-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

The Role of Automation in PCB Assembly: Accelerating Production and Reducing Costs

[ad_1]

The Role of Automation in PCB Assembly: Accelerating Production and Reducing Costs

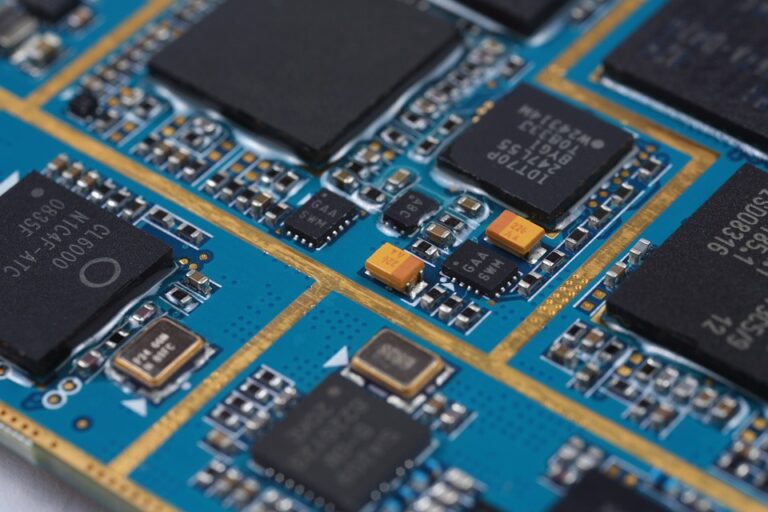

The printed circuit board (PCB) assembly process is a complex and labor-intensive process that requires precision, accuracy, and speed. In recent years, the rise of automation has revolutionized the way PCBs are assembled, enabling manufacturers to accelerate production, reduce costs, and improve product quality. In this article, we will explore the role of automation in PCB assembly, its benefits, and the different types of automation used in this process.

Why Automation in PCB Assembly?

PCB assembly is a manual-intensive process that requires a high level of dexterity, attention to detail, and repetitive tasks. Human error, burnout, and fatigue can compromise the quality of the assembly process, leading to defects, rework, and increased costs. Automation, on the other hand, brings numerous benefits, including:

- Increased accuracy and precision: Automation minimizes human error, ensuring precise assembly and reduced defect rates.

- Reduced labor costs: Automation can eliminate or reduce the need for manual labor, resulting in significant cost savings.

- Improved productivity: Automation enables 24/7 production, allowing manufacturers to increase production volumes and reduce lead times.

- Enhanced product quality: Automation enables real-time monitoring and control, ensuring that each component is assembled with precision and accuracy.

Types of Automation in PCB Assembly

Through-Hole Technology (THT) Automation: This type of automation is used for the assembly of components that require through-hole assembly, such as electrolytic capacitors, inductors, and transformers. THT automation ensures accurate placement and soldering, reducing defect rates and increasing production speeds.

Coiled Component Assembly (CCA) Automation: This type of automation is used for the assembly of coiled components, such as wire harnesses, coils, and transformers. CCA automation enables high-speed assembly, reducing production times and increasing efficiency.

Rigid-Flex PCB Assembly Automation: This type of automation is used for the assembly of rigid-flexible PCBs, which combine the benefits of rigid and flexible circuits. Rigid-flex PCB assembly automation enables high-speed assembly, reducing production times and increasing efficiency.

Benefits of Automation in PCB Assembly

The benefits of automation in PCB assembly are numerous, including:

- Improved accuracy and precision: Automation minimizes human error, ensuring precise assembly and reduced defect rates.

- Reduced labor costs: Automation can eliminate or reduce the need for manual labor, resulting in significant cost savings.

- Increased productivity: Automation enables 24/7 production, allowing manufacturers to increase production volumes and reduce lead times.

- Enhanced product quality: Automation enables real-time monitoring and control, ensuring that each component is assembled with precision and accuracy.

Conclusion

In conclusion, automation plays a crucial role in PCB assembly, enabling manufacturers to accelerate production, reduce costs, and improve product quality. The benefits of automation in PCB assembly are numerous, including improved accuracy, reduced labor costs, increased productivity, and enhanced product quality. By incorporating automation in their production lines, manufacturers can gain a competitive edge in the market, increase customer satisfaction, and reduce the risk of defects and rework.

FAQs

Q: What are the common types of automation used in PCB assembly?

A: The common types of automation used in PCB assembly are SMT, THT, CCA, and Rigid-Flex PCB assembly automation.

Q: How does automation reduce labor costs in PCB assembly?

A: Automation can eliminate or reduce the need for manual labor, resulting in significant cost savings.

Q: What are the benefits of automation in PCB assembly?

A: The benefits of automation in PCB assembly include improved accuracy, reduced labor costs, increased productivity, and enhanced product quality.

[ad_2]