-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

Types of PCB Assembly: Choosing the Right Method for Your Project

[ad_1]

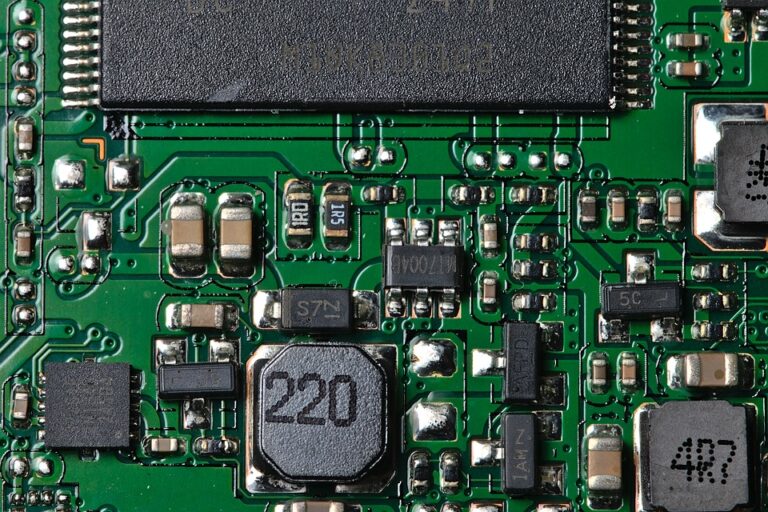

Printed circuit boards (PCBs) have become an essential component in various electronic devices, from consumer products to complex industrial systems. With the increasing demand for PCBs, there are various methods of assembly, each with its own advantages and disadvantages. In this article, we will explore the different types of PCB assembly, the factors to consider when choosing the right method for your project, and the benefits and limitations of each approach.

Surface Mount Technology (SMT) Assembly

SMT assembly is the most widely used method of PCB assembly. It involves mounting surface-mount devices (SMDs) on the PCB using a wet or dry process. The SMDs are small components, such as resistors, capacitors, and semiconductors, which are placed on the surface of the PCB. This method is popular due to its high speed, low cost, and accurate placement.

Through-Hole Technology (THT) Assembly

Through-hole technology involves inserting components, such as diodes, resistors, and capacitors, through holes in the PCB and soldering them in place. This method is traditionally used for components that are too large for SMT or require a specific power rating. THT assembly is still widely used in industrial equipment, automotive, and aerospace applications.

Mixed-Technology Assembly

Mixed-technology assembly combines SMT and THT components on the same PCB. This approach is used for devices that require a mix of small and large components, or for applications where both SMT and THT are required. This method offers the benefits of both technologies, including increased component density and flexibility.

Pallet- and Wave-Through-Hole Assembly

Pallet- and wave-through-hole assembly is a hybrid method that combines the speed and efficiency of SMT with the precision of THT. In this method, components are placed on a pallet or waveguide, which is then fed into a machine that places and solder the components on the PCB. This method is ideal for high-volume production and is often used in the automotive and consumer electronics industries.

Chip-on-Board (COB) Assembly

COB assembly involves mounting integrated circuits (ICs) directly onto the PCB, eliminating the need for a ceramic or plastic package. This method is used for applications where space is limited, such as in mobile devices, wearables, or IoT devices. COB assembly offers high reliability, high integration, and low cost.

Evaluation and Selection of PCB Assembly Method

The choice of PCB assembly method depends on several factors, including:

- Component size and type

- Cost and production volume

- Space constraints and design requirements

- Quality and reliability requirements

To choose the right method, consider the following questions:

- What is the size and type of components required?

- What is the production volume and budget?

- What are the space constraints and design requirements?

- What are the quality and reliability requirements?

Conclusion

PCB assembly is a complex process that requires careful consideration of various factors to ensure successful and efficient production. By understanding the different methods of PCB assembly, including SMT, THT, mixed-technology, pallet- and wave-through-hole, and COB assembly, you can choose the best approach for your project. Remember to evaluate your project’s specific needs, component requirements, space constraints, and quality and reliability expectations to select the right PCB assembly method.

FAQs

Q: What is the most common method of PCB assembly? A: SMT assembly is the most widely used method of PCB assembly.

Q: What is the difference between SMT and THT? A: SMT involves mounting small components on the surface of the PCB, while THT involves inserting components through holes in the PCB.

Q: What is mixed-technology assembly? A: Mixed-technology assembly combines SMT and THT components on the same PCB.

Q: What is the benefit of COB assembly? A: COB assembly offers high reliability, high integration, and low cost.

Q: How do I choose the right PCB assembly method for my project? A: Consider the component size and type, cost and production volume, space constraints, and quality and reliability requirements to select the right method for your project.

[ad_2]