Montagem de placa de circuito: Guia avançado de fabricação de PCB 2025

Introdução

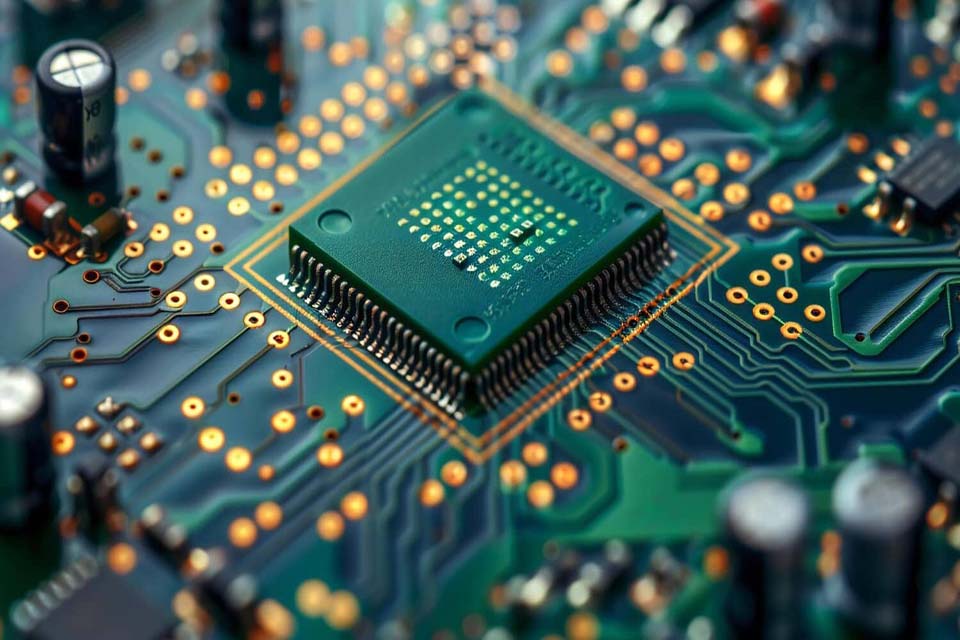

Circuit card assembly represents the foundation of modern electronic devices producing. This comprehensive procedure transforms bare published motherboard right into useful digital systems. Engineers and suppliers count on sophisticated circuit card assembly techniques to develop reputable digital tools. The sector needs accuracy, effectiveness, and quality assurance throughout every setting up phase. Comprehending circuit card setting up basics makes it possible for far better decision-making in electronics production. This overview checks out sophisticated production processes, quality requirements, and sector ideal methods for optimum results.

Tabela de Conteúdo

What Specifies Circuit Card assembly in Modern Electronics?

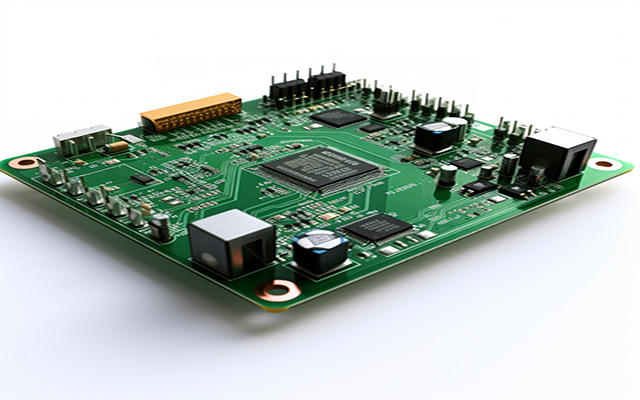

Circuit card assembly incorporates the systematic assimilation of peças eletrônicas onto published circuit boards. This process develops useful digital circuits with specific component positioning and soldering techniques. Modern circuit card assembly uses advanced manufacturing devices to accomplish constant results. The process begins with bare PCB substrates and finishes in completely operational digital modules.

Contemporary circuit card setting up techniques stress automation and accuracy. Designers style setting up sequences to enhance production performance while maintaining top quality criteria. Advanced placement equipments setting components with micron-level accuracy. Soldering procedures create dependable electric links between components and PCB traces.

The development of circuit card setting up mirrors technical advancement in electronic devices manufacturing. Miniaturization patterns drive advancements in component placement and affiliation techniques. Modern setting up methods accommodate increasingly intricate circuit layouts and greater part thickness.

How Does PCB Circuit Setting Up Differ from Typical Approaches?

