-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

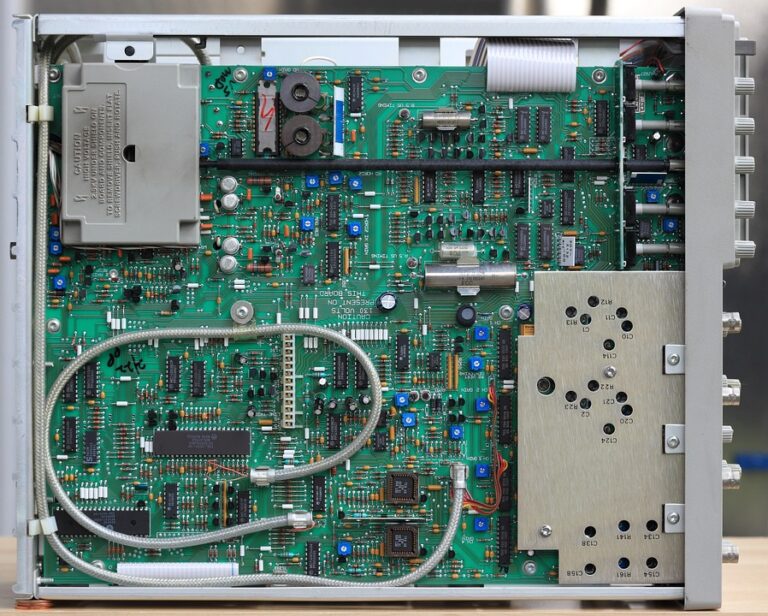

A Guide to Choosing the Right PCB Assembly Company for Your Business

[ad_1]

A Guide to Choosing the Right PCB Assembly Company for Your Business

When it comes to printed circuit board (PCB) assembly, having the right partner can make all the difference in successfully bringing your product to market. With so many PCB assembly companies to choose from, it can be overwhelming to determine which one is best for your business. In this guide, we’ll walk you through the key factors to consider when selecting a PCB assembly company, ensuring you find the right partner for your needs.

1. Industry Expertise and Specialization

Before selecting a PCB assembly company, it’s crucial to evaluate their experience and specialization in your industry or niche. Companies that have a proven track record in your industry will likely bring valuable knowledge and insight to the table. Consider the following questions when assessing a company’s expertise:

- Does the company have experience working with similar products or industries as yours?

- Have they successfully assembled PCBs for other companies in your specific sector?

- Do they have in-house expertise in specialized technologies, such as high-speed design or rigid-flex construction?

Having a company with relevant industry expertise can help you avoid costly delays, reduce risks, and ensure your product meets the necessary regulatory requirements.

2. Quality Control and Compliance

Quality control is vital in the PCB assembly process. When evaluating potential partners, consider the following quality control measures:

- Do they have a robust quality control process in place, including design for manufacturability (DFM) and failure mode and effects analysis (FMEA)?

- Are they ISO 9001:2015 certified, indicating their commitment to quality management systems?

- Do they have a cleanroom environment and rigorous testing procedures to ensure the quality of their PCBs?

A company with a strong quality control system will help you ensure your PCBs meet your standards and are free from defects, thereby reducing the risk of product recalls and rework.

3. Capabilities and Resources

Consider the company’s capabilities and resources when selecting a PCB assembly partner. Ask yourself:

- What are their production capacities and lead times? Is their capacity scalable to meet your needs?

- Do they have in-house expertise in design for manufacturing (DFM), allowing them to optimize your design for high-volume production?

- Are they equipped with state-of-the-art equipment and technology, such as automatic optical inspection (AOI) and x-ray inspection systems?

A company with the necessary capabilities and resources can help you bring your product to market faster, reduce costs, and maintain quality standards.

4. Communication and Accountability

Open and transparent communication is crucial in any partnership. Look for a company that:

- Provides regular updates and progress reports throughout the production process

- Is transparent about their processes, including any changes or delays that may affect your project

- Takes ownership of quality issues and is proactive in addressing and resolving them

Good communication and accountability can minimize misunderstandings, reduce stress, and ensure your project stays on track.

5. Flexibility and Adaptability

Your business needs may change, and your PCB assembly partner should be able to adapt. Look for a company that:

- Offers flexible production schedules and capabilities to accommodate changing market demands

- Is willing to work with you to develop a customized production plan that meets your specific needs

- Can pivot quickly to respond to changes in your project requirements

A flexible and adaptable partner can help you stay competitive and respond to changes in the market.

Conclusion

By considering these factors when selecting a PCB assembly company, you can ensure a successful partnership that meets your business needs. Remember to evaluate the company’s industry expertise, quality control and compliance, capabilities and resources, communication and accountability, and flexibility and adaptability. With the right partner, you can bring your product to market faster, reduce costs, and maintain quality standards.

FAQs

What is the best way to evaluate a PCB assembly company’s expertise?

Assess their experience working with similar products or industries as yours, and ask for references from previous clients in your sector.

What are the most important quality control measures to look for in a PCB assembly company?

Look for ISO 9001:2015 certification, a robust quality control process, and rigorous testing procedures to ensure the quality of their PCBs.

How can I determine if a PCB assembly company has the necessary capabilities and resources?

Ask about their production capacities, lead times, and in-house expertise in design for manufacturing (DFM), as well as the equipment and technology they use.

What is the key to effective communication and accountability with a PCB assembly company?

Regular updates and progress reports, transparency about processes, and a proactive approach to addressing and resolving quality issues are crucial for a successful partnership.

CAN I TRUST MY PCB ASSEMBLY PARTNER WITH MY TRADE SECRETS?

You should consider the company’s non-disclosure agreement (NDA) and intellectual property (IP) protection policies before sharing sensitive information.

Note: This article is provided in HTML format, but you can convert it to any other format (e.g., Markdown, Text) as needed.

[ad_2]