Was ist der Unterschied zwischen teilbestückter und komplett bestückter Leiterplattenbestückung?

Understand the two leading PCB setting up strategies– consigned and turnkey– to enhance your production procedure, equilibrium control and threat, and accomplish faster item launch. .

Abstrakt

When partnering with a PCB setting up maker , choosing between consigned Und vollständig models significantly effects production efficiency, expense, threat, and control. This short article discusses these 2 methods thoroughly. It assists designers, buyers, and OEMs make educated choices that line up with their supply chain capacities, project timelines, and organization techniques. Viewers will certainly get insight into the compromises, dangers, and advantages of each model in the context of Leiterplatte (PCB) Und Leiterplattenbaugruppe Produktion.

Inhaltsverzeichnis

Intro: Warum Ihre Wahl der PCB-Einrichtung Versionsprobleme verursacht

In today’s hectic electronic devices making landscape, selecting the right PCB assembly option is important. 2 extensively utilized versions– consigned PCB assembly Und turnkey PCB setting up — use different advantages depending on your job’s scope and your degree of control over component sourcing.

Making the wrong decision may delay your product launch or rise prices. The ideal strategy, however, simplifies procedures, makes certain quality, and increases time-to-market. Allow’s explore both alternatives extensive.

1. Was ist die Einrichtung einer Konsignations-Leiterplatte?

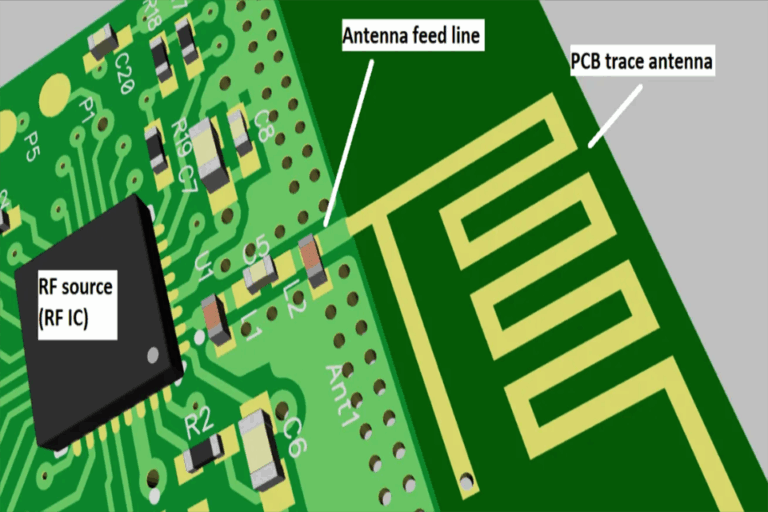

Consigned PCB assembly is a manufacturing strategy where the customer supplies all or most of the products, consisting of PCB boards , digital elements , and special directions. The PCB setting up producer focuses only on putting together the product.

Geheime Funktionen der beauftragten Einrichtung

- Client-supplied materials like resistors, capacitors, ICs, and bare PCBs.

- Control over part selection, vendor sourcing, and quality assurance.

- Frequently chosen by firms with established supply chains or tight design controls.

2. Was ist die schlüsselfertige Einrichtung von Leiterplatten?

Turnkey PCB setting up is a complete option. The PCBA producer takes care of everything– from part procurement to end product screening. This model enables clients to focus on core R \ & D and market strategy.

Trickfunktionen der vollständigen Baugruppe:

- Der PCB assembly service provider takes care of the full process.

- Lowers inner work and streamlines production.

- Suitable for startups, small businesses, or immediate task timelines.

3. Worin unterscheiden sich Eigentum und Verantwortung?

In Auftragsmontage:.

- Client keeps ownership of all offered parts.

- They are responsible for any type of shortages , defective components , oder logistical concerns .

In Vollständige Einrichtung:.

- Assembly service provider has the materials till shipment.

- They manage stock , quality control , Und supply chain risks .

Possession straight affects risk exposure and functional intricacy.

4. That Controls the High Quality in Each Design?

Consigned Model .

- The customer oversees component authenticity Und Leistung .

- Matched for high-reliability applications like clinical gadgets oder aerospace systems .

Complete Version .

- The supplier assumes complete QA/QC duties .

- They may supply automatic optical inspection (AOI), X-ray, and ICT screening.

5. What Regarding Risk and Obligation Circulation?

Consigned Setting Up Threats: .

- Customers deal with risks like delivery damage or EOL elements .

- Any kind of delay in supplying products delays the PCBA timetable .

Turnkey Setting Up Risks: .

- Setting up partner bears dangers of sourcing and purchase.

- Customers trust the service provider’s BOM experience Und provider network .

6. Exactly how Does Each Version Affect Task Timelines?

Consigned PCB Assembly: .

- Longer lead times as a result of element logistics.

- Hold-ups from internal buying or personalizeds concerns.