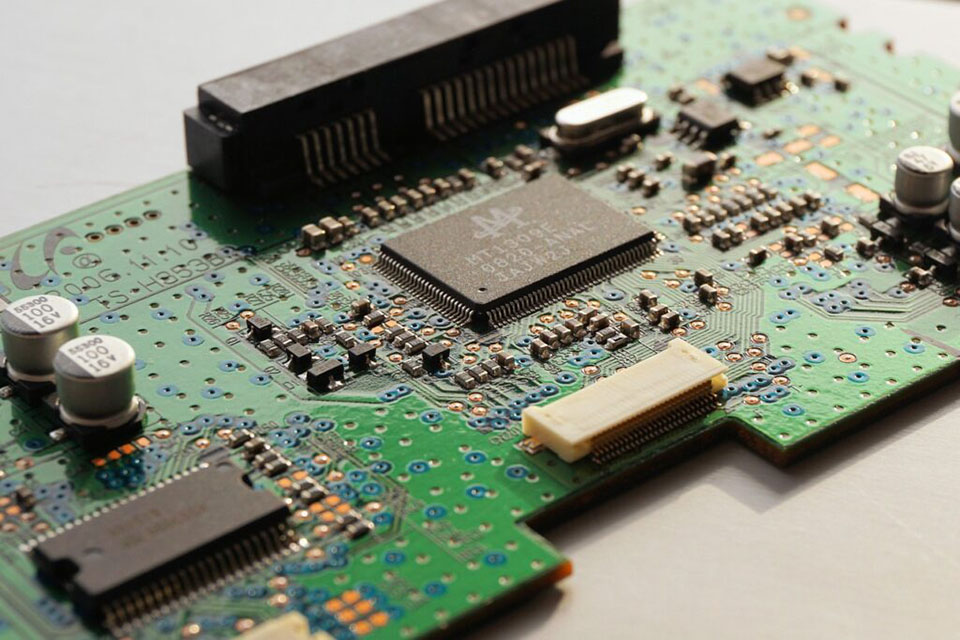

PCB circuit setting up reinvents electronics making through standardized processes and automatic production. Standard setting up methods depended greatly on manual labor and point-to-point circuitry techniques. Modern PCB circuit setting up uses innovative machinery for element placement and soldering operations.

Automated PCB circuit assembly systems achieve premium uniformity contrasted to hands-on techniques. Pick-and-place makers placement parts with remarkable precision and rate. Reflow ovens develop uniform solder joints across whole circuit card simultaneously. These breakthroughs substantially lower manufacturing problems and manufacturing expenses.

Quality control in PCB circuit setting up goes beyond traditional manufacturing abilities. Automated optical evaluation systems find defects unnoticeable to human drivers. X-ray examination discloses surprise solder joint concerns in complex assemblies. Statistical procedure control keeps track of manufacturing parameters continuously.

Which Components Are Necessary for Circuit Card Manufacturing?

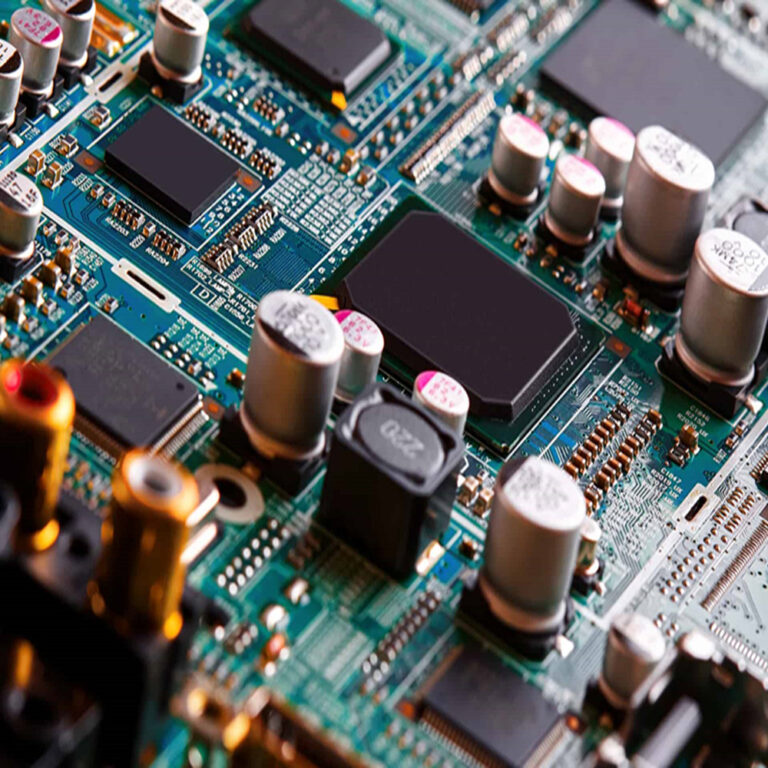

Circuit card manufacturing integrates diverse electronic elements to attain desired functionality. Easy parts include resistors, capacitors, and inductors that supply standard circuit functions. Energetic components such as integrated circuits, transistors, and diodes make it possible for signal handling and amplification.

