-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

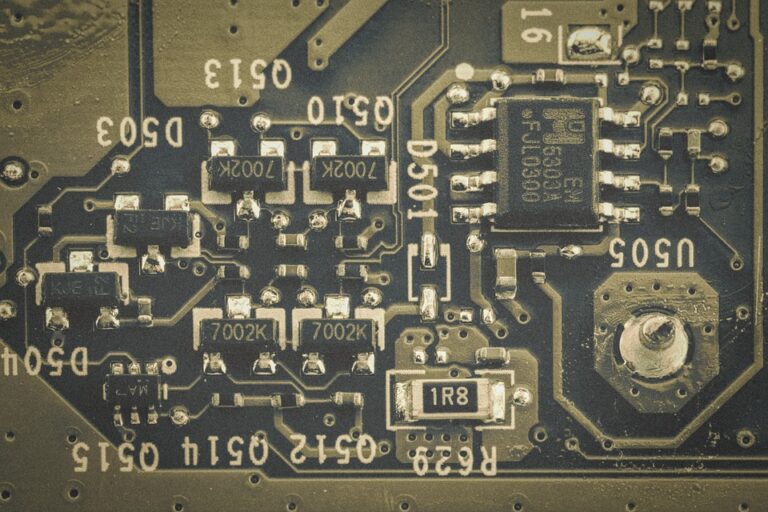

PCB Material Selection: Choosing the Right Substrate for Your Application

[ad_1]

**Material Properties to Consider**

When selecting a PCB material, certain properties must be considered. These include:

* Thermal Properties: thermal expansion, thermal conductivity, and operating temperature range

* Mechanical Properties: flexural strength, tensile strength, and coefficient of thermal expansion

* Electric Properties: dielectric constant, dielectric strength, and dissipation factor

*

**Types of PCB Materials**

PCB materials can be broadly classified into two categories: standard and advanced.

* Standard Materials: FR4 (Fiberglass-reinforced epoxy), FR5 (FRG epoxy), FR6 (FRG-copper), and FR7 (FRG-nickel)

* Advanced Materials: high-frequency materials (e.g., RO3000, RT/Duroid), high-temperature materials (e.g., Amidon’s Toroyd), and high-frequency, high-temperature materials (e.g., Rogers Corporation’s RO4000)

**Standard PCB Materials**

FR4 and FR5 are the most widely used PCB materials. FR4 is a cost-effective option with a simple fabrication process, but it has some limitations, such as high thermal expansion and lower frequency performance. FR5 is more expensive but offers better thermal properties and electrical performance. FR7 is a more expensive option with high thermal and electrical performance but is typically used for high-frequency or high-reliability applications.

**Advanced PCB Materials**

High-frequency materials like RO3000 and RT/Duroid are designed for high-frequency applications, such as antennas, filters, and amplifiers. They offer low dielectric losses, high thermal conductivity, and high-frequency stability. High-temperature materials like Amidon’s Toroyd are designed for high-temperature applications, such as aerospace and defense. RO4000 from Rogers Corporation is a high-frequency, high-temperature material suitable for both high-frequency and high-reliability applications.

**Considerations for Selecting a PCB Material**

When selecting a PCB material, consider the following factors:

* Operating temperature range

* Frequency and impedance

* Thermal and mechanical stress

* Cost and manufacturing complexity

* Reliability and durability

* Time-to-market and production volume

**Case Studies**

To illustrate the importance of selecting the right PCB material, let’s consider two case studies:

* Case Study 1: High-Frequency PCB for RF Amplifier: A high-frequency PCB material like RO3000 or RT/Duroid is required to ensure low dielectric losses and high-frequency stability for a high-frequency RF amplifier.

* Case Study 2: High-Temperature PCB for Aerospace Application: A high-temperature material like Amidon’s Toroyd is necessary to ensure reliable operation in extreme temperatures and harsh environments.

**Conclusion**

Choosing the right PCB material for your project is crucial to ensure reliable, high-performance, and cost-effective PCBs. By considering the required material properties, such as thermal, mechanical, and electric properties, and the specific application requirements, you can select the most suitable PCB material from the available options. Remember to also consider factors like manufacturing complexity, cost, and time-to-market when making your decision.

**FAQs**

Q: What is the main difference between FR4 and FR5?

A: FR4 has a higher thermal expansion coefficient and lower frequency performance, while FR5 has better thermal properties and electrical performance.

Q: What is the primary use of high-frequency materials like RO3000?

A: High-frequency materials are used in high-frequency applications, such as antennas, filters, and amplifiers.

Q: When would you use a high-temperature material like Amidon’s Toroyd?

A: High-temperature materials are used in high-temperature applications, such as aerospace and defense, where reliability and durability are critical.

Q: How do you select the right PCB material for a specific application?

A: Consider the required material properties, application requirements, manufacturing complexity, and cost when selecting the best PCB material for your project.

By considering the factors discussed in this article, you can ensure that you select the right PCB material for your application and achieve the desired performance, reliability, and cost-effectiveness for your project.

[ad_2]