Was ist eine schlüsselfertige Leiterplattenbestückung? Der Leitfaden für PCBA- und PCB-Einrichtungslösungen für Produktionsstätten

Abstrakt:

Complete PCB setting up is transforming exactly how electronic devices firms bring products to market. This guide explains the complete PCB setting up procedure, its advantages, and why dealing with a specialist PCB assembly factory is the best choice for effectiveness, top quality, and cost savings. Whether you’re a designer, buyer, or business owner, this post will certainly aid you comprehend exactly how turnkey PCBA services can streamline your production and enhance your one-upmanship.

Intro: Die Macht der schlüsselfertigen Leiterplattenbestückung

In the fast-moving globe of electronic devices, rate and reliability are every little thing. Turnkey PCB assembly uses a total option for firms that intend to streamline their supply chain and concentrate on technology. By letting a solitary PCB assembly manufacturing facility handle every action– from design to delivery– you conserve time, lower costs, and ensure regular quality. This post discovers exactly how turnkey PCBA functions, why it matters, and just how it can aid your business prosper in today’s requiring market.

Inhaltsverzeichnis

Was ist die schlüsselfertige Leiterplattenbestückung?

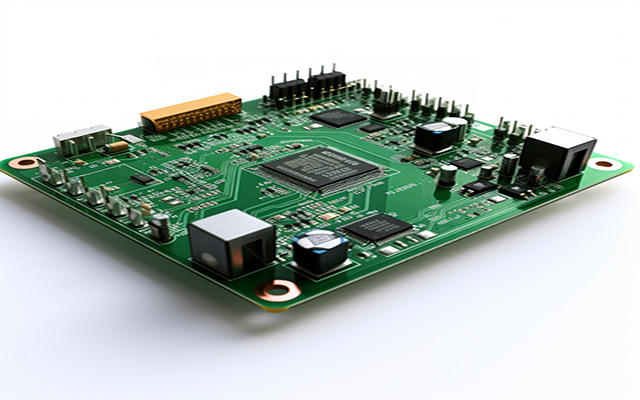

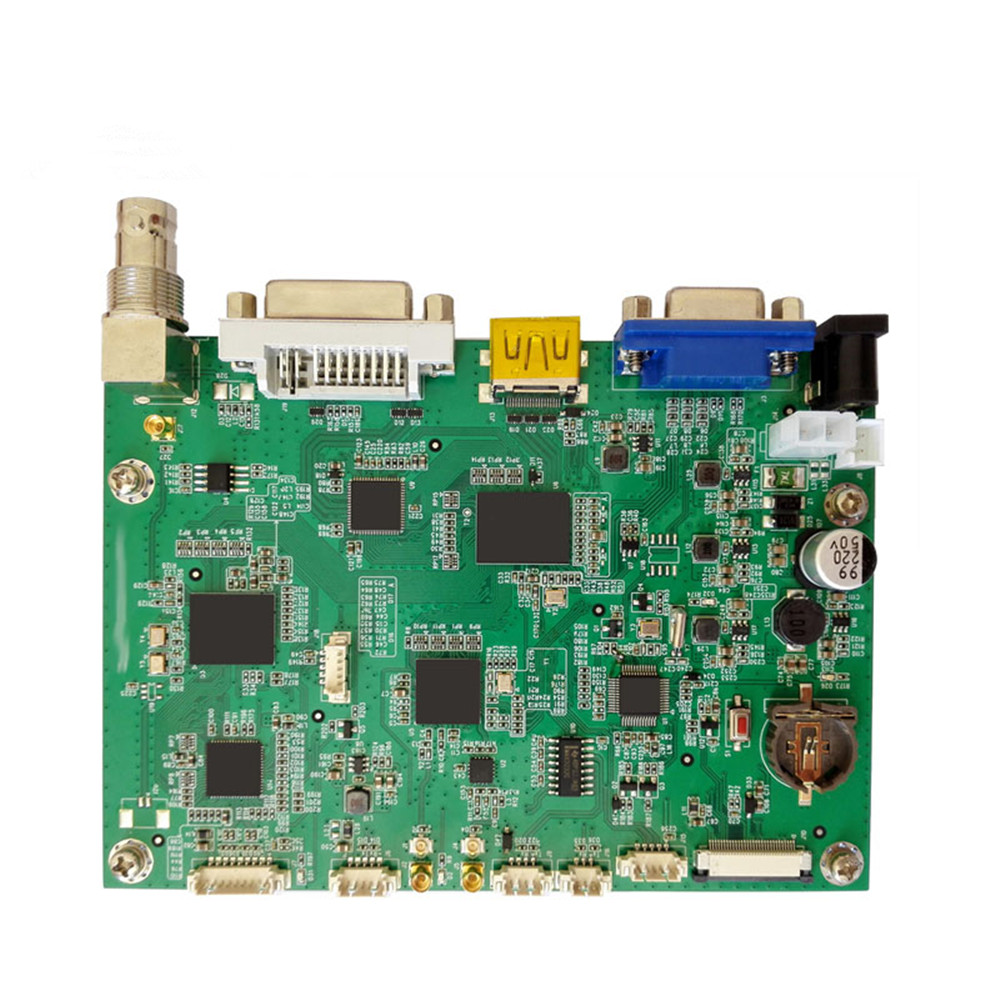

Complete PCB setting up is a comprehensive service where a single supplier manages every element of printed motherboard manufacturing. The consumer sends style documents, such as Gerber documents and an Expense of Materials (BOM), and the PCB setting up factory deals with every little thing else: element sourcing, PCB fabrication, assembly, testing, packaging, and delivery. The outcome is a completely practical, ready-to-use PCB that can be incorporated directly right into your item

