What is IC Programming Service?

IC programming

1.1 What is IC programming(IC Burn-in)?

IC burn-in (chip programming) is the process of writing program code or data into an integrated circuit (IC), so that the chip has the ability to perform specific functions. This process is usually accomplished with a BURNER (PROGRAMMER) and is an integral part of electronics manufacturing.

The nature of IC programming:

- Memory Cell Programming: writing data into the memory area of the chip through techniques such as Floating Gate Transistor (Flash) and Fuse.

- Functional Verification: After burning, it is necessary to ensure the correctness of the program through CRC32 checksums, readback comparison and other means.

Key Value:

- Flexibility: replaces fixed-function ICs and reduces preparation complexity.

- Scalability: Support firmware update to extend product life cycle.

- Cost Optimization: Reduce IC type procurement and lower inventory cost.

- Environmental Adaptability: Supports wide temperature range (-40°C~125°C), adapting to the needs of industrial-grade products.

- Security encryption: Some burners support AES-256 encryption to prevent program piracy.

Why IC Programming(Chip Burn-in) work?

Why IC programming? 6 Key Reasons Explained

Activating chip functions

Writing a program to a chip through firmware programming gives it the ability to perform a specific operation.Configure Programmable Logic

PLD/FPGA is required to burn a logic configuration file to realize dynamic arithmetic and signal processing functions.Storage of key data

Boot ROM/Flash need to be burned boot program, font or high-definition picture, to protect the product operation base.Encryption protection program Encryption protection program AES-256 encryption AES-256 encryption prevents code piracy and ensures IC burning security and intellectual property protection.

Optimize production efficiency

Batch burn-in supports 32-channel parallel operation, dramatically shortening electronic product manufacturing cycle.Compatible with upgrade requirements

OTA update supports remote firmware upgrade, prolonging the life cycle of smart devices and function expansion.

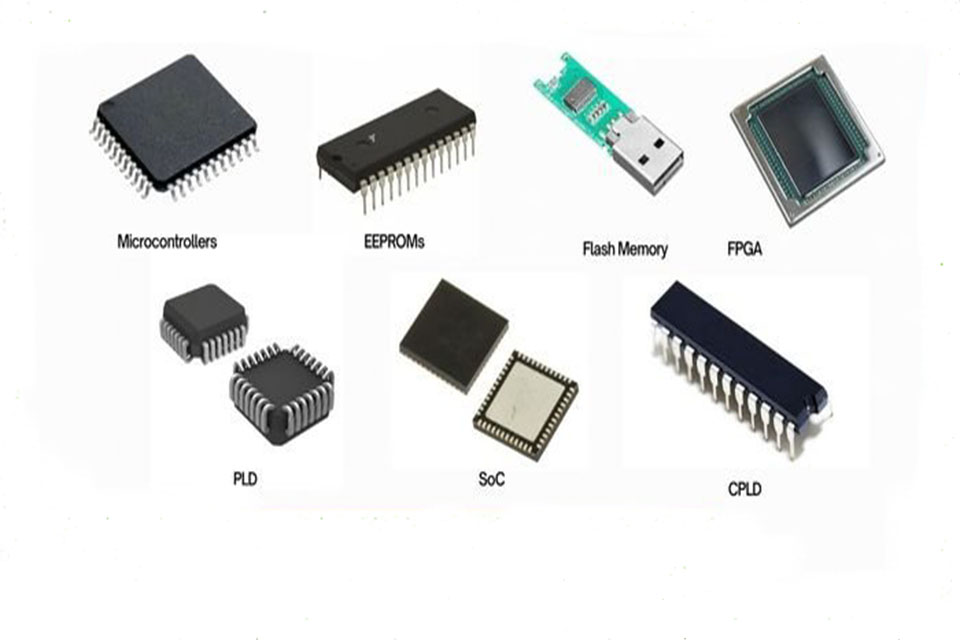

What Key type of IC programming Service ?

Which chips need to be burned?

Common types of burnable chips

Microcontrollers (MCU)

- Application Scenario: Home appliance control, automotive electronics, industrial automation.

- Features: Supports OTP (One Time Programming) or MTP (Multi Time Programming).

Programmable Logic Devices (PLD)

- Representative chip: FPGA, CPLD.

- Use: Dynamic configuration of logic circuits, suitable for signal processing and arithmetic.

Memory chips

- Type: Flash (NAND/NOR), EEPROM, SPROM.

- Cases: USB flash disk, MP3 player, electronic dictionary.

Specialized Chip (ASIC) Module

- Requirements: Some ASICs need to be configured with parameters to achieve function customization through burning.

What IC Programmer Types we have ?

