Die Leistungsfähigkeit der schlüsselfertigen Leiterplattenfertigung für eine effiziente Produktion freisetzen

Abstrakt:

In today’s electronic devices market, companies demand efficient, dependable, and affordable solutions for published circuit card (PCB) manufacturing and setting up. Complete PCB production stands out as a one-stop remedy, dealing with every action from layout to delivery. This short article explores what turnkey PCB manufacturing suggests, its benefits, the vital procedures entailed, and why choosing the appropriate PCB setting up producer can drive your product’s success. If you want to streamline your supply chain, conserve time and money, and make certain product top quality, this write-up is a must-read.

Inhaltsverzeichnis

What Is Turnkey PCB Manufacturing?

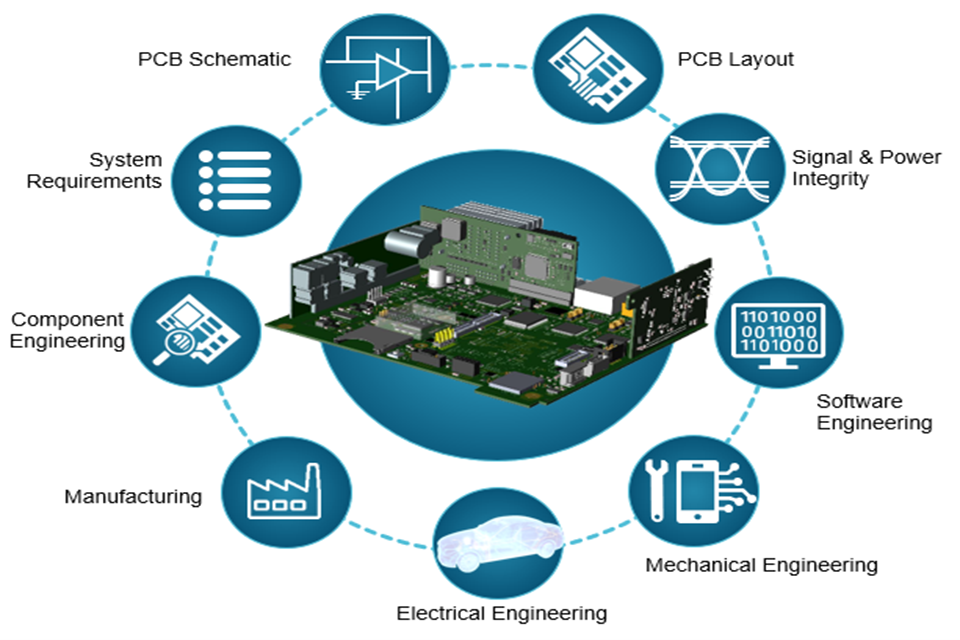

Turnkey PCB production is an extensive service where a solitary supplier handles the entire process of creating published circuit boards. From first design and engineering to product sourcing, manufacturing, setting up, testing, packaging, and shipping, the turnkey company manages everything. Customers just provide their styles or requirements, and the supplier supplies a completed, ready-to-use PCB.

Trick Terms: .

- Leiterplattenproduktion .

- PCB assembly supplier .

- One-stop PCB service .

- EMS carrier (Electronics Manufacturing Provider).

This approach gets rid of the demand for customers to coordinate with multiple suppliers, minimizing complexity and conserving valuable time.

How Does Turnkey PCB Manufacturing Work?

Der complete PCB process begins when a customer sends their item concept or design data. The PCB setting up producer then takes control of, managing all succeeding actions. This consists of:.

- Layout Testimonial: Specialists check files for manufacturability and suggest improvements.

- Product Procurement: The carrier resources all elements and basic materials.

- PCB Manufacture: The real boards are manufactured according to specs.

- Assembly and Screening: Components are installed and soldered, complied with by practical testing.

- Product packaging and Shipping: Finished products are securely packaged and supplied.

Using a complete service suggests you gain from a solitary point of get in touch with und ein streamlined process .

