-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

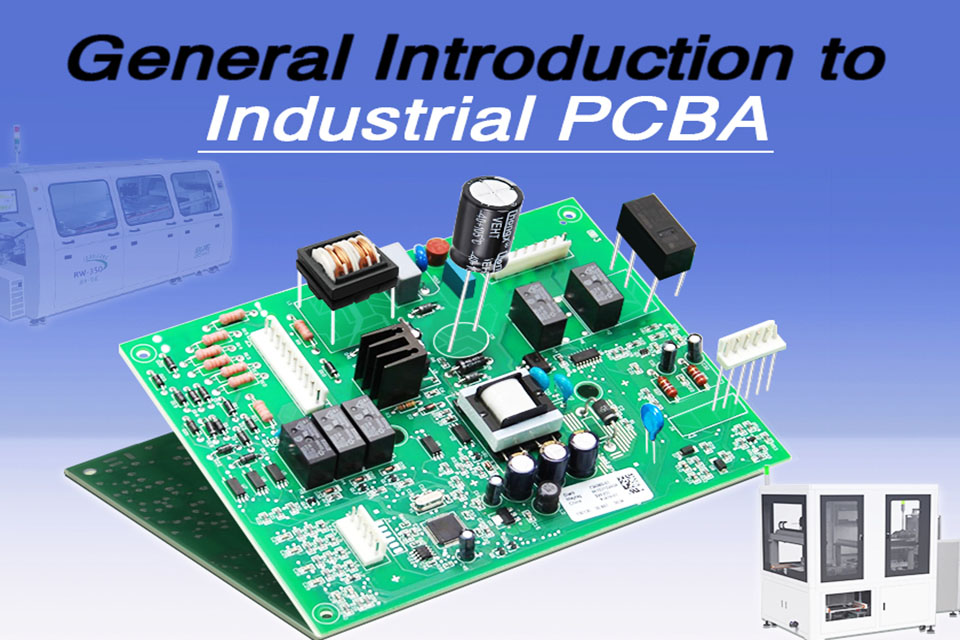

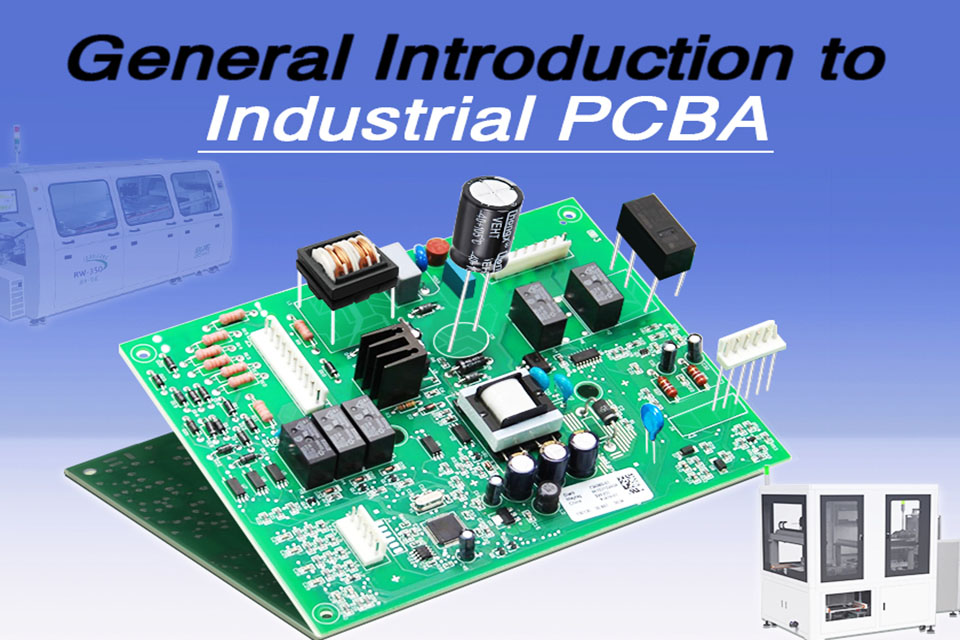

Industrial PCBA Service: Key Technologies for Structure High-Reliability AutomationControl Systems .

Abstract .

