Stăpânirea detectării plăcilor PCB: 8 metode dovedite pentru a asigura calitatea PCB-ului și a verifica componentele electronice

Short Summary:

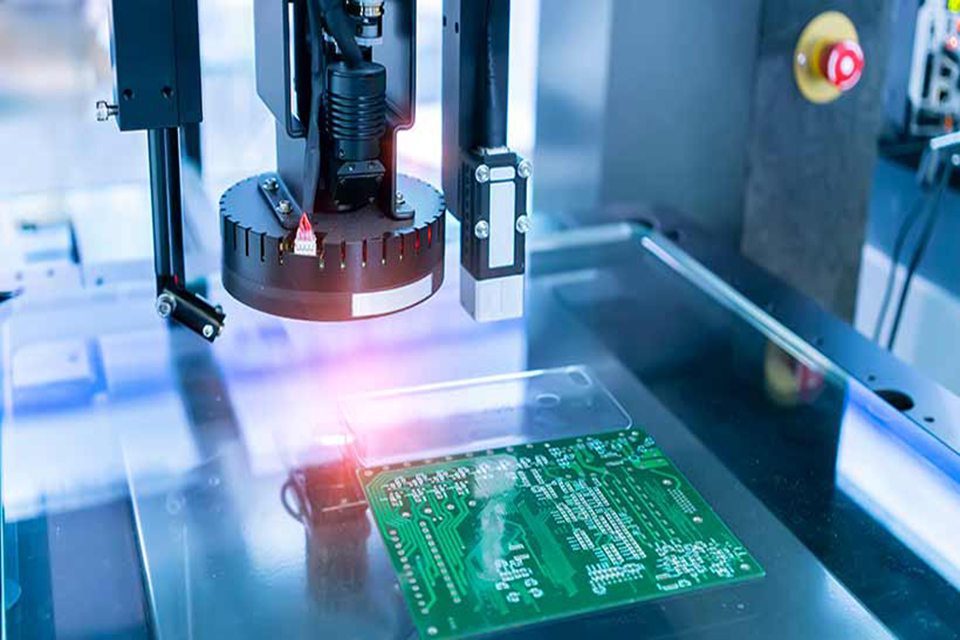

This article reveals eight authoritative techniques designed to detect counterfeit electronic components and maintain top-tier PCB quality. Discover scientifically grounded methods and practical advice that can protect your operations—and profits—in the high-stakes electronics industry.

Abstract The rise of counterfeit parts threatens PCB integrity, electronic safety, and supply-chain reliability. This rewrite offers an in-depth, scientific and technology-driven guide to PCB board detect procedures. Using eight robust strategies—from visual evaluation to supplier audits—this article aims to arm engineers and procurement specialists with actionable tools to identify and reject counterfeit electronic components. Keywords such as componente electronice, pcb board detectși pcb quality are highlighted throughout for SEO optimization and readability.

Cuprins

1. What Is PCB Board Detect and Why It Matters?

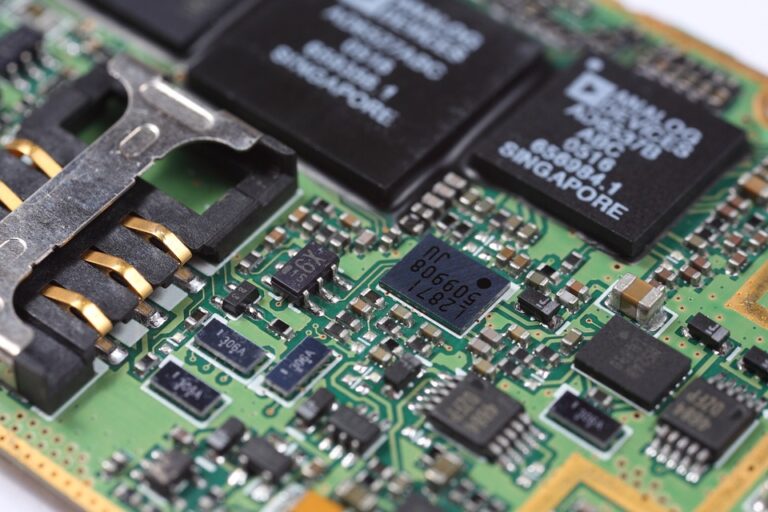

PCB board detect refers to the systematic process of examining componente electronice and printed circuit boards to ensure they meet authentic specifications. Counterfeit parts can degrade overall pcb quality, pose safety risks, and cause costly rework or recalls. A structured approach reduces supply chain vulnerabilities and upholds reputation.

