-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

PCB Assembly for Dummies: A Beginner’s Guide to Understanding the Process

[ad_1]

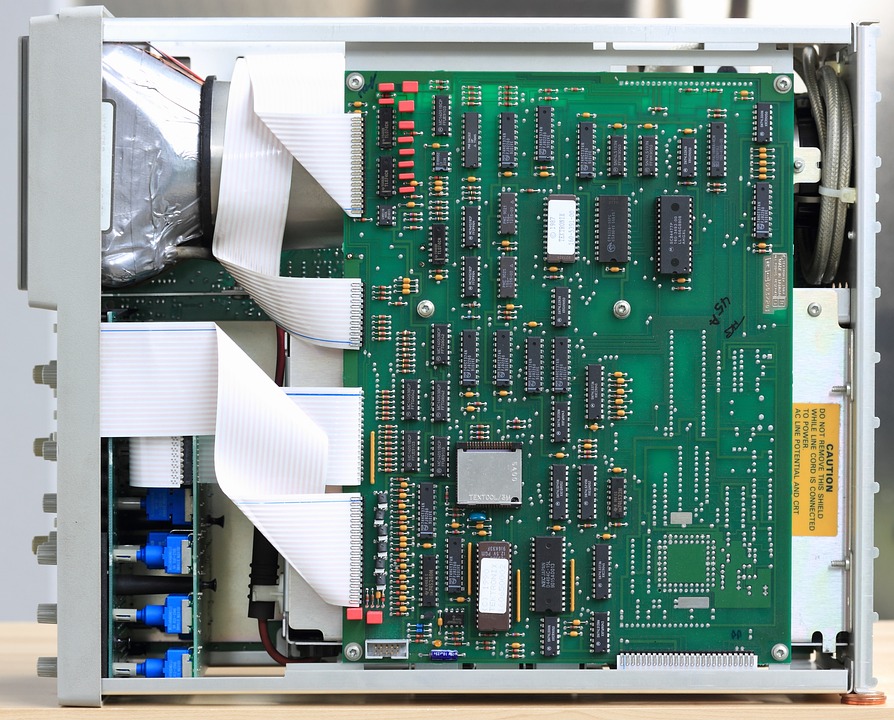

PCB assembly, or printed circuit board assembly, is the process of attaching electronic components to a printed circuit board (PCB) to create a functional electronic device. In this article, we’ll take a step-by-step look at the PCB assembly process, covering the basics, components, and best practices for beginners.

What is PCB Assembly?

PCB assembly is the process of mounting electronic components, such as resistors, capacitors, and integrated circuits, onto a printed circuit board. The PCB serves as the foundation for the electronic device, providing a platform for the components to connect and function together.

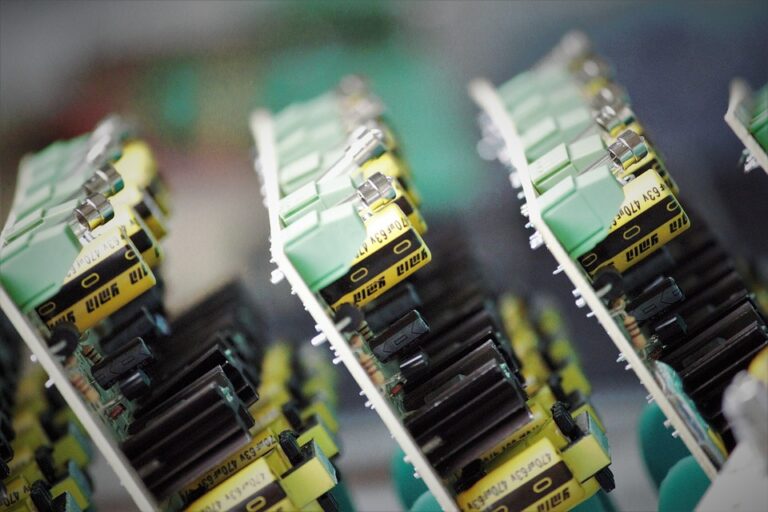

The PCB Assembly Process

The PCB assembly process typically involves the following steps:

- Component preparation**: Electronic components are prepared for assembly by cleaning, inspecting, and sorting them according to their type and value.

