-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

The Benefits of SMT vs. Through-Hole Mounting: Which is Right for Your PCB?

[ad_1]

SMT (Surface Mount Technology) vs. Through-Hole Mounting: Which is Right for Your PCB?

Introduction

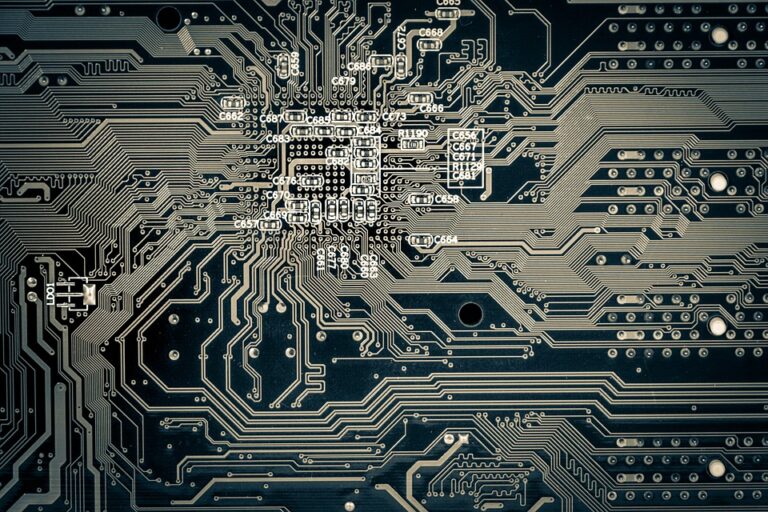

In the world of printed circuit boards (PCBs), two main mounting technologies dominate the scene: Surface Mount Technology (SMT) and Through-Hole Mounting. While both methods have their advantages and disadvantages, choosing the right one for your project can make all the difference. In this article, we’ll delve into the benefits of SMT and compare them to those of Through-Hole Mounting, helping you make an informed decision for your PCB.

