-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

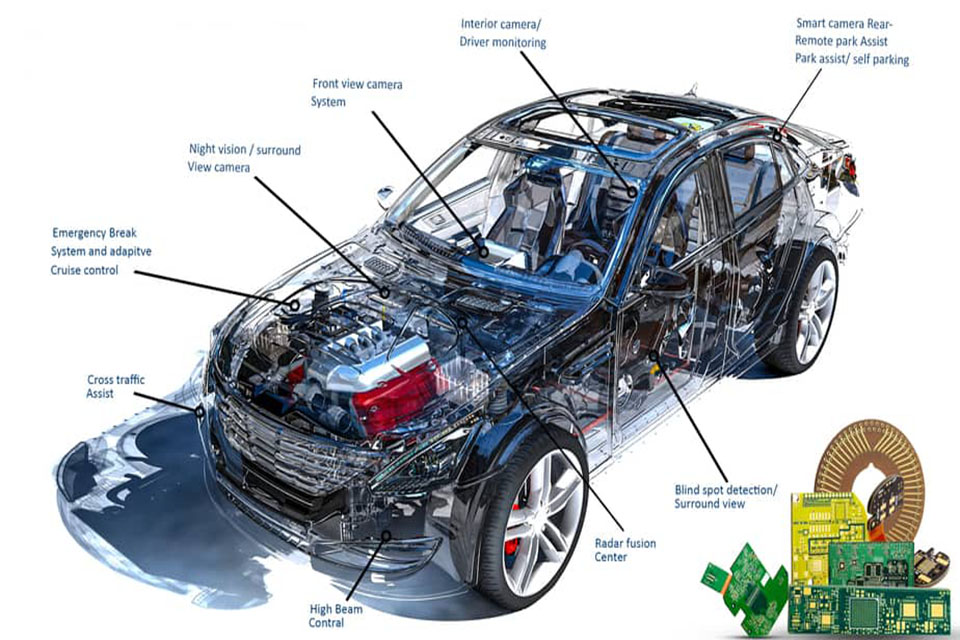

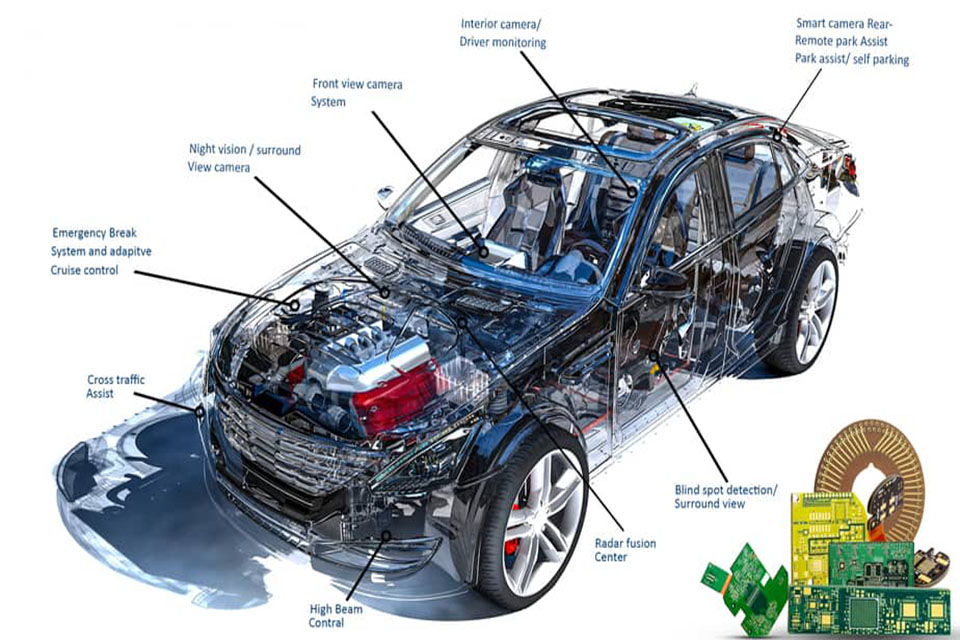

Full analysis of PCBA solutions in automotive electronic

Complete analysis of PCBA options in automotive electronic devices applications

Intro.

With the rapid development of smart driving technology, automotive electronic systems are going through advanced changes. From basic ECU control to complex autonomous driving architecture, PCBA (Printed Circuit Board Assembly) as a core hardware provider has actually become an important part of modern automobile electronic systems. This article will deeply examine the crucial application situations of PCBA in the field of automotive electronic devices and explore its technological development path.

