-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

SMT vs. thru-Hole: The Pro and Cons of Each PCB Assembly Technique

[ad_1]

PCB (Printed Circuit Board) assembly is a crucial step in the production of electronic devices. Over the years, the industry has witnessed two popular techniques used for PCB assembly: Surface Mount Technology (SMT) and Thru-Hole (TH). Each technique has its advantages and disadvantages, which are crucial for designers, manufacturers, and end-users to consider. In this article, we’ll delve into the world of PCB assembly and explore the pros and cons of SMT and TH.

SMT: The Pros

Advantage 1: Higher Component Density

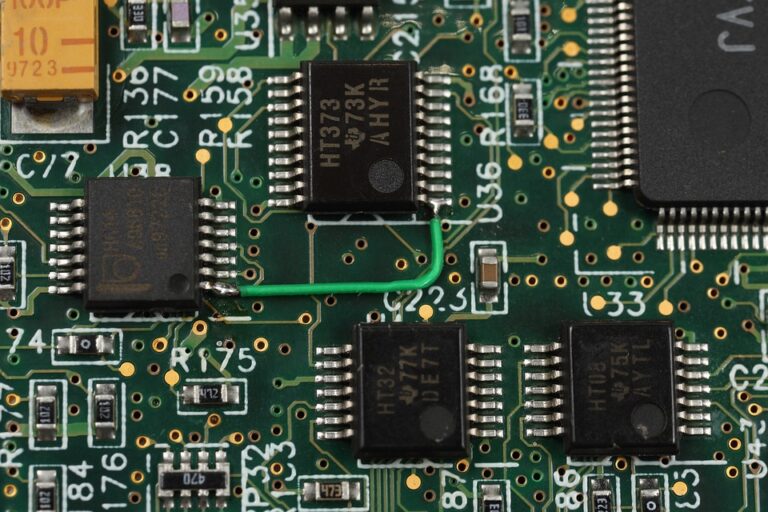

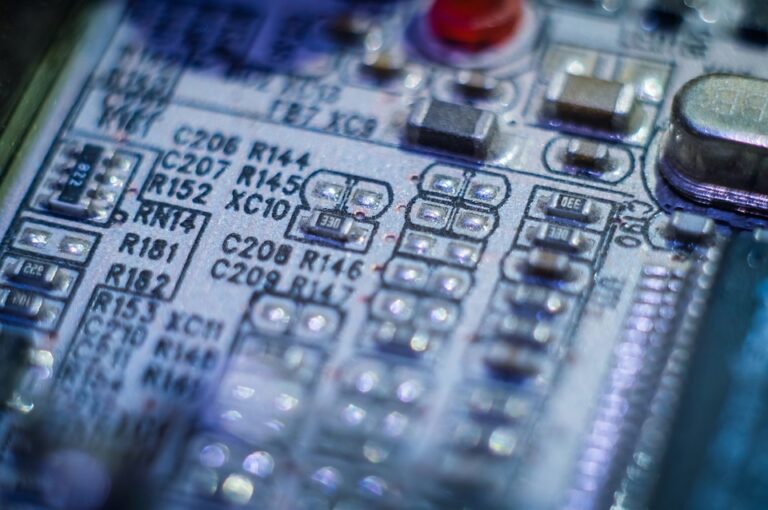

SMT allows for a significantly higher component density on the PCB. This is because SMT components are smaller and more compact compared to TH components, enabling more components to be placed on a single PCB. This increased component density enables designers to create smaller, more powerful devices with improved performance.

Advantage 2: Reduced Weight and Size

SMT components are also much lighter and smaller than TH components, making PCBs with SMT components more compact and portable. This is particularly beneficial for applications where size and weight are critical, such as in mobile devices, wearables, or IoT gadgets.

Advantage 3: Lower Production Costs

SMT PCB assembly is often less expensive than TH assembly. This is due to the following factors: (1) lower component costs, (2) reduced labor costs, and (3) increased efficiency in the assembly process. This results in lower production costs, making SMT a cost-effective option for designers and manufacturers.

Advantage 4: Improved EMI Performance

SMT components are less prone to electromagnetic interference (EMI) due to their smaller size and reduced lead length. This leads to a cleaner signal and improved EMI performance, essential for high-frequency applications or noise-sensitive devices.

SMT: The Cons

Disadvantage 1: Lead Time and Cost for Assembly

SMT component assembly often requires specialized equipment and trained technicians, increasing lead times and costs. This can be a significant barrier for designers and manufacturers with limited resources or experience in SMT assembly.

Disadvantage 2: Quality Control Challenges

SMT components can be more difficult to inspect and test due to their smaller size and the need for precision bending and assembly. This can pose quality control challenges, as defects may go undetected during testing and inspection.

Disadvantage 3: Component Counting and Tracing Difficulties

SMT components, with their small size and tiny leads, can be challenging to count and trace during assembly. This can result in errors and part number mismatches, leading to costly rework and delayed production.

TH: The Pros

Advantage 1: Simpler Assembly Process

TH components are larger and easier to handle, making the assembly process less labor-intensive and more straightforward. This results in reduced labor costs and faster production times.

Advantage 2: Easier Component Inspection and Testing

TH components are larger and easier to inspect and test, reducing quality control challenges and ensuring a higher level of accuracy during testing and inspection.

Advantage 3: Component Counting and Tracing Easier

TH components are larger and have longer leads, making component counting and tracing simpler and more reliable, reducing the risk of errors and part number mismatches.

Advantage 4: Familiarity and Ease of Use

Many designers and manufacturers are already familiar with TH technology, making it a more comfortable choice for those without extensive experience in SMT assembly. This familiarity can reduce training requirements and streamline the production process.

TH: The Cons

Disadvantage 1: Larger PCB Size

TH components require more space on the PCB, resulting in larger overall size and weight. This can be a limitation for applications where size and weight are critical, such as in mobile devices or wearables.

Disadvantage 2: Higher Component Costs

TH components are generally more expensive than SMT components, primarily due to their larger size, material usage, and assembly requirements. This can increase production costs and limit profit margins for designers and manufacturers.

Disadvantage 3: Signal Attenuation and EMI Issues

TH components can generate more EMI and signal attenuation due to their larger size and longer leads, potentially affecting the performance and reliability of the PCB.

Conclusion

In conclusion, both SMT and TH PCB assembly techniques have their strengths and weaknesses. SMT offers advantages in component density, weight, and size, as well as lower production costs. However, SMT assembly can be more challenging, with quality control, component counting, and tracing difficulties. TH, on the other hand, is simpler to assemble and test, with easier component inspection and counting, but larger PCB sizes, higher component costs, and potential signal attenuation and EMI issues.

Ultimately, the choice between SMT and TH will depend on the specific design and manufacturing requirements, as well as the expertise and resources available to the design team. Careful consideration of these factors will ensure the best possible outcome for the final product.

FAQs

Q: What is the typical cost difference between SMT and TH?

The cost difference between SMT and TH can vary depending on the components used, assembly method, and geographic location. However, a general estimate would be a 10-20% difference in favor of SMT components.

Q: What is the typical size difference between SMT and TH components?

SMT components are usually 70-90% smaller than TH components, depending on the specific type and application.

Q: How do I determine whether to use SMT or TH?

Determine the design requirements, manufacturing resources, and expertise. If space and weight are critical, SMT might be a better choice. If simplicity and ease of assembly are key, TH might be a better fit.

[ad_2]