Aperçu complet de 2025 des services de fabrication électronique (EMS) : procédures astucieuses, avantages et perspectives du secteur

Abstrait:

Electronic Manufacturing Services (EMS) play a transformative duty in today’s international electronics sector. This comprehensive guide explores EMS producing solutions, from style and setting up to quality assurance and supply chain monitoring. The article highlights why EMS is vital for companies seeking affordable, scalable, and premium digital manufacturing. Keep reading to discover how EMS carriers can help your service stay competitive, ingenious, and reliable.

Table of Contents

Introduction.

Electronic manufacturing services (EMS) develop the structure for a number of today’s most advanced products, from consumer electronics to industrial systems. As technology develops, business progressively depend upon EMS making services to streamline manufacturing, keep high quality, and respond quickly to market demands. This article clarifies what EMS is, its core processes, and just how choosing the appropriate EMS companion can provide an one-upmanship in the electronics market.

1. Que sont les fournisseurs de production numérique ?

Digital manufacturing services, or EMS, refer to a series of specialized tasks that third-party service providers provide to original equipment producers (OEMs). These services include designing, putting together, testing, and providing digital items. EMS companies, also referred to as digital agreement manufacturers, aid business bring premium electronics to market quickly and successfully.

By utilizing EMS manufacturing solutions, OEMs can focus on their product vision and client partnerships. Meanwhile, EMS firms deal with the complex production procedures. This method enables businesses to take advantage of the latest production technologies while controlling expenses and reducing risk.

Trick Terms: .

- Electronic manufacturing services .

- EMS manufacturing solutions .

- Electronic production .

2. En quoi les services de fabrication électronique diffèrent-ils exactement de la fabrication en interne ?

Several companies debate whether to keep making internal or outsource to an EMS carrier. EMS production services vary from in-house manufacturing in several methods. EMS companies concentrate on electronic production, often investing in innovative devices, competent workers, and robust top quality systems.

Outsourcing to EMS allows business stay clear of heavy financial investments in equipment and centers. EMS providers deliver scalable remedies for projects big and small, adapting quickly to altering demand. This versatility contrasts with the dealt with overhead and slower feedback times of in-house manufacturing.

Key Terms: .

- Digital contract making .

- EMS manufacturing .

- Scalable production .

