5G IoT PCBA : Assemblage de cartes de circuits imprimés avancé pour la connectivité nouvelle génération

Intro: The Structure of Modern Connection

5G IoT PCBA represents the technical foundation of our increasingly linked world. These sophisticated Printed Circuit Board Assemblies work as the vital infrastructure allowing gadgets to harness the power of fifth-generation cordless technology while participating in the extensive Web of Things environment. The merging of 5G networks and IoT applications needs unprecedented degrees of performance, integrity, and efficiency from digital elements.

This thorough guide discovers the detailed world of 5G IoT PCBA technology. We analyze the basic concepts governing these advanced assemblies, their style considerations, making processes, and real-world applications. Recognizing these parts becomes necessary as markets accept digital transformation and wise connectivity options.

The assimilation of 5G capacities with IoT capability calls for specialized PCBA layouts that can handle extreme efficiency needs. These assemblies need to process high-frequency signals, preserve outstanding signal honesty, and operate efficiently under demanding problems. The stakes are high, as these elements straight impact the efficiency of crucial applications ranging from autonomous automobiles to commercial automation systems.

Table of Contents

Reconnaître la technologie 5G et ses besoins

Fifth-generation wireless modern technology reinvents interaction standards through unprecedented rate, transmission capacity, and responsiveness. 5G networks provide information transmission prices exceeding 10 Gbps, representing a hundred-fold enhancement over previous generations. This dramatic efficiency improvement necessitates equally innovative PCBA options with the ability of taking care of such requiring requirements.

Le 5G spectrum operates throughout numerous regularity bands, including sub-6 GHz and millimeter-wave frequencies prolonging past 24 GHz. These high-frequency operations existing one-of-a-kind obstacles for PCBA designers. Circuit card should keep signal honesty throughout these raised frequencies while minimizing electromagnetic disturbance and power consumption.

Low latency represents one more essential 5G particular that impacts PCBA style. Applications requiring real-time responsiveness, such as self-governing driving systems and industrial robotics, depend on latency dimensions below one millisecond. PCBA assemblies have to sustain these ultra-low latency demands through enhanced signal routing and advanced part placement strategies.

Aperçu de l'écosystème de l'Internet des objets (IoT)

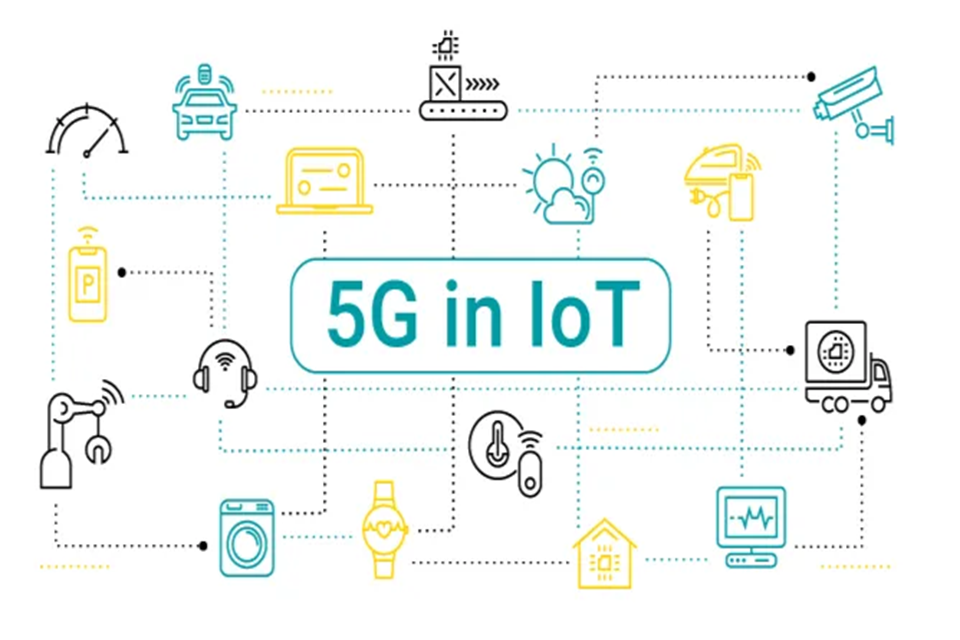

Le Net of Points encompasses billions of interconnected tools generating, handling, and exchanging data constantly. IoT applications cover many markets, consisting of medical care, production, transport, and smart city facilities. Each application presents one-of-a-kind needs for PCBA design and implementation.

