¿Por qué los fabricantes chinos de PCB seguirán siendo una parte importante de la cadena de suministro

Abstracto

In today’s hyperconnected electronics landscape, collaboration is no longer optional; it’s essential. No single country holds a monopoly on innovation, and no one company or country can go it alone. Electronics manufacturing is very much a global business, and this will not change, no matter how the tariffs and global trade winds are blowing. Whether you’re a startup founder building your prototype, an aerospace engineer pushing the boundaries of performance, or a supply chain leader managing a complex global network, Chinese PCB fabricators have likely already touched your world. Chinese PCB fabricators, with their technological depth and ability to supply in quantity, will remain an essential part of the global manufacturing puzzle.

As many of my Chinese PCB competitors , we don’t simply manufacture; we partner, innovate, and adapt at scale, which is exactly what our customers ask for and what the global electronics manufacturing industry needs to fuel all our success. Here’s what top-tier Chinese PCB fabricators bring to the table, and why these partnerships are transformational. And though every business owner today is grappling with the sometimes daily changes that will affect our businesses and profitability in the near term, I dedicate this column to real talk about the global electronics manufacturing supply chain and enabling and growing real solutions.

Here are some reasons why Chinese PCB fabricator partners will remain a vital element in global manufacturing success.

Tabla de contenido

1. Technology That’s on Par or Ahead

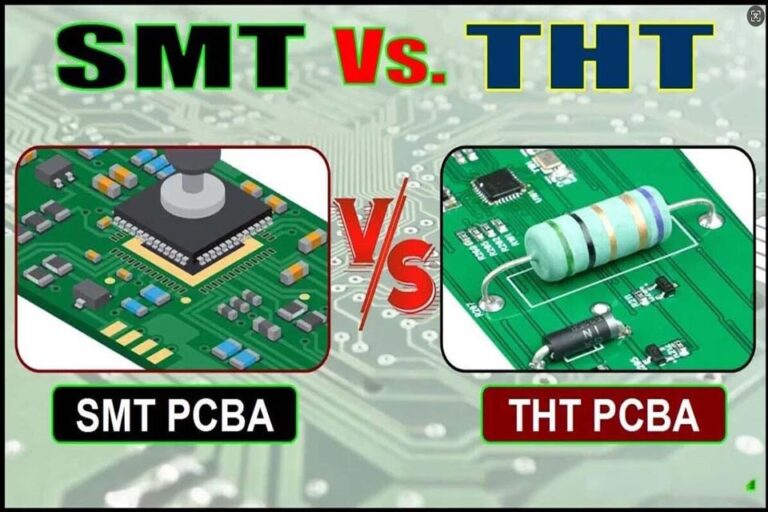

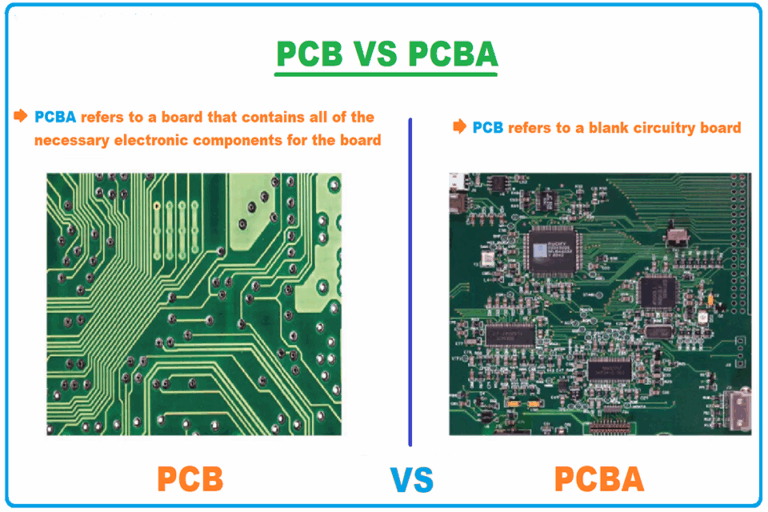

There’s a myth in some circles that Chinese fabricators only offer low-end tech. That story may have had a hint of truth 20 years ago. Today, that myth is just that, a myth. China’s leading PCB manufacturers invest heavily in next-generation technologies, including ultra HDI, RF/microwave, embedded component boards, metal core PCBs, IC substrates, and advanced rigid-flex capabilities.

They aren’t just keeping up with the rest of the world; they’re leading in areas where demand is growing fast. There’s a global shift toward electric vehicles, 5G infrastructure, and IoT, all sectors that require extreme miniaturization, high layer counts, and thermal stability. Chinese fabricators are delivering on those requirements, and in most cases, the only ones who can at scale. State-of-the-art clean rooms, laser direct imaging (LDI), plasma treatment, and automation at every stage of production are the baseline, matching step-for-step as global OEMs raise the bar for performance.

