¿Cómo ensamblar manualmente una placa PCB?

Introducción

El assembled pcb board stands for an essential skill in modern-day electronic devices producing. This extensive guide checks out hands-on PCB setting up options that enable both specialists and enthusiasts to put together digital parts properly. Recognizing correct setting up strategies guarantees trusted motherboard capability and ideal performance in electronic devices.

Guidebook PCB setting up stays essential regardless of computerized production breakthroughs. This post provides useful understandings into part placement, soldering techniques, and quality assurance steps that ensure effective job results.

Tabla de contenido

What is assembled pcb board and Why Does It Matter?

Configuración de PCB entails placing electronic elements onto published circuit boards to produce functional electronic gadgets. This procedure changes bare circuit card into working digital systems that power everything from smartphones to industrial equipment.

El setting up procedure needs accuracy and technical understanding. Elements should line up properly with marked pads. Solder joints require proper formation to make sure electric continuity. Temperature level control stops part damage throughout assembly operations.

Modern electronic devices depend heavily on effective PCB setting up services . Without correct assembly strategies, electronic devices fail to work correctly. Quality setting up procedures prolong product lifespan and improve overall dependability.

Exactly how Do You Prepare for Manual PCB Assembly?

Preparation determines assembly success rates dramatically. Proper office setup eliminates contamination risks that impact solder joint top quality. Tidy settings minimize defect prices and improve general setting up end results.

Vital prep work actions consist of arranging components systematically. Label storage space containers to avoid component mix-ups during assembly. Verify part values against schematic needs before beginning the procedimiento de montaje .

Fixed security steps stop semiconductor damage during handling. Anti-static mats and wrist bands discharge dangerous electric build-up securely. These preventative measures preserve component integrity throughout the construct treatment.

What Tools Are Important for PCB Setting Up?

Successful Configuración de PCB needs specific devices made for electronic job. Standard tool collections consist of precision cord cutters, needle-nose pliers, and temperature-controlled soldering terminals. These tools make certain precise element positioning and reputable solder connections.

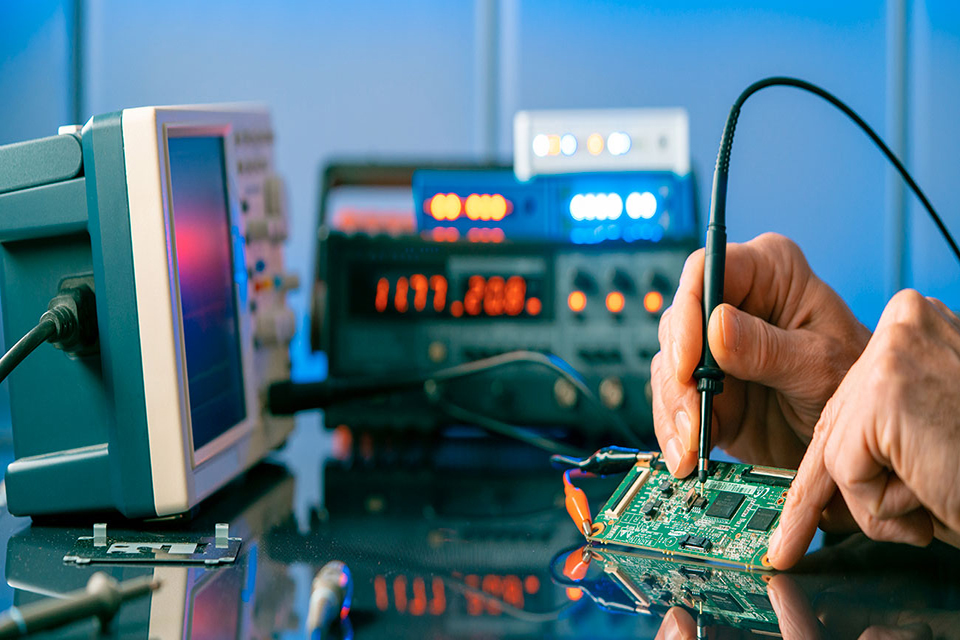

Specialized tools improves assembly capabilities considerably. Amplifying glasses or microscopes boost exposure for tiny parts. Digital multimeters verify electrical links and element values during assembly confirmation.

