Ce este un asamblator PCB? Prezentare generală cuprinzătoare a fabricilor de asamblare PCB și a fabricilor SMT

Abstract:

O asamblator PCB is necessary in the electronic devices sector, transforming bare published circuit card into completely practical electronic devices. This guide discovers the duties of a PCB assembler, the processes associated with PCB setting up, and the relevance of PCB assembly manufacturing facilities and SMT setting up factories. Whether you are an electronics fanatic, an entrepreneur, or a purchase expert, comprehending the globe of PCB setting up is vital for making educated choices. Keep reading to find exactly how PCB assemblers drive technology and reliability in modern-day electronics.

Cuprins

Introduction: The Role of PCB Assemblers in Modern Electronic Devices.

PCB assemblers are the foundation of the electronic devices manufacturing industry. They change raw circuit boards right into the heart of every digital gadget you make use of daily. From smart devices to industrial machinery, the know-how of a skilled PCB assembler makes certain that devices work accurately and effectively. This post looks into the world of PCB assembly manufacturing facilities and SMT assembly manufacturing facilities, highlighting their importance, procedures, and how they form the future of technology.

What Is a PCB Assembler?

O asamblator PCB is either a knowledgeable individual or a specialized firm in charge of installing digital elements onto a published circuit card (PCB). This process turns a basic board into a complicated, useful electronic gadget. PCB assemblers follow accurate layouts, utilize innovative devices, and make certain every element is appropriately put and soldered.

Trick Terms: PCB assembler, PCB assembly factory, SMT setting up factory, electronic components, motherboard setting up.

PCB assemblers operate in various setups, from tiny workshops to large PCB setting up factories. Their proficiency makes certain that each board satisfies rigorous quality standards and carries out as meant.

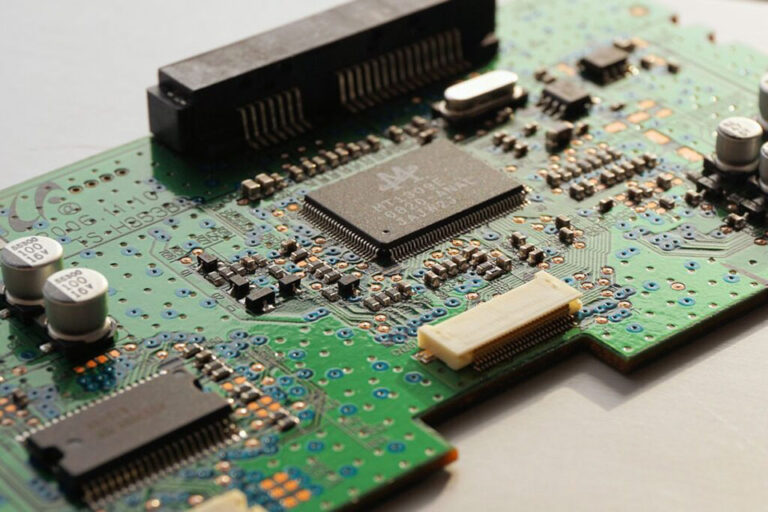

Comprehending Printed Circuit Boards (PCBs).

O printed circuit card (PCB) is the structure of all electronic devices. It consists of a non-conductive substrate, usually made of fiberglass, with copper traces that link different digital parts. These traces develop the electrical paths that enable signals and power to move throughout the gadget.

Trick Terms: PCB, printed motherboard, copper traces, digital components, substratum.

PCBs are available in various sizes and shapes, depending upon the application. They can be single-sided, double-sided, or multi-layered, each providing different levels of intricacy and performance.

