Remote Control PCBA performance capacities. Настройка печатной платы styles integrating SiC power tools accomplish 15-20% effectiveness improvements over conventional silicon-based options. This technology innovation enables печатная плата systems to satisfy requiring auto efficiency needs.

Radar fusion modern technologies increase Remote PCBA application opportunities. Сборка печатной платы systems incorporate 4D millimeter-wave radar capabilities to attain placing accuracy within ± 5cm resistances. These sophisticated печатная плата remedies enable innovative vehicle automation and safety and security attributes.

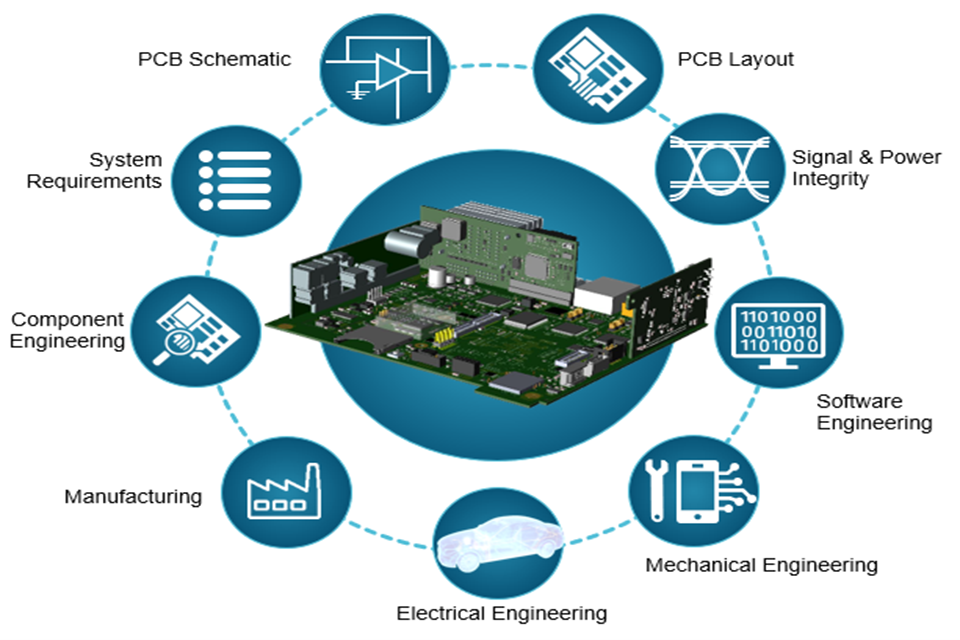

Сотрудничество в цепочке поставок

Industry community collaboration enhances Remote Control PCBA growth capacities. Настройка печатной платы manufacturers develop critical collaborations with OEMs, Tier 1 providers, and material suppliers. These collaborative relationships enable печатная плата business to access advanced innovations and broaden market chances.

Innovation sharing campaigns speed up Remote PCBA technology cycles. Настройка печатной платы companies participate in joint research study programs to create next-generation solutions. These collaborative initiatives make it possible for печатная плата makers to remain affordable in rapidly evolving automobile markets.

Upright assimilation strategies boost Push-button control PCBA making capacities. Сборка печатной платы companies broaden procedures to consist of product handling and component production. This assimilation allows печатная плата manufacturers to regulate high quality criteria and reduce supply chain dependences.

Which Selection Criteria Determine PCBA Success?

Material Option Guidelines

Remote PCBA product selection substantially influences system efficiency and dependability. Настройка печатной платы applications calling for high-frequency procedure take advantage of PTFE and Rogers substrate materials. These advanced products make it possible for печатная плата systems to maintain signal honesty throughout extended regularity ranges.

Ecological resistance requirements influence Remote PCBA material options. Настройка печатной платы systems operating in rough vehicle atmospheres call for polyimide substrates with OSP surface area therapies. These material combinations enable печатная плата items to hold up against temperature extremes and chemical exposure.

