-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

SMT Assembly

Whis is SMT Assembly ?

Surface mount technology (SMT), also known as surface mount technology, achieves high-density and high-reliability circuit connection by precisely mounting leadless/short-lead components (SMC/SMD) on the printed circuit board (PCB) surface and using reflow soldering/dip soldering process. Its core advantages include:

• Volume reduction of 40%-60%, weight reduction of 60%-80%, meeting the miniaturization needs of electronic products;

• Automation rate exceeds 90%, production efficiency increased by 50%+, cost savings of 30%-50%;

• High-frequency characteristics optimization, reducing electromagnetic interference, and solder joint defect rate is less than 0.01%.

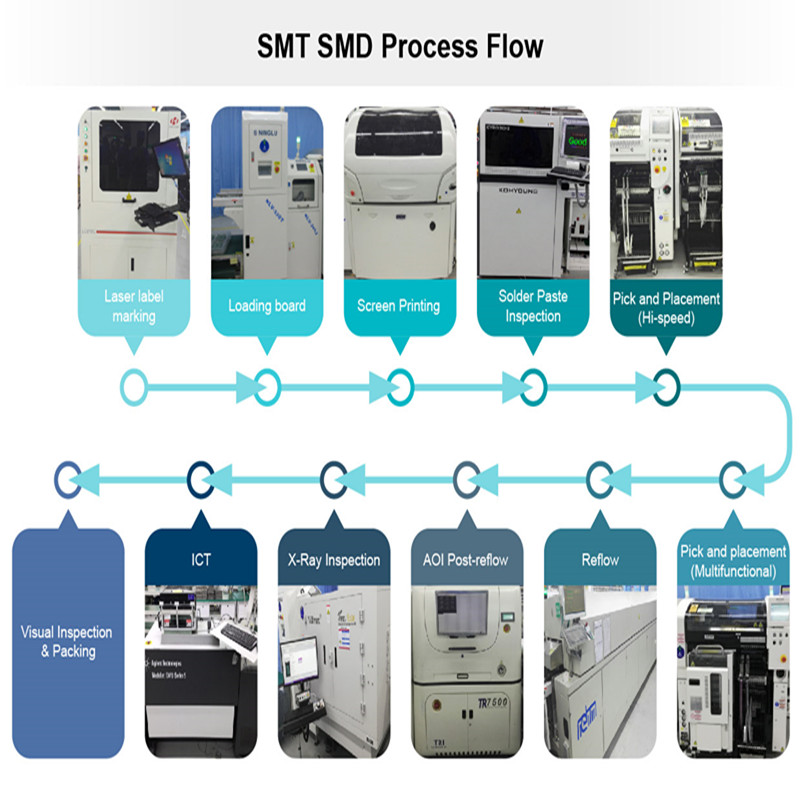

What process of SMT PCB Assembly ?

The following are the 10 Key process of SMT Assembly, :

Steel mesh design and production Precise hole opening process to ensure the consistency of solder paste printing

Solder paste printing (tin paste coating) Fully automatic high-precision printing, suitable for micro-pitch components

3D SPI detection Laser scanning solder paste thickness to prevent cold soldering/bridging defects

High-speed precision patch Multi-head linkage placement, compatible with 0201 to BGA packaging

Nitrogen reflow soldering Ten temperature zone curve control to reduce oxidation defect rate

AOI optical inspection AI intelligent comparison to identify offset/tombstone/missing

X-RAY layered scanning Through-detection of BGA/QFN hidden problems

Online functional test (ICT/FCT) Simulate terminal environment to verify circuit performance

Triple-proof coating process Nano-level protective coating to improve environmental tolerance

Failure analysis and rework BGA ball planting/hot air rework station to accurately repair defective products

