Configuración de PCB personalizada: Soluciones de ensamblaje de PCB personalizadas para electrónica avanzada

Abstracto

Customized PCB assembly concentrates on putting together electronic elements on printed circuit card according to details client requirements. Unlike typical approaches, this procedure provides flexibility, performance, and accuracy, supporting markets with specialized needs. This write-up discusses the range, advantages, methods, and applications of personalized PCB assembly , with SEO-optimized structure and keyword phrase density, to boost online presence and drive conversions.

Tabla de contenido

Introducción

In today’s electronics-driven world, one-size-fits-all manufacturing models no longer suffice. Personalized PCB setting up has come to be crucial for products needing customized capability, one-of-a-kind type factors, or enhanced electrical performance. This highly versatile procedure differs considerably from common assembly lines, supplying bespoke solutions to meet precise consumer demands.

Whether it’s developing low-volume models or constructing complicated commercial systems, companies rely on specialized PCB setting up manufacturing facilities to make and produce printed motherboard suited to their specific applications. This short article uses a complete guide to understanding personalized PCB solutions, highlighting their advantages, common use situations, and just how to choose the best solution partner.

¿Qué es el ensamblaje de PCB hecho a medida?

Custom-made PCB assembly includes positioning electronic components onto a PCB that has been tailored for a specific application. This consists of using non-standard board measurements, custom materials, particular stack-ups, and distinct directing approaches. Customers offer input for style, functionality, and efficiency, making it possible for an extremely enhanced end product.

This approach improves performance by accommodating specialized design rules, thermal administration requirements, and kind factors not sustained by off-the-shelf PCBs.

¿En qué se diferencia exactamente la configuración de PCB personalizada del ensamblaje estándar?

While typical PCB assembly caters to automation with generalized specifications, custom PCB setting up adapts every component to match the client’s goals. Here’s a comparison:

| Función | Standard Setting up | Personalized PCB Setting Up |

|---|---|---|

| Style Flexibility | Minimal | Alto |

| Part Selection | Standard parts just | Complete customization |

| Quantity | High-volume | Reduced to mid-volume, models |

| Expense Efficiency | Affordable at range | Maximized for specialized usage |

| Performance Optimization | General-purpose | Application-specific |

¿Cuáles son las acciones centrales en el ensamblaje de PCB personalizado?

A PCB assembly manufacturing facility performs the complying with stages:

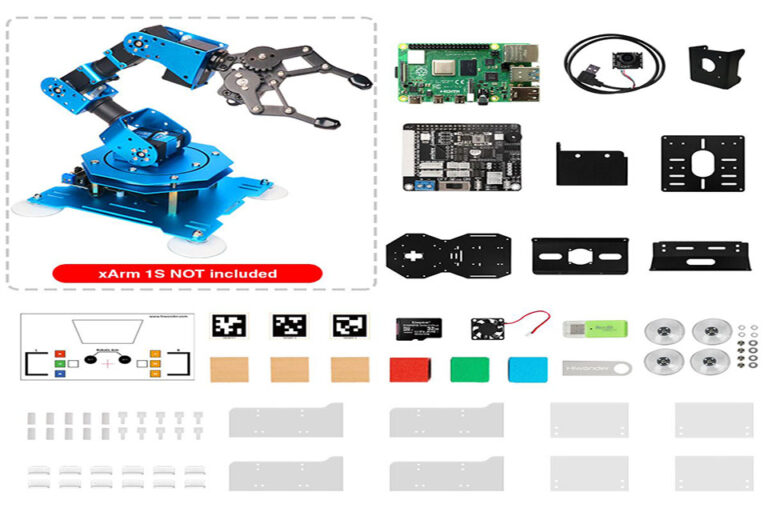

- Style Consultation — Client shares schematic and style requirements.

- Product Option — Choose ideal substrates, copper thickness, and components.

- Prototyping — Develop example boards for performance and performance screening.

- Setting up Refine — Includes SMT, through-hole soldering, and inspection.

- Quality control — Testing ensures each board satisfies standards.

These actions make sure a very trustworthy and high-performance motherboard ideal for its designated usage.

¿Por qué elegir la configuración de PCB personalizada para prototipos?

Personalized PCB services offer an excellent option for constructing models. Design groups can iterate designs rapidly and incorporate specialized attributes. Advantages consist of:

- Faster time-to-market.

- Ability to test product-specific problems.

- Decreased risk of style failure.

Working with a dedicated PCB assembly manufacturing facility throughout the prototype stage makes certain limited comments loopholes and fast changes.

¿Qué industrias dependen del ensamblaje de PCB personalizado?

A number of areas benefit considerably from customized PCB setting up :.

- Medical Gadgets — High reliability and accuracy called for.

- Aerospace & Defense — Personalized boards for mission-critical systems.

- Automotive — Electronic devices for security and infotainment systems.

- Industrial Controls — Specialized PCBs for harsh atmospheres.

Each sector calls for unique board features, such as warm resistance, size restraints, or multi-layer intricacy.