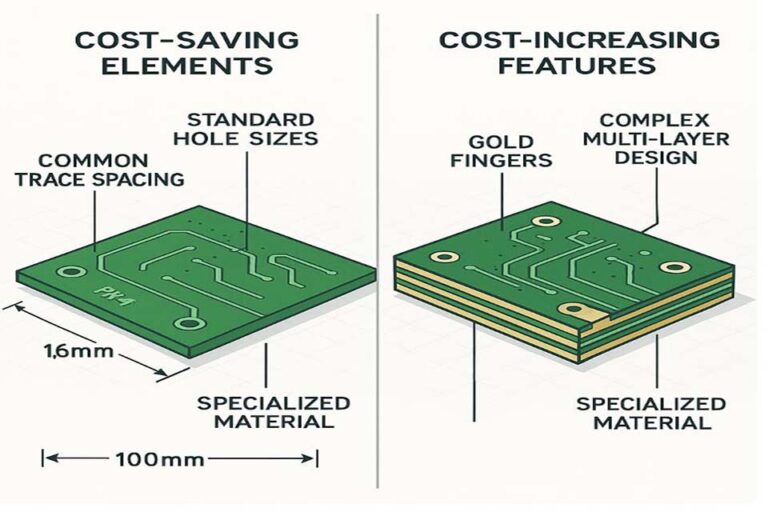

Cost optimization considerations balance Push-button control PCBA performance demands with budget constraints. Настройка печатной платы applications using FR-4 substrates with HASL treatments supply superb value for conventional auto applications. These product selections allow печатная плата makers to attain competitive rates while preserving quality standards.

Collaboration Version Analysis

OEM partnership models offer Push-button control PCBA consumers with rapid product delivery abilities. Сборка печатной платы firms offering standard items achieve preparations under 2 weeks. These partnerships make it possible for печатная плата clients to react swiftly to market chances and manufacturing demands.

ODM cooperation enables Remote PCBA modification for details applications. Настройка печатной платы firms offer total style and production solutions with development timelines ranging from 8-12 months. These collaborations permit печатная плата consumers to create one-of-a-kind items that separate their market offerings.

Joint study initiatives increase Push-button control PCBA modern technology improvement. Сборка печатной платы business participating in collaborative study programs buy next-generation modern technologies. These collaborations enable печатная плата producers to develop cutting-edge remedies that meet future market needs.

When Should Firms Purchase Advanced Remote PCBA Technologies?

Market Timing Factors To Consider

Push-button control PCBA market problems show ideal investment timing for innovation upgrades. Сборка печатной платы need increases correlate with electrical lorry adoption prices surpassing 30% in significant markets. This growth produces considerable possibilities fo печатная плата producers to broaden market share and earnings.

Innovation maturation cycles affect Remote PCBA financial investment choices. Сборка печатной платы firms take advantage of buying tried and tested innovations while checking arising developments. Strategic печатная плата investment timing allows business to optimize return on investment while preserving affordable benefits.

Competitive pressure drives Remote PCBA innovation adoption timelines. Сборка печатной платы firms must respond to competitor advancements to keep market position. Aggressive печатная плата technology investment allows firms to lead market fads as opposed to comply with competitors.

ROI Calculation Techniques

Remote Control PCBA financial investment returns depend upon several performance aspects. Настройка печатной платы companies examine yield renovations, cycle time decreases, and high quality improvements when computing investment returns. Comprehensive печатная плата ROI evaluation consists of both measurable and qualitative benefits.

Functional cost decrease represents significant Remote Control PCBA financial investment value. Сборка печатной платы automation lowers labor prices while improving consistency and top quality. These печатная плата functional enhancements produce considerable lasting worth for producing firms.

Market expansion chances enhance Push-button control PCBA financial investment beauty. Настройка печатной платы business accessing brand-new markets with innovation upgrades accomplish higher earnings development prices. Strategic печатная плата investments enable business to record arising market possibilities and broaden client bases.

Where Are PCBA Production Innovations Heading?

Future Technology Directions

Artificial intelligence integration transforms Push-button control PCBA making abilities. Сборка печатной платы facilities execute AI-powered aesthetic inspection systems achieving 99.9% issue discovery rates. These advanced печатная плата quality assurance systems lower waste while improving product reliability.

Machine learning applications enhance Push-button control PCBA production procedures. Настройка печатной платы systems use anticipating analytics to avoid devices failings and maximize upkeep timetables. These technologies allow печатная плата makers to attain higher functional performance and decreased downtime.

Internet of Points connectivity enhances Push-button control PCBA producing visibility. Настройка печатной платы tools combination with IoT platforms enables real-time monitoring and remote diagnostics. These capabilities allow печатная плата producers to enhance manufacturing efficiency and respond promptly to functional concerns.

Arising Applications

Independent lorry technologies develop new Push-button control PCBA application chances. Настройка печатной платы systems supporting Level 4 and Degree 5 automation call for advanced handling capacities and reliability requirements. These arising печатная плата applications represent considerable development opportunities for ingenious manufacturers.

Vehicle-to-everything communication expands Remote PCBA functionality demands. Настройка печатной платы systems have to support 5G connection and side computer capabilities. These innovative печатная плата applications allow lorries to interact with facilities, various other lorries, and cloud services.

Electrification patterns drive Remote Control PCBA power management innovations. Сборка печатной платы systems must take care of greater power degrees while preserving performance and dependability. These growths produce opportunities for печатная плата suppliers specializing in power electronic devices and thermal management.

How Can Business Enhance PCBA Production Processes?