Why Select a Turnkey PCB Setting Up Supplier?

Partnering with a reputable PCB assembly manufacturer offers several advantages. First, you avoid the inconvenience of coordinating with numerous distributors for different stages of production. Second, your job take advantage of the supplier’s experience and established procedures.

Secret Advantages: .

- Regular High Quality: Unified processes make certain uniform criteria.

- Faster Turnaround: Integrated operations accelerate manufacturing.

- Expense Efficiency: Bulk acquiring and streamlined logistics minimize expenditures.

A trustworthy PCB setting up manufacturer can take your concept from principle to market efficiently.

What Are the Essential Steps in Turnkey PCB Manufacturing?

Comprehensive complete PCB manufacturing includes numerous interconnected stages:.

- Layout and Prototyping: . The procedure starts with design support to enhance PCB layouts for manufacturability and expense.

- Product Sourcing: . The maker obtains all elements, making sure both quality and supply chain dependability.

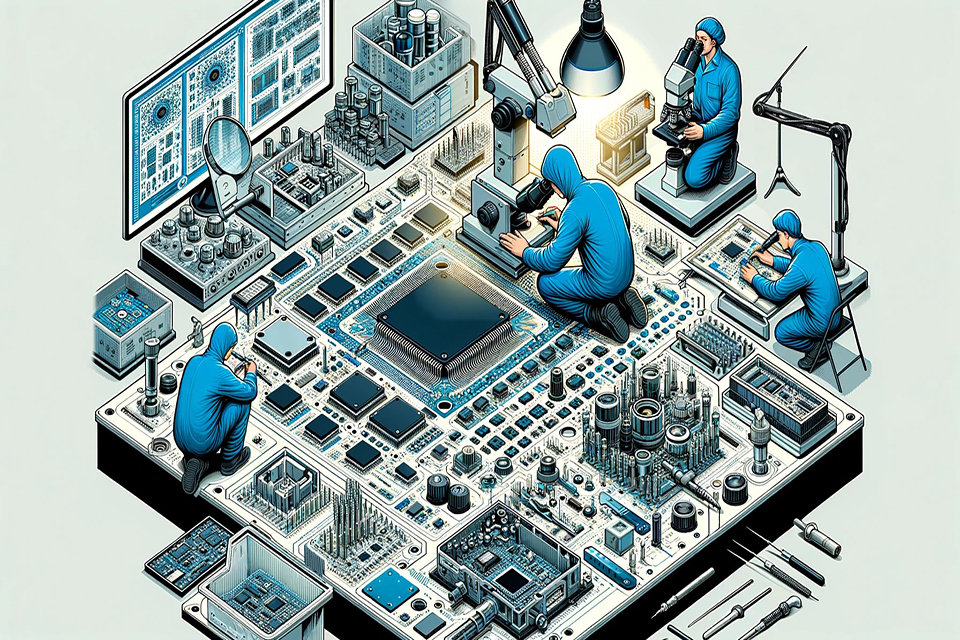

- Production and Setting up: . Advanced machinery produces the boards and constructs parts, utilizing surface-mount technology (SMT) and through-hole methods.

- Examination and Testing: . Quality control checks include AOI (automated optical assessment), X-ray assessment, and functional testing.

- Product packaging and Shipping: . Finished PCBs are packaged securely and shipped directly to the customer or end consumer.

Key Terms: .

- BOM (Bill of Products) administration .

- DFM (Layout for Manufacturability) .

- AOI (Automated Optical Evaluation) .

Just How Does Turnkey PCB Production Streamline Supply Chains?

Complete PCB production simplifies the supply chain by combining all production phases under one roof covering. This approach lessens interaction malfunctions, reduces preparations, and simplifies logistics.

Perks: .

- Centralized Purchase: The manufacturer manages all material sourcing and supply.

- Simplified Logistics: Less deliveries and hand-offs accelerate distribution.

- Faster Trouble Resolution: One carrier addresses any kind of problems promptly.

