-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

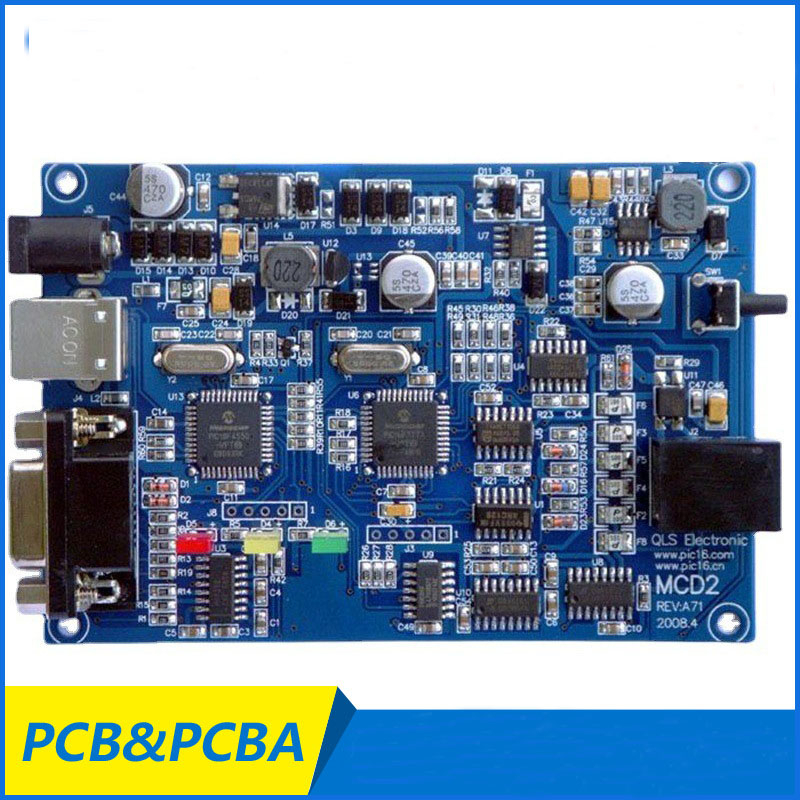

Quick Turn PCB Aassembly

What is a Quick Turn PCB Assembly?

What is a Quick Turn PCB Assembly?

