-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

SMT vs. Through-Hole: Which Component Mounting Technique is Best for Your PCB?

[ad_1]

<!DOCTYPE html>

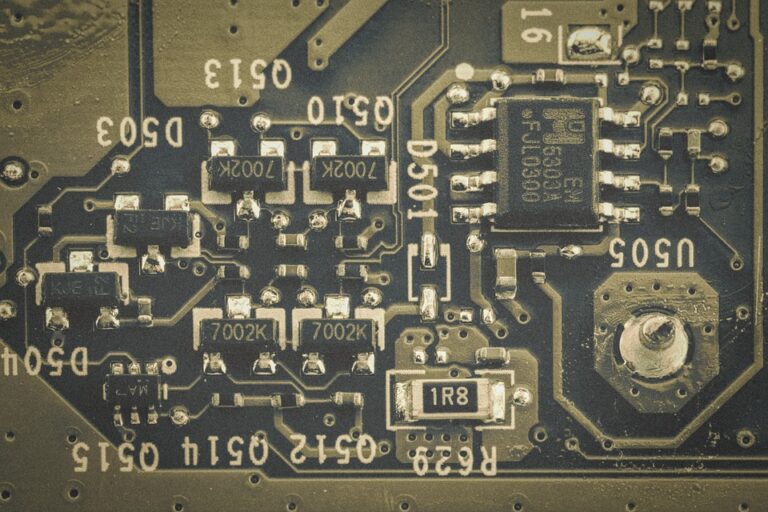

The choice between surface mount technology (SMT) and through-hole (TH) component mounting techniques is a crucial decision for any printed circuit board (PCB) design. Both methods have their advantages and disadvantages, and the right choice depends on the specific application, component requirements, and manufacturing constraints. In this article, we will explore the differences between SMT and TH, helping you make an informed decision for your next PCB design project.

**What is SMT?**

SMT is a component mounting technique where components are attached to the PCB using a soldering process. SMT uses surface mount devices (SMDs), which are components with a flat, square or rectangular shape and a metalization pattern on one side. The SMDs are placed on the PCB using a specialized pick-and-place machine, and then soldered using a reflow soldering process or a wave soldering process.

**Advantages of SMT:**

1. **Reduced space requirements**: SMT components take up less space on the PCB, making them ideal for compact designs.

2. **Higher component density**: SMT allows for a higher component density, enabling more functions to be packed into a smaller area.

3. **Faster assembly**: SMT assembly is generally faster than TH assembly, as the components can be placed quickly and easily on the PCB.

4. **Lower weight**: SMT components are typically lighter in weight, making them preferred for applications where weight is a concern.

**What is Through-Hole?**

Through-hole (TH) is a component mounting technique where components are inserted through holes in the PCB and soldered to the board on both sides. TH components are typically pins or wires with a cylindrical shape and are typically used for components like resistors, capacitors, and inductors.

**Advantages of TH:**

1. **Easy to handle**: TH components are easy to handle and assemble, as they do not require precision placement like SMDs.

2. **Robust connections**: TH connections are generally more robust, as they are soldered on both sides of the PCB.

3. **Less sensitive to handling**: TH components are less sensitive to handling errors, as they can be inserted through a hole and then soldered.

**Comparison of SMT and TH:**

| | SMT | TH |

| — | — | — |

| Component type | Surface mount devices (SMDs) | Through-hole components (THCs) |

| Assembly process | Pick-and-place and soldering | Insertion and soldering |

| Component density | Higher | Lower |

| Space requirements | Lower | Higher |

| Weight | Lower | Higher |

| Handling requirements | Higher | Lower |

**When to Choose SMT:**

1. **High-density designs**: SMT is ideal for designs that require a high component density, such as mobile devices or IoT devices.

2. **Space-constrained applications**: SMT is suitable for applications where space is limited, such as automotive electronics or aerospace.

3. **Fast assembly**: SMT assembly is the preferred choice for applications that require fast production times, such as telecommunications or consumer electronics.

**When to Choose TH:**

1. **Legacy components**: TH is the preferred choice for components that are still widely available in TH versions, such as resistors or capacitors.

2. **High-reliability requirements**: TH connections are generally more reliable, making them suitable for high-reliability applications, such as medical devices or industrial control systems.

3. **Easy assembly**: TH is the preferred choice for applications where ease of assembly is crucial, such as repair and maintenance operations.

**Conclusion:**

When designing a PCB, the choice between SMT and TH mounting techniques depends on several factors, including component requirements, space constraints, and manufacturing constraints. SMT is suitable for high-density designs, space-constrained applications, and fast assembly, while TH is ideal for legacy components, high-reliability requirements, and easy assembly. By understanding the advantages and disadvantages of each technique, you can make an informed decision for your next PCB design project.

**Frequently Asked Questions:**

Q: What is the difference between SMT and TH?

A: SMT uses surface mount devices, while TH uses through-hole components. SMT components are placed on the PCB using a pick-and-place machine, while TH components are inserted through holes in the PCB.

Q: Which is faster, SMT or TH assembly?

A: SMT assembly is generally faster, as SMT components can be placed quickly and easily on the PCB using a pick-and-place machine.

Q: Which is more reliable, SMT or TH?

A: TH connections are generally more reliable, as they are soldered on both sides of the PCB. However, SMT connections can be made reliable with proper assembly and soldering techniques.

Q: Can I use both SMT and TH components on the same PCB?

A: Yes, it is possible to use both SMT and TH components on the same PCB, but it requires careful planning and design considerations to ensure proper assembly and functionality.

I hope this article has helped you understand the differences between SMT and TH component mounting techniques and make an informed decision for your next PCB design project.

[ad_2]