-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

The Importance of Quality Control in PCB Assembly: Ensuring Reliability and Efficiency

[ad_1]

The Importance of Quality Control in PCB Assembly: Ensuring Reliability and Efficiency

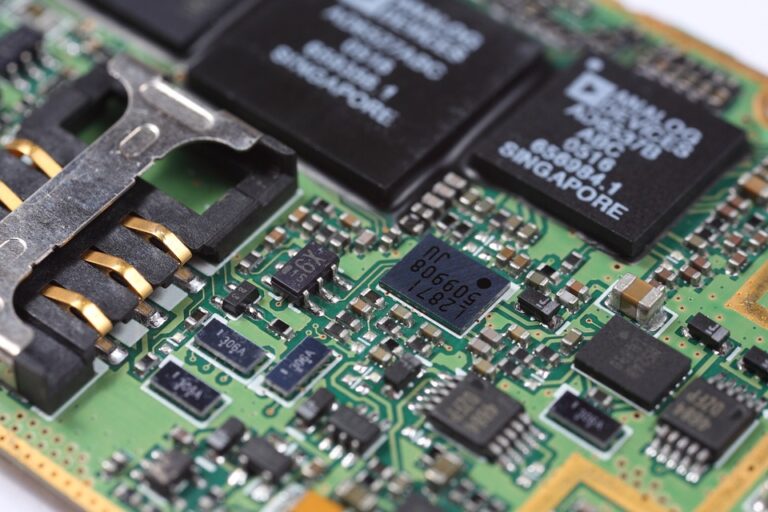

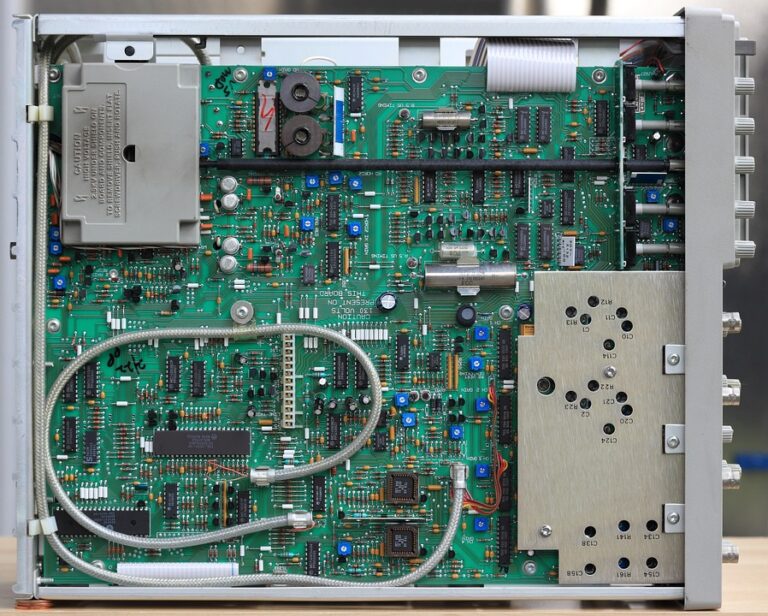

In today’s fast-paced and competitive electronic manufacturing industry, quality control is a crucial aspect of PCB (Printed Circuit Board) assembly. The process of assembling a PCB involves numerous steps, from component placement to soldering and testing. If any of these steps are not performed correctly, it can result in defective products, recalls, and even loss of business reputation. Therefore, it is essential to implement quality control measures to ensure the reliability and efficiency of the PCB assembly process.

Quality control is a systematic process that involves inspecting and testing the PCB assembly at various stages to identify defects and errors. This process helps to detect any deviations from the specified standards, specifications, and design requirements. By implementing quality control measures, manufacturers can reduce the risk of defects, improve product reliability, and increase customer satisfaction.

Benefits of Quality Control in PCB Assembly

Implementing quality control measures in PCB assembly offers numerous benefits, including:

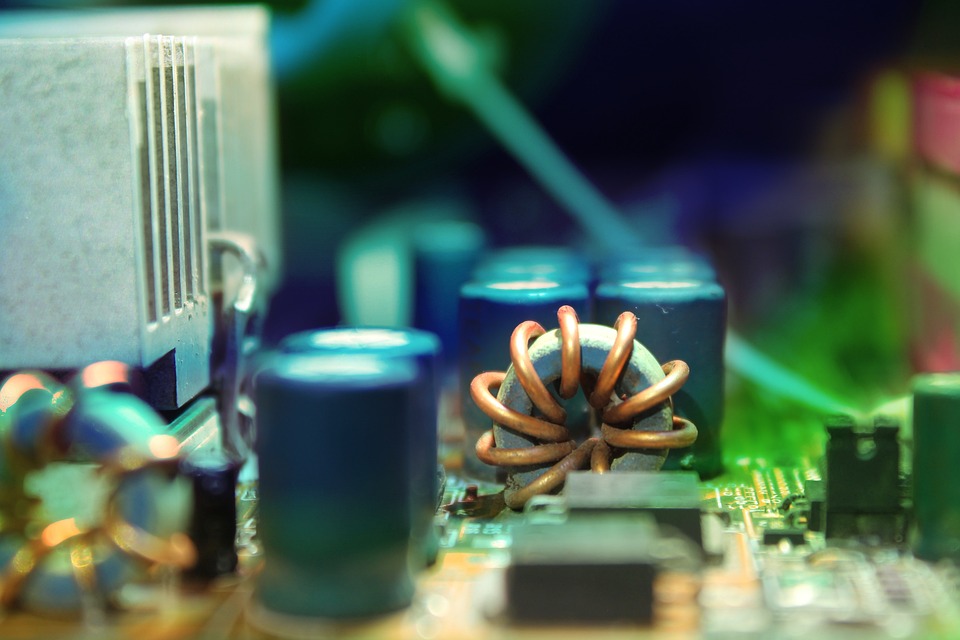

- Improved product reliability: Quality control helps to detect and correct defects and errors, resulting in reliable and high-quality products.