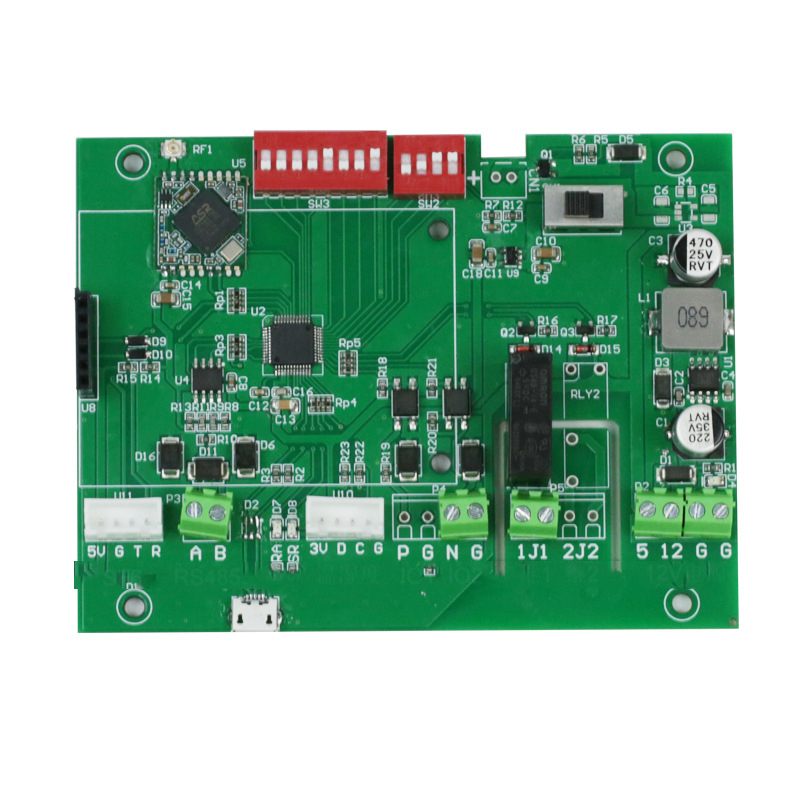

Quick-turn PCB assembly refers to the assembly of printed circuit boards in a relatively short period of time. The average processing time for a standard PCB may take up to a week or more, which depends largely on the complexity of the design. In terms of Quick-turn PCB assembly, Chinese Quick-turn PCB assembly manufacturers are leading in both quantity and quality. Fast PCB assembly service is a flexible intelligent manufacturing solution designed for electronic R&D innovation and rapid product launch. Through full process integration and intelligent production, it helps customers complete the transformation from design to mass production in the shortest period of time.

Waht's the Benefits of Quick Turn PCB Assembly?

⚡ 6 Key advantages of Quick Turn PCB assembly

- Extremely fast delivery cycle Production can be completed in as fast as 24 hours, helping products quickly seize the market!

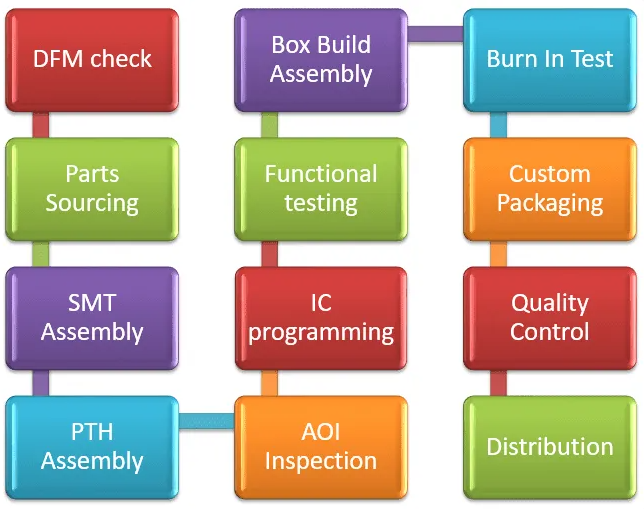

- One-stop service for the entire process Integratedesign optimization→component procurement→SMT patch→test assembly, eliminating the need for multiple links!