1. The core value of PCBA in the automotive electronic system architecture.

1.1 Composition of automotive electronic systems . Modern automotive electronic systems are made up of 3 major modules:.

- Power control module (engine management, transmission control).

- Body electronic module (lighting, doors and windows, seat adjustment).

- Infotainment module (navigation, voice interaction, automobile network).

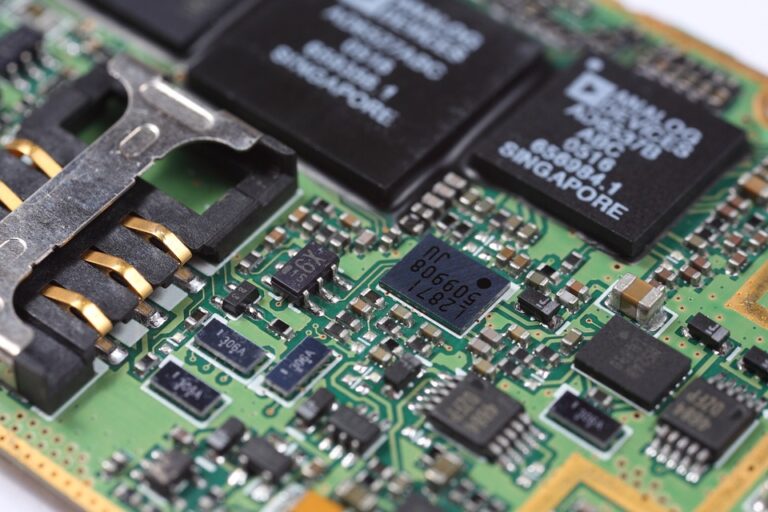

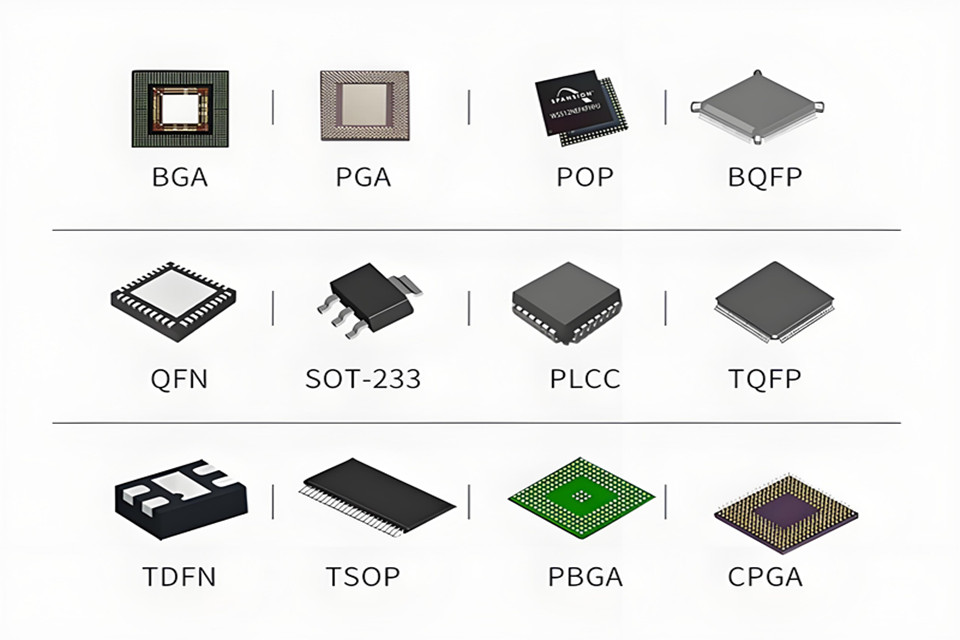

1.2 Technical characteristics of PCBA . PCBA attains the following functions through high-density electrical wiring, multi-layer board design and accuracy welding procedure:.

- Miniaturization integration : Incorporate sensing units, MPUs, actuators and other elements into millimeter-level space.

- Environmental adaptability : Usage shockproof finishings and temperature-resistant materials to handle -40 ℃ ~ 150 ℃ workplace.

- Signal stability : Usage differential signal transmission technology to reduce electromagnetic disturbance.

1.3 Market information comparison .

| Application scenarios | Average number of PCBA layers | Signal frequency range | Typical power intake |

|---|---|---|---|

| Engine ECU | 4 layers | 10MHz ~ 100MHz | 5 ~ 15W |

| Autonomous driving domain controller | 8 layers + HDI | 1GHz ~ 5GHz | 50 ~ 150W |

| In-automotive electronic infotainment system | 6 layers | 200kHz ~ 200MHz | 10 ~ 30W |

2. 6 ingenious applications of automotive electronic PCBA.