This short article deeply evaluates the Industrial PCBA core design concepts, execution procedure and key success aspects of PCBA (Printed Circuit Board Assembly) in the field of commercial automation. By combining industry cases and technical practices, it offers producing companies with a full-process service from need analysis to after-sales support, helping companies to achieve efficient, stable and smart production system upgrades. The article especially highlights the value of high-reliability design , environmental adaptability optimization and customized services , offering a possible recommendation guide for commercial automation equipment makers.

I. Core Value of Industrial Automation PCBA Service .

Under the wave of intelligent production and Industry 4.0, PCBA, as the “nerve center” of commercial control devices, its performance directly identifies the stability, precision and effectiveness of the assembly line. With 10 years of industry experience, 7 PCBA offers international clients with one-stop services such as SMT spots, DIP plug-ins, PCBA OEM and materials , assisting consumers shorten the R&D cycle by more than 30% and reduce the failure rate by more than 40%.

Core benefits include: .

- High-precision production : Adopt AI visual assessment system to guarantee 0.1 mm part welding accuracy.

- Environmental versatility design : Pass -40 ℃ to 85 ℃ temperature level cycle test to satisfy the requirements of extreme working conditions.

- Quick action : Complete little batch trial production within 72 hours to support emergency situation order delivery.

II. Analysis of the entire procedure of PCBA option design .

1. Thorough demand mining .

- Conduct multi-dimensional need research with customers (functional signs, environmental criteria, security standards).

- Use DFM (Style for Manufacturability) tools to predict potential process dangers ahead of time.

- Describe ISO 13849 and other worldwide standards to formulate safety level requirements.

2. Modular circuit design .

- Layered design method :.

- Power module: Integrated DC-DC converter, supports broad voltage input (9-36V DC).

- Signal processing module: Embrace differential signal transmission innovation, anti-interference capability is enhanced by 50%.

- Communication interface: Assistance RS485/Modbus/TCP/ IP multi-protocol compatibility.

3. Part selection requirements .

- Industrial-grade part certification : Prioritize AEC-Q100/ AEC-Q200 automotive-grade components.

- Supply chain management : Establish a strategic stock library to guarantee delivery stability.

- Life cycle management : Supply an element replacement database to prevent the danger of discontinuation.

3, six regularly asked concerns (Frequently asked questions) .

Q1: How does industrial PCBA guarantee reliability in extreme environments? .

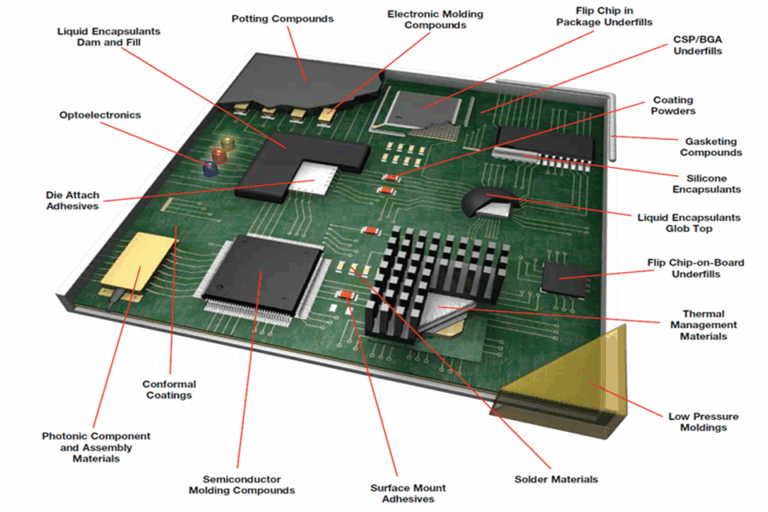

A: Through Conformal Finishing procedure to attain moisture-proof, dust-proof and corrosion-proof. Usage FPC flexible circuit board to adjust to vibration environment, and pass low and high temperature level effect test (IEC 60068-2-2) confirmation.

Q2: For how long does the advancement process of personalized PCBA take? .

A: 7 PCBA supplies a 3-stage accelerated development design :.

- Complete schematic and layout style (consisting of simulation confirmation) in 2 weeks.

- Complete proofing and practical testing in 3 weeks.

- Total small-batch trial production in 1 week.

Q3: How to make sure the long-term supply stability of PCBA? .