Remodel devices end up being needed when modifications are required. Solder wick removes excess solder successfully. Desoldering pumps essence solder from through-holes easily. These tools enable mistake modification without board damages.

Which Soldering Equipment Functions Ideal for Assembly?

Temperature-controlled soldering stations offer optimal outcomes for electronic setting up procedure operations. These systems keep consistent suggestion temperature levels that avoid part damages. Variable temperature level settings suit different element thermal requirements.

Hot air rework terminals excel at surface-mount tool assembly. These systems warm components consistently without straight get in touch with. Compatible nozzles match specific part package dimensions accurately.

Iron idea choice affects soldering high quality straight. Fine tips function well for little parts and limited spaces. Chisel pointers distribute warmth effectively for larger links. Routine idea maintenance makes certain consistent performance.

What Kind of Solder Should You Utilize?

Leaded solder alloys offer excellent circulation characteristics for manual assembly work. The 60/40 tin-lead make-up melts at about 183 ° C(361 ° F ). This temperature level range supplies great working time for precise joint development.

Lead-free choices satisfy ecological policies in business manufacturing. These alloys usually have tin, silver, and copper combinations. Higher melting temperatures need modified iron settings to prevent part damages.

Flux-core solder streamlines the proceso de configuración by getting rid of different change application. Rosin-based change gets rid of oxidation efficiently throughout heating. Appropriate ventilation avoids hazardous fume inhalation throughout soldering procedures.

How Do You Solder Through-Hole Parts Effectively?

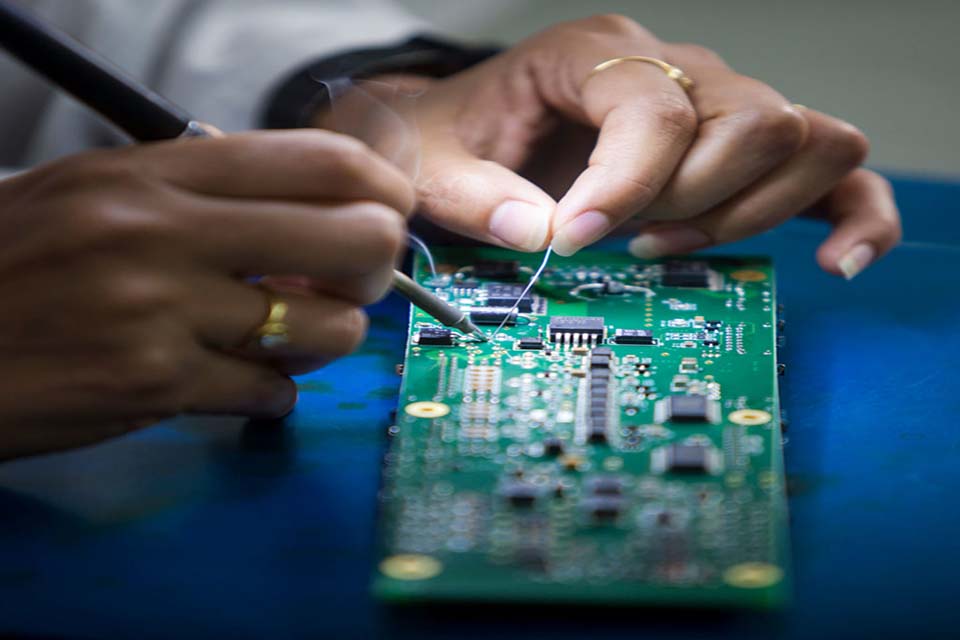

Through-hole part assembly begins with appropriate part insertion. Bend leads somewhat to secure elements throughout soldering. Avoid excessive bending that may harm part bodies or create stress and anxiety points.