This strategy simplifies manufacturing. You do not need to collaborate with multiple suppliers or fret about sourcing parts. Rather, you focus on product layout and let the professionals deal with the technological details. The term “turnkey” indicates the product awaits immediate use– just like turning a vital to begin a vehicle

Wie genau funktioniert der komplette Leiterplattenbestückungsprozess?

Der complete PCB setting up procedure adheres to a clear, step-by-step process:.

- Design Entry: You supply in-depth layout data, including Gerber documents, BOM, and assembly illustrations.

- Part Sourcing: The assembly factory obtains all essential components, guaranteeing quality and compatibility.

- PCB Fabrication: The factory produces the physical PCB according to your specifications.

- Setting up: Automated machines and competent service technicians area and solder components onto the board.

- Evaluating: Extensive screening guarantees each board fulfills performance and reliability criteria.

- Packaging and Shipping: The ended up PCBs are packaged and shipped to your area

This end-to-end solution guarantees a smooth experience, with the PCB assembly manufacturing facility taking full obligation for each phase.

Was sind die Knackpunkte bei der kompletten PCBA?

Allow’s break down each stage of the complete PCBA procedure:.

1. Layout und Engineering.

- Engineers evaluate your design apply for manufacturability.

- Layout for Production (DFM) checks determine prospective problems early.

- The factory might recommend renovations to enhance efficiency and reduce expenses

2. Elementbeschaffung.

- The factory resources components from trusted suppliers.

- Mass investing in decreases expenses and ensures accessibility.

