Cât costă asamblarea PCB în 2025?

Brief overview:

This article explores PCB setting up expense and setting up service expenditure in an in-depth, clinical means. It explains crucial expense chauffeurs, uses actionable optimization approaches, and solutions typical questions on Asamblare PCB maker pricing decisions.

Cuprins

Abstract.

In this technological and argumentative short article, we analyze just how much PCB assembly price affects layout choices and making strategy. We take a look at the duties of PCB assembly manufacturer options, assembly service types, quantity, testing demands, and sourcing designs. We supply understandings on enhancing cost-per-unit and boosting cost-efficiency in PCB setting up. With clear sections, active‑voice statements, and even keyword circulation, we intend to guide designers and purchase specialists in making critical options, Each section includes thorough description using crucial pcb assembly price , pcb setting up supplier , setting up solution , and basic synonyms such as electronics assembly rates, surface‑mount setting up expense, complete PCB solution.

What influences PCB assembly price?

PCB assembly cost depends on lots of variables. The setting up service provider establishes pricing based on board intricacy, components, amount, screening, and labor. A reputable pcb setting up supplier will establish last cost by balancing accuracy, throughput, and part expenses.

You must recognize exactly how each element adds. Component sourcing, making technique, and maker location influence expense straight. You should examine overall cost framework when you evaluate pcb setting up cost or compare assembly service supplies from various pcb setting up supplier candidates.

Just how does board complexity influence pcb assembly price?

Board intricacy raises cost. A board with even more layers raises construction trouble. High component thickness compels the pcb setting up supplier to use fine‑pitch machines and even more manual assessment. You increase pcb assembly expense when you add layers or micro‑components. SMT versus through‑hole assembly also matters. SMT assembly solution usually decreases expense for huge sets because it quickens positioning. Through‑hole assembly solution includes labor and slows down throughput, increasing the cost unless you have low volume or special parts.

Why do component kinds and sourcing impact assembly solution rates?

Part cost affects overall pcb setting up cost. Utilizing high‑value parts like BGAs, QFNs, or custom components increases setting up service cost. A pcb assembly supplier fees extra when it have to manage expensive or vulnerable parts. Sourcing strategy matters also. If you supply elements on your own (” partial complete” or “bare board setting up”), the assembly solution cost might drop. If you pick full turnkey service, the maker sources whatever, possibly at mark‑up, influencing pcb setting up expense.

How do different setting up solution designs compare cost‑wise?

- Complete turnkey assembly solution uses ease. The pcb assembly supplier takes care of PCB construction, element sourcing, assembly, and often final screening. You pay a premium however prevent supply chain risks.

- Parțial la cheie service divides duties. You supply some components; the pcb assembly manufacturer supplies the remainder and handles assembly. This crossbreed assembly service can lower pcb setting up expense while preserving top quality.

- Bare board setting up means you offer both PCB and parts. The assembler just places and solders. This version typically yields the most affordable pcb setting up expense each– if you take care of sourcing well.

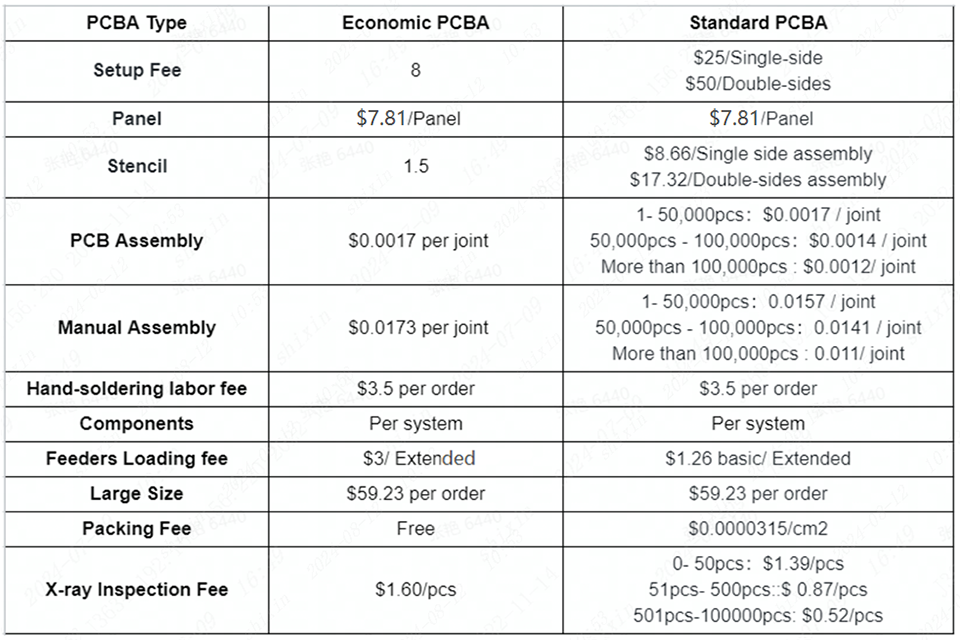

Does order quantity really alter pcb assembly price each?