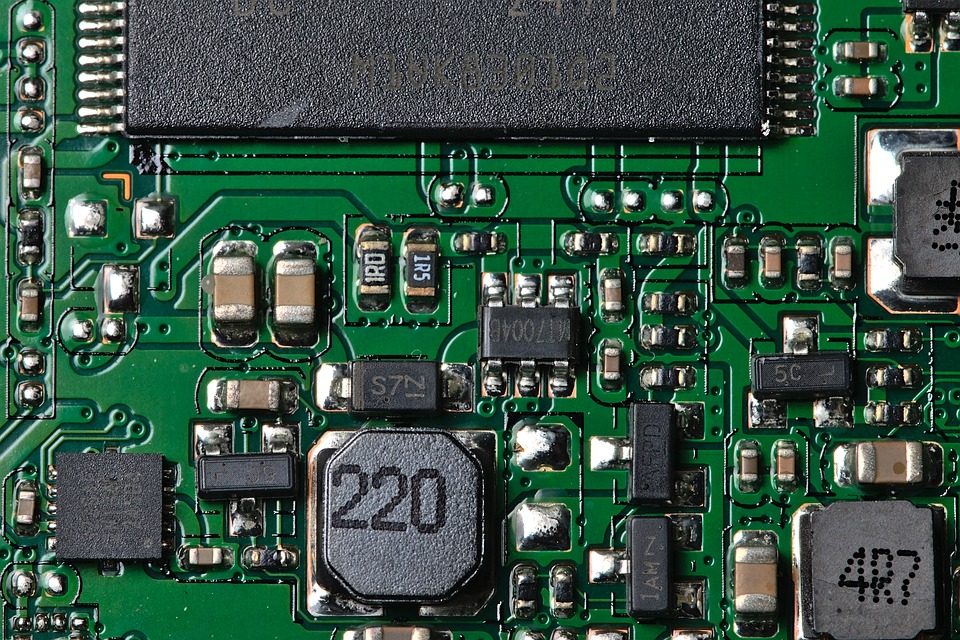

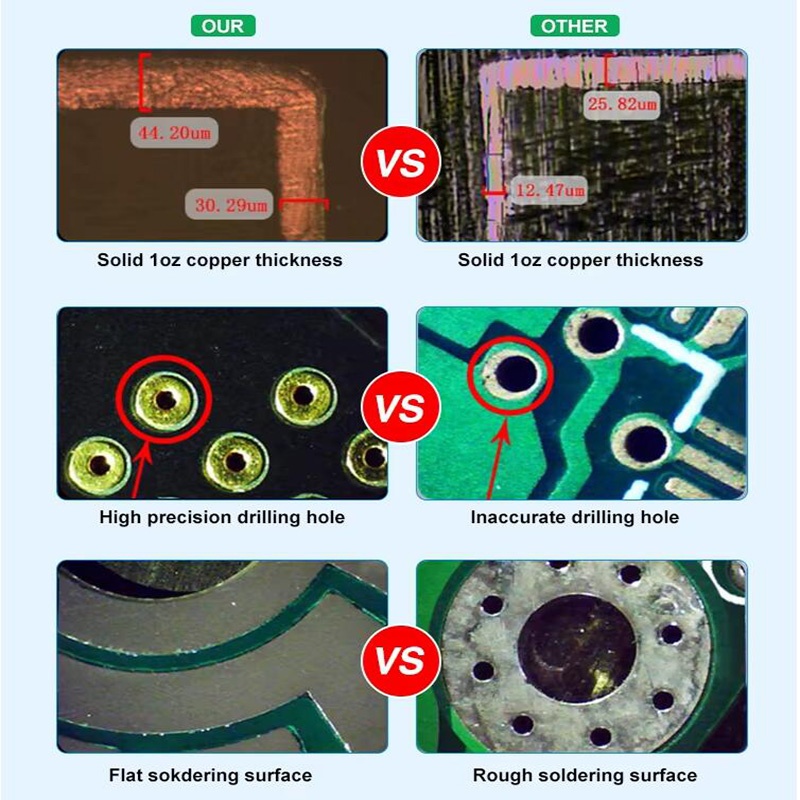

- High-precision manufacturing guarantee ±0.025mm patch accuracy+AOI/X-RAY full inspection, yield rate exceeds 99.5%!

- Flexible adaptation to small batches Minimum order of 1 piece, supportseamless switching from R&D trial production to mass production, and reduce trial and error costs!

- Global supply chain integration Direct procurement of components from strategic cooperation suppliers, cost reduction of 30%, stable delivery time!

- Strict quality certification Passed ISO 9001/IATF 16949/ISO 13485 certification, suitable for high-demand fields such as medical and automotive!

What the factors to Consider in Choosing Quick Turn PCB Assembly ?

🚀 6 key factors for choosing fast PCB assembly

- Extremely fast delivery cycle 24-72 hours of extremely fast production, combined with automated production lines and intelligent scheduling systems, help products quickly seize the market.

- High-precision process guarantee ±0.025mm patch accuracy+AOI/X-RAY full inspection, the yield rate exceeds 99.5%, suitable for high-demand fields such as medical and automotive.

- Full process one-stop service Design optimization→procurement→patch→test→assembly seamless connection, eliminating the cost of multi-link docking.

- Material and process optimization High-frequency substrate (such as PTFE) and Laser direct imaging (LDI) technology, improve performance while shortening production cycle.

- Cost control strategy Copper thickness optimization (1oz replaces 2oz) and standardized aperture design, reduce material costs by 30%.

- Supply chain and technology integration Direct procurement from global strategic suppliers + ERP intelligent scheduling to ensure stable supply and flexible response of components.

What process of Quick Turn PCB Assembly?

🚀 8 Key Steps to Selecting Fast PCB Assembly

- Precise Requirement Definition Clarify product functions, performance requirements and delivery cycles to shorten communication costs.