- Quality control checks verify credibility and compliance with requirements

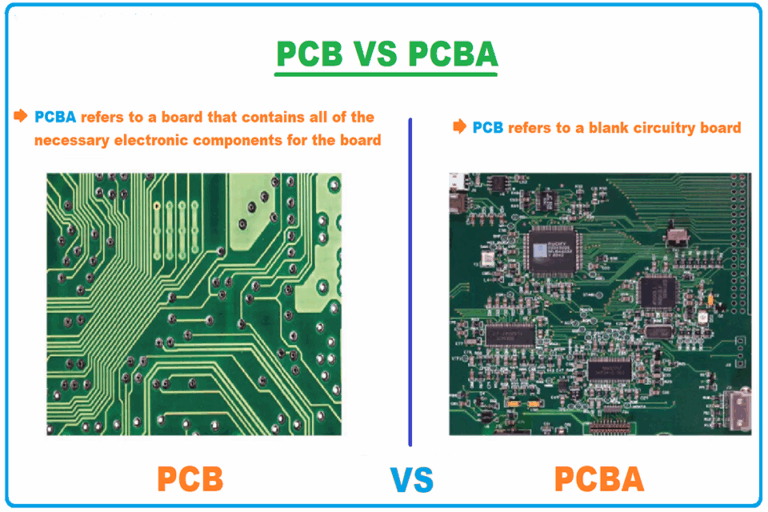

3. PCB-Konstruktion.

- Advanced manufacturing strategies develop precise, trustworthy boards.

- Procedures include etching, drilling, and layering.

- Factories utilize materials like FR4, polyimide, or steel core for specific applications

4. Lotpastenapplikation.

- Automated stenciling applies solder paste to marked areas.

- This step ensures solid, dependable solder joints.

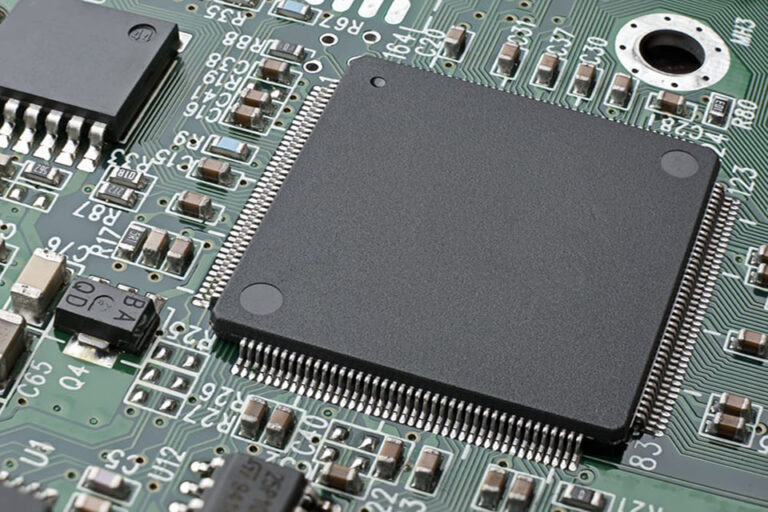

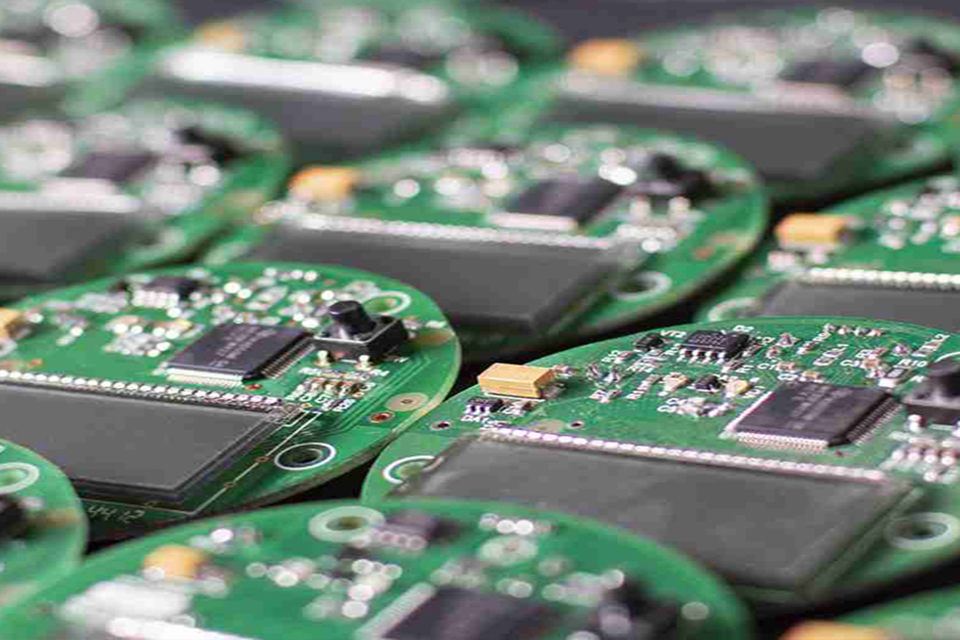

5. Komponentenpositionierung.

- Surface Area Mount Technology (SMT) machines put parts with high accuracy.