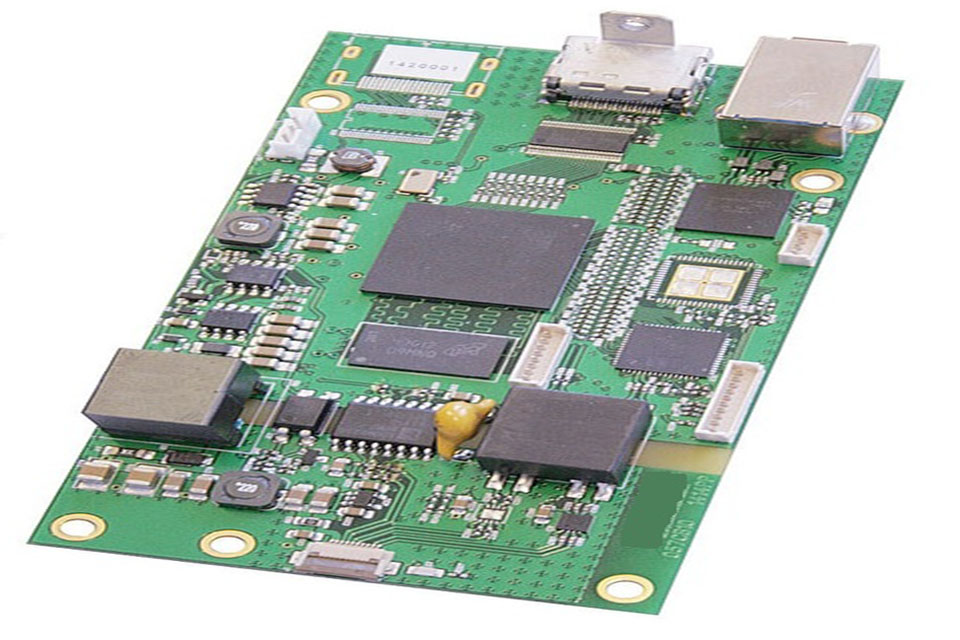

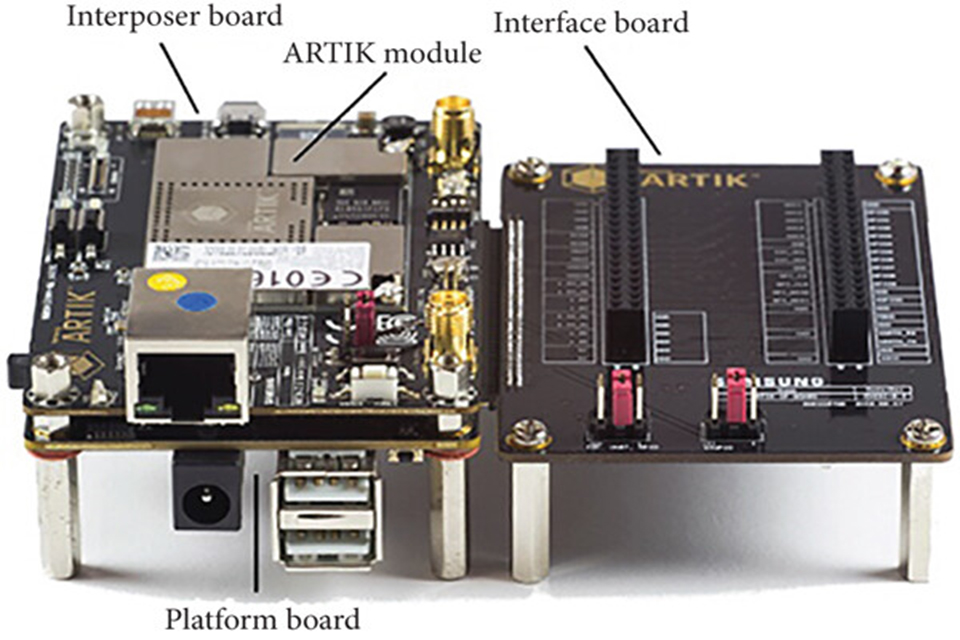

Just how Does a PCB Setting Up Factory Operate?

O PCB assembly factory is a facility outfitted to manage the automation of set up motherboard. These manufacturing facilities make use of automated machinery and competent specialists to area and solder parts onto PCBs efficiently.

Trick Terms: PCB setting up manufacturing facility, automated assembly, mass production, quality assurance, assembly line.

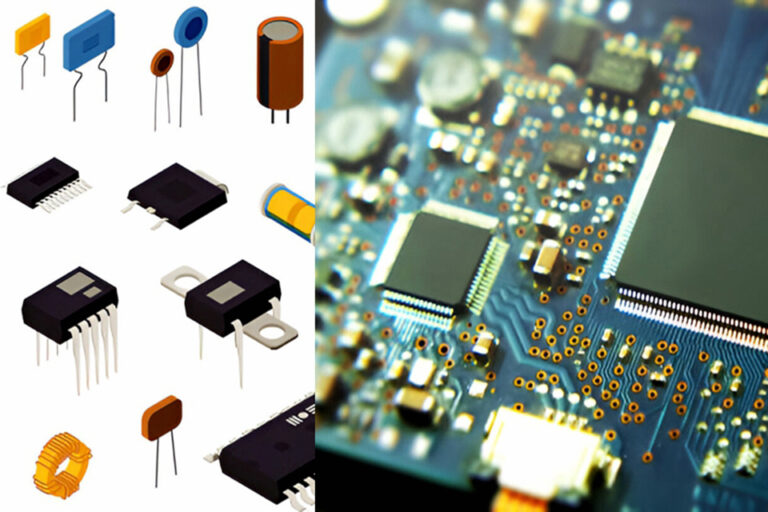

The regular operations in a PCB assembly factory consists of:.