3. Phases délicates des services de fabrication électronique.

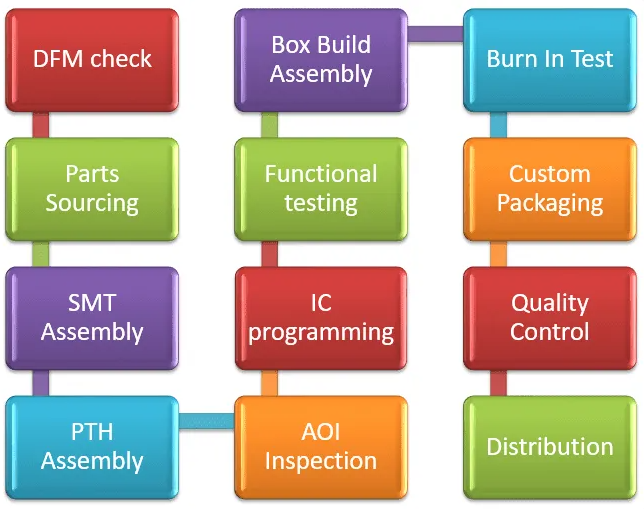

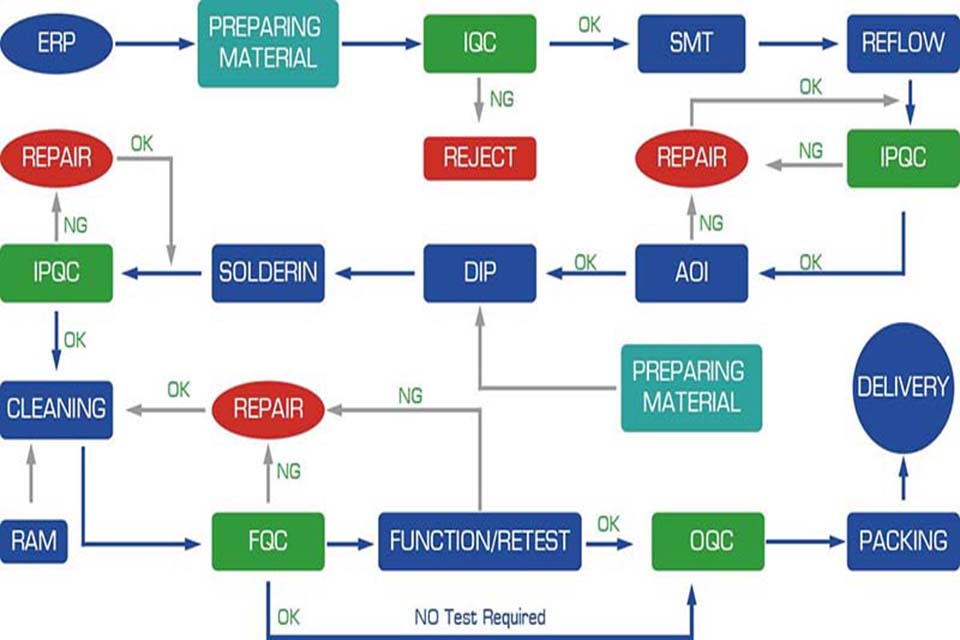

EMS production services cover every stage of product understanding. The major phases include:.

- Layout and Engineering: From principle to model.

- Element Purchase: Sourcing trusted parts.

- Assembly: PCB setting up, cable setting up, and system integration.

- Examining and Quality Assurance: Making certain product dependability and conformity.

- Supply Chain Management: Coordinating materials and logistics.

- Aftermarket Solutions: Repair, remodel, and support.

- Obsolescence Administration: Managing element lifecycles.

Each phase uses innovative approaches and strict quality controls. EMS companies use terms like surface area place technology (SMT) , assemblage traversant , et automated optical examination (AOI) to describe their procedures.

4. À quoi les fournisseurs de services de conception et de fabrication électronique (EMS) sont-ils confrontés ?

EMS manufacturing solutions begin with design and design. Service providers help transform concepts into manufacturable items. They provide assistance in:.

- Schematic style .

- PCB layout and construction .

- Fast prototyping .

- Layout for manufacturability (DFM) analysis .

These solutions guarantee that styles meet performance, expense, and integrity targets. EMS specialists make use of CAD devices , simulation software , et engineering adjustment administration systems to simplify item growth.

Key Terms: .

- PCB layout .

- Prototyping .

- Electronic style services .

5. Comment les fournisseurs de services de fabrication électronique (EMS) gèrent-ils la fabrication et l'assemblage ?

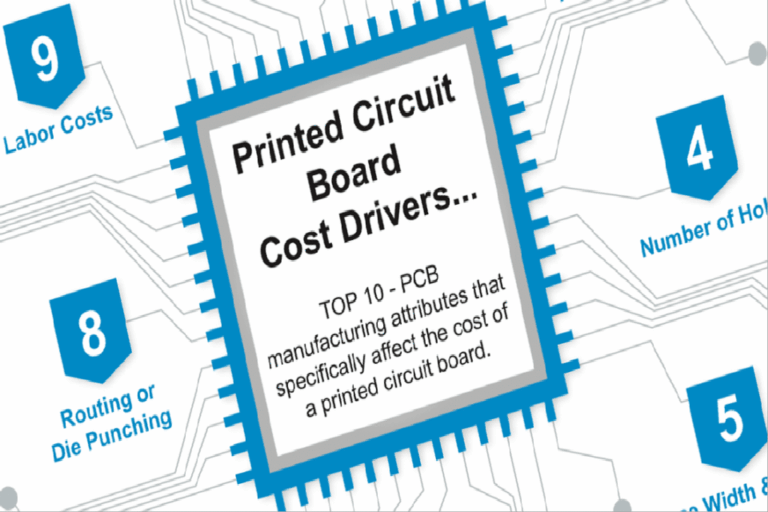

The core of digital manufacturing services lies in reliable assembly and production. EMS business source elements, develop published circuit boards (PCBs), and construct finished products. Their capacities include:.

- Surface area install assembly .

- Through-hole soldering .

- Box build and system integration .

- Automated testing .

Modern EMS facilities make use of robotic production line , pick-and-place equipments , et real-time production tracking . These innovations make sure consistency, decrease mistakes, and range result to satisfy demand.

Trick Terms: .

- Assemblage de circuits imprimés .