- Reduced waste and rework: Quality control measures reduce the risk of defects and rework, which can save time, money, and resources.

- Increased customer satisfaction: By ensuring the quality of the products, manufacturers can improve customer satisfaction and build trust.

- Compliance with regulations: Quality control measures help manufacturers comply with industry regulations and standards, reducing the risk of fines and penalties.

- Cost savings: Implementing quality control measures can help manufacturers reduce costs associated with rework, repair, and replacement.

Quality Control Measures in PCB Assembly

There are several quality control measures that can be implemented in PCB assembly, including:

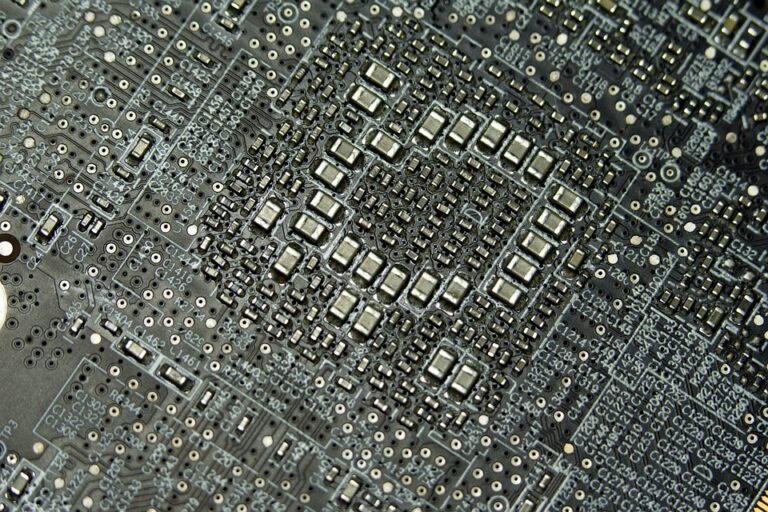

- In-process inspection: This involves inspecting the PCB assembly at various stages to detect defects and errors.

- Visual inspection: This involves visually inspecting the PCB assembly for defects and errors.

- X-ray inspection: This involves using X-ray technology to inspect the PCB assembly for defects and errors.

- Audits and testing: This involves conducting regular audits and testing to ensure compliance with industry regulations and standards.

- Corrective action: This involves taking corrective action to address any defects or errors detected during quality control checks.

Challenges in Implementing Quality Control in PCB Assembly

Implementing quality control measures in PCB assembly can be challenging, especially in high-volume production environments. Some of the challenges include:

- Resource constraints: Implementing quality control measures requires significant resources, including personnel, equipment, and facilities.

- Cost considerations: Implementing quality control measures can be expensive, especially if manufacturers need to invest in new equipment and facilities.

- Time constraints: Implementing quality control measures can take time, which can delay production and impact business operations.

- Complexity: Implementing quality control measures can be complex, especially if manufacturers need to comply with multiple industry regulations and standards.

Solutions to Overcome Challenges in Implementing Quality Control in PCB Assembly

To overcome the challenges in implementing quality control measures in PCB assembly, manufacturers can consider the following solutions:

- Invest in quality control software: This can help streamline the quality control process, reduce errors, and improve efficiency.

- Train personnel: Providing personnel with quality control training can help them understand the importance of quality control and ensure that they are equipped to implement quality control measures effectively.

- Partner with quality control experts: Manufacturers can partner with quality control experts to gain access to expertise, resources, and equipment.

- Outsource quality control: Manufacturers can outsource quality control to third-party providers to reduce costs and improve efficiency.

Conclusion

In conclusion, quality control is a crucial aspect of PCB assembly. Implementing quality control measures can help manufacturers ensure the reliability and efficiency of the PCB assembly process, improve product quality, reduce waste and rework, and increase customer satisfaction. While implementing quality control measures can be challenging, there are solutions available to overcome these challenges. By investing in quality control software, training personnel, partnering with quality control experts, and outsourcing quality control, manufacturers can ensure that their PCB assemblies meet the required standards and specifications.

FAQs

Q: What is the importance of quality control in PCB assembly?

A: Quality control is essential in PCB assembly to ensure the reliability and efficiency of the process, improve product quality, reduce waste and rework, and increase customer satisfaction.

Q: What are the benefits of implementing quality control measures in PCB assembly?

A: The benefits of implementing quality control measures in PCB assembly include improved product reliability, reduced waste and rework, increased customer satisfaction, compliance with regulations, and cost savings.

Q: What are some common quality control measures in PCB assembly?

A: Common quality control measures in PCB assembly include in-process inspection, visual inspection, X-ray inspection, audits and testing, and corrective action.

Q: What are some challenges in implementing quality control in PCB assembly?

A: Challenges in implementing quality control in PCB assembly include resource constraints, cost considerations, time constraints, and complexity.

Q: How can manufacturers overcome challenges in implementing quality control in PCB assembly?

A: Manufacturers can overcome challenges in implementing quality control in PCB assembly by investing in quality control software, training personnel, partnering with quality control experts, and outsourcing quality control.

[ad_2]