- Component Positioning: Makers or specialists place resistors, capacitors, and incorporated circuits onto the board.

- Lipire: Soldering machines or manual soldering safe the components to the PCB.

- Examination and Testing: Quality control groups inspect and check each board to make sure capability.

PCB setting up manufacturing facilities focus on rate, precision, and reliability, making them necessary companions for electronics manufacturers worldwide.

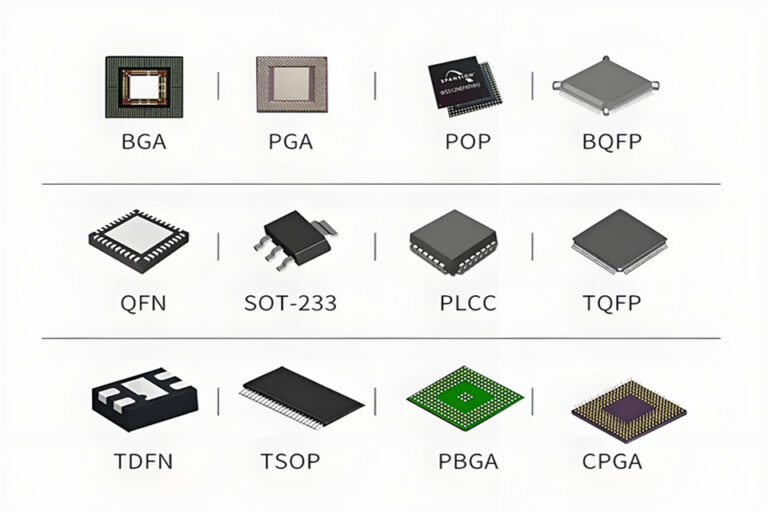

What Is SMT Assembly and Why Is It Important?

Surface Area Mount Innovation (SMT) setting up is an approach where components are mounted straight onto the surface of the PCB. SMT assembly manufacturing facilities concentrate on this strategy, which permits smaller, much more effective, and extra reputable electronic tools.

Key Terms: SMT setting up, SMT assembly manufacturing facility, surface mount technology, miniaturization, high-density setting up.

SMT assembly uses several advantages:.

- Compact Layout: Elements are smaller sized and can be positioned more detailed with each other.

- Automated Production: SMT assembly manufacturing facilities utilize high-speed devices for accurate positioning.

- Enhanced Efficiency: SMT boards typically have better electrical efficiency and integrity.

SMT assembly has come to be the sector criterion for contemporary electronics, making it possible for the production of innovative tools like mobile phones, laptops, and clinical equipment.

Trick Jobs and Skills of a PCB Assembler.

O asamblator PCB should master a number of critical jobs to make sure high-quality setting up:.

- Checking out Schematics: Recognizing circuitry representations and setting up directions.

- Part Option: Choosing the best resistors, capacitors, and chips for each job.

- Specific Placement: Making use of devices or makers to place components properly.

- Lipire: Developing strong, trusted electric connections.

- Evaluating: Confirming that the constructed PCB functions correctly.

Trick Terms: PCB assembler, soldering, part placement, testing, quality assurance.

Knowledgeable PCB assemblers incorporate technical understanding with focus to detail, making certain every board satisfies the greatest standards.

PCB Setting Up Factory vs. SMT Assembly Manufacturing Facility: What’s the Distinction?

While both sorts of factories construct PCBs, there are vital distinctions:.

- PCB Setting Up Factory: Deals with both through-hole and surface area place elements. Deals adaptability for different job types.

- SMT Assembly Factory: Specializes in surface area install technology, focusing on high-speed, high-density assembly.

Secret Terms: PCB assembly factory, SMT assembly factory, through-hole setting up, surface area mount setting up, production approaches.

Picking the ideal factory depends on your project’s needs, such as part kinds, production volume, and desired turnaround time.

Why Is PCB Setting Up Crucial for Electronic Devices?