- Electromechanical assembly .

- Automated producing .

6. Pourquoi le dépistage et le contrôle de la qualité sont-ils essentiels dans les services de fabrication électronique ?

Quality assurance is a cornerstone of EMS manufacturing solutions. Service providers use strenuous screening methods, such as:.

- Useful testing .

- In-circuit testing (ICT) .

- Environmental anxiety testing (ESS) .

- X-ray assessment .

These treatments determine issues very early and guarantee items satisfy industry criteria. Quality control teams monitor every action, using metrics like problem rates , yield evaluation , et traceability .

Secret Terms: .

- Examining services .

- Assurance qualité .

- Product reliability .

7. Qu'est-ce qui rend l'administration de la chaîne d'approvisionnement EMS si efficace ?

EMS production services stand out for their supply chain effectiveness. Providers take care of:.

- Material sourcing .

- Stock control .

- Supplier partnerships .

- International logistics .

By incorporating supply chain software application and predictive analytics, EMS firms enhance material flow and decrease hold-ups. They likewise track component lifecycles, helping customers avoid scarcities or obsolescence.

Trick Terms: .

- Supply chain administration .

- Supply optimization .

- Logistics services .

8. Comment les services d'administration après-vente et d'obsolescence ajoutent-ils de la valeur ?

After an item ships, EMS service providers supply aftermarket support. This consists of:.

- Repair work and remodel .

- Warranty solutions .

- Extra components management .

Obsolescence monitoring is likewise vital. EMS companies keep track of element schedule and recommend options when parts come to be obsoleted. This positive method keeps products running and expands their valuable life.

Trick Terms: .

- Aftermarket support .

- Obsolescence management .

- Lifecycle administration .

9. Quels sont les principaux avantages des solutions de production EMS ?

EMS manufacturing services provide numerous advantages:.

- Price Performance: Leverage economic situations of range and prevent capital investments.

- Accelerated Time to Market: Streamline manufacturing and speed up launches.

- Access to Competence: Take advantage of experienced engineers and advanced technology.

- Scalability: Readjust manufacturing volumes as need changes.

- Boosted Quality: Take advantage of durable testing and evaluation.

These benefits make EMS the go-to solution for start-ups and recognized firms alike.

Trick Terms: .

- Cost reduction .

- Time to market .

- Production expertise .

10. Comment choisir exactement le bon partenaire EMS pour votre entreprise ?

Choosing the best EMS company is important. Consider these elements:.

- Technical abilities and accreditations .

- Experience in your industry .

- Production ability and scalability .

- Quality administration systems .

- Customer support and interaction .

Request study and visit their facilities ideally. A strong EMS partner will certainly straighten with your service goals and supply constant worth.

Trick Terms: .

- EMS companion .

- Vendor choice .

- Customer assistance .

11. FAQ sur les services de fabrication électronique.

Quels marchés utilisent les services de production numérique ?

EMS producing services support industries like consumer electronic devices, vehicle, health care, aerospace, telecommunications, and commercial automation.

Les fournisseurs de services EMS peuvent-ils gérer les faibles volumes ou les séries de modèles ?

Yes, the majority of EMS firms offer versatile remedies for models, tiny sets, and large-scale manufacturing.

Comment les entreprises EMS s'assurent-elles de la qualité des articles ?

EMS companies execute strict quality controls, progressed testing, and conformity with sector standards like ISO 9001 and IPC.

Quel est le délai d'exécution habituel pour les projets EMS ?

Timelines differ by job complexity, but EMS companies frequently supply models in weeks and complete manufacturing in a couple of months.

Comment les entreprises de SME gèrent-elles le droit d'auteur et la confidentialité ?

Trusted EMS companions authorize NDAs, utilize safe and secure data systems, and respect customers’ intellectual property legal rights.

What worth does supply chain management include in EMS?

A6: Effective supply chain management makes certain timely shipment, reduces prices, and avoids part shortages or delays.

12. inal Thought: Making Best Use Of Worth with EMS Manufacturing.

Electronic manufacturing solutions empower organizations to innovate, range, and complete in a fast-moving market. By partnering with knowledgeable EMS carriers, firms access to sophisticated technology, skilled labor, and durable supply chains. EMS manufacturing solutions drive cost financial savings, high quality improvement, and faster time to market, making them a crucial part of modern-day electronics manufacturing.