SMD vs THT: Qual è il migliore per il tuo PCBA?

Recap:

SMD vs THT:Picking between Surface Area Mount Gadget (SMD) and Through-Hole Modern Technology (THT) is a pivotal decision in semiconductor PCB assembly layout. This post discovers the advancement of PCB manufacturing, compares SMD vs THT, and provides actionable assistance for optimizing your PCB layout. Whether you are creating high-performance semiconductor boards or consumer electronic devices, understanding these innovations will help you attain trusted, economical, and scalable results.

Why Read This Post? . This comprehensive overview will assist you make informed decisions regarding PCB assembly, enhance your design’s manufacturability, and boost your product’s performance. By the end, you’ll know how to choose the best technology for your next task and optimize your PCB production performance.

Sommario

Introduzione all'impostazione del PCB e allo sviluppo del design.

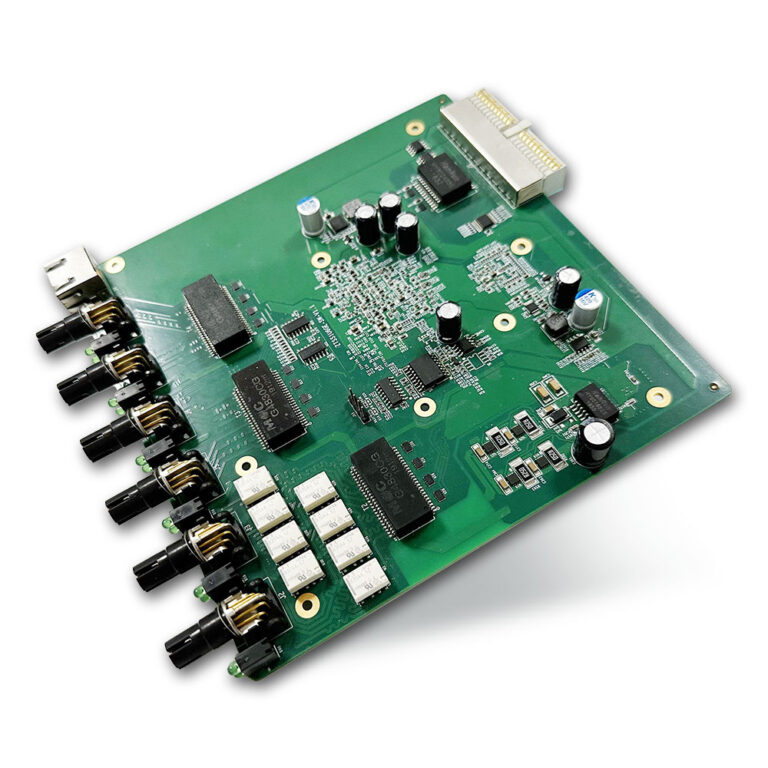

Printed circuit board (PCB) setting up has transformed considerably over the previous decades. As electronic tools have become smaller and extra effective, PCB layout and production approaches have actually advanced to meet new demands. Today, PCB assembly goes to the heart of every digital device, from smart devices to industrial controllers.

The shift from huge, bulky parts to small, high-density settings up has actually driven the fostering of sophisticated modern technologies. Recognizing the distinctions in between SMD and THT is necessary for any individual associated with PCB setting up, PCB design, or PCB production.

Riconoscere le tecnologie SMD e THT.