This design allows businesses focus on their core expertises while the complete companion takes care of production.

What Are the Secret Perks of Turnkey PCB Manufacturing?

Turnkey PCB manufacturing supplies a wide range of benefits, making it a preferred choice for lots of business:.

- Time Financial Savings: Simplified operations cut preparations considerably.

- Price Decrease: Consolidated purchasing and logistics lower total costs.

- Quality control: Integrated high quality checks at every phase make sure remarkable items.

- Threat Reduction: Less suppliers imply much less danger of miscommunication or supply chain interruptions.

- Accessibility to Know-how: Manufacturers bring thorough knowledge of PCB technologies and sector criteria.

Related Terms: .

- End-to-end PCB services .

- Full-service PCB carrier .

- SMT-Einrichtung .

How Do You Select the Best Complete PCB Manufacturing Partner?

Die Wahl des Besten PCB assembly supplier is vital. Consider the following aspects:.

- Experience: Seek firms with a proven record in your industry.

- Quality Certifications: ISO 9001, IPC criteria, and RoHS compliance show high quality.

- Technology Capabilities: Advanced SMT lines, AOI systems, and X-ray assessment ensure precision.

- Customer Assistance: Receptive service and clear interaction are necessary.

Ask about their design support, prototyping solutions, and capability to manage large or complicated jobs.

What Are the Typical Challenges in PCB Manufacturing and Just How Does Turnkey Service Aid?

Standard Leiterplattenproduktion often faces challenges such as:.

- Supplier Sychronisation: Managing multiple vendors raises the risk of delays and errors.

- Part Shortages: Sourcing issues can halt production.

- Top quality Variability: Various vendors may follow differing requirements.

Turnkey PCB production addresses these issues by offering a combined solution. The supplier manages every information, from component sourcing to last screening, making certain regular top quality and timely delivery.

How Does Complete PCB Manufacturing Enhance Item High Quality and Integrity?

A turnkey PCB assembly maker makes certain high product quality with:.

- Integrated Quality Assurance: High quality checks occur at each phase, from style to shipment.

- Traceability: All parts and processes are documented, assisting troubleshooting.

- Advanced Screening: Useful and environmental examinations assure performance.

This technique results in trustworthy, high-grade PCBs that meet or surpass sector criteria.

What’s the Future of Complete PCB Manufacturing?

195. Die Zukunft der complete PCB manufacturing looks encouraging. Fads include:.

- Increased Automation: Robotics and AI enhance performance and precision.

- Smarter Supply Chains: Digital systems optimize purchase and inventory.

- Sustainability Initiatives: Environment-friendly materials and processes lower ecological impact.

Services that accept turnkey PCB services will benefit from faster innovation cycles and improved competition.

Häufig gestellte Fragen (FAQs)

What is complete PCB production?

Turnkey PCB production is a full-service approach where a single carrier takes care of all processes from style to delivery.

Exactly how do I pick a reliable PCB assembly supplier?

Check for market accreditations, advanced technology, consumer evaluations, and responsive support.

What are the primary advantages of complete PCB manufacturing?

Trick benefits consist of time and price financial savings, improved top quality, and streamlined supply chain management.

Can complete suppliers handle large or complex jobs?

Yes, knowledgeable service providers have the proficiency and sources for high-volume or elaborate layouts.

Are complete PCB remedies ideal for start-ups?

Definitely. Start-ups gain from skilled assistance, reduced access obstacles, and much faster time-to-market.

Does complete PCB making assistance quick prototyping?

A lot of carriers provide quick-turn prototyping services as component of their turnkey option.

Final thought: Why Complete PCB Production Is a Smart Selection.

Turnkey PCB production offers a streamlined, affordable, and dependable path from concept to end product. By settling all producing stages, companies save time, decrease expenses, and accomplish better. Dealing with a proven PCB setting up maker ensures competence and responsibility, aiding your products get to the market quicker and extra successfully.