Solución de ensamblaje de PCB y estándares de solución de ensamblaje SMT que necesita conocer. Optimización del ensamblaje electrónico con información profesional

This write-up explores necessary PCB assembly service and SMT setting up solution ideal techniques. It gives organized, SEO-optimized, scientific‑technical assistance to streamline manufacturing, lessen issues, and improve performance and integrity. Worth analysis if you’re a PCB setting up maker or service technician aiming to raise your procedures and increase conversions.

Abstracto.

This guide outlines core PCB setting up guidelines– from style for setting up (DFA) via soldering and quality control– geared toward any PCB assembly manufacturer. It explains exactly how to take advantage of PCB assembly solution and SMT setting up solution methods to maximize your process, improve return, and lower errors. We check out essential terms, present actionable ideas, contrast options, and enhance principles with basic synonyms and long‑tail variations for search engine optimization. Anticipate tangible value, Frequently asked questions, and exterior links for additional referral.

Tabla de contenido

1. ¿Qué es el servicio de ensamblaje de PCB?

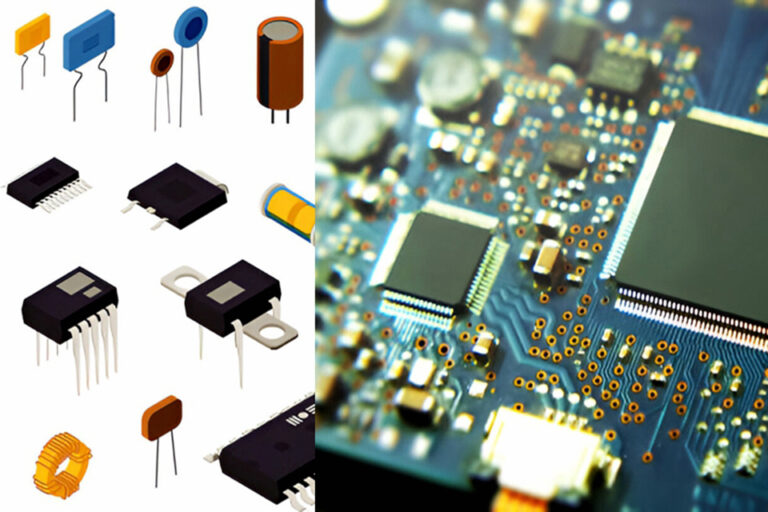

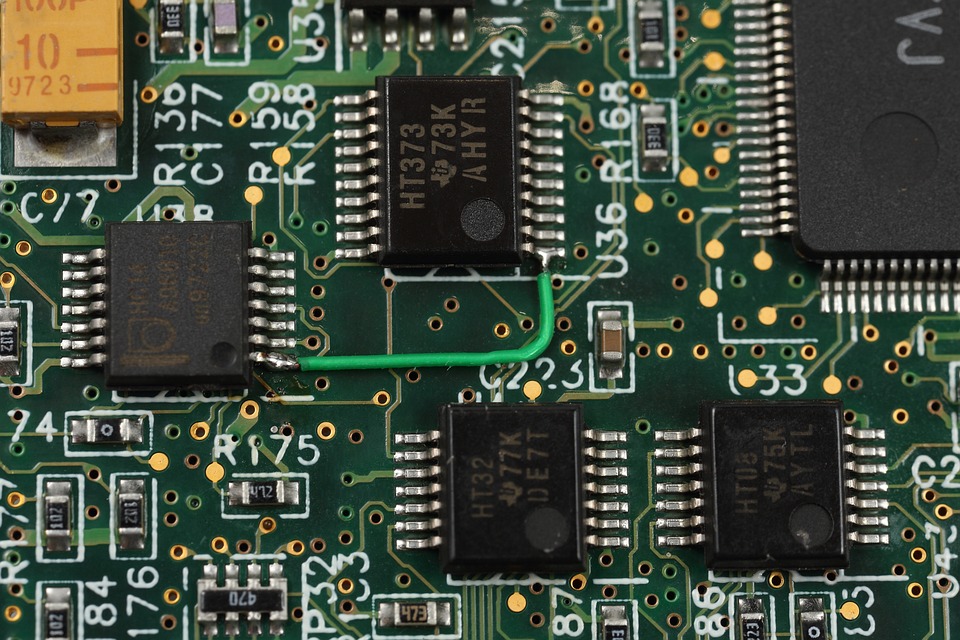