We have different chip burners (IC programmer)to meet different production and customer needs.for example :Manual Burner,Automated Burners,UFS Burner,Inline Burner,Specialized Burner,Universal Burner

Common Chip Burner Types and Comparison Table of Advantages and Disadvantages

| Burner Types | Pros | Cons | Usage Scenarios |

|---|---|---|---|

| Manual burners | Low cost entry, stable offline burn-in | Low efficiency, manual intervention required | Small batch R&D/prototyping |

| Automated Burners | Highly Parallel, Highly Efficient for High Volume Production | Expensive Equipment | Industrial Volume Production/High Capacity Requirements |

| UFS Burner | Multi-Channel Expansion (up to 96 seats) | Insufficient Flexibility, Specialized Fixtures Required | Medium Volume Production/Multi-Model Compatibility |

| Inline Burn-in | Direct Burn-in on PCB, low cost | Difficulty in rework, high risk of false soldering | PCB debugging/small batch trial production |

| Specialized burner | Accurate matching of specific IC, easy to operate | Narrow scope of application, only support for a single chip | Single-model mass production/education scenarios |

| Universal Burner | Strong compatibility (supports hundreds of ICs) | High cost (from tens of thousands of dollars) | R&D Lab/Multi-Project Testing |

How to choose a Chip Burner(programmer)?

Key factors for selection

Chip package compatibility

- Support DIP, QFN, BGA and other mainstream packages.

- Provide chip specification (pin number, pitch, size). 2.

Durability and Re-usability Durability and Re-usability **Durability and Re-usability

- High-frequency burn-in requires the selection of gold-plated probes and antioxidant materials.

Data transfer speed

- Support SPI/I2C/UART and other protocols to enhance the efficiency of batch burn-in.

Signal Integrity

- Reduce contact resistance (<5Ω) to avoid burn-in failure due to insufficient voltage.

What Common Problems and solution for failures IC programming ?

Solutions for Burning Failures Problem Analysis

| Problem Type | Reason | Solution |

|---|---|---|

| Burning Failure | Poor Contact, Wrong Parameter Setting | Check Burner Block Compatibility, Re-calibrate Voltage |

| Data validation error | Misplaced address mapping, protocol mismatch | Verify with Golden Sample database |

| Overheat protection | High chip temperature due to long time burn-in | Add heat sink, batch operation |

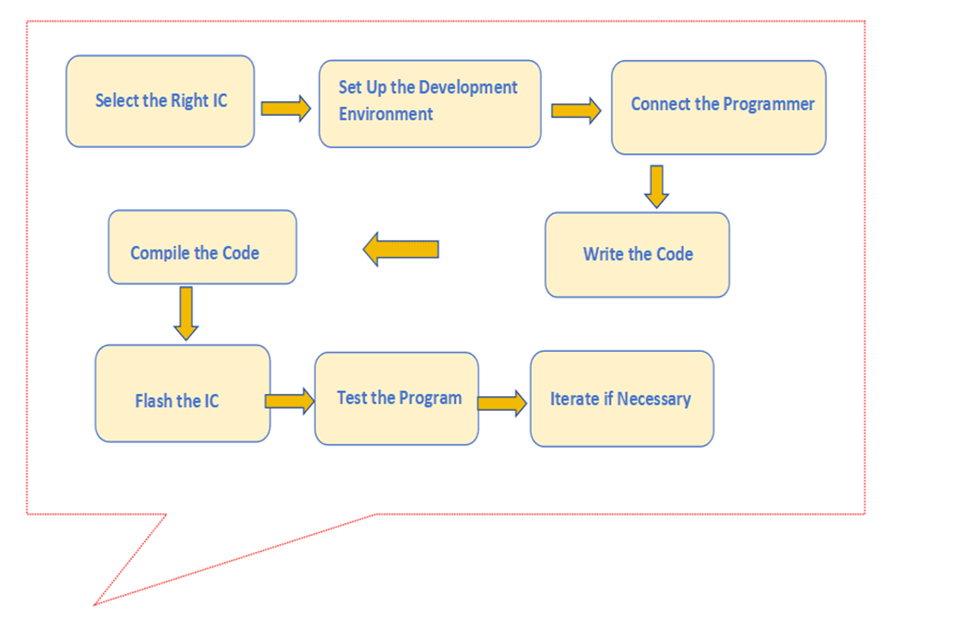

What the Steps of IC Programming ?

Chip burn-in full flow summary (7 steps)

Confirm the chip model number

- MCU burning need to match the model, memory and interface protocol.

Preparing program files

- Load HEX/BIN/ELF format code, verify data integrity.

Select burner tool

- Hardware burner (e.g. UFS) + software tool (STM32Cube Programmer).

Connect the burner interface **JTAG/SWAG/JTAG/STM32Cube Programmer

- JTAG/SWD/ISP interface wiring (pins TCK/TMS/SWCLK etc.).

Set burn parameters Configuration

- Configure start address/erase mode/burning speed (full/partial erase).

Execute the burn operation.

- Start the tool and monitor the burning progress and status in real time.

Verify chip function.

- Read data and test MCU operation status to ensure successful burn-in.

Why US be your IC programming partner ?

Why choose our IC programming service?

Professional programming team, years of experience to ensure quality

Multi-package compatibility, covering SOP8/WSON/LGA and other models

Customized encryption solution, protect intellectual property security

Fast delivery cycle, shorten production waiting time

Full process quality inspection, ensure reliable chip function

Successful case support, well-known enterprise cooperation endorsement