IoT gadgets commonly run under rigorous power restraints, commonly relying upon battery power for extended durations. This requirement drives PCBA developers to apply sophisticated power administration strategies, consisting of vibrant voltage scaling, sleep setting optimization, and power harvesting capacities. The difficulty heightens when incorporating IoT performance with 5G connection, as greater performance generally correlates with raised power consumption.

Security factors to consider end up being vital in IoT PCBA designs. Connected tools represent potential entrance points for cyber hazards, needing robust hardware-level protection executions. PCBA assemblies must integrate security processors, secure boot systems, and tamper-resistant hardware parts to protect versus sophisticated assaults.

The variety of IoT applications needs adaptable PCBA remedies. Smart sensors need various requirements contrasted to commercial control systems or clinical monitoring tools. This irregularity necessitates modular design methods that can accommodate various efficiency requirements while maintaining cost-effectiveness and producing performance.

Qu'est-ce qui rend le PCBA IoT 5G unique en son genre ?

5G IoT PCBA assemblies incorporate the demanding requirements of both 5G connectivity and IoT performance. These hybrid systems have to take care of high-frequency 5G signals while maintaining the power effectiveness necessary for IoT applications. This double demand creates special layout challenges that identify these settings up from standard circuit boards.

Advanced substrate materials become crucial for 5G IoT PCBA implementations. Traditional FR4 products prove insufficient for high-frequency applications, requiring specialized substrates such as Rogers products, PTFE-based laminates, or ceramic substrates. These materials supply remarkable dielectric buildings, lower loss tangents, and boosted thermal qualities vital for 5G performance.

Multi-layer stack-up arrangements make it possible for 5G IoT PCBA layouts to accommodate complicated signal directing demands. These assemblies usually feature 8-16 layers or even more, with dedicated airplanes for power circulation, ground referencing, and high-speed signal routing. The stack-up layout directly affects signal stability, electro-magnetic compatibility, and thermal administration performance.

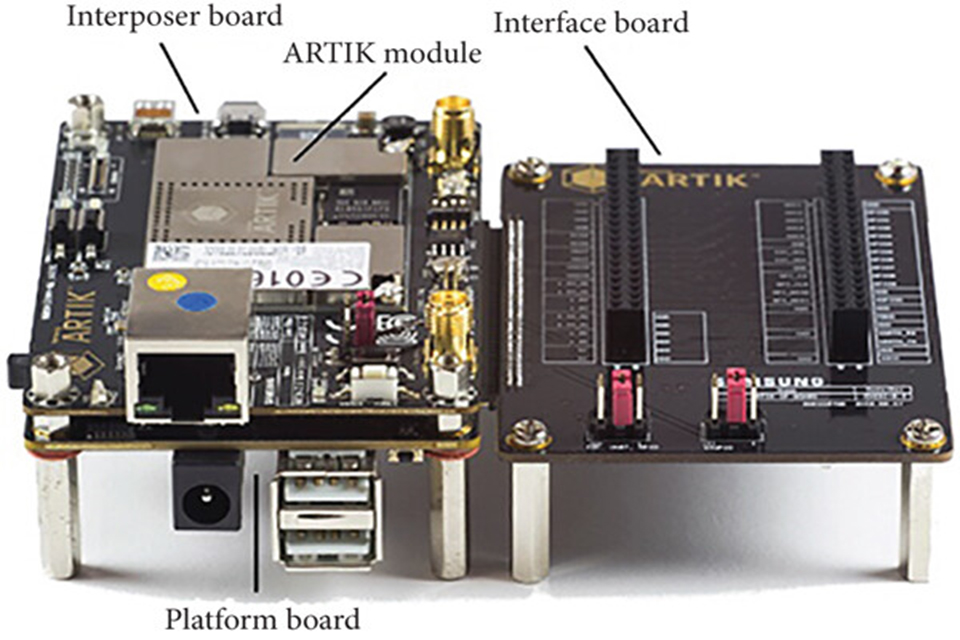

Component miniaturization reaches extreme levels in 5G IoT PCBA applications. These settings up have to pack extraordinary functionality into progressively small form factors. This demand drives the adoption of advanced product packaging innovations, including system-in-package (SiP) solutions, embedded elements, and 3D combination techniques.