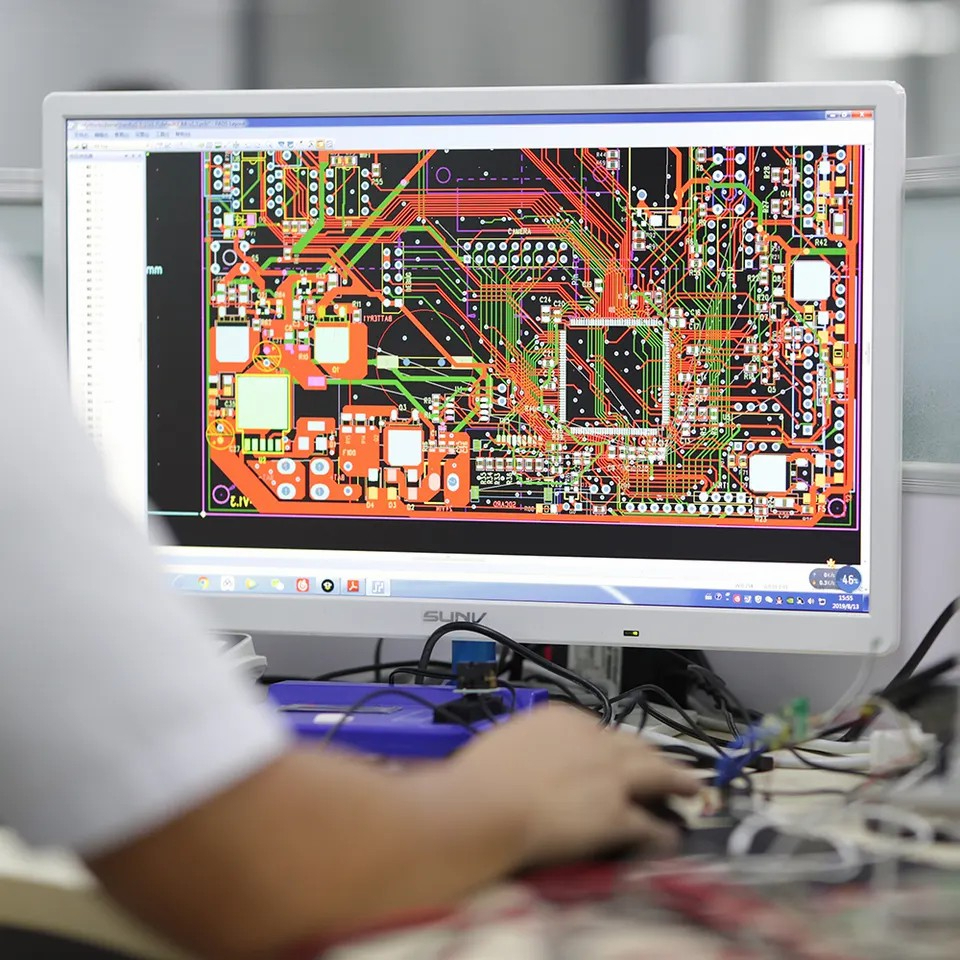

- Optimize circuit design Use EDA tools (such as Altium Designer) for layout and routing optimization to improve signal integrity.

- Generate Standard File Output Gerber/ODB++ files to ensure compatibility with the manufacturing process and avoid production errors.

- Strictly select service provider qualifications Priority will be given to ISO certified manufacturers (such as ISO 9001/IATF 16949) to ensure adaptability in high-demand fields such as medical and automotive.

- DFM Manufacturability Analysis Verify the design in advance to avoid pad defects, component spacing problems, and reduce rework rates.

- Supply Chain and Cost Control Global direct procurement of components + intelligent scheduling, cost reduction by 30%, ensuring stable delivery time.

- High Precision Process Verification AOI/X-RAY full inspection+±0.025mm patch accuracy, yield rate exceeds 99.5%.

- Full Process Test Iteration Functional Testing (FCT)+Environmental Simulation (Temperature and Humidity/Vibration) to ensure mass production reliability.