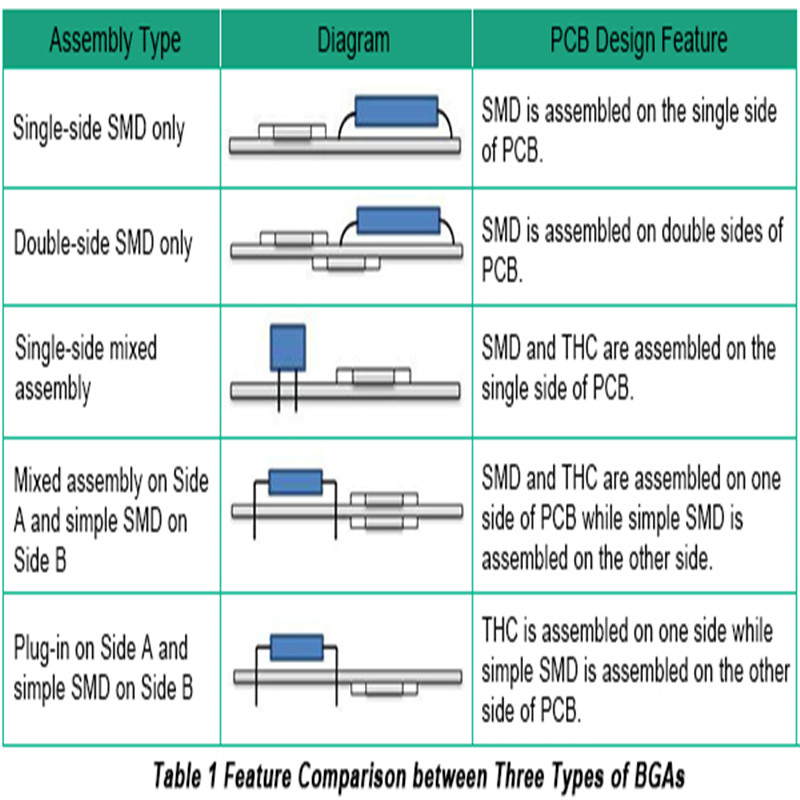

What the type of SMT Assembly ?

The following are the 6 Key types of SMT Assembly service

Fully automatic patch process High-speed and high-precision placement, suitable for BGA/0201 micro components

Lead-free reflow soldering Ten temperature zones nitrogen protection, RoHS environmental certification process

Laser reflow soldering Precise temperature control without thermal damage, the preferred solution for micro IC chips

Wave soldering hybrid (Mixed) Assembly Simultaneous soldering of plug-in and patch, compatible with red glue process

Conformal Coating package Nano coating protection, improve PCB corrosion resistance

AOI+X-RAY double inspection AI optical+layer scanning, zero-defect quality control guarantee

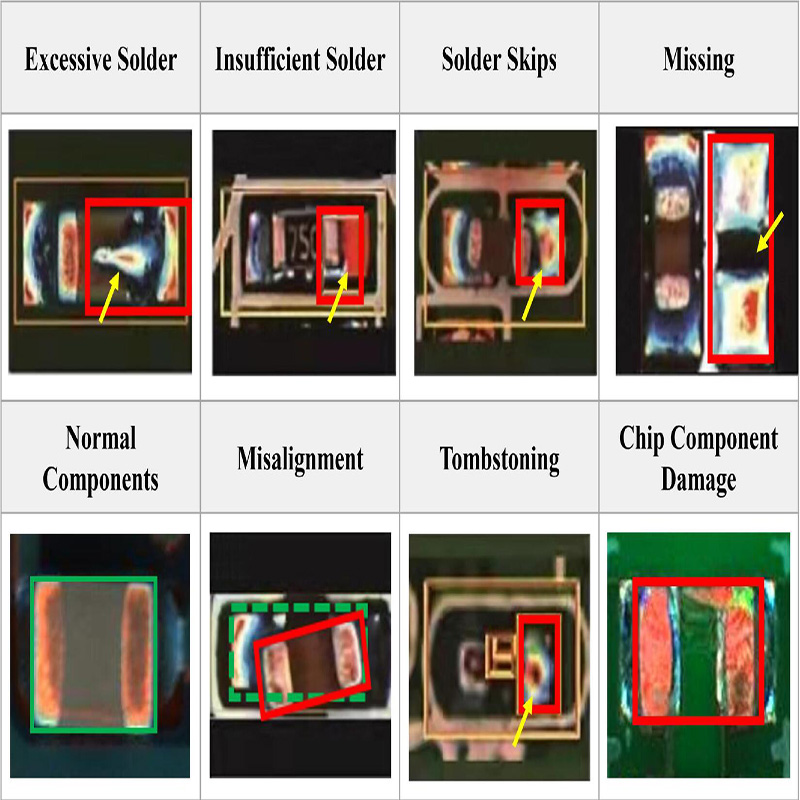

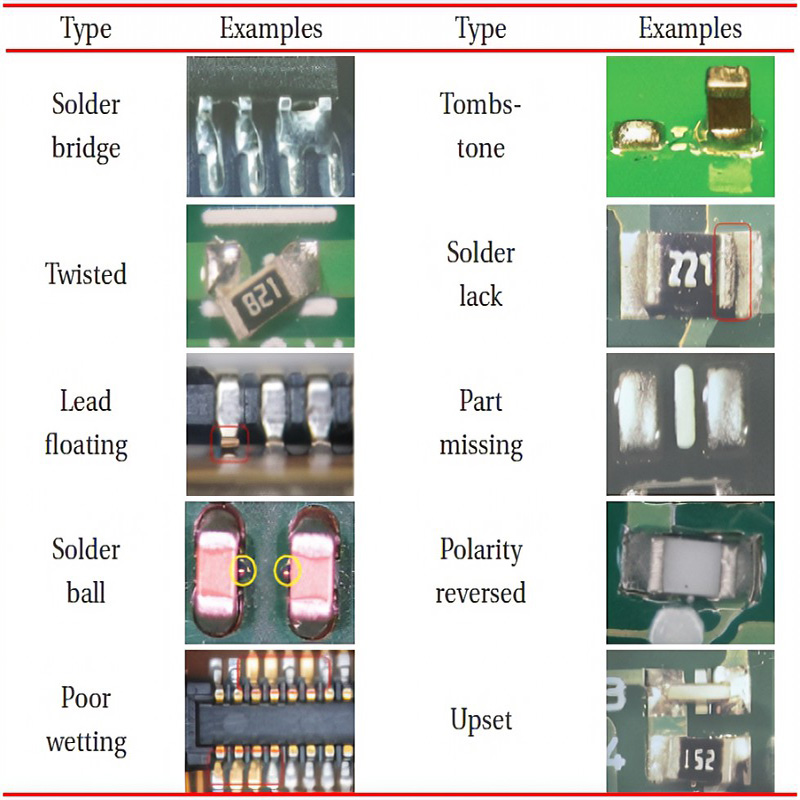

What the top 10 errors in SMT Assembly Technology ?

