What is Electronics Manufacturing?

Electronics manufacturing means the complete production processes of electronic devices. It includes PCB fabrication, PCB assembly, electromechanical assembly, testing and inspections, or even electronic design, packaging and distribution. Electronics Manufacturing Services (EMS) supply full turnkey electronics manufacturing services to brank owners and original equipment manufacturers (OEMs).Electronics Manufacturing refers to the production of any kind of electronic products. Our company provides electronic products that are widely used in many industry fields, such as consumer electronics, industrial electronics, agricultural equipment, automotive, communications and wireless, lighting industry, Internet of Things, computers and storage, test and measurement, robotics, medical, military, aerospace and satellite, etc.

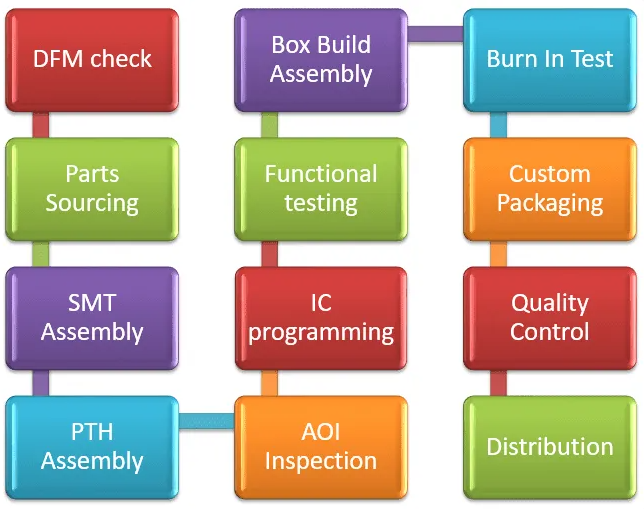

10 Key Steps in Electronics Manufacturing

The electronic manufacturing process includes several aspects such as PCB manufacturing, PCB assembly, whole machine assembly, functional testing, quality inspection and packaging. The following are the main processes of electronic manufacturing.