Refine Renovation Strategies

Lean producing concepts boost Remote PCBA manufacturing efficiency. Сборка печатной платы business implementing constant improvement approaches accomplish considerable waste reduction and cycle time renovations. These печатная плата optimization efforts generate significant operational advantages and price savings.

Analytical process control makes certain Remote PCBA high quality consistency. Сборка печатной платы centers making use of SPC approaches preserve tight procedure controls and reduce variation. These quality systems make it possible for печатная плата manufacturers to achieve regular item performance and consumer fulfillment.

Employee training programs enhance Remote PCBA making capacities. Сборка печатной платы firms purchasing labor force growth accomplish greater efficiency and high quality standards. Knowledgeable specialists allow печатная плата makers to execute advanced modern technologies and keep competitive advantages.

Modern Technology Integration Approaches

Modular devices style facilitates Remote Control PCBA making adaptability. Сборка печатной платы systems utilizing modular configurations allow quick reconfiguration for various products. This flexibility enables печатная плата makers to react promptly to changing market needs and production demands.

Scalable automation options sustain Remote PCBA company development. Сборка печатной платы companies executing modular automation systems can broaden ability as need boosts. These scalable печатная плата services reduce initial investment while offering growth adaptability.

Digital twin innovation enhances Remote PCBA manufacturing performance. Настройка печатной платы centers making use of online modeling can optimize processes before implementation. These electronic печатная плата simulations lower danger and speed up process renovation efforts.

Часто задаваемые вопросы

What are the crucial technical specs for Push-button control PCBA manufacturing?

A: Push-button control PCBA systems need specific requirements consisting of FR-4/ PTFE substrate materials, copper density ranging 1/3oz -6 oz, board density control 0.21-6.0 mm, minimal 0.20 mm aperture precision, and surface treatments like HASL or gold plating for ideal efficiency and reliability.

Just how do automated production lines boost PCB Setting up top quality?

. A: Automated PCBA assembly line attain 99.5%+ yield rates via real-time top quality surveillance, dual-parameter pressure/displacement control ( ± 0.1 N precision), and digital traceability systems. These renovations stand for considerable development over typical 85-90% return prices.

Which products are best for high-frequency Push-button control PCBA applications?

. A: High-frequency PCBA applications take advantage of PTFE and Rogers substrate products with gold or OSP surface area treatments. These materials maintain signal honesty across extensive frequency varieties while giving outstanding environmental resistance for automotive applications.

What certification requirements apply to automobile PCBA manufacturing? .

A: Automotive PCBA manufacturing calls for conformity with ISO9001, CE, TUV, ROHS, and AEC-Q100 requirements. These accreditations guarantee product top quality, environmental conformity, and automotive-specific dependability needs for lasting procedure.

How does electrical automobile adoption influence PCBA innovation advancement?

A: Electric car development drives PCBA development through SiC power device integration (15-20% performance enhancement), 4D radar fusion abilities ( ± 5cm positioning precision), and progressed encryption technologies. Federal government targets of 20-30% EV fostering develop considerable market need.

What collaboration designs function best for PCBA production companies?

. A: Effective PCBA collaborations include OEM models for fast shipment (< 2 weeks), ODM partnerships for personalization (8-12 months development), and joint R&D campaigns for cutting-edge technology advancement. Each version offers various market needs and tactical objectives.

Summary and Secret Recommendations.

Remote PCBA producing innovation continues developing rapidly, driven by automobile electrification patterns and automation advances. Настройка печатной платы companies need to adjust to altering market needs while preserving top quality criteria and functional performance. The adhering to tactical recommendations guide effective печатная плата making makeover:.

- Invest in computerized manufacturing systems that achieve 99.5%+ yield prices and decrease cycle times to under 360 seconds per unit.

- Carry out innovative material modern technologies consisting of PTFE/Rogers substrates for high-frequency applications and polyimide for rough environments.

- Deploy electronic traceability systems with RFID and MES combination to make sure total product lifecycle paperwork.

- Develop critical collaborations with OEMs, Rate 1 suppliers, and innovation providers to accessibility advanced innovations.

- Create AI-powered quality control systems accomplishing 99.9% flaw discovery prices for exceptional item reliability.

- Concentrate on SiC power tool integration to achieve 15-20% efficiency improvements in electric lorry applications.

- Develop adaptable production capabilities supporting numerous product with transition times under 15 minutes.

- Reinforce supply chain collaboration through upright combination and ecosystem collaborations.

- Buy workforce advancement programs to keep competitive technological capabilities.

- Screen emerging technologies including 5G connectivity, independent lorry systems, and IoT combination for future opportunities.

The Remote Control PCBA industry stands at a critical improvement factor where conventional production strategies pave the way to intelligent, computerized production systems. Firms welcoming these technical advancements while keeping concentrate on top quality, efficiency, and client complete satisfaction will certainly record the greatest market chances in the progressing automobile electronics landscape.