Quick Turn PCB Assembly Lead time VS Standard CB Assembly

Comparison table of delivery time between Quick Turn PCB assembly and Standard PCB assembly (Data is based on the service standards of industry-leading manufacturers, covering mainstream application scenarios)

| PCB type | Quick Turn PCB assembly | Standard PCB assembly | Applicable scenarios | Key advantages and technical support |

|---|---|---|---|---|

| Single/double-sided board | 12-24 hours | 3-5 days | Smart home, consumer electronics iteration | Fully automated production line + intelligent scheduling system, support 1 piece minimum order, guarantee 99% yield rate. |

| 4-6 layer board | 24-48 hours | 5-7 days | Industrial control, medical equipment | AOI/X-RAY full inspection + ±0.025mm patch accuracy, adapt to high-frequency and high-speed signal requirements. |

| 8-12 layer boards | 48-72 hours | 7-10 days | 5G communications, automotive electronics | Laser drilling technology + HDI blind buried hole process to meet high-density interconnection and harsh environment reliability. |

| Multilayer boards above 14 layers | 72-96 hours | 10-15 days | Aerospace, high-end servers | Global supply chain direct procurement + ERP intelligent scheduling, support small batch trial production to mass production seamless switching. |

| Special process boards | 3-5 days | 7-15 days | Flexible circuits (FPC), high-frequency boards | Multi-stage lamination process + special materials (such as PTFE) to ensure signal stability and mechanical strength. |

Key comparison and user value

Efficiency advantage • Fast assembly: Delivery cycle shortened by 50%-80%, helping products to be launched 3-5 days earlier and seize market opportunities. • General assembly: suitable for non-urgent projects with limited budgets and loose cycles.

Technology and certification • Fast service providers have passed ISO 9001/IATF 16949 certification and support high-reliability fields such as medical and automotive. • Most general service providers lack a full-process quality control system, and the yield rate is only 90%-95%.

Cost and flexibility • Fast assembly: reduce component procurement costs through global supply chain integration (up to 30%), and support 24-hour emergency response. • General assembly: low cost for bulk orders, but poor flexibility and cannot adapt to emergency needs.

Why Choose SevenPCBA for for Quick Turn PCB Assembly Services ?

🔍 Eight core reasons for choosing a fast PCB assembly factory

- Extremely fast delivery cycle 24-72 hours of extremely fast production, automated production line + intelligent scheduling, seize the market opportunity.

- High-precision process guarantee ±0.025mm patch accuracy+AOI/X-RAY full inspection, yield rate exceeds 99.5%.

- Full process one-stop service Design optimization→procurement→patch→test seamless connection, saving multiple links cost.

- Flexible adaptation to small batch demand 1 piece minimum order, support R&D trial production to mass production, reduce trial and error risks.

- Global supply chain integration Direct procurement from strategic suppliers, component costs directly reduced by 30%, stable delivery time.

- Strict quality certification system ISO 9001/IATF 16949 certification, adapt to high-demand fields such as medical and automotive.

- Cost control and cost performance Copper thickness optimization + standardized design, saving material costs by 25%.

- Technical support and quick response DFM design optimization + 24-hour after-sales support, accelerating product iteration.

Conclusion

🚀 China’s high-precision PCB assembly: ultra-fast delivery empowers global electronic innovation

With the surge in demand for 5G communications and AI computing power, high-frequency and high-speed PCB assembly has become the key to success in electronic manufacturing. As the core of global PCB production capacity (accounting for more than 50%), China leads the industry innovation with military-grade technology + flexible production services.

3 Key advantages of choosing Chinese manufacturers

- 24-hour ultra-fast delivery Automated production line + intelligent scheduling system achieves 12-hour proofing of single/double-sided panels, with a delivery on-time rate of 99.9%.

- Full industry chain collaboration EDA design → 32-layer board production → AOI/X-RAY full inspection one-stop service, with a yield rate of more than 99.5%.

- Cost reduction of 30% Through copper thickness optimization and global strategic procurement, help customers such as Tesla and Mindray Medical reduce costs and increase efficiency.

Successful Cases: How SevenPCBA Breaks the Game

• Smart wearable devices: Using the 6th-order HDI process to reduce the PCB volume by 40%, and completing prototype verification in 7 days.

• Automotive electronic control: Using aluminum substrate + thick copper process to improve heat dissipation efficiency by 60% and reduce costs by 25%.