2.1 Autonomous driving system . Technological advancement :.

- Multi-sensor fusion PCBA style (LiDAR + Vision + Millimeter Wave).

- Hardware velocity module for real-time decision-making algorithm.

- Dual-channel PCBA layout with redundant security architecture.

2.2 In-vehicle infotainment system (IVI) . Innovative options :.

- RF PCBA module supporting 5G interaction.

- Dispersed architecture design for multi-screen display screen.

- DSP processing unit committed to voice interaction.

2.3 Body control system . Innovation evolution :.

- Transition from single-chip control to SoC combination.

- High-speed interaction PCBA using CAN FD bus.

- Hardware redundancy design of fault medical diagnosis module.

2.4 In-vehicle network system . Technical points :.

- Antenna integration solution for V2X communication module.

- Hardware implementation of network security file encryption chip.

- User interface circuit design for cloud OTA upgrade.

2.5 Battery Management System (BMS) . Key innovations :.

- Multi-channel voltage sampling PCBA design.

- Sensing unit array for thermal runaway warning.

- Digital power module for vibrant stabilizing control.

2.6 Intelligent security system . Development instructions :.

- Signal processing PCBA for four-dimensional radar.

- Hardware acceleration unit for emergency situation braking system.

- Bioelectric signal acquisition module for tiredness monitoring.

3. automotive electronic adjustment of PCBA manufacturing process.

3.1 Process standard upgrade .

- AEC-Q100 certification : Dependability test standard for automotive-grade PCBs.

- HALT test : Extremely sped up life test makes sure stability under severe working conditions.

- X-Ray examination : Attain 0.1 mm precision solder joint quality examination.

3.2 Product innovation .

| Product type | Efficiency attributes | Common application circumstances |

|---|---|---|

| High Tg FR-4 | Temperature level resistance increased to 170 ℃ | Engine compartment control module |

| Rogers product | Low dielectric loss (Df<0.003) | RF communication module PIPE_CHAR. |

PIPE_CHAR. Metal substrate|Heat dissipation efficiency increased by 300%|Power electronic control unit PIPE_CHAR.

3.3 Intelligent manufacturing.

- AI visual inspection system: Defect recognition accuracy >< 0.003)|RF communication module|| Metal substrate|Heat dissipation performance increased by 300%|Power electronic control unit| 3.3 Smart production .- AI visual examination system: Defect acknowledgment accuracy > 99.99%.

- Digital twin technology: Accomplish PCBA virtual simulation confirmation.- Green manufacturing: Halogen-free procedure decreases 70% of damaging compounds.

FAQ.

Q1: What is the crucial function of PCBA in self-governing driving systems? . A1: Self-governing driving PCBA needs to integrate multi-sensor data processing units, real-time decision-making algorithm hardware acceleration modules and redundant safety architecture to make sure millisecond action speed and system dependability.

Q2: How to select a producer of automotive electronic PCBA? . A2: It ought to concentrate on whether the maker has AEC-Q series accreditation, whether it has experience in vehicle electronic jobs, and whether it can offer tailored screening services.

Q3: How does PCBA respond to the unique requirements of electric lorries? . A3: It is necessary to utilize high-voltage materials, boost thermal management style, incorporate devoted circuits for battery status tracking, and pass rigorous EMC electromagnetic compatibility tests.

Q4: In what elements does PCBA innovate in in-vehicle infotainment systems? . A4: It is generally reflected in 5G interaction module combination, multi-screen display screen architecture design, voice interaction dedicated DSP development, and OTA upgrade interface optimization.

Q5: How to ensure the stability of PCBA in severe environments? . A5: Through stop high sped up life test, moisture-proof and shock-proof finish, X-Ray three-dimensional detection and other process implies, guarantee that the product meets the working requirements of -40 ℃ ~ 150 ℃.

Q6: What are the current technological patterns in PCBA production? . A6: Current patterns include the application of high-density adjoin (HDI) innovation, the popularization of AI-assisted style tools, the integration of digital twin technology, and the upgrading of green manufacturing procedures.

Conclusion.

As the “electronic brain” of clever vehicles, automobile lectronic devices PCBA is driving the industry to establish in a more effective and more secure direction. With the improvement of autonomous driving levels and the popularization of new energy automobiles, the performance requirements for PCBA will continue to increase. Manufacturers require to build distinguished competitiveness through product development, process upgrades and smart production. In the future, with the enhancement of vehicle-road cooperative systems, PCBA will play a more vital role in the intelligent transport ecosystem.