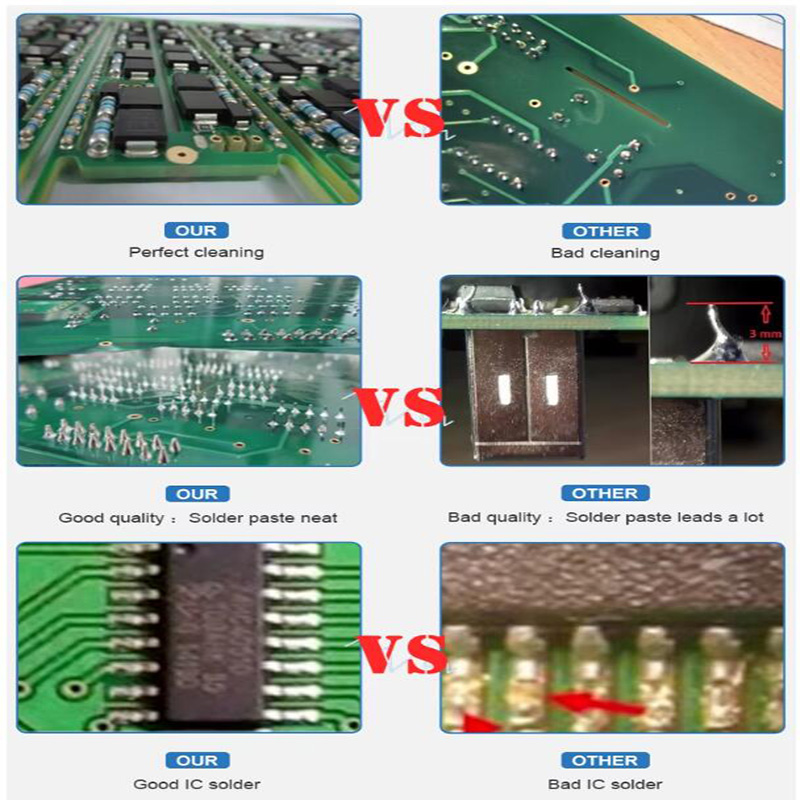

we are a UL certified factory with 13 years experance ,we are fouce on increase SMT succeed rate,we can find the problem and know how to solve the problem ,Here is 10 Comment Error in Surface mount Technology (SMT)

The following are the top 10 common errors and high conversion rate solutions for SMT Assembly.

1.Poor soldering (false soldering/short circuit)

Solution: optimize the reflow soldering temperature curve, use highly active solder paste, and calibrate the steel mesh thickness.

2.Component lift

Solution: balance the pad thermal capacity design and enable solder paste anti-offset printing technology.

3.Solder ball/solder ball residue

Solution: reduce the heating rate of the preheating zone and increase the cleaning frequency of the bottom of the steel mesh.

4.BGA tinning/false soldering

Solution: X-Ray layer detection, adjust the reflow soldering pressure and temperature gradient.

5.Component offset (mounting misalignment)

Solution: calibrate the nozzle accuracy of the placement machine and enable the visual alignment compensation system.

6.PCB oxidation/contamination

Solution: store PCB in nitrogen and add plasma cleaning process.

7.Uneven solder paste printing (little tin/missing printing)

Solution: replace the laser steel mesh and adjust the scraper pressure and demolding speed.

8.Component falling off (mechanical stress)

Solution: Optimize the Z-axis pressure of mounting and use the red glue process with low voiding rate.

9.Cold soldering (dull solder joints)

Solution: Extend the constant temperature zone time and upgrade the multi-temperature zone reflow soldering equipment.

10.Solder paste collapse (bridging risk)

Solution: Use anti-collapse solder paste formula to shorten the furnace time after printing.

Why US as your SMT Assembly Partner ?

The following are the core advantages and solutions for choosing our SMT Assembly service:

5 major reasons for selection & solutions

High-precision mounting technology Solution: Imported mounting machine with ±0.02mm accuracy, suitable for 0201/BGA micro-pitch mounting solution, BGA rework technology

Fully automated production line efficiency Solution: Intelligent production scheduling system, 24-hour fast proofing delivery, SMT fast proofing

Military-grade quality control standards Solution: AOI+X-RAY double inspection, defect rate <0.3%

One-stop PCBA service Solution: Full process coverage from PCB design to three-proof coating, PCBA one-stop service

Transparent cost control Solution: BOM intelligent price comparison system, reduce procurement costs by 20%, low-cost proofing