- Solder paste application**: A layer of solder paste is applied to the PCB’s pads, where the components will be attached.

- Soldering**: The PCB is then subjected to a soldering process, where the solder paste melts and forms a strong bond between the components and the PCB.

- Inspection and testing**: The assembled PCB is inspected for defects and tested to ensure it functions as intended.

li>Component placement**: Components are carefully placed onto the PCB, ensuring they are aligned with the pads and pads are not damaged.

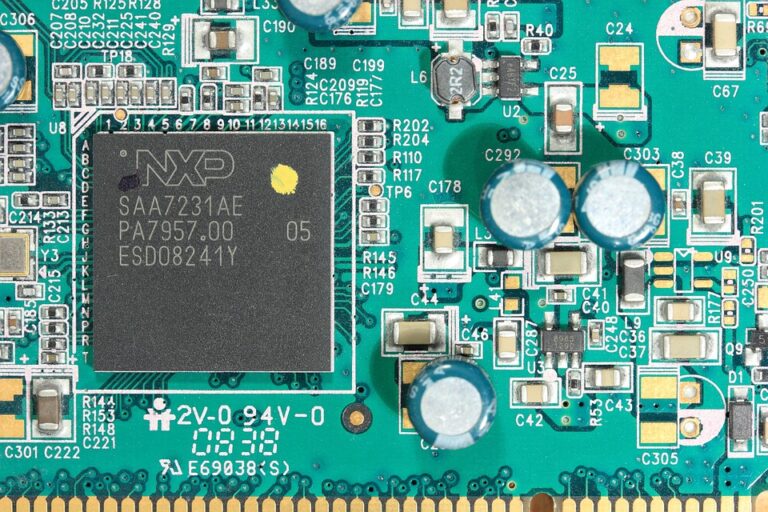

Components Used in PCB Assembly

PCB assembly requires a variety of electronic components, including:

- Passive components**: Resistors, capacitors, and inductors that do not amplify or modify the signal.

- Active components**: Integrated circuits, diodes, and transistors that amplify or modify the signal.

- Interconnects**: Wires, connectors, and sockets that connect components together.

- PCB materials**: Printed circuit board materials, such as FR4, FR5, and Rogers, that provide the foundation for the assembly.

Best Practices for PCB Assembly

To ensure a successful PCB assembly, it’s essential to follow best practices, including:

- Component handling**: Handle components carefully to avoid damage and ensure they are properly aligned during placement.

- Soldering techniques**: Use proper soldering techniques, such as using a soldering iron with a controlled temperature and applying the right amount of solder.

- PCB cleaning**: Clean the PCB regularly to remove dirt, dust, and other contaminants that can affect the assembly process.

- Component inspection**: Inspect components and the PCB for defects before and after assembly to ensure a high-quality finish.

Conclusion

PCB assembly is a complex process that requires attention to detail, precision, and a solid understanding of the components and techniques involved. By following the steps outlined in this article, beginners can gain a better understanding of the PCB assembly process and produce high-quality assemblies. Remember to handle components carefully, use proper soldering techniques, and inspect the PCB regularly to ensure a successful assembly.

FAQs

Q: What is the most common type of PCB material used in assembly?

A: FR4 (Flame Retardant 4) is the most common type of PCB material used in assembly.

Q: What is the best way to handle components during assembly?

A: Handle components carefully, using tweezers or a component handler, to avoid damage and ensure proper alignment during placement.

Q: What is the most common defect in PCB assembly?

A: The most common defect in PCB assembly is solder bridging, where excess solder forms a bridge between two pads.

Q: Can I assemble a PCB by myself?

A: Yes, with proper training and equipment, it is possible to assemble a PCB by yourself. However, it’s recommended to seek guidance from an experienced assembler or take a training course to ensure a high-quality finish.

Q: What is the best way to clean a PCB during assembly?

A: Use a gentle cleaning solution, such as isopropyl alcohol, and a soft-bristled brush to clean the PCB regularly during assembly.

[ad_2]