-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

Understanding PCB Production: The Foundation of Printed Circuit Board Assembly

Understanding PCB Production: The Foundation of Printed Circuit Board Assembly

When it pertains to electronic gadgets, comprehending the complexities of PCB production is vital. From the design phase to Printed Circuit Board Assembly, the journey of a printed circuit board (PCB) is detailed yet impressive. This brief article is worth a read for anybody in the electronic devices location, whether you’re an enthusiast, a professional, or an entrepreneur aiming to comprehend the production processes that underpin your products. I’ll share my firsthand experience in PCB assembly and why sourcing quality elements is crucial to supplying dependable options.

Post Summary

- What is PCB Production? .

- What is the Distinction In Between PCB and Printed Circuit Board Assembly? .

- What Are the Secret Parts in a Printed Circuit Board Assembly? .

- What Are the Kinds Of Printed Circuit Board Assembly Service Providers? .

- How is the PCB Assembly Process Performed? .

- What Are Some Applications of PCBA? .

- How Essential is Part Sourcing? .

- What is SMT and How Does It Effect PCBA? .

- What Are the Typical Difficulties in PCB Manufacturing? .

- Why Select the Right PCBA Manufacturer? .

What is PCB Manufacturing?

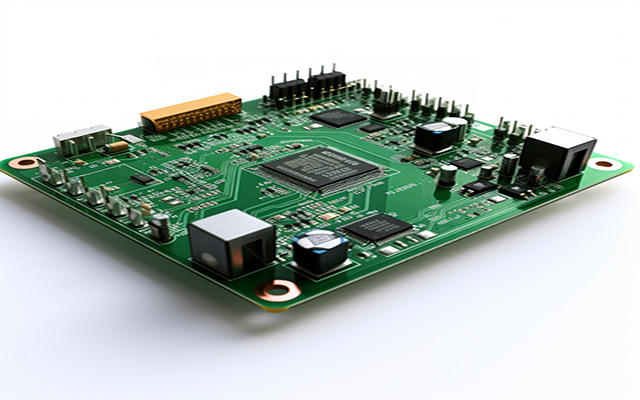

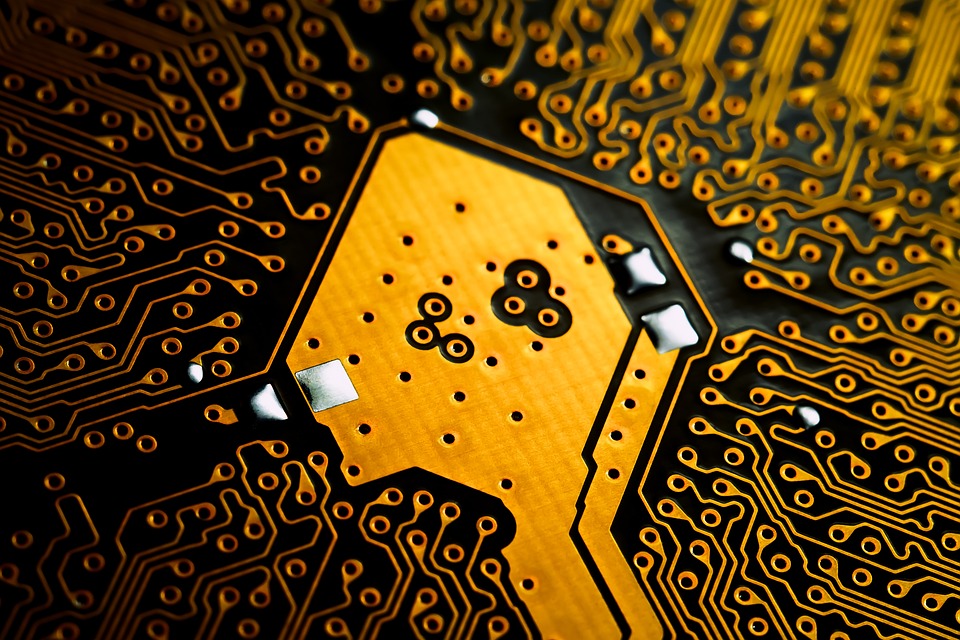

PCB production involves producing printed circuit boards that work as the structure for electronic devices. It includes various procedures like style, board fabrication, and assembly, enabling electrical connections to be made in between different components.

The treatment starts with PCB style, where engineers utilize software to develop styles highlighting how electrical components will connect. After the style phase, the real magic starts with producing the board itself, where layers of copper are printed onto insulating item, forming the preferred circuit.