Complete PCB Assembly: .

- Faster turnaround as a result of vendor-managed sourcing.

- Appropriate for quick prototyping Und quantity production .

7. Welche Preisauswirkungen hat das jeweils?

| Cost Element | Consigned Setting up | Complete Assembly |

|---|---|---|

| Component Price | Client-controlled | Vendor markup consisted of |

| Purchase Overhead | Inner initiative needed | Vendor takes care of everything |

| Supply Administration | Client manages | Supplier maintains |

| Assembly Charge | Typically lower | Somewhat higher as a result of solution range |

8. Welche Branchen bevorzugen welche Version?

- Medical and Aerospace frequently choose consigned due to strict governing sourcing.

- Startups and IoT brand names favor schlüsselfertig to lower expenses and speed up go-to-market.

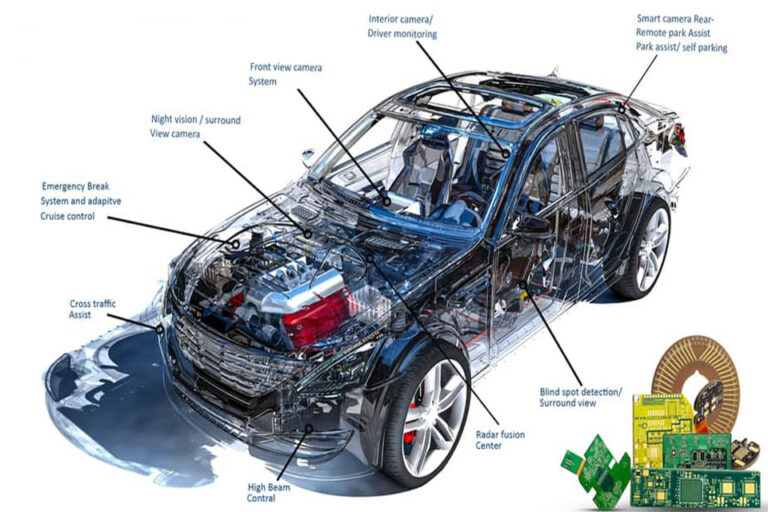

- Leiterplatten für die Automobilindustrie producers may select hybrid versions for equilibrium.

9. Was sind die Vor- und Nachteile?

✅ Vorteile der Einrichtung eines Konsignationslagers

- Greater control over components and vendors.

- Useful for particular niche or high-precision PCB projects .

- Secures exclusive BOMs and part sources.

❌ Nachteile der Einrichtung eines Konsignationslagers

- Rises procurement work.

- Risk of component inequality or hold-up.

✅ Pros of Complete Setting Up

- Time-saving and fully managed.

- Less internal competence required for sourcing.

- Alles aus einer Hand PCB setting up option .

❌ Disadvantages of Turnkey Setting Up

- Less control over component choice.

- Reliance on company’s top quality requirements.

10. When Should You Choose One Over the Other?

Select consigned PCB assembly if:.

- You have specialized or uncommon components.

- You require tight control over every manufacturing detail.

- Your internal team is capable of dealing with logistics and QA.

Wählen turnkey PCB setting up if:.

- You’re under time constraints.

- You want to streamline operations.

- You do not have internal procurement resources.

Final thought

Recognizing the distinction between schlüsselfertig Und consigned PCB setting up aids organizations make much better production choices. Complete streamlines the procedure, while consigned deals tighter control. The ideal choice depends upon your task demands, available resources, and resistance for risk. By aligning your setting up strategy with your functional goals, you’ll boost manufacturing performance and product high quality.

FAQs

What is the main benefit of complete PCB assembly?

Complete saves time and streamlines production by letting the producer deal with sourcing, testing, and shipment.

Is consigned PCB assembly cheaper than complete?

Not constantly. While the assembly cost may be reduced, general prices might rise as a result of internal procurement and logistics burdens.

Can I mix both turnkey and consigned designs in one task?

Yes. Many PCB setting up suppliers support hybrid models, allowing clients to supply some components while the supplier sources others.

Who takes care of quality assurance in complete PCB assembly?

The assembly supplier handles top quality checks making use of advanced evaluation tools, minimizing your interior QA effort.

When should a start-up select consigned assembly?

Hardly ever. Startups frequently profit more from complete models due to restricted sources and time restrictions.

Just how does turnkey PCBA assistance much faster item launch?

By removing sourcing delays and element mismatches, complete services accelerate model and production distribution.

Zusammenfassung

- Schlüsselfertig = Complete remedy with much less control yet faster outcomes.

- Consigned = Client-controlled with even more obligation and oversight.

- Select based upon control needs, sources, and risk tolerance.

- Both models are widely sustained by PCB assembly suppliers .

- Lasting method benefits from examining hybrid services.

- Select a dependable PCBA companion that offers both versions for adaptability.