Order quantity drastically influences pcb setting up price. Huge volume orders enjoy scaling benefits: setup fees topped more systems, products and sourcing become more affordable per unit. Prototype or small-run assemblies set you back even more per board. Makers might bill configuration fees, pattern costs, and screening overhead even for reduced quantities. So per-unit pcb setting up price drops significantly when you order quantities of 100, 1,000, or 10,000.

How do labor and overhead variables evaluate on assembly expense?

Your pcb assembly price reflects labor rates and expenses at the setting up house. Places with reduced wage structures lower assembly service price. Automation decreases labor strength. Expenses includes equipment depreciation, energies, high quality systems, certification (e.g. IPC, ISO), and center upkeep. A pcb setting up maker with top notch qualifications might charge a lot more, yet provides much better yield– usually decreasing complete cost.

Exactly how do screening and quality control influence total pcb assembly price?

Extensive screening contributes to pcb setting up cost. Useful screening, ICT (in‑circuit test), X‑ray, boundary scan, and AOI (automated optical inspection) increase service fee. Nevertheless, they lower downstream flaws. Purchasing testing at setting up time decreases price of rework, returns, and credibility impact. You ought to consider assembly service price against expense of failures post‑delivery.

How can design for manufactur ability lower pcb assembly price?

Implementing layout for manufacturability (DFM) policies cuts pcb setting up expense. You can lower layer matter, team component kinds, avoid limited pitch elements, maximize pads and spacing. You can select components that prevail, high-availability, and footprint‑compatible. You can minimize part variations. These techniques lower setting up solution expense and streamline supply chain risk.

How should you choose a pcb assembly producer or setting up service?

You must contrast pcb setting up manufacturer quotes. Search for transparency in price failure: board rate, placement, material price, testing, overhead. Review certifications (IPC, ISO). Review lead times, minimum order quantity, and quality track record. Ask if the setting up solution offers turnkey or partial turnkey choices. Confirm whether they manage component sourcing or you do.

What tips guarantee cost‑effective pcb assembly on the whole?

Follow a structured process:.

- Estimate pcb setting up price by means of numerous pcb setting up supplier quotes.

- Enhance your BOM: select cost‑effective components, typical package kinds.

- Style DFM‑friendly boards.

- Pick correct setting up solution version (complete vs partial vs bare board).

- Batch order purposefully for reduced per‑unit price.

- Request testing and QC aligned with risk and price trade‑off.

- Monitor last yield and performance.

Întrebări frecvente

What is the typical series of pcb assembly price per square inch?

Anticipated ranges differ from a couple of cents to almost half a dollar per square inch, relying on intricacy and volume.

Does turnkey assembly price more than bare board assembly?

Yes. Full complete solution consists of sourcing and component markup, so it typically costs much more.

Exactly how large an order reduces pcb setting up cost one of the most?

Costs go down substantially when you go from prototype (1– 10 boards) to production runs of 100 or even more devices.

Can DFM minimize assembly solution price?

Definitely. Designing panels with standard impacts, spacing, and common components makes setting up faster and more affordable.

Do I need testing to maintain costs down?

Examining adds upfront cost yet prevents flaws. In the long-term, it saves money by preventing rework and area failings.

Just how can I contrast pcb setting up supplier estimates efficiently?

Demand itemized cost break downs: products, placement, testing, setup. Compare qualifications, lead times, and quantity discounts.

Concluzie

In recap, pcb setting up price depends on board intricacy, component option, quantity, setting up service design, labor and overhead, and screening. A careful design approach and notified selection of pcb assembly maker şi setting up solution can reduce expenses while preserving top quality. Designers and purchase teams have to balance ease, rate, quality, and risk to maximize value.

Summary & Trick Takeaways

- PCB assembly price climbs with intricacy, little elements, and through‑hole methods.

- Aprovizionare cu piese choices (complete vs partial complete) dramatically affect rate.

- Ridicat order quantity decreases cost per unit; small runs cost even more.

- Labor rates, automation, accreditations influence total cost.

- Adding testing and quality control increases upfront expense however minimizes long‑term danger.

- Excellent DFM design and standard components decrease assembly solution price.

- Picking the best pcb setting up manufacturer makes sure transparency and cost‑effective setting up solution.

- Strategic preparation and vendor comparison deliver best value.