1.DFM check

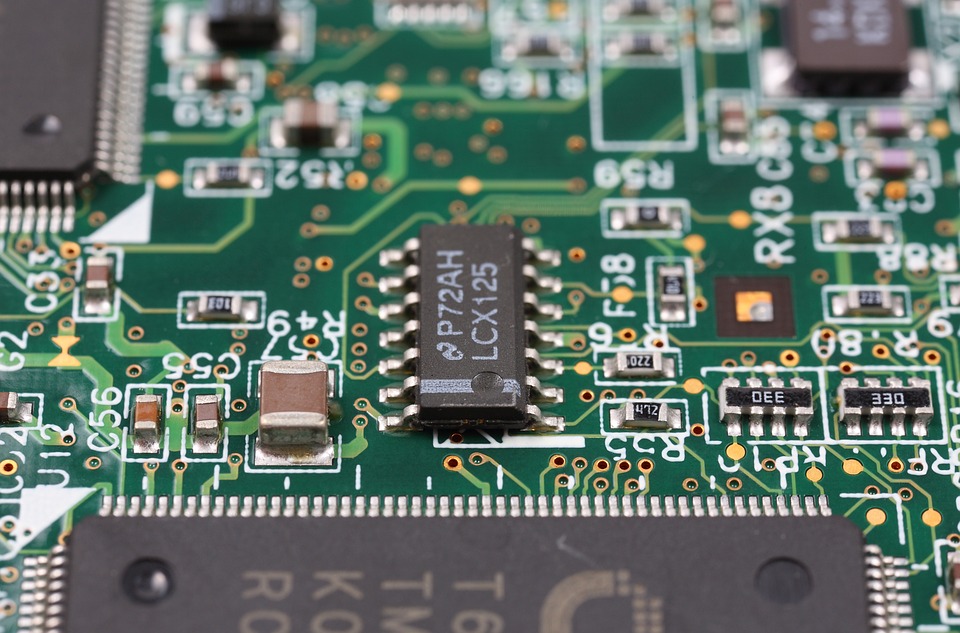

2.PCB manufacturering and components

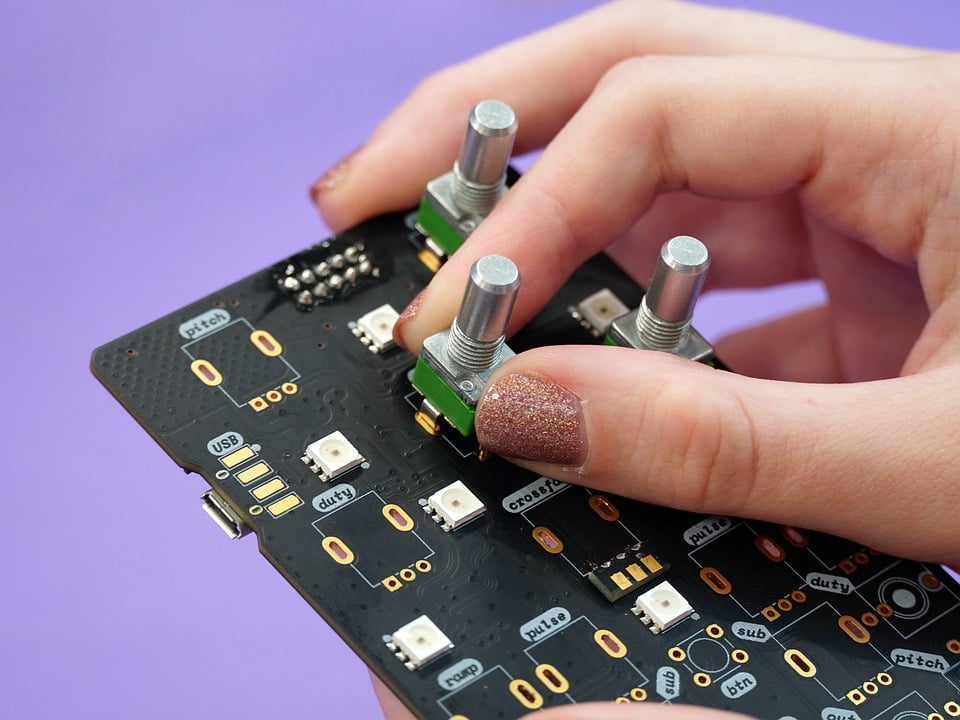

3.SMT Assembly

4.PTH Assembly

5.Box Build Assembly

6.Functional Testing

7.IC programming

8.AOI Inspection

9.Brun In Test

10.Quality Control

How Start Electronics Manufacturing with us?

We request below files to start the electronics Manufacturing

1.PCB gerber files and Bom list

2. IC programming like Hex files

3.Functional test document

4.Box drawing like CAD files

5.package details information

What is the Benefits of Electronics Manufacturing Services?

1. Cost optimization and economic benefit maximization

Electronic manufacturing services (EMS) significantly reduce PCBA production costs through large-scale production, supply chain resource integration and lean management. Professional PCBA factories use global procurement networks to optimize component procurement costs while reducing equipment investment and labor expenses. By reducing the total cost of electronic manufacturing (TCO), companies can focus resources on core R&D and market expansion to achieve ROI (return on investment) improvement.

2. Full-process technical expertise and experience accumulation

EMS providers bring together senior engineers and SMT patch technology experts in the field of electronic assembly, covering the entire chain from design verification (DFM), prototype development to mass production. Its PCB assembly process experience can avoid design defects and improve product reliability. It is particularly good at handling advanced electronic manufacturing technologies such as high-density interconnection (HDI) and complex BGA packaging.

3. Accelerate product launch cycle (Time-to-Market)

Professional PCBA factories rely on mature fast prototyping services and automated production lines to significantly shorten electronic product development cycles. Through concurrent engineering management and JIT (Just-in-Time) production mode, customers can seize market opportunities, especially suitable for high-speed iteration industries such as consumer electronics and medical equipment.

4. Strict quality control and compliance certification guarantee

We have passed ISO 9001, IATF 16949, IPC-A-610 and other international certifications, all production we provide include multi-layer quality control systems such as AOI , X-ray inspection, and functional testing (FCT) to ensure the production meet industry standards. In addition, professional electronics foundries are proficient in environmental compliance requirements** such as RoHS and REACH, reducing legal risks.

5. Flexible production capacity and elastic expansion capability

From small batch customized production to million-level large-scale manufacturing, EMS services provide scalable electronic manufacturing solutions. Customers do not need to be limited by their own production capacity bottlenecks, and can flexibly respond to seasonal demand fluctuations or sudden orders to achieve light asset operation mode.

6. Supply chain risk management and global resource collaboration

PCBA factories effectively respond to electronic component supply chain challenges such as chip shortages and extended delivery times through diversified supplier base and real-time inventory monitoring systems. Some manufacturers provide VMI (vendor managed inventory) and localized alternatives to ensure production continuity and reduce the risk of supply chain disruptions.

7. Focus on core business and release corporate innovation potential

Outsourcing electronic manufacturing services (ODM/OEM) enable companies to get rid of production chores and focus on product research and development, brand building and market strategy. Especially for startups and technology companies, EMS partners can act as technical co-innovators, providing end-to-end support from hardware design to mass production.

8. Green manufacturing and sustainable development practices

Leading PCBA factories adopt lead-free soldering processes, energy-efficient equipment and waste recycling systems to meet low-carbon electronic manufacturing trends. By optimizing material utilization and carbon footprint tracking, we help customers achieve ESG (environment, society, governance) goals and enhance brand social responsibility.