Warm both the part lead and PCB pad concurrently for efficient solder joints. Apply solder to the contrary side of the iron tip. Enable solder to move entirely around the link before removing warm.

Joint look shows high quality levels precisely. Shiny, scooped fillets show appropriate heating and solder circulation. Boring or raised joints suggest inadequate warm or movement throughout air conditioning.

What Tests Exist with Two-Sided Board Assembly?

Two-sided boards call for solder penetration through layered holes completely. Insufficient home heating protects against proper opening dental filling and develops unreliable links. Adequate heat ensures solder flows to both board surfaces.

Element placement ends up being a lot more crucial with double-sided layouts. Components have to align precisely with both top and bottom pad patterns. Imbalance develops assembly troubles and potential connection failures.

Aesthetic evaluation shows more tough with two-sided assemblies. Both board surface areas require assessment for appropriate solder joint formation. Through-hole links require verification from both sides.

Just how Do You Set Up Surface Area Mount Elements?

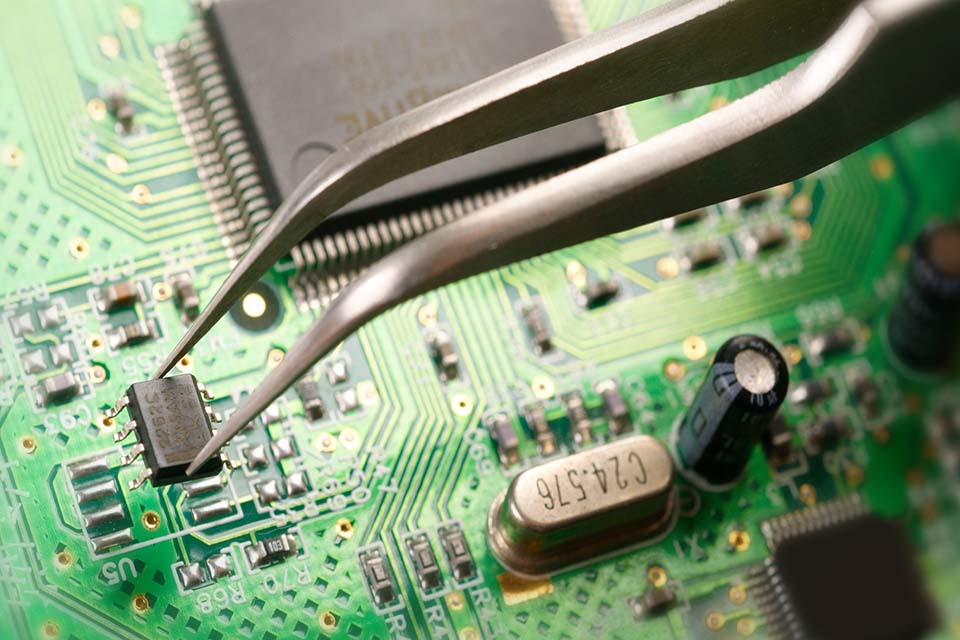

Surface-mount tool (SMD) setting up procedure needs precision and stable hands. Begin by applying little solder total up to one element pad. This method enables temporary element positioning throughout setting up.

Component alignment requires careful focus during positioning. Suit part markings with PCB silkscreen indications precisely. Misoriented components usually stop working to operate properly or damages circuits permanently.

Fine-pitch parts test hand-operated setting up abilities substantially. Hot air stations offer better results for intricate bundles. Solder paste stencils make sure constant paste application throughout numerous pads.

What Element Types Require Special Delivery?

Electrolytic capacitors require proper polarity orientation during setting up. Turned around links create part failing and potential circuit damages. Validate polarity markings very carefully before soldering components completely.