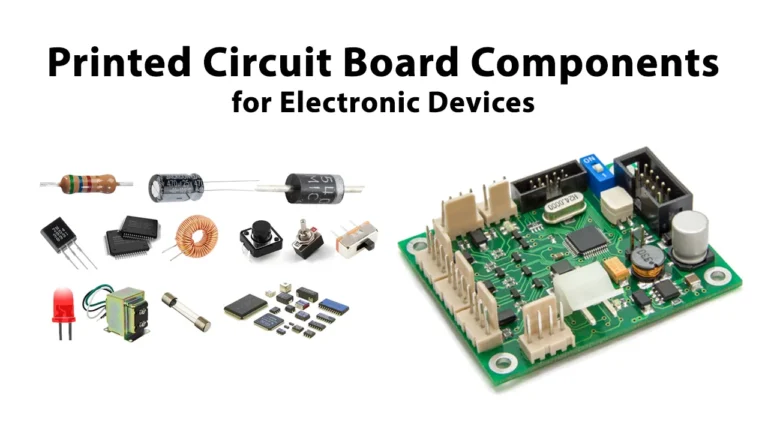

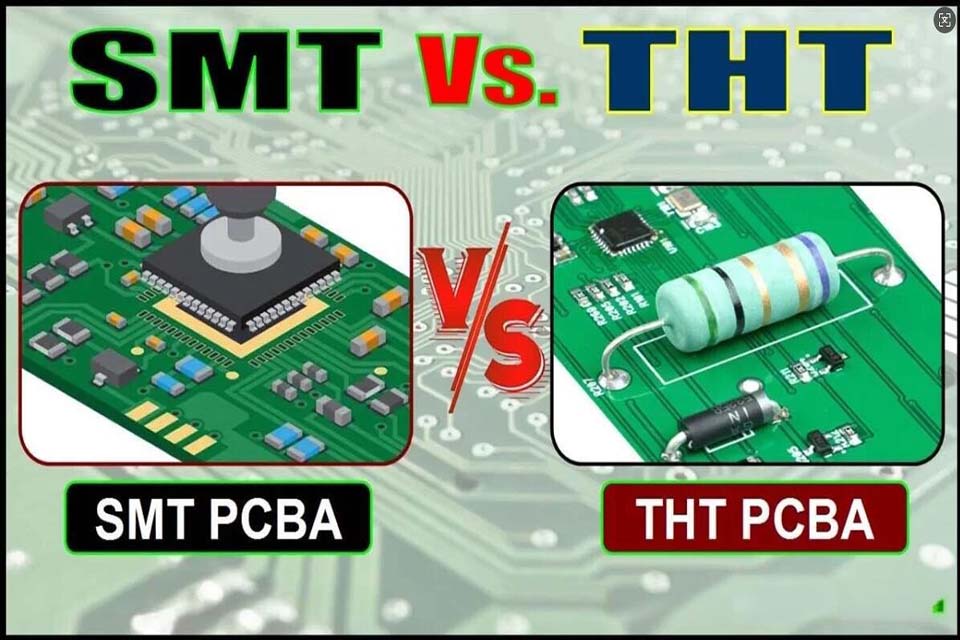

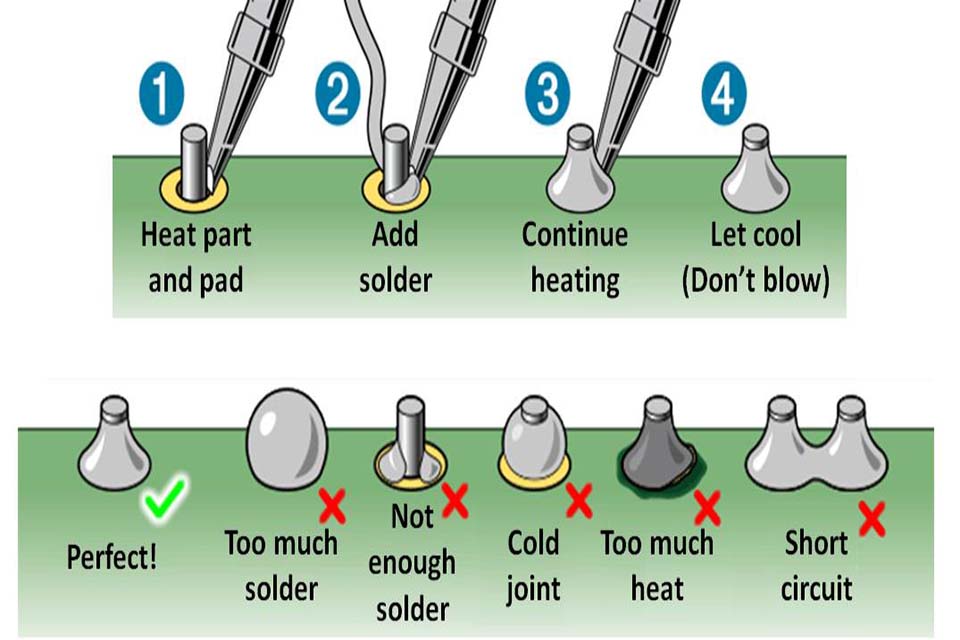

Surface Mount Instruments (SMD) E Through-Hole Modern Technology (THT) represent 2 basic approaches to mounting elements on a PCB.

- SMD involves positioning elements directly onto the surface of the PCB. This technique sustains high-density designs and is perfect for computerized assembly.

- THT calls for inserting element leads through holes pierced in the PCB. Soldering protects the leads on the opposite side, developing durable mechanical links.

Both innovations play crucial functions in contemporary PCB setting up, however each has unique toughness and restrictions.

Il ruolo dell'assemblaggio PCB nei moderni dispositivi elettronici.

PCB assembly is greater than simply affixing components to a board. It is a tactical process that determines the performance, integrity, and manufacturability of electronic items.

- Layout PCB establishes the foundation for setting up by specifying element positioning, routing, and stackup.

- produzione di PCB brings the style to life, using either SMD, THT, or a mix of both.

Picking the right assembly approach effects whatever from signal honesty to thermal monitoring and long-lasting sturdiness.

Differenze Segrete Tra SMD e THT

Recognizing the differences in between SMD and THT is important for efficient PCB setting up style.

SMD (Strumenti per montaggio superficiale).

- Components are mounted straight on the PCB surface area.

- Sustains high element density and miniaturization.

- Enables automated, high-speed setting up.

- Ideal for multi-layer PCB designs and high-pin-count semiconductors.

THT (Tecnologia Moderna Through-Hole)

- Parts have leads that go through holes in the PCB.