Comment les signaux à haute fréquence affectent-ils la conception des PCBA ?

High-frequency signal monitoring represents the most vital element of 5G IoT PCBA conception. 5G applications run at frequencies where traditional PCB style guidelines become insufficient. Signal wavelengths come close to the physical dimensions of circuit traces, developing transmission line effects that must be very carefully regulated.

Insusceptibility control ends up being extremely important at 5G regularities. Circuit traces need to preserve consistent particular insusceptibility to stop signal reflections and ensure dependable information transmission. This demand demands accurate control over trace geometry, substrate density, and dielectric residential properties. Even minor variations can significantly affect signal integrity and system efficiency.

Via style calls for unique interest in 5G IoT PCBA applications. Typical through-hole vias create impedance suspensions that come to be problematic at high frequencies. Designers use techniques such as back-drilling, micro-vias, and blind/buried vias to lessen these suspensions and maintain signal stability.

Crosstalk mitigation becomes progressively challenging as frequencies boost. Adjacent traces can pair electro-magnetic power, producing interference that breaks down signal top quality. 5G IoT PCBA designs apply different strategies to minimize crosstalk, including raised spacing, guard traces, and orthogonal transmitting methods.

Pourquoi l'honnêteté du signal est-elle importante dans les applications IoT 5G ?

Signal integrity figures out the integrity and performance of 5G IoT PCBA systems. Poor signal stability can cause information corruption, enhanced error rates, and system failings. The high-speed nature of 5G interactions makes these systems especially prone to signify stability concerns.

Jitter and timing become crucial parameters in 5G IoT applications. Clock signals have to preserve specific timing connections to ensure correct system operation. PCBA layouts need to lessen jitter through cautious clock circulation networks, appropriate discontinuation schemes, and seclusion methods.

Power stability straight impacts signal stability in 5G IoT PCBA systems. High-speed switching creates significant power supply noise that can pair right into delicate analog circuits. Efficient power circulation networks, consisting of decoupling capacitors, power aircrafts, and voltage regulation, end up being essential for preserving signal high quality.

Electromagnetic disturbance (EMI) positions significant difficulties for 5G IoT PCBA styles. The high-frequency nature of 5G signals makes these systems both susceptible to disturbance and possible sources of interference. Appropriate protecting, filtering, and design methods become crucial for EMI compliance and system dependability.

Quels sont les défis secrets de la surveillance de l'alimentation ?

Power administration in 5G IoT PCBA systems offers distinct challenges because of the contradictory demands of high-performance 5G connection and energy-efficient IoT procédure. 5G transceivers can eat several watts during transmission, while IoT sensors should operate for years on battery power.

Dynamic power scaling makes it possible for 5G IoT tools to optimize power usage based on operational requirements. These systems can readjust cpu regularities, disable unused peripherals, and implement innovative rest settings to lessen power intake during still durations. PCBA designs must sustain these vibrant power monitoring techniques through adaptable power distribution styles.

Power supply sound comes to be specifically problematic in 5G IoT PCBA applications. High-current switching from 5G transceivers can create power supply fluctuations that impact sensitive IoT sensors and analog circuits. Efficient power supply design requires cautious factor to consider of regulator choice, filtering, and circulation network layout.

Battery monitoring systems come to be complicated in 5G IoT applications because of the wide variety of power intake circumstances. These systems must handle high-current pulses from 5G transmissions while preserving efficient procedure throughout low-power IoT noticing tasks. Advanced battery administration ICs and power course optimization become important components.

Comment l'administration thermique affecte-t-elle exactement les performances ?

Thermal monitoring becomes increasingly important as 5G IoT PCBA systems load even more functionality into smaller plans. 5G transceivers generate considerable warmth throughout procedure, while IoT parts require secure operating temperature levels for trustworthy procedure. Effective thermal style ensures system dependability and protects against efficiency deterioration.