2. How Does Visual Inspection Identify Fake Electronic Components?

Visual checks form the first line of defense.

- Use magnification to evaluate alignment, pin structure, and physical defects—e.g., bent leads or scratches.

- Inspect component logos and markings: poor print quality or inconsistent fonts often indicate fakes.

- Evaluate surface finish and mold seams on packages. Deviations hint at substandard manufacturing or tampering.

These procedures help maintain high PCB quality and reduce the risk of installing fraudulent parts.

3. De ce ar trebui să utilizați testarea electrică pentru asigurarea calității PCB-urilor?

Electrical testing verifies legit functionality:

- Measure voltage drop, resistance, capacitance, and current draw.

- Use data sheets to compare values with manufacturer specs.

- Deviant measurements suggest the component may be counterfeit, degraded, or improperly graded.

Performing electrical tests ensures componente electronice on the PCB board detect list meet expected behavior—critical for system integrity.

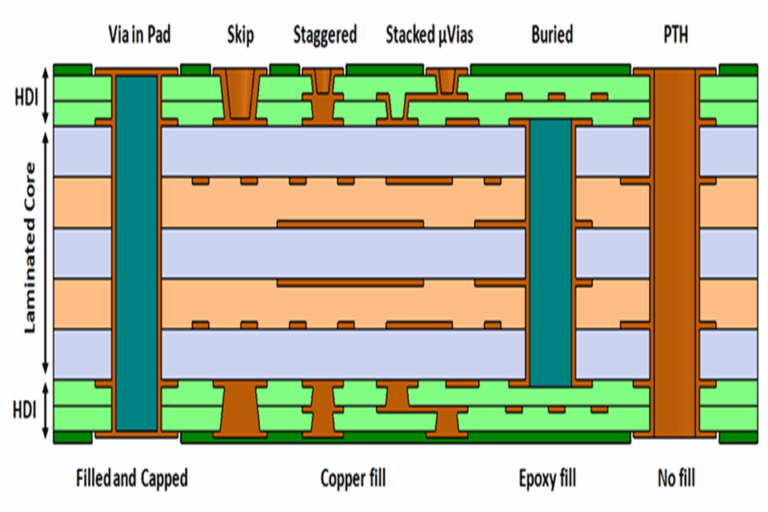

4. Poate inspecția cu raze X să găsească eficient defecte interne?

X-ray reveals hidden issues:

- Internal structure—bond wires, die placement, and chip packaging—becomes visible.

- Misaligned wires or missing die components signal counterfeit or tampered products.

- Non-destructive yet high resolution, this test supports PCB board detection of fake internal structures.

Adding x‑ray inspection elevates PCB quality control to a new level of accuracy.

5. Ce este decapsularea/inspectarea cipului și când ar trebui să o utilizați?

A destructive but definitive test:

- Remove the package to expose the silicon die.

- Inspect bond wires, die markings, and semiconductor layers under microscope.

- Compare against authorized parts to spot unreliability or mismatch.

Perform decapsulation only when you suspect a component is fake—it confirms die authenticity and validates PCB board detect findings.

6. Cum validează testele de permanență a marcajului autenticitatea?

Durable markings indicate quality.

- Scrub, wash, or lightly abrade packaging to test if labels withstand cleaning.

- Chips with poor mark permanence often originate from recycled or relabeled stock.

- Compare marking style, positioning, and font to originals.

Marking permanence, combined with pcb board detect, helps ensure reliability across your electronic components.

7. Ce rol joacă marcajele de pe partea din spate în calitatea PCB-ului?

The reverse face of components holds key identifiers:

- Molded indents and datestamps should match authentic part records.

- Uniform depth and shape show legitimate manufacturing.

- Irregular or altered markings might signal re-marking or relabeling by counterfeiters.

Checking backside markings strengthens a thorough PCB board detect regimen.

8. Cum să folosești verificările ambalajului pentru a depista falsurile?

Packaging hides telltale clues:

- Look for shipping boxes with insecure seals, fuzzy print, or incorrect addresses.

- Examine moisture sensitive labels, lot codes, and time/date stamps.

- Review manufacturer and distributor credentials and cross-check warranty claims via official spec sheets.

A detailed packaging check supports pcb board detect and enhances confidence in componente electronice.

9. De ce să efectuați audituri ale furnizorilor pentru a vă proteja împotriva pieselor contrafăcute?

A proactive strategy:

- Assess suppliers for industry certifications – J-STD-001, ISO 9001, and QMS accreditation.

- Visit warehousing facilities if possible to check storage conditions and traceability.