- Supplies strong mechanical bonds, suitable for high-stress settings.

- Easier to model and repair service.

- Ideal for bigger elements and connectors.

Comparison Table: .

| Caratteristica | SMD | THT |

|---|---|---|

| Assembly Rate | Quick, computerized | Slower, handbook or wave |

| Densità parziale | Alto | Inferiore |

| Resistenza meccanica | Moderare | Alto |

| Repairability | Challenging | Less complicated |

| Costo | Lower for mass production | Greater for big quantities |

Quando dovresti scegliere SMD per la produzione di PCB?

SMD modern technology controls contemporary PCB manufacturing for several reasons:.

- Miniaturizzazione: SMD components are smaller, enabling portable PCB designs.

- High-Speed Setting Up: Automated pick-and-place equipments can swiftly construct SMD boards.

- Price Effectiveness: SMD reduces labor prices and material waste in high-volume production.

- Efficiency: Much shorter signal paths boost electric performance and lower EMI.

Use SMD when: .

- You require to fit lots of components in a little space.

- Your style calls for high-speed signals or high-frequency operation.

- Automated assembly is a top priority for price and scalability.

Quando THT è l'opzione migliore per la progettazione del tuo PCB?

THT stays pertinent in particular circumstances:.

- Mechanical Strength: THT gives robust connections, perfect for parts subject to mechanical stress.

- Prototyping: THT is easier to hand-solder and change throughout development.

- Power Components: Big ports, transformers, and power semiconductors frequently require THT for heat dissipation and toughness.

Select THT when: .

- Your item will encounter vibration, shock, or frequent handling.

- You need to utilize big or hefty elements.

- Repairability and prototyping adaptability are essential.