When I initially got involved in PCB production, I was overwhelmed by the complexity. Nevertheless, seeing a basic style change into a practical board triggered my passion for electronic devices. This understanding is important for anyone intending to establish dependable electronic devices.

What is the Distinction Between PCB and Printed Circuit Board Assembly?

Comprehending the distinction between a PCB and PCB assembly (PCBA) is essential for any person in the electronic gadgets industry. PCB refers to the bare board without aspects, while Printed Circuit Board Assembly includes both the board and the elements that have been soldered onto it.

One day, while discussing tasks with colleagues, I discovered a considerable confusion. Lots of would explain recently put together PCBs as PCBs, not understanding that without parts, they were simply circuits gotten ready for assembly. Acknowledging this difference formed my technique to both design and assembly procedures.

What Are the Secret Parts in a Printed Circuit Board Assembly?

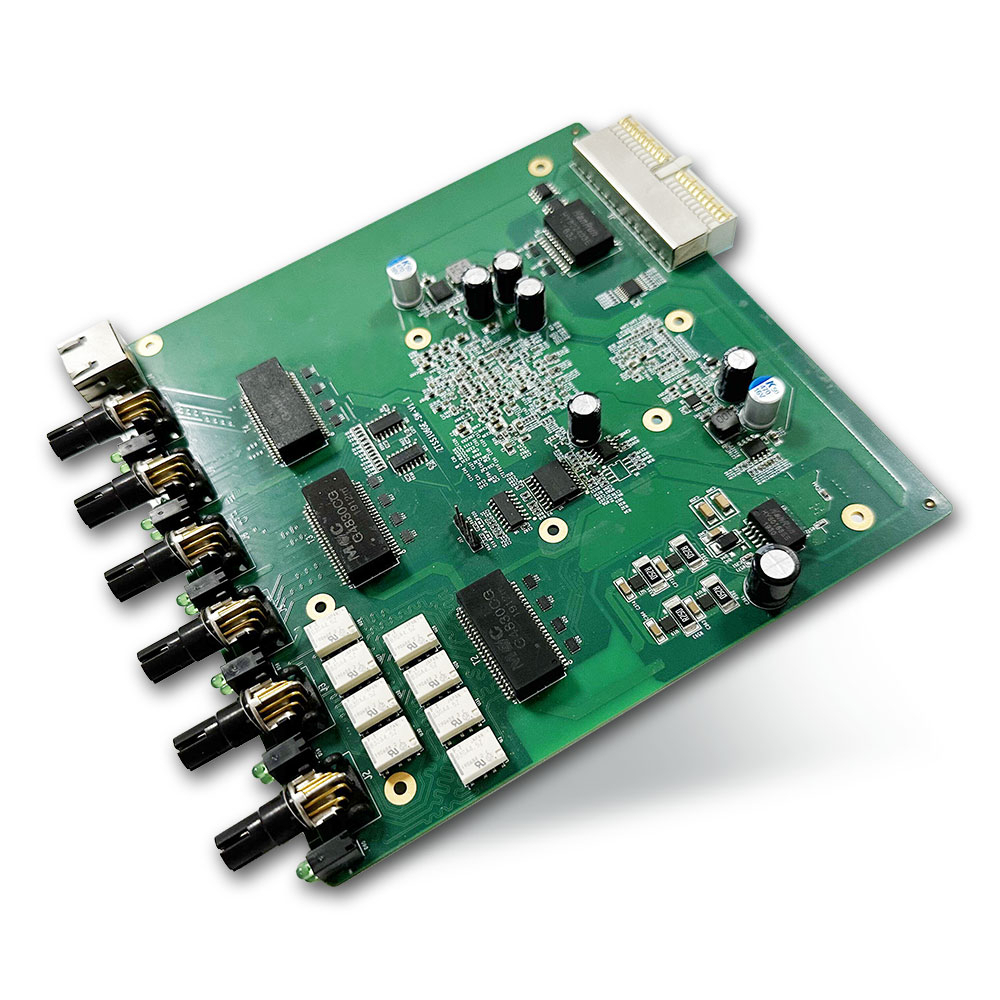

A typical Printed Circuit Board Assembly consists of numerous basic elements, consisting of resistors, capacitors, transistors, and incorporated circuits. These parts serve particular functions, making them necessary for the circuit’s operation.