Surface mount elementos control modern-day circuit card setting up as a result of their small dimension and efficiency advantages. These elements place straight onto PCB surface pads without needing through-holes. Chip resistors, ceramic capacitors, and ball grid selection cpus represent common surface mount elements.

Through-hole parts stay crucial for specific circuit card setting up applications. These parts place through PCB holes and solder to both sides of the board. Connectors, transformers, and high-power parts frequently utilize through-hole placing for mechanical stability.

What Are the Trick Presents in the Circuit Card Setting Up Process?

Circuit card setting up adheres to systematic phases to ensure constant production top quality. The procedure starts with solder paste application using accuracy patterns. Precise paste deposition creates the structure for trustworthy solder joints. Display printing or estêncil printing methods distribute paste evenly throughout component pads.

Part placement stands for the following critical point in circuit card setting up. High-speed pick-and-place equipments setting parts according to programmed works with. Vision systems verify part alignment and placement precision. This phase calls for cautious programming to suit various component types and dimensions.

Soldagem por refluxo finishes the key setting up process for surface area mount parts. Regulated temperature level profiles melt solder paste and create long-term connections. Thermal profiling ensures optimum soldering conditions throughout the entire circuit card. Cooling phases strengthen solder joints and complete the electric connections.

Exactly How Do Surface Area Mount and Through-Hole Technologies Compare?

Surface install innovation dominates modern circuit card setting up as a result of several advantages. SMT elementos require much less PCB realty, allowing higher circuit thickness. Automated positioning equipment manages surface area place elements more successfully than through-hole alternatives. Cost benefits make SMT attractive for high-volume manufacturing.

Through-hole modern technology keeps significance for details circuit card setting up needs. Mechanical connections in through-hole assemblies supply remarkable toughness for stress-prone applications. Warm dissipation attributes prefer through-hole mounting for high-power parts. Revamp and fix operations confirm easier with through-hole elements.

Mixed-technology circuit card setting up incorporates both placing methods strategically. Important components may make use of through-hole installing for dependability while basic components use surface area place technology. This method maximizes both efficiency and producing effectiveness. Style engineers pick placing technologies based upon certain application requirements.

What Quality Assurance Measures Make Sure Reliable Circuit Card Assembly?

Quality assurance systems check every element of circuit card assembly manufacturing. Inbound assessment confirms component specs and PCB quality prior to setting up begins. Statistical sampling strategies make sure depictive top quality analysis without 100% inspection expenses. Vendor credentials programs keep regular element top quality.

In-process tracking finds setting up issues during production phases. Automated optical examination systems examine solder paste down payments after screen printing. Post-placement evaluation confirms part presence, positioning, and placing accuracy. Real-time feedback allows immediate process modifications.

Final inspection and testing confirm finished circuit card setting up capability. Automated test equipment performs electric parameter confirmation. In-circuit testing checks individual part values and circuit continuity. Functional screening makes certain appropriate procedure under specified conditions.

Which Industries Advantage The Majority Of from Advanced PCB Circuit Assembly?

Aerospace sectors demand highest-reliability circuit card setting up for mission-critical applications. Extensive credentials processes guarantee settings up endure extreme environmental problems. Advanced products and processes fit temperature extremes and resonance requirements. Traceability systems track every component throughout the setting up procedure.

Clinical gadget production needs specialized circuit card setting up techniques. Biocompatible materials and contamination control procedures make sure patient safety. Regulative compliance drives documents and recognition needs. Miniaturization allows implantable gadget development and portable diagnostic devices.

Automotive electronic devices use durable circuit card setting up methods for severe operating environments. Temperature cycling, resonance, and moisture resistance specify automobile setting up demands. Advanced vehicle driver help systems require high-reliability circuit assemblies. Electric vehicle applications need high-power circuit card assembly abilities.

Exactly How Do Automated Systems Improve Circuit Card Production Efficiency?