¿Cómo las fábricas de configuración de PCB ayudan con los pedidos personalizados?

PCB assembly manufacturing facilities offer customized workflows to handle diverse demands:.

- Advanced tools for non-standard setting up.

- Engineers to evaluate and enhance customer designs.

- Dedicated lines for prototypes and small-volume runs.

Factories commonly incorporate DFM (Design for Manufacturability) checks to stay clear of pricey mistakes throughout production.

¿Cuáles son los beneficios clave de la configuración de PCB hecha a medida?

- Performance Optimization — Suit element layout to details signal and power needs.

- Compact Styles — Reduce board dimension without endangering functionality.

- Enhanced Sturdiness — Select materials for temperature level, dampness, or vibration resistance.

- Lower Long-Term Price — Greater in advance prices stabilized by efficient performance and low failing rates.

These benefits drive numerous tech business to buy tailored PCB setting up servicios.

¿Qué tener en cuenta al seleccionar una instalación de fabricación de ensamblaje de PCB?

Search for these attributes:.

- Certifications (ISO, IPC standards).

- Prototyping Capabilities .

- Lead Time and Manufacturing Scalability .

- Support for Custom Components and Layouts .

Ask about their record with custom PCB setting up tasks and whether they provide layout support.

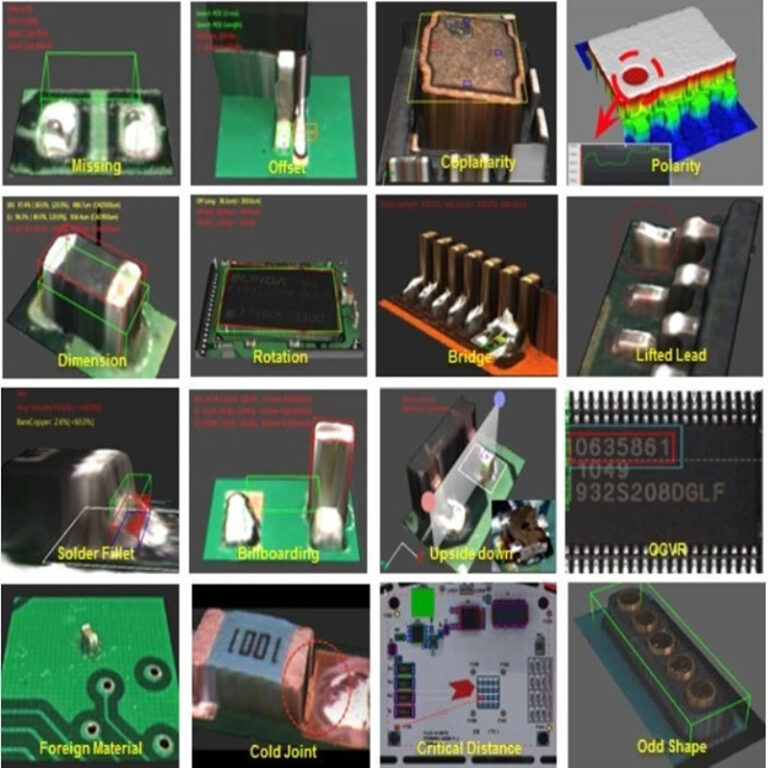

¿Cómo garantizar una alta calidad en la fabricación de PCB a medida?

Make sure top quality by:.

- Selecting seasoned PCB manufacturing facilities with robust screening.

- Requesting AOI and X-ray examination reports .

- Performing electric testing under real-world problems.

Quality assurance is important, especially for industries with regulatory conformity requirements.

What’s the Future of Custom-made PCB Assembly?

Arising patterns consist of:.

- AI-assisted PCB Design .

- 3D-printed motherboard .

- Flexible and wearable electronic devices .

- Eco-friendly producing .

As demands for high-performance, small gadgets grow, custom-made PCB setting up will certainly stay an essential manufacturing procedure.

Preguntas frecuentes.

What’s the future of tailored PCB assembly?

Anticipate automation, AI in design, and lasting production approaches to drive future changes.

¿Cuál es la diferencia entre la configuración de PCB común y la personalizada?

Criterion PCBs are general-purpose, while customized ones are designed for particular applications with tailored requirements.

¿Por qué es vital la configuración de PCB personalizada para los prototipos?

It allows quick layout version and assimilation of special features for screening and recognition.

¿Qué mercados utilizan la configuración de PCB personalizada con mayor frecuencia?

Medical, aerospace, vehicle, and industrial industries.

¿Cómo elegir la mejor fábrica de ensamblaje de PCB?

Look for certifications, prototyping capability, lead time, and previous experience with customized projects.

Are personalized PCBs much more expensive than typical PCBs?

They have higher ahead of time expenses but usually conserve cash with time through reduced failings.

Recap.

- Personalized PCB setting up allows customized remedies.

- Crucial for models, aerospace, medical, and extra.

- Provides layout versatility and lasting price financial savings.

- Pick a factory with strong technical capabilities.

- Future fads will enhance adaptability and speed.