In my early tasks, I found out that sourcing quality elements substantially effects dependability. Making use of low-grade parts can lead to failure, threatening your whole project. Today, I focus on quality when sourcing parts. It’s a financial investment that pays off in concerns to resilience and effectiveness.

What Are the Kinds Of Printed Circuit Board Assembly Solutions?

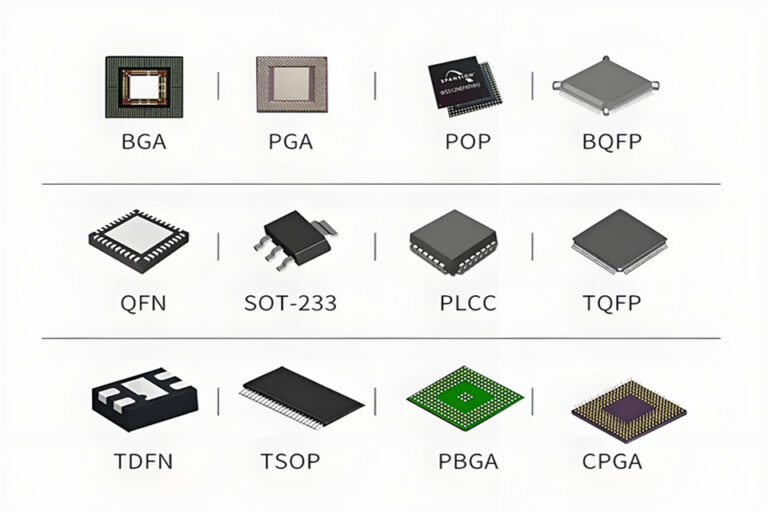

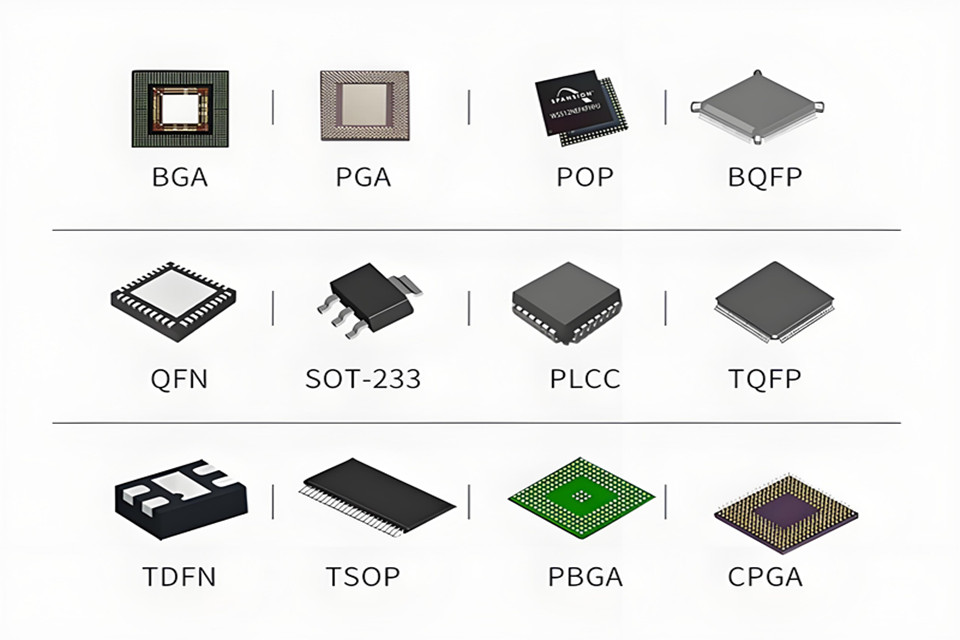

PCB assembly services been available in various types, consisting of surface install technology (SMT) and through-hole assembly. Each service has its applications, depending upon the job requirements.

When I began assessing which service best matched my tasks, I discovered that SMT permits placing of smaller sized components on both sides of the board, making the most of area performance. If you’re working on space-constrained styles– like customer electronic devices– selecting the best service is vital to your success.

How is the PCB Assembly Process Carried Out?

The PCB assembly procedure includes numerous actions: element positioning, soldering, examination, and screening. Each action plays a crucial function in ensuring that the assembled board functions correctly.

I plainly remember the very first time I saw the soldering treatment in action. It was interesting to see how solder assists to electrically link the aspects onto the board. Paying attention to each step ensures that the end product satisfies quality and reliability requirements.