Benefits of SMT

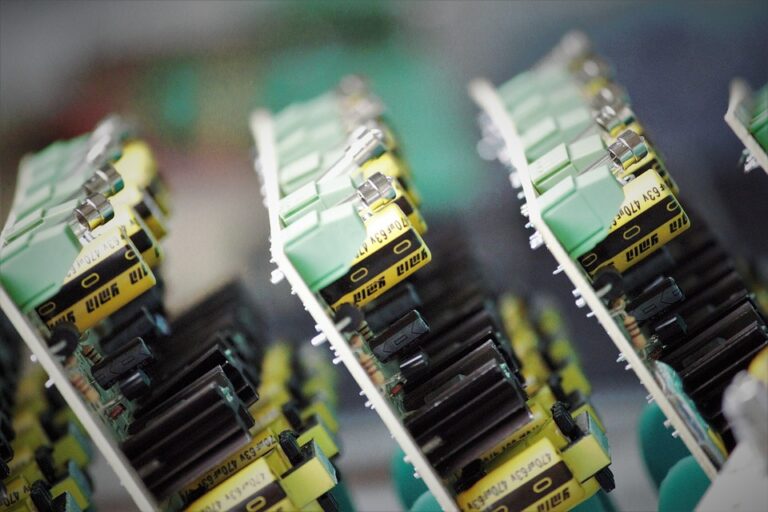

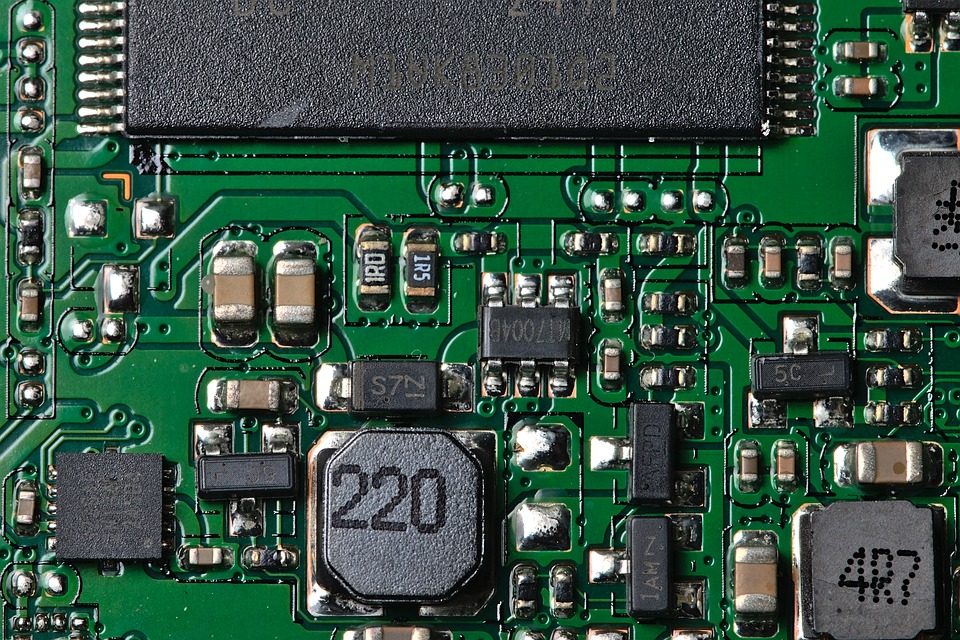

SMT, also known as surface mount assembly, involves mounting components directly onto the surface of the PCB, rather than inserting them through holes. This method offers several benefits that have contributed to its widespread adoption in modern electronics.

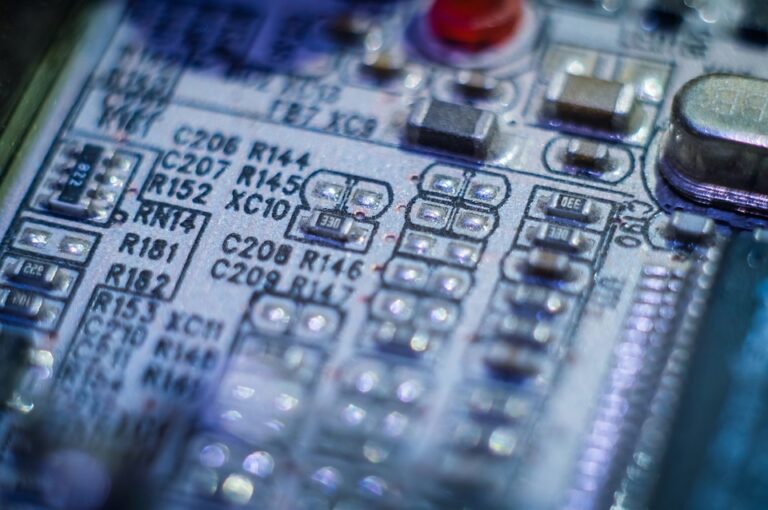

- Increased Density: SMT allows for a much higher component density, enabling smaller PCBs with increased functionality. This is because surface-mount components take up less space than their through-hole counterparts.

- Faster Assembly: SMT components are easily placed on the PCB using a pick-and-place machine, making the assembly process significantly faster and more efficient. This leads to reduced production times and costs.

- Lower Profile: The smaller size and flat profile of SMT components result in a lower overall profile for the PCB, making them ideal for applications where space is limited, such as in wearable electronics or consumer gadgets.

- Improved Thermal Dissipation: SMT components tend to have better thermal dissipation than through-hole components, as the heat can dissipate more efficiently through the PCB’s surface. This is crucial for components that generate a significant amount of heat, such as power supplies or high-power amplifiers.

- Cost Savings: SMT components are generally cheaper than through-hole components, due to the lower material costs and reduced labor requirements for assembly.