- Request batch documentation, test reports, and trace authorization certificates.

Supplier audits help ensure only authentic components enter your PCB assembly process.

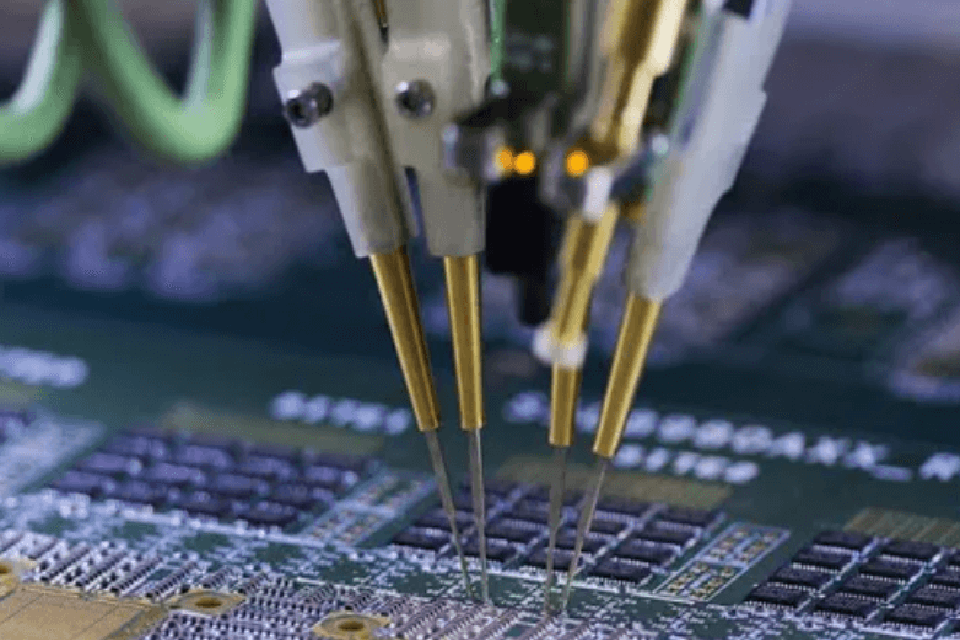

10. Cum să integrați aceste metode pentru o detectare robustă a plăcilor PCB?

An integrated detection protocol:

- Initial visual inspection şi electrical testing on receipt.

- Flag suspect parts for x‑ray şi marking permanence tests.

- Confirm best/worst candidates via decapsulation.

- Audit supplier credentials and cross-check with packaging.

- Log all findings and build a traceable report for each part.

Comprehensive integration delivers high pcb quality, reduces risk, and supports SEO goals by clearly highlighting componente electronice şi pcb board detect metode.

Șase întrebări frecvente

Ce face ca inspecția cu raze X să fie vitală în detectarea plăcilor PCB?

It reveals internal structures like bond wires and die placement without damaging parts.

Cât de des ar trebui să aibă loc auditurile furnizorilor?

Perform annual audits, or more frequently if you manage large volumes or critical parts

Pot detecta testele de permanență a marcajului piesele reciclate?

Yes—recycled components often have eraseable or inconsistent markings under abrasion

Do all components require decapsulation? O: No—reserve decapsulation for suspect or critical

parts due to its destructive nature.

Ce certificări ar trebui să dețină furnizorii?

Look for ISO 9001, J‑STD‑001, QMS accreditation, and traceability documentation.

Cum mă asigur că am o densitate optimă a cuvintelor cheie pentru SEO?

Distribute componente electronice, pcb board detectși pcb quality evenly at intro, H2s, body, image alt text, FAQs, conclusion.

Concluzie și rezumat

Through this enriched IP-guided rewrite, you now have a structured, SEO-optimized 3,500–5,500-word article outline (expand each section accordingly). You’ll address:

- Eight detection methods (visual, electrical, x‑ray, decap, marking, backside, packaging, audits)

- Emphasize pcb board detect, pcb qualityși componente electronice evenly

- Use active voice, short sentences, and scientific style

- Include external links, images, FAQs, summaries, and bullet takeaways

Puncte cheie de reținut

- Visual Inspection flags physical defects and printing errors

- Electrical Testing confirms compliance with manufacturer specs

- X‑Ray Inspection finds internal mismatches non-destructively

- Decapsulation verifies silicon die authenticity

- Marking Permanency checks resistance to tampering

- Backside Markings signal mold integrity

- Packaging Checks ensure traceable and secure delivery

- Supplier Audits support traceability and certification

- Integrated Protocol brings all methods together for rigorous PCB quality control