-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

Printed Circuit Board Failure Analysis: How to Troubleshoot and Repair

[ad_1]

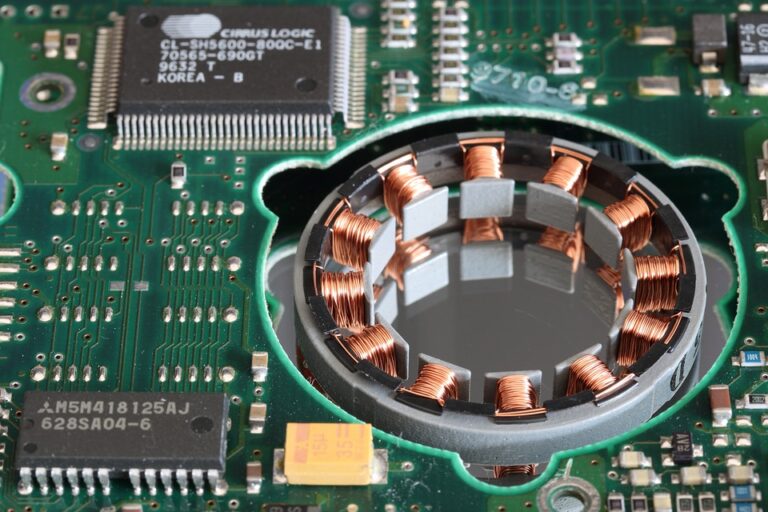

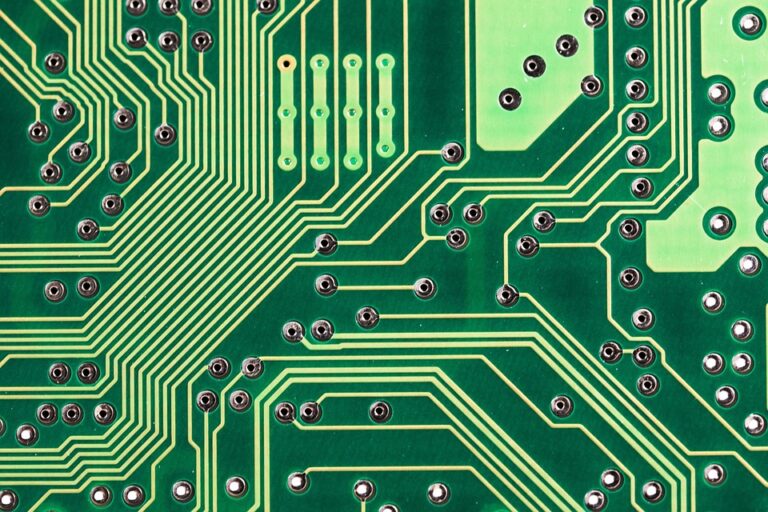

Printed Circuit Boards (PCBs) are a critical component in most modern electronic devices. They serve as the backbone of electronic circuits, connecting components such as integrated circuits, capacitors, and resistors to create a functioning system. However, PCBs can fail due to various reasons such as defects during manufacturing, contamination, poor soldering, and excessive voltage. When a PCB fails, it can cause costly downtime and disrupt production, resulting in financial losses. Therefore, it is essential to understand the causes of PCB failure and the steps involved in troubleshooting and repairing them.

In this article, we will delve into the world of Printed Circuit Board Failure Analysis, providing insights on how to troubleshoot and repair PCBs. We will cover the most common causes of PCB failure, the testing procedures used to diagnose issues, and the various techniques used to repair and salvage defective PCBs.

Causes of PCB Failure

PCBs can fail due to various reasons, including:

1. Defects during Manufacturing: PCB manufacturers can make mistakes during the fabrication process, such as misalignment of components or faulty solder joints. These defects can lead to intermittent or catastrophic failure of the board.

2. Contamination: PCBs can become contaminated during the manufacturing process, causing components to fail prematurely. Common contaminants include flux residues, acid rain, and mold.

3. Poor Soldering: Soldering defects, such as cold joints or poor heat transfer, can cause components to malfunction or fail.

4. Excessive Voltage: Overvoltage can damage or destroy PCB components, causing failure of the board.

5. Moisture Exposure: Moisture exposure can cause PCBs to become oxidized or corroded, leading to electrical shorts or failures.

6. Mechanical Stress: Physical damage or stress on PCBs, such as flexure or cracking, can cause component failure.

Troubleshooting and Repair Techniques

Troubleshooting and repair techniques for PCBs involve identifying the root cause of the failure and using appropriate repair methods. Here are some common troubleshooting and repair techniques:

1. Visual Inspection: Conduct a thorough visual inspection of the PCB to identify signs of damage or contamination.

2. Spectroscopy Analysis: Use spectroscopy techniques such as IR or UV analysis to detect the presence of contaminants or damage on the board.

3. Vibration Analysis: Perform vibration testing to identify faults caused by mechanical stress or contamination.

4. Solder Joint Testing: Test solder joints for cold joints, flux residue, or oxidation.

5. Electrical Testing: Use specialized testing equipment to measure resistance, capacitance, and other electrical parameters of PCB components.

Some common repair techniques include:

1. Resoldering: Resolder defective or corroded connections.

2. Cleanliness Treatment: Treat contaminated areas with specialized cleaning agents or solvents.

3. Mechanical Reinforcement: Add reinforcement materials or stress-relief zones to areas prone to mechanical stress.

4. Component Replacement: Replace damaged or defective components.

5. Burn-in Testing: Perform burn-in testing to verify the repaired PCB.

Consequences of Neglecting PCB Failure Analysis

Neglecting PCB failure analysis can have serious consequences, including:

1. Costly Downtime: Unresolved PCB failures can cause expensive downtime, impacting production and financial losses.

2.

3.

Conclusion

Printed Circuit Board failure analysis is a critical aspect of electronic manufacturing. By understanding the common causes of PCB failure, employing troubleshooting techniques, and utilizing repair methods, engineers and manufacturers can reduce the likelihood of failures and minimize the associated costs. Effective PCB failure analysis enables the quick and cost-effective diagnosis and repair of defects, minimizing downtime and maintaining productivity. As the use of PCBs continues to expand across various industries, the importance of PCB failure analysis will only grow, and the need for experts who can effectively troubleshoot and repair faulty PCBs will increase.

Frequently Asked Questions (FAQs)

Q: What are the most common causes of PCB failure?

A: Defects during manufacturing, contamination, poor soldering, excessive voltage, and moisture exposure are some of the most common causes of PCB failure.

Q: How do you diagnose PCB failures?

A: Common diagnostic techniques include visual inspection, spectroscopy analysis, vibration analysis, solder joint testing, and electrical testing.

Q: Can faulty PCBs be repaired?

A: Yes, most PCB failures can be repaired. The choice of repair method depends on the severity and nature of the failure.

Q: Why is PCB failure analysis important?

A: PCB failure analysis is crucial to ensuring the reliability and productivity of electronic devices. By diagnosing and repairing faults early, manufacturers can reduce downtime and associated costs.

Q: How do I ensure my PCBs are manufactured without defects?

A: Ensure your PCB manufacturer adheres to high-quality standards, maintains proper environmental conditions, and implements strict quality control measures.

[ad_2]