Warmth dissipation methods must fit the varying thermal loads of 5G IoT systems. Throughout 5G transmission, power dissipation can raise considerably, needing efficient heat removal systems. On the other hand, throughout IoT sensing operations, thermal lots continue to be minimal, enabling easy air conditioning methods.

Thermal user interface products play crucial functions in 5G IoT PCBA thermal monitoring. These materials facilitate warmth transfer from hot components to warmth sinks or thermal spreaders. Option criteria consist of thermal conductivity, reliability, and making compatibility. Advanced materials such as graphene-based thermal pads provide exceptional performance for requiring applications.

Element placement methods significantly affect thermal performance in 5G IoT PCBA styles. Warm components should be placed to minimize thermal communications and promote warmth elimination. Thermal modeling and simulation devices aid designers optimize component placement and anticipate thermal actions under different operating problems.

Quel rôle joue la miniaturisation dans les styles modernes ?

Miniaturization drives innovation in 5G IoT PCBA technology as applications require smaller, a lot more portable devices. This fad offers significant engineering obstacles, requiring developers to preserve performance while reducing size, weight, and power consumption.

Part combination gets to new degrees in miniaturized 5G IoT PCBA designs. System-in-package (SiP) solutions combine multiple features into solitary bundles, minimizing board space requirements and improving efficiency. These incorporated services commonly consist of 5G transceivers, processors, memory, and passive components within portable components.

3D packaging technologies make it possible for upright combination of parts, optimizing functionality within restricted board room. Strategies such as package-on-package (PoP) piling, through-silicon vias (TSV), and ingrained elements allow developers to attain extraordinary levels of combination.

Production restraints end up being much more difficult as 5G IoT PCBA designs diminish. Fine-pitch parts, micro-vias, and tight spacing needs push making capabilities to their limits. Design for manufacturability (DFM) considerations come to be crucial for guaranteeing reputable production and cost-effective production.

Which Industries Advantage Most from 5G IoT PCBA?

Automotive applications represent among the largest markets for 5G IoT PCBA innovation. Connected and autonomous lorries call for dependable, high-speed connection for real-time communication with facilities, various other cars, and cloud services. 5G IoT PCBA settings up enable advanced driver support systems, vehicle-to-everything (V2X) interaction, and over-the-air updates.

Automatisation industrielle leverages 5G IoT PCBA technology to allow Industry 4.0 efforts. Smart factories call for real-time surveillance and control of producing processes, anticipating upkeep systems, and versatile manufacturing capacities. 5G connection supplies the data transfer and reduced latency required for these demanding applications.

Healthcare checking applications gain from 5G IoT PCBA modern technology with remote client monitoring, telemedicine, and medical tool connection. These applications need trusted, safe connection with strict regulative compliance. 5G IoT PCBA layouts need to integrate medical-grade components and meet rigid security requirements.

Smart city infrastructure depends on 5G IoT PCBA modern technology for web traffic administration, environmental surveillance, and public safety and security applications. These systems require robust, weatherproof styles with the ability of operating dependably in rough exterior atmospheres for prolonged periods.

Exactly How Are Manufacturing Processes Evolving?

Advanced setting up strategies come to be required for 5G IoT PCBA producing because of the intricacy and precision requirements of these systems. Surface area place technology (SMT) processes must take care of progressively fine-pitch elements, while preserving high yield prices and integrity standards.

Automated optical evaluation (AOI) systems come to be important for quality assurance in 5G IoT PCBA manufacturing. These systems can identify defects unseen to human assessors, including component misalignment, solder joint high quality, and trace integrity. Advanced AOI systems incorporate artificial intelligence algorithms to improve flaw detection accuracy.

X-ray evaluation becomes common method for 5G IoT PCBA manufacturing due to the frequency of hidden solder joints and complicated package types. These evaluation systems can recognize void formation, cool solder joints, and various other defects that might impact lasting dependability.

Examination and validation treatments must develop to resolve the distinct needs of 5G IoT PCBA systems. Functional screening must validate 5G connection efficiency, IoT sensing unit accuracy, and power management effectiveness. Specialized test devices capable of running at 5G frequencies becomes necessary for comprehensive recognition.

What Are the Future Trends and Innovations?