A: Execute a dual-source procurement strategy , sign a VMI (supplier managed inventory) contract with leading providers such as TI, ST, and Murata, and develop a product traceability system to attain complete life cycle management.

Q4: What are the common failure modes of commercial PCBA? .

A: Mainly consist of:.

- Soldering problems (can be minimized to 0.01% through AOI optical examination ).

- Power supply noise interference (optimized by multi-layer PCB style ).

- Thermal tension failure (optimize design through thermal simulation analysis ).

Q5: How to reduce the total cost of commercial PCBA? .

A: Advise Worth Engineering (VE) technique :.

- Enhance BOM structure: Replace non-critical components with industrial general designs.

- Enhance yield rate: Increase yield rate to 99.5% through SPC analytical procedure control .

- Large-scale production: Support batch orders beginning with 5,000 pieces/month.

Q6: What does after-sales technical assistance consist of? .

A: Supply 7 × 24 hours technical reaction , consisting of:.

- Remote medical diagnosis system (support remote OTA upgrade).

- On-site debugging service (get to the service point within 2 days).

- Regular health evaluation report.

IV. Typical application scenarios and cases .

1. Smart factory assembly line control .

- Case : After a specific automotive parts manufacturer deployed the PCBA control module, the assembly line OEE (equipment general performance) increased by 28%.

- Technical highlights : Integrated EtherCAT bus innovation to accomplish microsecond action speed.

2. Robot movement control system .

- Case : The collaborative robotic joint controller adopts a multi-layer PCB style, and the vibration life is extended by 3 times.

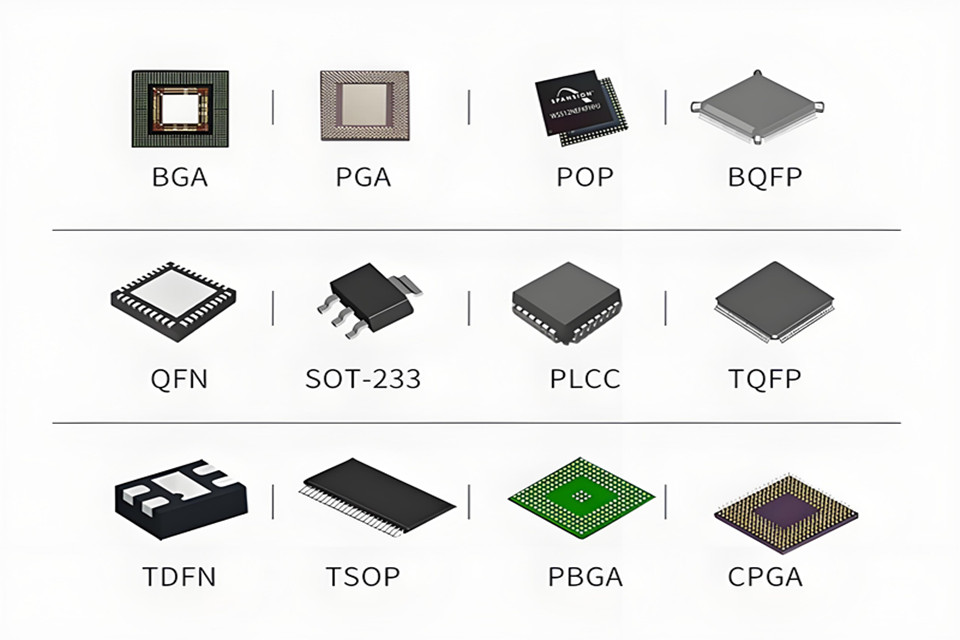

- Development : Use BGA product packaging technology to improve signal stability.

3. Energy management system .

- Case : Photovoltaic inverter PCBA passed CE/FCC accreditation, and the energy performance level reached Class A+.

- Secret technology : SiC MOSFET gadget application, changing loss minimized by 40%.

Summary .

Industrial automation PCBA options are the essential link between conventional production and wise factories. Seven PCBA supplies clients with personalized services with high performance, high dependability and financial efficiency through full-process digital management , worldwide supply chain combination and continuous technological innovation . With the rapid development of Industrial Web of Things (IIoT) and edge computing, PCBA design is evolving towards higher combination, lower power intake and stronger ecological versatility . Enterprises must grasp this pattern, achieve technological upgrades through expert PCBA company, and take the brand-new track of smart production.