Sfide di stile nel PCBA dei semiconduttori

Creating a semiconductor PCB setting up entails distinct difficulties:.

- Integrità del segnale: High-speed signals call for cautious trace routing and insusceptibility control.

- EMI Monitoring: Mixed-signal styles must lessen electromagnetic interference.

- Gestione termica: High-performance semiconductors create warmth that should be dissipated successfully.

Finest Practices: .

- Use ground planes and controlled impedance traces.

- Select materials with suitable dielectric homes.

- Prepare for appropriate warm sinking and air flow.

Considerazioni sulla produzione e sui test

Reliable PCB production relies on layout selections:.

- Stackup Complexity: Multi-layer boards support advanced SMD layouts yet boost producing complexity.

- Insusceptibility Control: Necessary for high-speed digital and RF circuits.

- Examining: Automated Optical Assessment (AOI), X-ray, and useful screening make sure assembly high quality.

Examining Approaches: .

- AOI for solder joint evaluation.

- In-circuit screening for electrical verification.

- Useful testing for end-to-end performance.

Verifica della progettazione e garanzia della qualità.

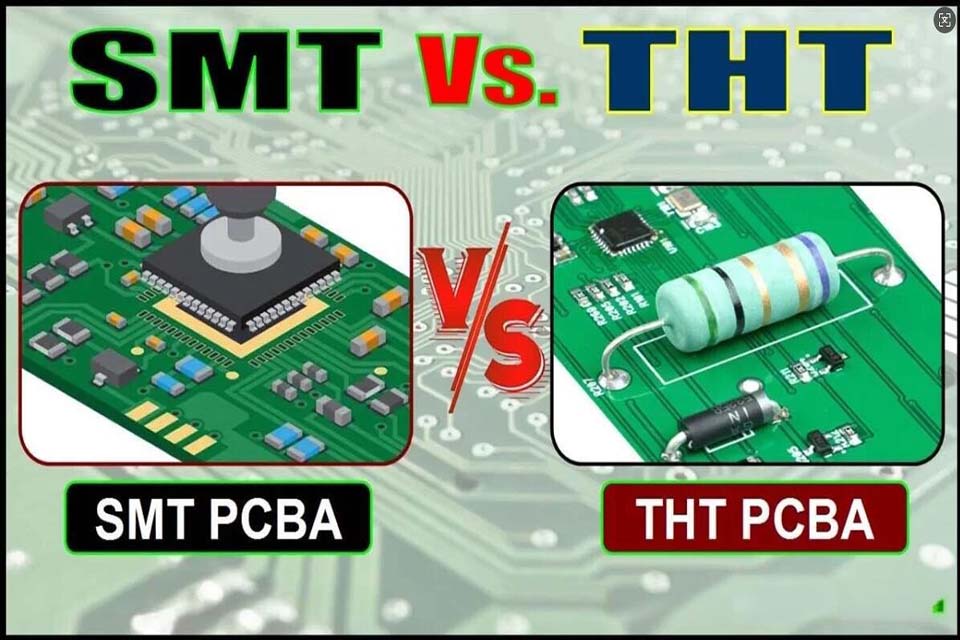

Verification is an important action in PCB setting up design:.

- Design for Manufacturability (DFM): Maximize formats to streamline assembly and lower errors.

- Layout for Assembly (DFA): Ensure element placement sustains efficient soldering and assessment.

- Quality Assurance: Apply rigorous testing to capture defects early.

Confirmation List: .

- Verify DFM and DFA compliance.

- Validate thermal and EMI efficiency.

- Check solder joints and mechanical honesty.