Expert system combination will certainly change 5G IoT PCBA capacities via side computing and artificial intelligence applications. These systems will certainly include AI accelerators and neural processing units straight into PCBA designs, enabling real-time choice making and flexible habits.

6G prep work starts affecting 5G IoT PCBA design approaches as scientists check out terahertz frequencies and progressed interaction technologies. These future systems will certainly need a lot more sophisticated PCBA layouts with boosted efficiency abilities.

Lasting style practices end up being increasingly important as ecological issues drive sector efforts. 5G IoT PCBA designers must consider material selection, energy efficiency, and end-of-life recycling throughout the design procedure.

Advanced products proceed evolving to satisfy the demanding requirements of 5G IoT applications. New substrate materials, conductive inks, and element product packaging innovations will allow improved efficiency and reduced costs.

Regularly Asked Inquiries (Frequently Asked Questions).

What makes 5G IoT PCBA various from standard PCB assemblies?

5G IoT PCBA settings up include specialized materials, progressed style methods, and optimized element positioning to take care of high-frequency 5G signals while maintaining the power performance required for IoT applications. These assemblies include multi-layer stack-ups, impedance-controlled directing, and innovative power administration systems.

Exactly how do high frequencies impact PCBA design factors to consider?

High frequencies develop transmission line impacts that need precise resistance control, specialized via layouts, and mindful crosstalk management. Standard PCB design guidelines come to be poor, requiring innovative modeling devices and specialized products to preserve signal integrity.

What are the primary difficulties in 5G IoT PCBA power administration?

The primary difficulty includes stabilizing the high power demands of 5G transceivers with the ultra-low power requirements of IoT sensors. This needs vibrant power scaling, innovative battery management, and progressed power distribution networks to take care of varying tons conditions effectively.

Which industries are driving 5G IoT PCBA fostering?

Automotive, commercial automation, healthcare, and wise city applications are the primary drivers of 5G IoT PCBA adoption. These sectors need the high-speed, low-latency connectivity that 5G supplies combined with the distributed noticing capacities of IoT systems.

Exactly how important is thermal management in 5G IoT PCBA styles?

Thermal monitoring is essential for making sure reputable procedure and protecting against performance destruction. 5G transceivers generate significant heat throughout procedure, requiring effective warmth dissipation approaches, thermal interface products, and optimized part placement.

What future trends will shape 5G IoT PCBA advancement? .

Key fads include AI assimilation for edge computer, prep work for 6G innovations, sustainable layout practices, and progressed materials growth. These trends will drive continued innovation and enable new applications and abilities.

Final thought: The Future of Connected Modern Technology.

5G IoT PCBA innovation represents the foundation of our connected future, enabling unmatched degrees of connectivity, efficiency, and capability. These advanced assemblies integrate the high-speed capacities of 5G connect with the dispersed knowledge of IoT systems, creating new opportunities for innovation throughout many markets.

The challenges facing 5G IoT PCBA developers continue progressing as applications become a lot more demanding and facility. Success requires deep understanding of high-frequency style principles, power administration approaches, thermal factors to consider, and producing constraints. The integration of these diverse needs interdisciplinary know-how and advanced design devices.

Market fostering of 5G IoT modern technologies will certainly accelerate as framework deployment expands and costs reduction. Early adopters in automotive, industrial, and health care industries are currently showing the transformative possibility of these innovations. The lessons gained from these introducing applications will certainly educate future growths and drive proceeded advancement.

The convergence of 5G et IoT modern technologies through innovative PCBA styles will enable brand-new applications and service designs that we can barely picture today. As these innovations grow and become extra easily accessible, they will basically change exactly how we communicate with the world around us, creating a really connected culture.

Trick Takeaways.

- 5G IoT PCBA settings up incorporate high-performance 5G connectivity with reliable IoT functionality.

- High-frequency design principles become crucial for maintaining signal honesty at 5G frequencies.

- Power management approaches need to balance high-performance requirements with power effectiveness.

- Gestion thermique ensures trusted procedure under varying load problems.

- Miniaturization drives technology in part assimilation and packaging technologies.

- Production procedures have to evolve to manage enhanced complexity and accuracy needs.

- Future patterns include AI combination, 6G prep work, and lasting style methods.