-

Xinxintian Industrial Zone, Shajing Street,Bao'an District, Shenzhen, China

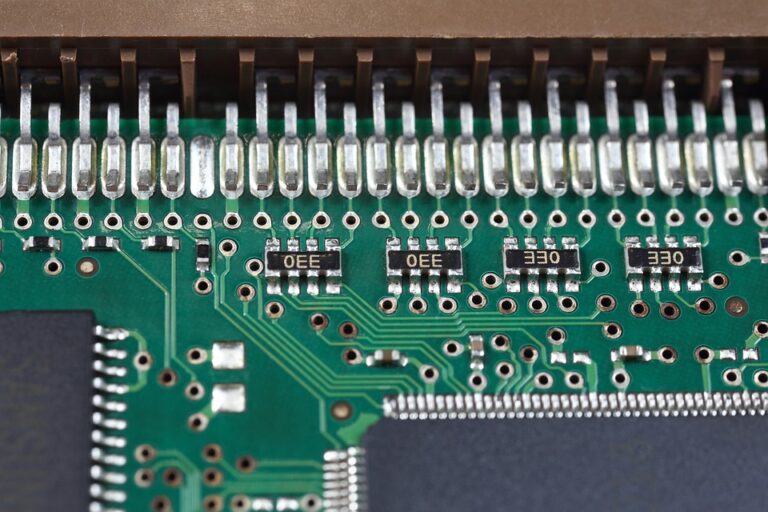

Troubleshooting Common PCB Problems: A Guide to Debugging and Repair

[ad_1]

In the world of electronics, printed circuit boards (PCBs) are the backbone of many electronic devices. A well-designed and manufactured PCB is crucial for the smooth operation of these devices. However, PCBs are prone to various types of problems that can cause errors, malfunctions, or even complete failure of the device. In this article, we will discuss common PCB problems, their causes, and methods for troubleshooting and repairing them.

Common PCB Problems

PCBs are prone to several types of problems, including:

- Solder joint failures

- Copper pad or land damage

- PCB contamination

- Poor PCB design or manufacturing quality

- Electrical overstress or ESD (Electrostatic Discharge)

li>

Component damage or wear and tear

These problems can occur due to various factors such as poor soldering techniques, environmental conditions, manufacturing defects, or human error.

Troubleshooting PCB Problems

Troubleshooting PCB problems requires a systematic approach to identify the root cause of the issue. The following steps can be followed:

- Identify the symptoms: Determine the exact symptoms of the problem, such as malfunctioning circuits, component failures, or visual damage.

- Isolate the problem area: Use electrical testing tools, such as a multimeter, oscilloscope, or logic analyzer, to isolate the problematic area of the PCB.

- Visual inspection: Perform a visual inspection of the PCB to identify any visible signs of damage, wear, or contamination.

- Test the PCB: Perform functional tests to verify the operation of each circuit or component on the PCB.

- Analyze the results: Analyze the test results to identify the root cause of the problem and determine the best course of action for repair or replacement.

In addition to these steps, the following techniques can be used to troubleshoot PCB problems:

- PCB desoldering and rework

- Component repair or replacement

- PCB cleaning and surface preparation

- Copper pad or land repair

- PCB redesign or remanufacturing

Repair and Replacement

Once the root cause of the problem has been identified, the next step is to decide whether to repair or replace the PCB. Repairing a PCB can be a cost-effective and environmentally friendly solution, but it may not always be possible. In some cases, it may be more efficient to replace the PCB with a new one, especially if the problem is caused by a design or manufacturing defect.

PCB Repair Techniques

PCB repair techniques vary depending on the type and severity of the problem. Some common techniques include:

- PCB desoldering and rework: Use desoldering wicks or hot air tools to remove defective components and replace them with new ones.

- Component repair or replacement: Use specialized tools and techniques to repair or replace components such as surface-mount devices (SMDs) or ball grid arrays (BGAs).

- PCB cleaning and surface preparation: Clean the PCB using solvents or ultrasonic cleaning equipment to remove contaminants and restore the surface to its original condition.

- Copper pad or land repair: Use specialized tools and techniques to repair or replace copper pads or lands on the PCB.

Conclusion

Troubleshooting common PCB problems requires a systematic approach and a variety of techniques and tools. By following the steps outlined in this article, engineers and technicians can identify the root cause of PCB problems and repair or replace the PCB as necessary. Remember that prevention is always better than cure, and by taking steps to prevent PCB problems from occurring in the first place, engineers can reduce the need for costly and time-consuming repair and replacement.

FAQs

Q: What are some common causes of PCB problems?

A: Some common causes of PCB problems include poor soldering techniques, environmental conditions, manufacturing defects, and human error.

Q: What are some common techniques for troubleshooting PCB problems?

A: Some common techniques for troubleshooting PCB problems include visual inspection, electrical testing, and analytical techniques such as Fourier analysis and spectral analysis.

Q: How can I repair a PCB that has been damaged by ESD?

A: ESD can cause damage to PCB components, including capacitors, resistors, and transistors. To repair a PCB damaged by ESD, use specialized techniques and tools, such as ultrasonic cleaning and surface preparation, to remove contaminants and restore the surface to its original condition. Then, reassemble the PCB and test its functionality.

Q: Can I repair a PCB that has been damaged by thermal stress?

A: Thermal stress can cause damage to PCB components, including SMDs and BGAs. To repair a PCB damaged by thermal stress, use specialized techniques and tools, such as hot air tools and desoldering wicks, to remove defective components and replace them with new ones.

Q: How can I prevent PCB problems from occurring in the first place?

A: To prevent PCB problems from occurring in the first place, follow proper soldering techniques, store PCBs in a controlled environment, and perform regular quality control checks on PCBs. Additionally, design PCBs with reliability and maintenance in mind, and use materials and components that are resistant to environmental stressors such as humidity and temperature.

[ad_2]