PCB assembly is the action that brings digital styles to life. Without competent PCB assemblers and progressed setting up manufacturing facilities, even the best-designed circuits would remain academic.

Trick Terms: PCB assembly, electronic device production, reliability, performance, advancement.

Appropriate assembly guarantees:.

- Integrity: Gadgets work as intended, with marginal danger of failure.

- Efficiency: Parts interact correctly, providing optimum performance.

- Scalability: Manufacturing facilities can generate large quantities efficiently, sustaining mass-market items.

Just how to Select the Right PCB Setting Up Factory.

Selecting the best PCB setting up factory sau SMT setting up factory is crucial for task success. Consider these variables:.

- Experience: Search for manufacturing facilities with a tried and tested record in your sector.

- Innovation: Guarantee they make use of modern tools and comply with industry requirements.

- Quality Control: Inquire about their evaluation and screening processes.

- Consumer Support: Pick a companion that interacts clearly and sustains your requirements.

Secret Terms: PCB setting up factory, SMT assembly manufacturing facility, quality control, customer support, market standards.

A dependable manufacturing facility can aid you prevent expensive blunders and deliver items that exceed expectations.

Future Fads in PCB Setting Up and SMT Modern Technology.

The globe of PCB assembly is frequently evolving. Key fads consist of:.

- Miniaturizare: Instruments are getting smaller, requiring a lot more precise setting up strategies.

- Automation: Factories are embracing robotics and AI for faster, extra exact production.

- Sustainability: Environment-friendly products and processes are coming to be standard.

Key Terms: PCB assembler, SMT assembly factory, automation, miniaturization, eco-friendly manufacturing.

Staying ahead of these fads ensures your items stay affordable and innovative.

Întrebări frecvente despre asamblatorii de PCB-uri și fabricile de asamblare PCB

Ce face un asamblator PCB?

A circuit board assembler’s primary responsibility is to build and assemble electronic components onto printed circuit boards (PCBs). This includes tasks like soldering components, reading wiring diagrams, and ensuring the boards function correctly after assembly. They also perform inspections and may operate automated assembly equipment.

What is the difference between a PCB setting up manufacturing facility and an SMT assembly manufacturing facility?

Fabricarea PCB este procesul de creare a plăcii goale în sine—substratul cu trasee de cupru, pad-uri și găuri. Asamblarea PCB este procesul ulterior în care un asamblator PCB ia acea placă goală și montează toate componentele electronice pe ea

De ce este important asamblarea SMT?

Asamblarea SMT (Surface Mount Technology) este crucială în electronica modernă datorită capacității sale de a crea dispozitive mai mici, mai ușoare și mai eficiente. Permite o densitate mai mare a componentelor, o producție mai rapidă și costuri reduse, făcând-o vitală pentru orice, de la smartphone-uri până la aplicații aerospațiale.

Cum aleg fabrica potrivită de asamblare PCB?

Pentru a selecta fabrica potrivită de asamblare PCB, trebuie să luați în considerare factori precum experiența lor, capacitățile de producție, certificările de calitate, termenele de producție, prețurile și serviciul clienți. Evaluați capacitatea lor de a satisface nevoile specifice ale proiectului dumneavoastră, inclusiv tipul PCB-ului, dimensiunea și cerințele de volum.

Care sunt ultimele tendințe în asamblarea PCB-urilor?

impulsul continuu pentru miniaturizare și interconexiuni de înaltă densitate (HDI), creșterea PCB-urilor flexibile și rigide-flex, integrarea AI și a automatizării și un accent tot mai mare pe sustenabilitate

De ce este asamblarea PCB critică pentru electronică?

creează circuitele funcționale care permit dispozitivelor să funcționeze

Concluzie: Valoarea Asamblatorilor Profesioniști de PCB-uri.

Professional PCB assemblers and advanced PCB assembly factories are crucial for the electronics industry. They transform ingenious designs into trustworthy products, sustaining everything from customer devices to commercial systems. By understanding the setting up procedure and selecting the ideal partners, you can ensure your digital tools satisfy the highest possible criteria of quality and performance.

Rezumat punctat.

- PCB assemblers change circuit boards into useful gadgets.

- PCB assembly manufacturing facilities make use of sophisticated technology for mass production.

- SMT setting up manufacturing facilities focus on high-density, surface mount setting up.

- Proper assembly makes sure gadget dependability and efficiency.

- Picking the right factory is essential to project success.

- Industry patterns consist of miniaturization, automation, and sustainability.