PCB assembly service describes the complete process where digital components install onto published motherboard. The service frequently includes solder paste printing, SMT part positioning, reflow soldering, and examination. A PCB setting up producer integrates accuracy equipments, quality assurance, and expertise to create useful circuit boards at scale.

Términos Clave Consistían En:.

- PCB setting up solution.

- PCB assembly manufacturer.

2. ¿Por qué elegir el servicio de ensamblaje SMT?

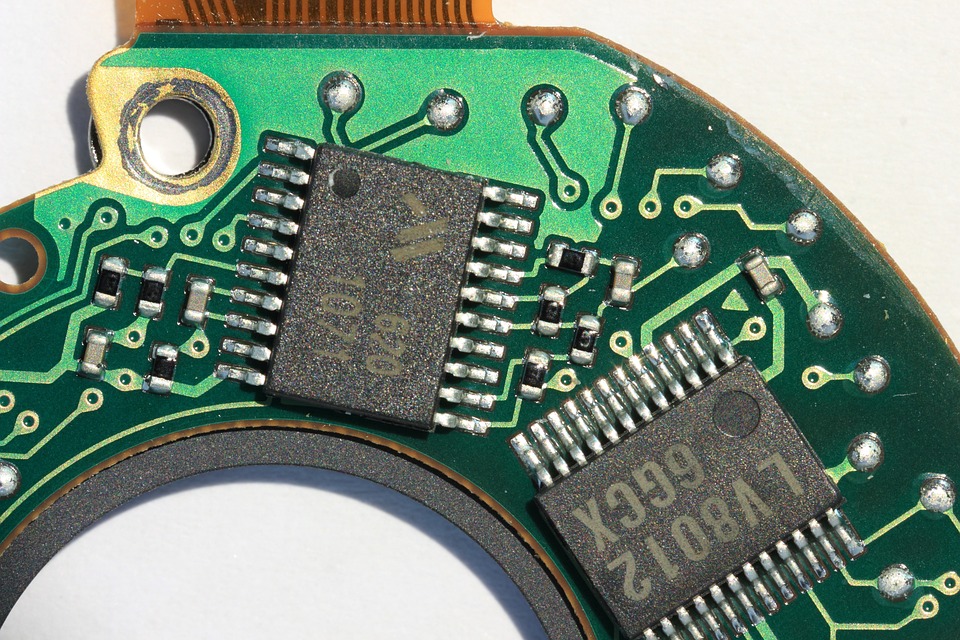

SMT setting up solution utilizes Surface Mount Modern technology to put low-profile parts directly onto PCB surfaces. This automation enhances speed, Miniaturization, and cost-efficiency. Utilizing SMT boosts consistency, especially for mass production, and sets completely with PCB setting up solution offerings.

3. ¿Cómo seleccionar un fabricante de configuración de PCB?

When selecting a PCB assembly producer, think about:.

- Tools: SMT pick-and-place speed, reflow stove areas.

- Certifications: ISO 9001, IPC-A-610.

- Capabilities: small-batch to mass PCB assembly service, BGA, micro-Via.

- Assistance: Technical appointment, DFx assistance.

A top-tier SMT setting up service masters flexibility, part sourcing, design evaluation, and traceability.

4. Diseño para el Montaje (DFA): ¿Qué Problema de Estándares?

Style for Assembly shapes just how easily a PCB setting up service can produce defect-free boards.