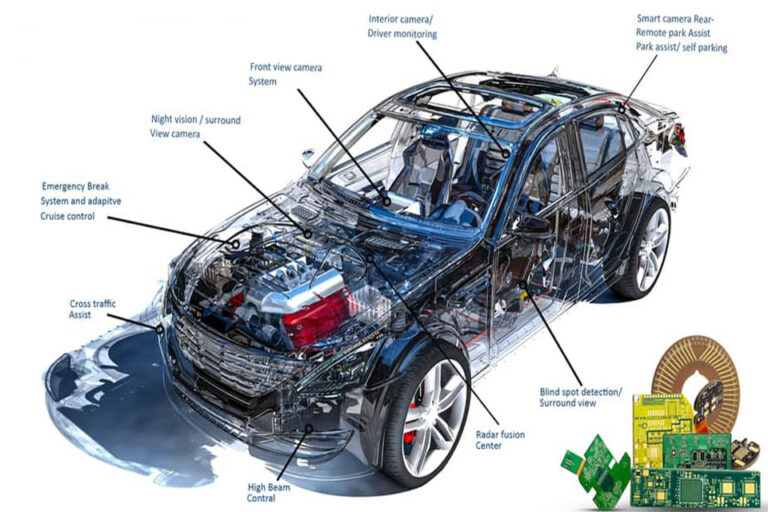

What Are Some Applications of Printed Circuit Board Assembly ?

PCBA finds use in a myriad of applications, from automobile electronic devices to consumer gadgets. This versatility speaks volumes about its crucial function in the electronic devices industry.

Amongst my favored tasks was developing a control system for a car application. The troubles of guaranteeing reliability in harsh environments taught me essential lessons in material choice and element durability. Every job adds to the abundant tapestry of experience in electronic devices making.

How Vital is Component Sourcing?

Component sourcing is a substantial aspect of the PCB assembly process. Selecting quality parts can make the distinction in between a successful product and a market failure.

I remember the numerous times I had to scramble to discover extra parts for a job. It made me understand that establishing strong relationships with reliable providers is essential for pleasing due dates and preserving product requirements. When part quality is jeopardized, the hazard of failure dramatically increases.

What is SMT and How Does It Effect Printed Circuit Board Assembly ?

Area Mount Technology (SMT) makes it possible for parts to be mounted straight onto the surface area of PCBs, improving efficiency and reducing the overall size of boards. SMT has actually transformed the manufacturing procedure, permitting the development of compact and flexible styles.

My early experiences with SMT exposed me the power of modern-day development in PCB production. The precision and speed of the assembly procedure amazed me and set the course for a great deal of my subsequent jobs. transition to SMT can substantially affect production efficiency and cost-effectiveness.

What Are the Common Obstacles in PCB Manufacturing?

While PCB production is a satisfying field, it doesn’t come without obstacles. Typical concerns include positioning mistakes, soldering problems, and sourcing quality components.

Through my journey, I dealt with numerous obstacles, consisting of misalignment throughout the assembly treatment. These experiences taught me to anticipate obstacles and carry out preventive steps, cultivating a culture of quality and reliability in every task.

Why Pick the Right Printed Circuit Board Assembly Producer?

Choosing the best PCBA maker can significantly affect the success of your product. Aspects to consider consist of experience, service quality, and adherence to market requirements.

Assessing my experiences, I have actually found that a relied on maker not simply provides quality services however similarly shares valuable insights throughout the procedure. Strong collaborations trigger enhanced collaboration, decreased preparations, and eventually greater quality items.

Summary: Secret Takeaways.

- PCB production is a complex yet exceptional procedure essential for producing electronic gadgets.

- Understanding the distinction in between PCB and Printed Circuit Board Assembly is essential for clear communication in the industry.

- Sourcing quality parts can significantly affect the reliability of your end product.

- Kinds of Printed Circuit Board Assembly services need to line up with the specific requirements of your projects for optimal results.

- Part sourcing relationships are essential for guaranteeing the quality and timeliness of production.

- Embrace innovations like SMT to enhance efficiency and item style.

- Eliminating normal challenges needs proactive steps and consistent knowing.

- Choosing the best PCBA maker boosts cooperation and causes greater quality results.

In the world of electronics, staying alerted and flexible is crucial. Whether you are designing from scratch or participated in PCB assembly, comprehending these principles will equip you to make better decisions and produce trustworthy electronic gizmos. For more tips and insights, explore our comprehensive guides on PCB Assembly Supplier, Part Sourcing , and PCB Style.