2. Capacidad que escala contigo

Do you need 10 boards? No problem. Do you need 10,000 boards by next week? Also, not a problem. Though this is not true for every organization, the flexibility of most Chinese PCB fabricator’s strength is the ability to adapt their capacity to scale. With vertically integrated supply chains, high-output plants, and flexible production lines, Chinese manufacturers can absorb sudden increases in demand that might overwhelm smaller or more rigid facilities.

This is particularly valuable in industries with unpredictable demand spikes, including medical, defense, and consumer electronics. The ability to pivot quickly, without sacrificing lead times or quality, gives customers a competitive edge. In addition to their ability to scale, organized Chinese fabricators solve problems, optimize production schedules, and anticipate your next move.

3. Capacidades en todo el espectro

Depth of technology and process capability is one of the most important factors in working with a Chinese PCB fabricator partner, offering everything from single-sided prototypes to 30-layer hybrid stackups to standard FR-4 to exotic materials like polyimide, ceramic, and aluminum-backed PCBs. High technology, HDI and uHDI capability considerations should include:

- Blind and buried vias

- HDI with stacked microvias

- Controlled impedance

- Mixed dielectric stackups

- Heavy copper PCBs

- High-Tg, low-Dk materials

- Embedded passives

- Rigid-flex integration

These capabilities are supported by a robust ecosystem of testing and certification—UL, ISO, IATF 16949, ITAR (in collaboration), and, in some cases, MIL-spec compliance. If you can design it, a capable Chinese shop can likely build it, often faster and more affordably than you’d expect, even in today’s market.

4. Innovación Que No Duerme

Innovation in China isn’t just confined to tech giants and startups in Shenzhen. It’s happening inside the walls of PCB factories every single day.

From smart factory automation to in-house material R&D, fabricators across the region are discovering new ways to reduce cycle times, cut costs, improve yields, and shrink environmental impact. Some are experimenting with AI-driven process control, while others are building digital twins of production lines to simulate efficiency gains. There’s a growing emphasis on green chemistry, closed-loop…

Of course. Here are three additional reasons, formatted in Markdown, that continue the theme and numbering of the original article.

5. Inigualable rentabilidad y valor

While the conversation has rightly shifted to technology and capability, cost-effectiveness remains a powerful and undeniable advantage. This isn’t about being the “cheapest” at the expense of quality, but about delivering superior value. Decades of focused investment have created immense economies of scale. Chinese PCB fabricators benefit from a highly optimized local supply chain for raw materials like copper foil, resins, and laminates, reducing transportation costs and lead times.

This, combined with a skilled and efficient labor force and high levels of automation, results in a total cost structure that is difficult to replicate elsewhere, especially at high volume. This financial advantage allows customers to price their own products more competitively or reinvest savings into crucial areas like research and development.

6. Un ecosistema profundamente integrado y maduro

A single PCB factory does not operate in a vacuum. China has cultivated the world’s most comprehensive and interconnected electronics manufacturing ecosystem. This means that right next door to the PCB fabricator, you will find world-class suppliers of components, assembly (EMS) providers, raw material vendors, and logistics experts. This tight geographic integration is a strategic superpower. It drastically shortens the supply chain, enables real-time collaboration between partners, and allows for a “one-stop-shop” approach where a product can go from fabrication to assembly to final packaging in a single region. This ecosystem provides a level of speed, efficiency, and resilience that is currently unparalleled on a global scale.

7. Tiempo de comercialización acelerado

In the electronics industry, speed is a currency of its own. Getting a product from concept to customer ahead of the competition can define its success. Chinese PCB fabricators are built for speed. The combination of immense capacity, 24/7 operations, and the integrated ecosystem allows them to compress timelines dramatically. The journey from quick-turn prototype to mass production can happen in weeks, not months. Furthermore, their engineers have accumulated vast experience in Design for Manufacturability (DFM). They can often identify and resolve potential production issues during the quoting stage, preventing costly and time-consuming redesigns down the line. This ability to move quickly without sacrificing quality gives their global partners a critical competitive edge.

Conclusión:

The future of electronics is global. Engineers in Munich can design ideas born in California, prototype them in Bangalore, and build them in Guangdong. Chinese PCB fabricators are not outsiders in this system—they’re vital contributors. They bring muscle, precision, adaptability, and technical know-how to the table. When viewed not as distant vendors but as integral teammates, the results speak for themselves: faster innovation, smoother production, and better products.

So, to the engineers, buyers, and builders around the world, if you’re looking for a partner that can scale, solve, and grow with you, don’t overlook what’s happening in China’s PCB industry. Because while others are talking about global collaboration, we’ve been doing it for years. We are here to help, and we’re just getting started.