Semiconductor gadgets are sensitive to electrostatic discharge and too much warm. Manage these components minimally and make use of anti-static safety measures continually. Limitation soldering time to prevent thermal damages.

Integrated circuits in dual in-line packages typically have outward-bent leads from production. Straighten out leads thoroughly to match PCB hole spacing. Make certain appropriate alignment making use of pin-one indicators prior to assembly.

How Do You Design Effective PCB Layouts for Assembly?

Computer-aided style (CAD) software program improves PCB format creation considerably. These programs offer comprehensive element libraries and automated style regulation checking. Professional results come to be possible for enthusiast tasks.

Component placement impacts proceso de configuración difficulty considerably. Group comparable components realistically to streamline assembly workflows. Preserve appropriate spacing between parts for soldering gain access to and aesthetic evaluation.

Hole sizing needs cautious factor to consider throughout design phases. Undersized holes stop appropriate part insertion. Extra-large openings lower solder joint reliability and mechanical toughness. Validate dimensions against part specifications.

What Quality Assurance Procedures Ensure Assembly Success?

Aesthetic assessment develops the structure of quality assurance treatments. Take a look at each solder joint for appropriate development and adequate fillet size. Examine part orientation and positioning accuracy systematically.

Electrical screening confirms circuit capability after assembly conclusion. Continuity checks confirm correct connections in between circuit nodes. Resistance dimensions identify prospective brief circuits or open links.

Functional testing validates overall circuit performance under operating problems. Apply ideal power levels and input signals to verify expected outputs. Document any type of variances from spec demands.

How Do You Execute Rework When Necessary?

Part removal requires proper methods to prevent board damage. Solder wick takes in dissolved solder properly from single-sided boards. Through-hole elements need desoldering tools for clean removal.

Trace repair work becomes required when copper damage takes place during rework. Cut damaged sections easily using sharp blades. Change links using point-to-point wiring techniques with ideal gauge cable.

Pad reconstruction may be called for after part removal operations. Tidy recurring solder completely from placing areas. Apply fresh solder to bring back appropriate pad conditions before brand-new element installation.

Frequently Asked Inquiries

What is one of the most crucial factor in effective PCB setting up?

Temperature control throughout soldering operations stands for one of the most essential success element. Appropriate home heating guarantees trustworthy solder joints while avoiding element damages from extreme temperature levels.

Just how do you protect against fixed damage during setting up?

Use anti-static mats and wrist bands consistently throughout the proceso de configuración . These gadgets safely discharge static electrical energy that could damage delicate semiconductor parts.

What’s the difference in between leaded and lead-free solder for assembly?

Leaded solder moves extra easily at lower temperature levels, making hands-on setting up easier. Lead-free options

How do you deal with blunders during PCB setting up?

Usage ideal rework tools like solder wick for excess solder elimination or desoldering pumps for part replacement. Cut and change harmed traces with point-to-point wiring when required.

What parts are hardest to set up manually?

Fine-pitch surface-mount packages with closely spaced pins offer the greatest hand-operated set up challenges. These parts often need warm air terminals or specialist assembly services.

Just how do you confirm setting up high quality before powering up circuits?

Do aesthetic evaluations for proper solder joints and part positioning. Use multimeters to check connection and resistance values prior to using power to constructed boards.

Recap: Secret Details to bear in mind

El PCB setting up procedure needs careful planning, appropriate devices, and proper techniques to achieve specialist results. Hands-on set up procedures remain valuable skills for prototyping and small-scale manufacturing needs.

- PCB setting up options depend upon proper prep work and part company

- Temperature-controlled soldering tools ensures consistent outcomes

- Through-hole and surface-mount components call for various setting up methods

- Quality assurance measures avoid defects and make certain dependable procedure

- Rework capacities allow error improvement without board substitute

- Design considerations affect setting up difficulty and success rates

- Safety preventative measures shield both assembler and components during operations

- Practice and experience improve setting up speed and top quality gradually