-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

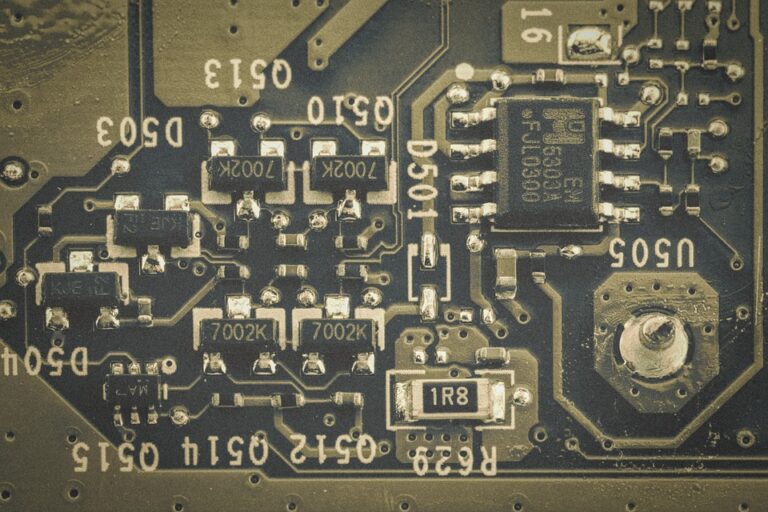

The Future of PCB Manufacturing: Trends and Predictions for 2023 and Beyond

[ad_1]

The printed circuit board (PCB) manufacturing industry has undergone significant transformations in recent years, driven by technological advancements, changes in consumer behavior, and evolving industry requirements. As we enter 2023 and beyond, it’s essential to understand the trends and predictions shaping the future of PCB manufacturing.

Trends in PCB Manufacturing

Some of the trends that will have a significant impact on the future of PCB manufacturing include:

- IoT and wearable technology:** The increasing demand for IoT and wearable devices will lead to the production of smaller, more complex, and higher-layer-count PCBs.

- Sustainable manufacturing:** The industry is shifting towards environmentally friendly practices, such as reduced waste, increased recycling, and the use of eco-friendly materials.

- Rapid prototyping:** The growing need for speed and agility will drive the adoption of rapid prototyping technologies, such as additive manufacturing and CNC machining.

- Cloud computing and automation:** The increasing adoption of cloud computing and automation technologies will improve supply chain visibility, reduce production costs, and enhance manufacturing efficiency.

- Advanced materials and substrates:** The use of advanced materials and substrates, such as flexible PCBs, high-speed substrates, and hybrid circuits, will enable the production of more complex and high-performance devices.

Predictions for 2023 and Beyond

Based on current trends and industry developments, here are some predictions for 2023 and beyond:

- Increasing adoption of PCB-as-a-Service (PCBaaS) models:** OEMs and design houses will continue to outsource PCB manufacturing, leading to a shift towards more flexible and customized PCBaaS models.

- Growth of PCBA manufacturing:** The increasing complexity of PCBAs will drive growth in PCBA manufacturing, leading to new business opportunities for suppliers and contract manufacturers.

- Increase in Asian manufacturing:** China and other Asian countries will continue to dominate PCB manufacturing, with India and other emerging markets experiencing significant growth.

- Integration of AI and machine learning:** The use of AI and machine learning will improve manufacturing efficiency, reduce waste, and enhance quality control, leading to significant improvements in productivity and profitability.

- Shift to decentralized manufacturing:** The increasing use of 3D printing, CNC machining, and other local manufacturing technologies will lead to a shift towards decentralized manufacturing, allowing for faster turnaround times and greater flexibility.

Challenges and Opportunities

While the future of PCB manufacturing holds much promise, it also presents significant challenges and opportunities. Some of the key challenges include:

- Shortages of key materials:** Supply chain disruptions, tariffs, and other factors could lead to shortages of key materials, such as copper, copper foil, and PCB materials.

- Escalating competition:** The growing number of low-cost PCB manufacturing options in Asia and other emerging markets will lead to increased competition and pricing pressures.

- Demand for skills and training:** The increasing use of automation and AI will create a need for skilled workers to operate and maintain these systems, as well as for training and development programs to upskill workers.

Conclusion

In conclusion, the future of PCB manufacturing is poised for significant change, driven by trends and predictions shaping the industry. From the adoption of IoT and wearable technology to the integration of AI and machine learning, there are many opportunities for growth, innovation, and improvement. While challenges exist, the industry’s ability to adapt and innovate will be key to success in 2023 and beyond.

FAQs

- What is the future of PCB manufacturing?** The future of PCB manufacturing is expected to be shaped by trends such as IoT and wearable technology, sustainable manufacturing, and the use of advanced materials and substrates.

- How will AI and machine learning impact PCB manufacturing?** AI and machine learning will improve manufacturing efficiency, reduce waste, and enhance quality control, leading to significant improvements in productivity and profitability.

- What are the main challenges facing PCB manufacturers?** Some of the main challenges facing PCB manufacturers include shortages of key materials, escalating competition, and demand for skills and training.

- What is the future of PCBA manufacturing?** The future of PCBA manufacturing is expected to be shaped by the increasing complexity of PCBAs, leading to new business opportunities for suppliers and contract manufacturers.

- What are the trends in sustainable manufacturing?** The industry is shifting towards environmentally friendly practices, such as reduced waste, increased recycling, and the use of eco-friendly materials.

[ad_2]