-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

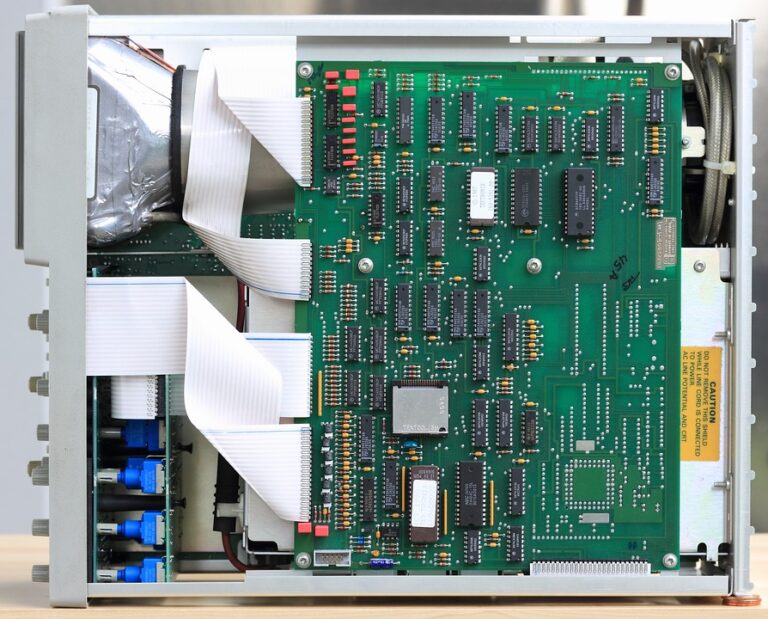

The Importance of PCB Assembly Quality Control: Ensuring Reliable Electronics

[ad_1]

PCB (Printed Circuit Board) assembly is a critical step in the production of electronic devices, and ensuring the quality of the assembly process is crucial for the reliability and performance of the final product. In this article, we will explore the importance of PCB assembly quality control and the benefits it provides.

Why is PCB Assembly Quality Control Important?

PCB assembly quality control is important for several reasons:

- Ensures Reliability: A high-quality PCB assembly ensures that the final product is reliable and functions as intended. Any defects or issues during the assembly process can lead to failures, which can result in costly recalls and damage to the company’s reputation.

- Prevents Defects: Quality control measures during the assembly process can identify and prevent defects, reducing the risk of faulty products reaching the market.

- Improves Performance: A well-assembled PCB can improve the overall performance of the electronic device, ensuring that it meets the required specifications and standards.

- Reduces Warranty Claims: By ensuring that the PCB assembly is of high quality, manufacturers can reduce the number of warranty claims and the associated costs.

- Enhances Customer Satisfaction: A reliable and high-quality PCB assembly can enhance customer satisfaction, leading to increased customer loyalty and repeat business.

What are the Key Aspects of PCB Assembly Quality Control?

The key aspects of PCB assembly quality control include:

- Inspection: Visual inspection of the PCB assembly is critical to ensure that it meets the required specifications and standards. This includes checking for defects, such as missing or damaged components, and ensuring that all components are properly installed.

- Testing: Testing the PCB assembly is essential to ensure that it functions as intended. This includes testing for electrical and mechanical performance, as well as checking for any defects or issues.

- Documentation: Maintaining accurate documentation of the PCB assembly process, including component usage, testing results, and quality control measures, is critical for ensuring the reliability and performance of the final product.

- Process Control: Implementing process control measures, such as quality control procedures and standards, is essential for ensuring that the PCB assembly process is consistent and reliable.

Benefits of PCB Assembly Quality Control

The benefits of PCB assembly quality control include:

- Reduced Costs: By identifying and preventing defects during the assembly process, manufacturers can reduce the costs associated with recalls, rework, and warranty claims.

- Improved Productivity: Implementing quality control measures can improve productivity by reducing the time and resources spent on rework and repairs.

- Enhanced Customer Satisfaction: By ensuring that the PCB assembly is of high quality, manufacturers can enhance customer satisfaction, leading to increased customer loyalty and repeat business.

- Compliance with Regulations: PCB assembly quality control ensures compliance with industry regulations and standards, reducing the risk of non-compliance and associated fines and penalties.

Conclusion

In conclusion, PCB assembly quality control is a critical step in the production of electronic devices, ensuring the reliability and performance of the final product. By implementing quality control measures, manufacturers can reduce costs, improve productivity, enhance customer satisfaction, and ensure compliance with regulations. By prioritizing PCB assembly quality control, manufacturers can ensure the reliability and performance of their products, leading to increased customer satisfaction and loyalty.

FAQs

Q: What are the most common defects found in PCB assemblies?

A: The most common defects found in PCB assemblies include component misplacement, soldering defects, and PCB damage.

Q: What is the most effective way to implement PCB assembly quality control?

A: The most effective way to implement PCB assembly quality control is to implement a combination of inspection, testing, and documentation, as well as process control measures.

Q: How can PCB assembly quality control be improved?

A: PCB assembly quality control can be improved by implementing advanced inspection and testing technologies, such as automated optical inspection (AOI) and x-ray inspection, as well as continuous monitoring and improvement of the assembly process.

Q: What are the consequences of not implementing PCB assembly quality control?

A: The consequences of not implementing PCB assembly quality control can include reduced product reliability, increased warranty claims, and damage to the company’s reputation.

Q: How can PCB assembly quality control be audited?

A: PCB assembly quality control can be audited by conducting regular inspections and testing, as well as reviewing documentation and process control measures.

[ad_2]