- Through-hole parts are put manually or by equipment, as required

6. Löten.

- Reflow ovens melt solder paste for SMT elements.

- Wave or careful soldering protects through-hole parts.

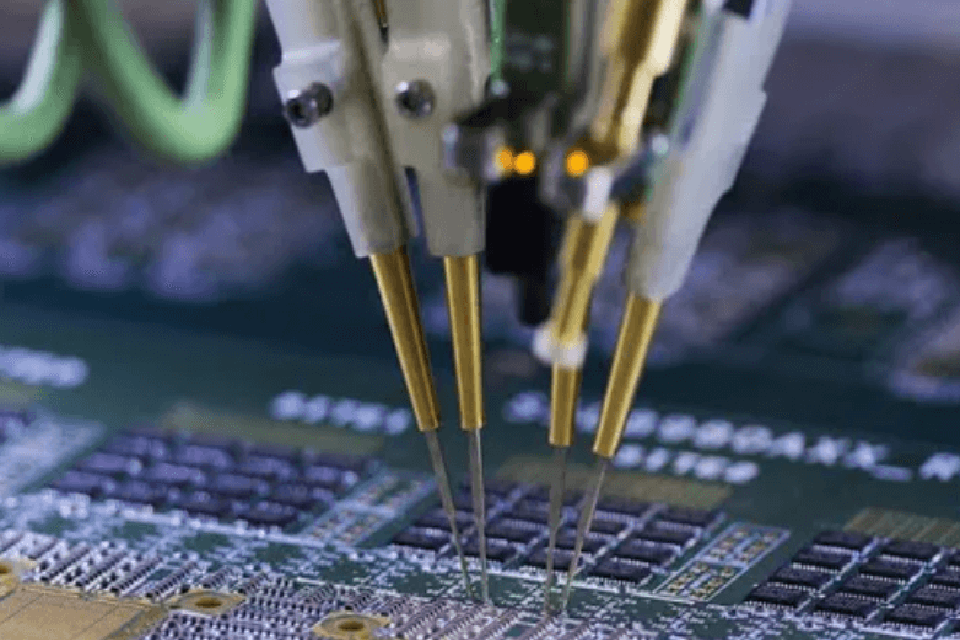

7. Inspektion und Überprüfung.

- Automated Optical Inspection (AOI) and X-ray checks detect issues.

- Practical screening mimics real-world operation to verify efficiency

8. Letzte Montage und Produktverpackung.

- Boards are cleaned up, labeled, and packaged for shipment.

- The manufacturing facility makes sure safe shipment to your place

Warum eine komplette Leiterplattenbestückungsfabrik wählen?

Selecting a specialist PCB setting up manufacturing facility for complete solutions offers several benefits:.

- Single Point of Contact: Simplifies interaction and project management.

- Expertise: Manufacturing facilities employ knowledgeable designers and specialists.

- Advanced Devices: Modern factories utilize cutting edge equipment for precision and performance.

- Qualitätssicherung: Integrated quality control at every phase guarantees dependable outcomes

By partnering with a trusted manufacturing facility, you gain access to market ideal practices and advanced innovation.

Was sind die Vorteile der schlüsselfertigen Leiterplattenbestückung?

Complete PCB assembly provides various advantages over traditional, fragmented strategies:.

- Time Financial Savings: Consolidating all actions under one roofing lowers lead times.

- Cost Efficiency: Mass buying and structured logistics reduced general prices.

- Constant Quality: Centralized quality control minimizes issues and revamp.

- Simplified Supply Chain: You prevent the intricacy of taking care of several suppliers.