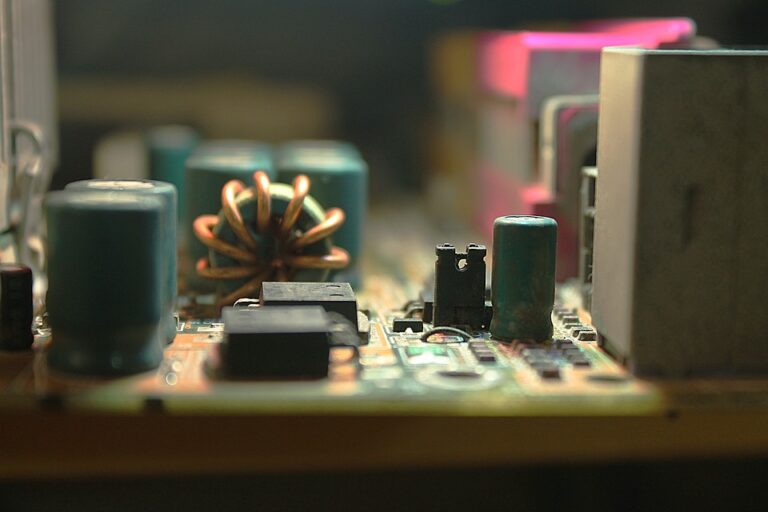

Benefits of Through-Hole Mounting

Despite the rise of SMT, through-hole mounting still has its advantages and applications where it is the better choice.

- Ease of Repair: Through-hole components are often easier to repair or replace, as they can be desoldered and removed without damaging the surrounding circuitry. This is particularly important for critical applications where maintenance is a high priority.

- Ruggedness and Durability: Through-hole components are generally more rugged and less prone to damage, as they are anchored securely to the PCB and less susceptible to vibration or impact.

- Simpler PCB Design: Through-hole components allow for simpler PCB designs, as the components can be placed in a more traditional “breadboard” layout, reducing the need for complex surface-mounted components and minimizing the risk of component-to-component shorts.

Comparing SMT and Through-Hole Mounting

While both SMT and through-hole mounting have their strengths and weaknesses, SMT is generally the preferred choice for modern PCBs. SMT’s benefits in terms of increased density, faster assembly, and cost savings make it an attractive option for many applications.

However, through-hole mounting still has its place in certain situations. For example, applications that require ease of repair, ruggedness, or simplicity may benefit from the use of through-hole components.

Conclusion

In conclusion, SMT offers several benefits that make it a popular choice for modern PCBs. From increased density and faster assembly to lower profile and improved thermal dissipation, SMT is a well-rounded technology that has become an essential part of the electronics industry.

That being said, through-hole mounting still has its advantages and applications where it is the better choice. When deciding which technology to use for your PCB, it’s essential to consider the specific requirements of your project, including the level of complexity, reliability, and maintenance needs.

By weighing the benefits of SMT and through-hole mounting, you can make an informed decision that ensures the success of your project and meets the demands of your customers.

| FAQs |

|---|

Frequently Asked Questions

- Q: What is the main difference between SMT and through-hole mounting? A: The main difference is that SMT components are mounted directly onto the surface of the PCB, while through-hole components are inserted through holes in the PCB.

- Q: Which technology is more expensive? A: Through-hole mounting is generally more expensive than SMT, due to the higher material costs and longer assembly times.

- Q: Can I mix SMT and through-hole components on the same PCB? A: Yes, it is possible to mix SMT and through-hole components on the same PCB, but this may require special consideration during design and assembly to ensure proper functioning and reliability.

- Q: Are SMT components more prone to failure than through-hole components? A: Generally, SMT components are not more prone to failure than through-hole components, but their small size and thin leads can make them more susceptible to damage or fatigue under certain conditions.

By understanding the benefits and drawbacks of SMT and through-hole mounting, you can make informed decisions about the technology to use for your PCBs and ensure the success of your projects.

[ad_2]