Automated circuit card setting up systems drastically raise production throughput while maintaining high quality uniformity. High-speed positioning equipments placement hundreds of elements per hour with extraordinary accuracy. Parallel handling capacities make it possible for synchronised operations on numerous circuit card. Lowered labor demands reduced production prices significantly.

Versatile automation adapts to differing manufacturing requirements in circuit card assembly operations. Quick changeover capabilities fit various item blends effectively. Programmable machinery handles varied component kinds and assembly arrangements. Modular system designs allow ability scaling based on demand fluctuations.

Information collection and evaluation maximize automated circuit card setting up efficiency. Real-time tracking systems track vital performance signs continually. Anticipating maintenance stops unexpected downtime and prolongs equipment life. Statistical process control determines trends and makes it possible for proactive modifications.

What Typical Obstacles Affect Circuit Card Assembly Procedures?

Component availability difficulties effect circuit card setting up scheduling and costs. Supply chain disruptions develop supply scarcities and shipment hold-ups. Obsolescence problems call for design modifications and certification initiatives. Phony components pose quality and dependability risks requiring cautious vendor administration.

Thermal management ends up being progressively essential in dense circuit card assembly designs. Warmth generation from high-performance parts calls for efficient dissipation strategies. Thermal profiling makes certain optimum soldering problems without component damages. Advanced materials and style strategies deal with thermal difficulties successfully.

Quality defects in circuit card setting up come from different resources needing systematic evaluation. Solder joint flaws might result from incorrect thermal accounts or contamination issues. Part placement mistakes take place as a result of setting blunders or devices calibration issues. Refine optimization calls for constant tracking and improvement initiatives.

How Will Future Technologies Transform PCB Circuit Setting Up?

Expert system combination promises innovative improvements in circuit card setting up procedures. Artificial intelligence algorithms optimize procedure criteria immediately based on historical information. Anticipating analytics allow aggressive upkeep and quality assurance measures. Computer vision systems enhance problem detection capacities past human limitations.

Advanced materials development allows next-generation circuit card assembly applications. Adaptable substrates fit wearable electronic devices and conformal styles. High-temperature products sustain extreme atmosphere applications. Installed component innovations incorporate passive elements within PCB substratums.

Industry 4.0 ideas transform circuit card assembly into totally attached wise production systems. IoT sensors give real-time production visibility and control capacities. Cloud-based analytics allow global optimization across multiple manufacturing websites. Digital twin technologies make it possible for virtual process optimization and troubleshooting.

Often Asked Concerns

What is the distinction between circuit card assembly and PCB manufacturing?

PCB production creates the bare published circuit board substratum, while circuit card setting up mounts digital components onto the PCB to produce useful circuits. Circuit card assembly is the succeeding process that transforms bare boards into operational digital components.

The length of time does typical circuit card setting up take?

Circuit card setting up time differs based on complexity, element count, and production volume. Straightforward settings up might complete in minutes, while complex multilayer boards with hundreds of elements need a number of hours. Automated production lines considerably decrease assembly time compared to manual methods.

What elements influence circuit card assembly cost?

Assembly prices depend on component complexity, board dimension, manufacturing quantity, and top quality requirements. High-mix, low-volume production typically costs even more each than high-volume runs. Element costs, labor rates, and equipment application likewise affect overall setting up expenditures.

Can circuit card assembly accommodate both SMT and through-hole components?

Yes, mixed-technology circuit card assembly commonly incorporates surface install and through-hole components on the same board. This method enhances both efficiency and cost by choosing suitable mounting methods for each part type based upon specific demands.

What quality criteria apply to circuit card setting up?

IPC standards specify circuit card setting up high quality needs, consisting of IPC-A-610 for acceptability requirements and IPC-J-STD-001 for soldering processes. Industry-specific requirements such as AS9100 for aerospace and ISO 13485 for clinical gadgets enforce added demands.

How do I select a circuit card setting up provider?

Examine prospective suppliers based on technical abilities, top quality qualifications, manufacturing capability, and industry experience. Consider factors such as component sourcing abilities, screening tools, distribution performance, and price competition. Demand examples and carry out center audits when feasible.

Recapitular

Circuit card assembly stands for a foundation innovation in modern-day electronics producing. Understanding PCB circuit setting up processes enables informed decision-making throughout item advancement cycles. Quality assurance measures make sure reliable efficiency throughout diverse application needs. Automation continues driving performance renovations while maintaining accuracy and uniformity.