- Scalability: Manufacturing facilities can deal with both little prototype runs and large manufacturing

These benefits make complete PCBA the recommended choice for lots of electronic devices producers.

Welche Herausforderungen gibt es bei der Einrichtung von schlüsselfertigen Leiterplatten?

In spite of its several benefits, turnkey PCB assembly provides some difficulties:.

- Part Shortages: International supply chain interruptions can delay purchase.

- Layout Issues: Inadequately enhanced layouts might cause production troubles.

- Quality Control: Making certain consistent top quality throughout large volumes requires robust systems.

- Interaction: Clear, ongoing interaction in between you and the factory is crucial

Leading factories resolve these obstacles by preserving solid supplier partnerships, purchasing innovative examination tools, and offering design assistance services.

Wie genau stellen Leiterplattenbestückungsfabriken eine hohe Qualität sicher?

High quality is extremely important in PCB setting up factory procedures. Manufacturing facilities apply rigorous quality assurance actions at every phase:.

- IPC and ISO Requirements: Manufacturing facilities adhere to industry requirements like IPC-A-610 and ISO 9001.

- Automated Assessment: AOI, X-ray, and practical screening catch defects early.

- Product Verification: Inbound materials undertake rigorous checks for credibility and compliance.

- Continual Renovation: Manufacturing facilities make use of feedback and information evaluation to fine-tune procedures

These techniques make certain that every PCBA satisfies or surpasses your assumptions.

What Are the most up to date Fads in Turnkey PCB Assembly?

Der turnkey PCB assembly sector is advancing swiftly. Secret fads consist of:.

- Miniaturisierung: High-Density Interconnect (HDI) PCBs make it possible for smaller sized, extra effective gadgets.

- Automation: Robotics and AI enhance effectiveness and minimize errors.

- Sustainability: Manufacturing facilities embrace environment-friendly materials and processes.

- 5G Combination: Advanced PCBs sustain high-frequency, high-speed communication.

- Fortgeschrittene Materialien: Use polyimide, ceramic, and steel core PCBs for specialized applications

Staying educated about these patterns assists you continue to be competitive and ingenious.

How Does Complete PCBA Compare to Other Approaches?

Turnkey PCBA stands out from typical PCB production approaches:.

- Traditional Approach: You handle design, purchase, manufacture, and setting up separately. This raises complexity, threat, and lead times.

- Turnkey Technique: A solitary provider handles every little thing, using a smooth, reliable experience.

- Partial Turnkey: Some customers go with partial solutions, but this can still include control challenges

Turnkey solutions use the very best equilibrium of speed, high quality, and cost-effectiveness.

Frequently Asked Questions Regarding Complete PCB Assembly

What is complete PCB setting up?

Complete PCB assembly is a service where a single supplier manages all elements of PCB manufacturing, from layout to distribution, guaranteeing a ready-to-use item

What are the main benefits of turnkey PCBA?

Trick advantages include time and expense financial savings, consistent high quality, streamlined task monitoring, and access to expert sources

Just how do factories make certain component high quality? .

Factories resource parts from relied on vendors, carry out high quality checks, and use advanced evaluation techniques to ensure integrity

Can complete PCB setting up handle both prototypes and automation?

Yes, the majority of manufacturing facilities offer flexible services for both little and large production runs

What challenges might I confront with turnkey PCBA?

Common obstacles include part lacks, style concerns, and communication voids. Selecting a seasoned manufacturing facility aids reduce these threats

Just how do I select the ideal PCB setting up factory?

Look for manufacturing facilities with solid market accreditations, sophisticated devices, positive customer testimonials, and clear interaction

Summary Bullet Details: .

- Turnkey PCB setting up streamlines the entire PCBA procedure.

- Factories handle layout, purchase, manufacture, assembly, and screening.

- Clients take advantage of lowered preparations, lower prices, and higher quality.

- Industry patterns consist of miniaturization, automation, and sustainability.

- Choosing the ideal manufacturing facility is crucial to task success.