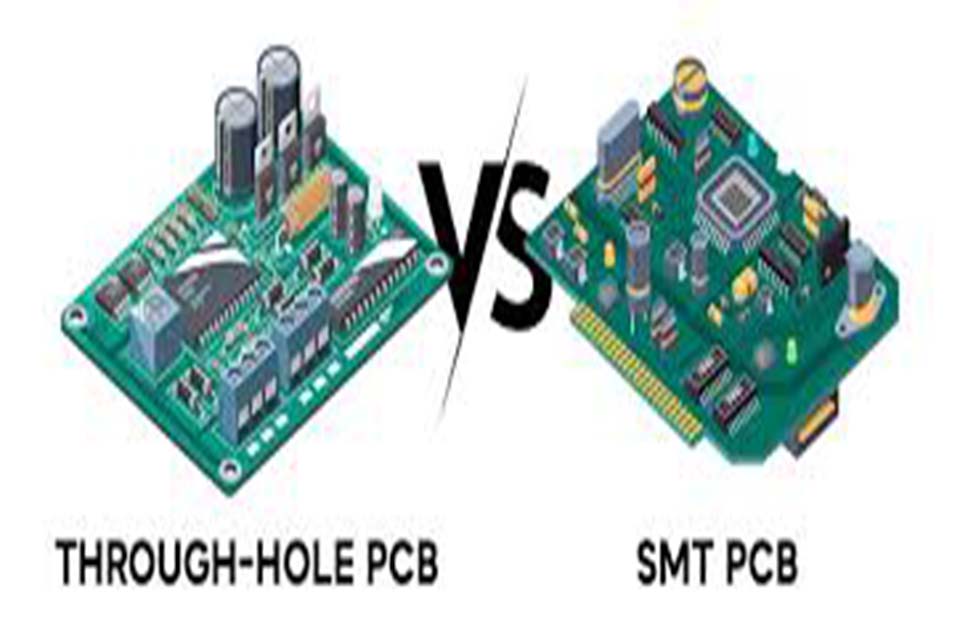

Scegliere l'opzione giusta: SMD o THT per il tuo compito.

Choosing in between SMD and THT depends upon your job’s requirements:.

- Performance Demands: SMD masters high-speed, high-density applications.

- Mechanical Demands: THT is much better for rugged, high-power designs.

- Manufacturing Volume: SMD is affordable for large-scale manufacturing.

- Prototyping and Repair: THT supplies flexibility during growth.

Choice Elements: .

- Examine your product’s environment and use.

- Think about long-lasting integrity and upkeep.

- Equilibrium price, performance, and manufacturability.

Domande frequenti

I componenti SMD possono sopportare lo shock della temperatura di riflusso?

Modern SMD packages are certified by Jedec J-STD-020 and can withstand three reflow processes with a peak temperature of 260 ° C

Is the THT process completely old?

In the military/aerospace sector, THT still takes 70% of the market share. Some high-evidence landscapes are irreparable.

How to balance the miniature and stability of SMD?

Using selective wave soldering + AOI inspection, combined with modular design, can increase 40%of maintenance efficiency.

Does mixed assembly production increases complexity?

Through DFM adaptation, the process of mixed assembly can be controlled within ± 5% of time cost increase to the window.

Which indicators affect the most technology selection?

According to industry research, priority is: Product quantity requirements (weight 30%), cost target (25%), reliability requirements (20%), and production cycle (15%).

How to verify the viability of assembly solution?

Apply the DOE (experimental design) method, focusing on testing: Milap joint power (bridge test), thermal cycle (1000 cycles), and vibration (20g shock).

Conclusion: Maximizing Your PCB Setting Up Method.

Picking between SMD and THT is a foundational choice in PCB setting up, PCB design, and PCB production. By understanding the staminas and limitations of each innovation, you can create trusted, high-performance electronic products. Constantly align your setting up method with your layout goals, manufacturing capacities, and end-user requirements.

Key Takeaways.

- SMD is optimal for small, high-speed, and automated PCB setting up.

- THT uses exceptional mechanical strength and is simpler to model and repair work.

- Stile PCB must consider signal integrity, EMI, and thermal management.

- Examining and verification are necessary for quality assurance.

- Select the appropriate technology based upon your item’s requirements and production range.