-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

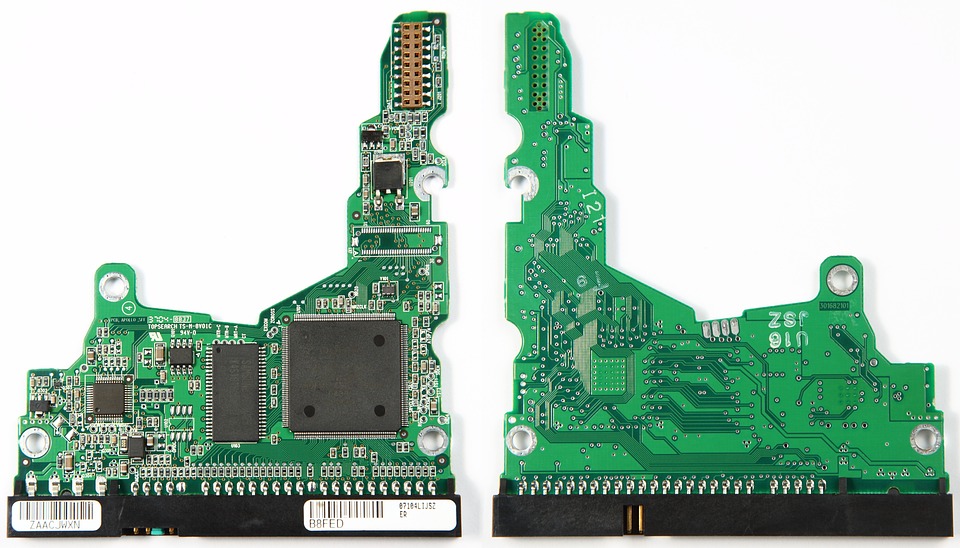

The Impact of PCB Materials on High-Speed Digital Design: A Review

[ad_1]

As the demand for faster, more efficient, and miniaturized electronic devices continues to grow, the need for high-speed digital design has become increasingly important. Printed Circuit Boards (PCBs) play a crucial role in these designs, as they are responsible for the layout and interconnection of electronic components on a board. However, selecting the right PCB material is crucial for achieving high-speed digital design and ensuring the optimal performance of these devices.

Introduction

High-speed digital design involves creating electronic devices that can operate at frequencies above 1 GHz, with signal integrity and power integrity being major concerns. The selection of a PCB material is a critical decision, as it can significantly impact the performance, reliability, and manufacturing cost of high-speed digital designs. In this article, we will review the impact of PCB materials on high-speed digital design and provide a comprehensive overview of the various options available.

The Impact of PCB Materials on High-Speed Digital Design

The choice of PCB material can affect the electrical properties of the board, such as signal integrity, power integrity, and thermal management. Different materials have different physical, electrical, and thermal properties that can impact the performance of high-speed digital designs.

Dielectric Properties

Dielectric properties, such as dielectric constant (Dk), dissipation factor (Df), and loss tangent (tan δ), play a critical role in signal integrity. The choice of PCB material can significantly impact these properties, affecting the signal delay, skew, and reflections on the board.

For example, FR4 (Flame Retardant 4) has a high Dk, which can cause signal reflections and skew, while FR5 has a lower Dk, making it a better choice for high-speed designs. Other materials, such as Rogers, offer even lower Dk and Df values, making them suitable for high-frequency applications.

Thermal Properties

Thermal management is critical for high-power devices, and PCB materials can play a significant role in thermal management. Thermal expansion, thermal conductivity, and thermal diffusivity are important thermal properties that can impact the reliability and performance of high-speed digital designs.

For example, aluminum-backed PCBs (ABP) have high thermal conductivity and can quickly dissipate heat, making them suitable for high-power devices. However, they can also experience thermal expansion, which can cause dimensional changes and affect the device’s performance.

Physical Properties

Physical properties, such as coefficient of thermal expansion (CTE), thickness, and layout, can also impact the reliability and performance of high-speed digital designs.

For example, PCBs with a high CTE can experience dimensional changes due to thermal expansion, which can cause delamination, cracking, or warpage. This can have a significant impact on the performance and reliability of high-speed digital devices.

Conclusion

In conclusion, the selection of a PCB material is crucial for achieving high-speed digital design, as it can significantly impact signal integrity, power integrity, thermal management, and physical properties. By understanding the properties of different PCB materials, designers can make informed decisions and select the optimal material for their specific application.

It is essential to evaluate the trade-offs between material properties, taking into account the specific requirements of the design, to achieve optimal performance, reliability, and cost.

FAQs

- What is the difference between FR4 and FR5? FR4 has a higher dielectric constant (Dk) than FR5, making it less suitable for high-speed designs, while FR5 is a better choice for high-frequency applications.

- What is the role of thermal conductivity in PCB materials? Thermal conductivity affects how quickly a material can dissipate heat, with high-thermal conductivity materials like aluminum-backed PCBs being suitable for high-power devices.

- How do physical properties impact high-speed digital design? Physical properties, such as coefficient of thermal expansion (CTE), thickness, and layout, can impact the reliability and performance of high-speed digital designs, as dimensional changes can cause delamination, cracking, or warpage.

- What is the importance of signal integrity in high-speed digital design? Signal integrity refers to the quality and reliability of the signals transmitted through the PCB, and is critical for high-speed digital designs, as signal reflections, delay, and skew can affect device performance.

[ad_2]