Comparison Table: DFA Considerations .

| Design Facet | Perks for SMT Setting Up | DFA Idea |

|---|---|---|

| Requirement Plans | Simplifies pick-and-place | Usage 0805, 1206 dimensions |

| Spacing & Clearance | Protects against collisions, boosts routing | Preserve ≥ 0.5 mm between components |

| Fiducial Markers | Ensures exact maker alignment | Place ≥ 2 fiducials per panel |

| Panelization | Simplifies manufacturing for quantity | Use rails, V-grooves, depaneling attributes |

5. Selección de piezas: ¿Qué ayuda al rendimiento?

Pick readily offered , industry-standard parts. That lowers material preparation and supply chain disruption. Consult your OEM supplier or PCB setting up service provider for sourcing tips. Use synonyms and long-tail keywords: componentes electrónicos , passive & active components , SMT elements , high-grade components .

6. Colocación de piezas: dónde van importa.

Effective placement boosts return and integrity.

- Prioritize vital orientation : LEDs, polarized capacitors, diodes.

- Team components by size/type: surface-mount components near each other, through-hole in different zones.

- Usage brief sentences, energetic voice: “Location parts to optimize air flow.”.

These approaches sustain smooth SMT setting up service.

7. Soldadura: Cómo hacer ciertas uniones fiables.

Solder paste application :.

- Use 0.1– 0.2 mm density, cover each pad equally.

- Use high‑quality stencils.

Soldadura por reflujo :.

- Use top‑mounted, 8‑zone convection ovens.

- Profile: soak → ramp → height \ ~ 240 ° C → regulated cooling.

Through-hole setting up :. Usage wave‑soldering or careful soldering. Keep larger parts evenly dispersed to avoid tomb‑stoning.

8. Garantía de Calidad: ¿Exactamente cómo mantener criterios altos?

Keep excellent quality by means of layered inspection:.

- Automated Optical Assessment (AOI) : flags missing/shifted parts.

- X‑Ray evaluation : captures concealed flaws under BGA/CSP.

- In‑Circuit Testing (ICT) : confirms connection, opens up, shorts.

- Practical Examining : tests real-world operation.

Usage Audit trails and board ID for traceability.

9. Paperwork & Traceability: Why They’re Vital.

Prepare detailed Gerber data , Lista de materiales , assembly drawings , y Pick and Place documents . These support reliable PCB setting up service and very easy error correction. Employ Statistical Process Control (SPC) tools and motivate continual improvement.

10. Resumen de las mejores prácticas para el ensamblaje de PCB.

- Use DFA: standard elements, proper spacing, fiducials.

- Embrace SMT setting up service finest practices.

- Usage automation: AOI, X‑Ray, ICT.

- Maintain documents, traceability, SPC.

- Select the ideal PCB setting up manufacturer.

- Take advantage of high-quality, practically audio procedures.

6 Preguntas frecuentes.

What’s the distinction between PCB setting up service and SMT assembly solution?

SMT assembly service is a subset of PCB assembly service– especially surface-mount components. PCB setting up consists of both SMT and through-hole procedures.

¿Qué dimensiones de paquete funcionan mejor para SMT?

Usual packages like 0805, 1206, and 0402 balance automation compatibility and component efficiency.

¿Por qué son vitales los bolígrafos fiduciarios?

They assist automated positioning machines line up the PCB precisely prior to element placement.

¿Qué técnicas de evaluación aseguran la calidad?

Combine AOI, X-ray, ICT, and useful screening to capture most defects.

Just how should I prepare my BOM?

Listing part numbers, manufacturers, bundle specs, approved replacements, and sourcing web links (e.g., Digi-Key, Mouser, Arrowhead).

How can I make sure setting up traceability?

Designate board ID numbers, track whole lot codes, and apply SPC records to trace manufacturing history.

✅ Final thought.

Taking on sophisticated PCB setting up service and SMT setting up service standards will improve production, lower errors, and raise item reliability. Concentrate on layout, element selections, solder processes, and quality assurance. The right PCB setting up producer will certainly sustain your objectives with technical resources and process quality. These steps increase your brand’s authority, increase client conversions, and foster long-lasting success.